1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

SC/T 3505-2006 English PDF (SCT3505-2006)

SC/T 3505-2006 English PDF (SCT3505-2006)

Regular price

$70.00 USD

Regular price

Sale price

$70.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click SC/T 3505-2006

Historical versions: SC/T 3505-2006

Preview True-PDF (Reload/Scroll if blank)

SC/T 3505-2006: Microcapsules of fish oil

SC/T 3505-2006

AQUACULTURE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 67.120.01

X 20

Microcapsules of Fish Oil

鱼油微胶囊

ISSUED ON: JANUARY 26, 2006

IMPLEMENTED ON: APRIL 01, 2006

Issued by: Ministry of Agriculture of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Requirements ... 5

4 Test Methods ... 6

5 Inspection Rules ... 8

6 Labeling, Packaging, Transportation, Storage ... 10

Appendix A (Normative) Determination of Surface Fat Content for Fish Oil

Microcapsules ... 11

Microcapsules of Fish Oil

1 Scope

This Standard specifies the requirements, test methods, inspection rules and labeling,

packaging, transportation and storage of fish oil microcapsule products.

This Standard is applicable to microcapsule products that are rich in polyene fatty acids

such as EPA, DHA, and processed with fish oil as the main raw material and modified

starch as the encapsulating material.

2 Normative References

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments

(excluding corrigendum) or revisions do not apply to this Standard, however, parties

who reach an agreement based on this Standard are encouraged to study if the latest

versions of these documents are applicable. For undated references, the latest edition

of the referenced document applies.

GB/T 4789.2 Microbiological Examination of Food Hygiene - Aerobic Plate Count

GB/T 4789.3 Microbiological Examination of Food Hygiene – Detection of Coliform

Bacteria

GB/T 4789.4 Microbiological Examination of Food Hygiene – Examination of

Salmonella

GB/T 4789.5 Microbiological Examination of Food Hygiene – Examination of

Shigella

GB/T 4789.10 Microbiological Examination of Food Hygiene – Detection of

Staphylococcus Aureus

GB/T 4789.15 Microbiological Examination of Food Hygiene – Examination of

Molds and Yeasts

GB/T 5009.11 Determination of Total Arsenic and Abio-Arsenic in Food

GB/T 5009.12 Determination of Lead in Food

Take 1g of sample into a 100 mL conical flask; add 10 mL of warm water at about 50°C;

and shake well. The product can form an emulsion with water and disperse evenly in

water.

4.2 Net content

Net content deviation shall be implemented in accordance with the provisions of JJF

1070.

4.3 Physicochemical index

4.3.1 EPA and DHA content

Perform inspection according to GB/T 5413.27.

If the fat used in the sample is esterification fish oil, the methanol shall be changed to

ethanol and perform the esterification of the sample. The corresponding EPA and DHA

standard samples shall use the ethyl ester type. The concentration of the prepared

standard solution is based on pure EPA and DHA.

4.3.2 Moisture

Perform inspection according to GB/T 5413.8.

4.3.3 Surface grease content

Perform in accordance with the provisions of Appendix A.

4.3.4 Fat peroxidation value

Take about 15g of the evenly-mixed sample (containing 2g~5g of fat); put it in a 100mL

beaker; add 50mL of water, stir until the sample is completely dispersed and dissolved;

transfer to a 250mL separatory funnel; add 50mL of ethanol and shake well; add 30mL

of ether, shake for 0.5min; add 30mL of petroleum ether (boiling range of 30°C~60°C)

and shake again for 0.5min to extract the fat. Let stand and separate; discard the lower

layer of water phase, the upper clear ether phase was transferred to a 250mL

stoppered conical flask contained with 5g of anhydrous sodium sulfate; shake for 1min

to remove water. The dehydrated ether phase was filtered by a quick filter paper into

a 250 mL iodine number flask that has been weighed (accurate to 0.0001g). In a fume

hood, the iodine number flask was placed on a 60°C water bath (distilled water for

water bath) and evaporated. The solvent was blown off by nitrogen till there is no

solvent. Wipe the water outside the bottle by filter paper, weigh it (accurate to 0.0001g),

calculate the fat mass, and then inspected according to 4.1 in GB/T 5009.37-2003.

NOTE: Fish oil is easy to be oxidized, and the process of extracting oil and fat shall be

completed in a short time as soon as possible and titrate in time.

The manufacturer shall take one sample at the same time and keep it in a cool and dry

sample room. Samples are required to be retained in accordance with the details of

the sampling when otherwise required during the supervision and sampling.

