1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

YS/T 820.3-2012 English PDF (YS/T820.3-2012)

YS/T 820.3-2012 English PDF (YS/T820.3-2012)

Regular price

$120.00

Regular price

Sale price

$120.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

YS/T 820.3-2012: Methods for chemical analysis of laterite nickel ores - Part 3: Determination of total iron content - Potassium dichromate titration

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click YS/T 820.3-2012 (Self-service in 1-minute)

Historical versions (Master-website): YS/T 820.3-2012

Preview True-PDF (Reload/Scroll-down if blank)

YS/T 820.3-2012

YS

NONFERROUS METALLURGY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 73.060

D 04

Methods for chemical analysis of laterite nickel ores -

Part 3. Determination of total iron content -

Potassium dichromate titration

ISSUED ON. NOVEMBER 07, 2012

IMPLEMENTED ON. MARCH 01, 2013

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Method summary ... 6

4 Reagents ... 6

5 Specimen ... 8

6 Analysis steps ... 8

7 Calculation of analysis results ... 9

8 Precision ... 10

9 Test report ... 10

Foreword

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

YS/T 820-2012 “Methods for chemical analysis of laterite nickel ores” consists

of 26 parts.

- Part 1. Determination of nickel content - Flame atomic absorption

spectrometry;

- Part 2. Determination of nickel content - Dimethylglyoxime

spectrophotometry;

- Part 3. Determination of total iron content - Potassium dichromate titration;

- Part 4. Determination of phosphorus content - Phosphorus molybdenum

blue spectrophotometry;

- Part 5. Determination of cobalt content - Flame atomic absorption

spectrometry;

- Part 6. Determination of copper content - Flame atomic absorption

spectrometry;

- Part 7. Determination of calcium and magnesium content – Flame atomic

absorption spectrometry;

- Part 8. Determination of silica content - Potassium silicafluoride titrimetric

method;

- Part 9. Determination of scandium and cadmium contents - Inductively

coupled plasma mass spectrometry;

- Part 10. Determination of calcium, cobalt, copper, magnesium, manganese,

nickel, phosphate and zinc content - Inductively coupled plasma atomic

emission spectrometry;

- Part 11. Determination of fluorine and chlorine contents - Ion

chromatography;

- Part 12. Determination of manganese content - Flame atomic absorption

spectrometry;

- Part 13. Determination of lead content - Flame atomic absorption

spectrometry;

- Part 14. Determination of the zinc content - Flame atomic absorption

spectrometry;

Methods for chemical analysis of laterite nickel ores -

Part 3. Determination of total iron content -

Potassium dichromate titration

1 Scope

This Part of YS/T 820 specifies the determination method of total iron content

in laterite nickel ores.

This Part is applicable to the determination of total iron content in laterite nickel

ores. The determination range is 7.00%~55.00%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

YS/T 820.24-2012, Methods for chemical analysis of laterite nickel ores -

Part 24. Determination hygroscopic moisture content - Gravimetric method

3 Method summary

The test material is melted with sodium peroxide. Use water to leach the cooled

melt out. Then use hydrochloric acid to acidize. Most of the iron is reduced by

stannous chloride. The remaining iron is reduced by titanium trichloride. Use

potassium dichromate solution to oxidize the excess reducing agent. Use

sodium diphenylamine sulfonate as indicator. Use potassium dichromate

standard titration solution to titrate the reduced amount of iron.

4 Reagents

Unless otherwise stated, only analytically pure reagents and distilled or

deionized water or water with equivalent purity are used in the analysis.

4.1 Sodium peroxide.

4.2 Hydrochloric acid (ρ1.19 g/mL).

5 Specimen

5.1 Specimen

The granularity of the specimen shall be less than 160 µm.

5.2 Determination of wet reserved water amount

While analyzing specimen, determine the wet reserved water amount according

to YS/T 820.24-2012.

6 Analysis steps

6.1 Test material

Weigh 0.20 g of specimen, to the nearest of 0. 0001 g.

6.2 Determination frequency

Carry out the determination twice, independently. Take the mean value.

6.3 Blank test

Carry out the blank test with test material (see 6.4.4 for requirements).

6.4 Determination

6.4.1 Decomposition of test material

Place the test material (6.1) in a 30mL corundum crucible. Add 2g~3g of sodium

peroxide (4.1). Mix well. Then add 1 g of sodium peroxide (4.1) to cover. Melt

in a muffle furnace at 800°C for 8min~10min. Take out and cool for a while.

Leach in a 300mL beaker that containing 40mL of water. Add 25 mL of

hydrochloric acid (4.2). Heat on an electric furnace to near boiling.

6.4.2 Reduction

Immediately drop stannous chloride solution (4.9), reduced iron (III). Keep

stirring the crucible and solution till the solution becomes light yellow. Clean the

inner wall of the beaker with small amount of water. Cool with running water to

room temperature. Add 15 drops of sodium tungstate solution (4.13) as indicator.

Reduce the remaining iron (III) with titanium trichloride solution. Keep stirring

till the solution becomes blue.

6.4.3 Titration

While stirring, drop the potassium dichromate solution (4.8) till colorless. Add