5.2.2 Sampling shall be recorded. The necessary contents of the record shall include

product name, batch number, production date, sampling location, and environmental

conditions.

5.3 Inspection classification

Product inspection is divided into exit-factory inspection and type inspection.

5.3.1 Exit-factory inspection

Each batch of products must undergo exit-factory inspection. The exit-factory

inspection is performed by the quality inspection department of the manufacturer. The

inspection items are determined by the manufacturer. The main technical indicators

that can quickly and accurately reflect the quality of the products shall be selected. The

inspection certificate is issued if the inspection is qualified, and the product is stored in

the warehouse or shipped from the factory with the certificate.

5.3.2 Type inspection

Type inspection shall be carried out in one of the following cases; and the inspection

items shall be all the items specified in this Standard.

a) When production resumes, after a long-term production suspension;

b) When raw materials are changed or the main production process is changed,

which may affect product quality;

c) When the National Quality Supervision and Inspection Institution proposes a type

inspection requirement;

d) When there is a big difference between the exit-factory inspection result and the

previous type inspection.

5.4 Judgment of results

5.4.1 In the sensory item, if the rancid flavor of fish oil is severe, it is unqualified; if one

of safety and hygiene indicators does not meet the standard requirements, the batch

of products is judged to be unqualified.

5.4.2 When one of the physicochemical indicators and the net content test results do

not meet the standard requirements, double sampling is allowed to re-inspect the such

indicator once. If the re-inspect results still do not meet the standard requirements, the

batch of products is judged to be unqualified.

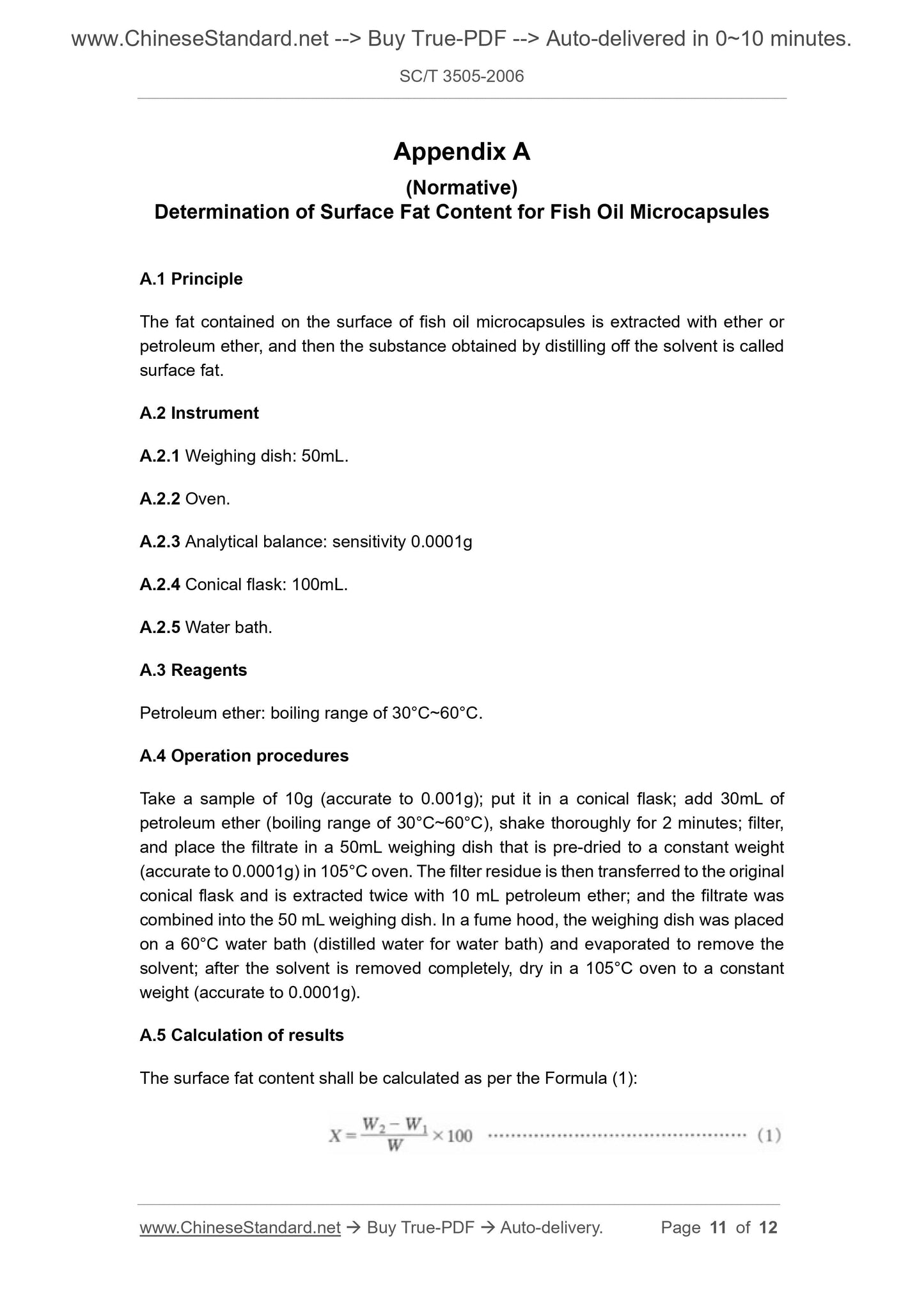

Appendix A

(Normative)

Determination of Surface Fat Content for Fish Oil Microcapsules

A.1 Principle

The fat contained on the surface of fish oil microcapsules is extracted with ether or

petroleum ether, and then the substance obtained by distilling off the solvent is called

surface fat.

A.2 Instrument

A.2.1 Weighing dish: 50mL.

A.2.2 Oven.

A.2.3 Analytical balance: sensitivity 0.0001g

A.2.4 Conical flask: 100mL.

A.2.5 Water bath.

A.3 Reagents

Petroleum ether: boiling range of 30°C~60°C.

A.4 Operation procedures

Take a sample of 10g (accurate to 0.001g); put it in a conical flask; add 30mL of

petroleum ether (boiling range of 30°C~60°C), shake thoroughly for 2 minutes; filter,

and place the filtrate in a 50mL weighing dish that is pre-dried to a constant weight

(accurate to 0.0001g) in 105°C oven. The filter residue is then transferred to the original

conical flask and is extracted twice with 10 mL petroleum ether; and the filtrate was

combined into the 50 mL weighing dish. In a ...

Get QUOTATION in 1-minute: Click SC/T 3505-2006

Historical versions: SC/T 3505-2006

Preview True-PDF (Reload/Scroll if blank)

SC/T 3505-2006: Microcapsules of fish oil

SC/T 3505-2006

AQUACULTURE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 67.120.01

X 20

Microcapsules of Fish Oil

鱼油微胶囊

ISSUED ON: JANUARY 26, 2006

IMPLEMENTED ON: APRIL 01, 2006

Issued by: Ministry of Agriculture of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Requirements ... 5

4 Test Methods ... 6

5 Inspection Rules ... 8

6 Labeling, Packaging, Transportation, Storage ... 10

Appendix A (Normative) Determination of Surface Fat Content for Fish Oil

Microcapsules ... 11

Microcapsules of Fish Oil

1 Scope

This Standard specifies the requirements, test methods, inspection rules and labeling,

packaging, transportation and storage of fish oil microcapsule products.

This Standard is applicable to microcapsule products that are rich in polyene fatty acids

such as EPA, DHA, and processed with fish oil as the main raw material and modified

starch as the encapsulating material.

2 Normative References

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments

(excluding corrigendum) or revisions do not apply to this Standard, however, parties

who reach an agreement based on this Standard are encouraged to study if the latest

versions of these documents are applicable. For undated references, the latest edition

of the referenced document applies.

GB/T 4789.2 Microbiological Examination of Food Hygiene - Aerobic Plate Count

GB/T 4789.3 Microbiological Examination of Food Hygiene – Detection of Coliform

Bacteria

GB/T 4789.4 Microbiological Examination of Food Hygiene – Examination of

Salmonella

GB/T 4789.5 Microbiological Examination of Food Hygiene – Examination of

Shigella

GB/T 4789.10 Microbiological Examination of Food Hygiene – Detection of

Staphylococcus Aureus

GB/T 4789.15 Microbiological Examination of Food Hygiene – Examination of

Molds and Yeasts

GB/T 5009.11 Determination of Total Arsenic and Abio-Arsenic in Food

GB/T 5009.12 Determination of Lead in Food

Take 1g of sample into a 100 mL conical flask; add 10 mL of warm water at about 50°C;

and shake well. The product can form an emulsion with water and disperse evenly in

water.

4.2 Net content

Net content deviation shall be implemented in accordance with the provisions of JJF

1070.

4.3 Physicochemical index

4.3.1 EPA and DHA content

Perform inspection according to GB/T 5413.27.

If the fat used in the sample is esterification fish oil, the methanol shall be changed to

ethanol and perform the esterification of the sample. The corresponding EPA and DHA

standard samples shall use the ethyl ester type. The concentration of the prepared

standard solution is based on pure EPA and DHA.

4.3.2 Moisture

Perform inspection according to GB/T 5413.8.

4.3.3 Surface grease content

Perform in accordance with the provisions of Appendix A.

4.3.4 Fat peroxidation value

Take about 15g of the evenly-mixed sample (containing 2g~5g of fat); put it in a 100mL

beaker; add 50mL of water, stir until the sample is completely dispersed and dissolved;

transfer to a 250mL separatory funnel; add 50mL of ethanol and shake well; add 30mL

of ether, shake for 0.5min; add 30mL of petroleum ether (boiling range of 30°C~60°C)

and shake again for 0.5min to extract the fat. Let stand and separate; discard the lower

layer of water phase, the upper clear ether phase was transferred to a 250mL

stoppered conical flask contained with 5g of anhydrous sodium sulfate; shake for 1min

to remove water. The dehydrated ether phase was filtered by a quick filter paper into

a 250 mL iodine number flask that has been weighed (accurate to 0.0001g). In a fume

hood, the iodine number flask was placed on a 60°C water bath (distilled water for

water bath) and evaporated. The solvent was blown off by nitrogen till there is no

solvent. Wipe the water outside the bottle by filter paper, weigh it (accurate to 0.0001g),

calculate the fat mass, and then inspected according to 4.1 in GB/T 5009.37-2003.

NOTE: Fish oil is easy to be oxidized, and the process of extracting oil and fat shall be

completed in a short time as soon as possible and titrate in time.

The manufacturer shall take one sample at the same time and keep it in a cool and dry

sample room. Samples are required to be retained in accordance with the details of

the sampling when otherwise required during the supervision and sampling.

5.2.2 Sampling shall be recorded. The necessary contents of the record shall include

product name, batch number, production date, sampling location, and environmental

conditions.

5.3 Inspection classification

Product inspection is divided into exit-factory inspection and type inspection.

5.3.1 Exit-factory inspection

Each batch of products must undergo exit-factory inspection. The exit-factory

inspection is performed by the quality inspection department of the manufacturer. The

inspection items are determined by the manufacturer. The main technical indicators

that can quickly and accurately reflect the quality of the products shall be selected. The

inspection certificate is issued if the inspection is qualified, and the product is stored in

the warehouse or shipped from the factory with the certificate.

5.3.2 Type inspection

Type inspection shall be carried out in one of the following cases; and the inspection

items shall be all the items specified in this Standard.

a) When production resumes, after a long-term production suspension;

b) When raw materials are changed or the main production process is changed,

which may affect product quality;

c) When the National Quality Supervision and Inspection Institution proposes a type

inspection requirement;

d) When there is a big difference between the exit-factory inspection result and the

previous type inspection.

5.4 Judgment of results

5.4.1 In the sensory item, if the rancid flavor of fish oil is severe, it is unqualified; if one

of safety and hygiene indicators does not meet the standard requirements, the batch

of products is judged to be unqualified.

5.4.2 When one of the physicochemical indicators and the net content test results do

not meet the standard requirements, double sampling is allowed to re-inspect the such

indicator once. If the re-inspect results still do not meet the standard requirements, the

batch of products is judged to be unqualified.

Appendix A

(Normative)

Determination of Surface Fat Content for Fish Oil Microcapsules

A.1 Principle

The fat contained on the surface of fish oil microcapsules is extracted with ether or

petroleum ether, and then the substance obtained by distilling off the solvent is called

surface fat.

A.2 Instrument

A.2.1 Weighing dish: 50mL.

A.2.2 Oven.

A.2.3 Analytical balance: sensitivity 0.0001g

A.2.4 Conical flask: 100mL.

A.2.5 Water bath.

A.3 Reagents

Petroleum ether: boiling range of 30°C~60°C.

A.4 Operation procedures

Take a sample of 10g (accurate to 0.001g); put it in a conical flask; add 30mL of

petroleum ether (boiling range of 30°C~60°C), shake thoroughly for 2 minutes; filter,

and place the filtrate in a 50mL weighing dish that is pre-dried to a constant weight

(accurate to 0.0001g) in 105°C oven. The filter residue is then transferred to the original

conical flask and is extracted twice with 10 mL petroleum ether; and the filtrate was

combined into the 50 mL weighing dish. In a ...

Share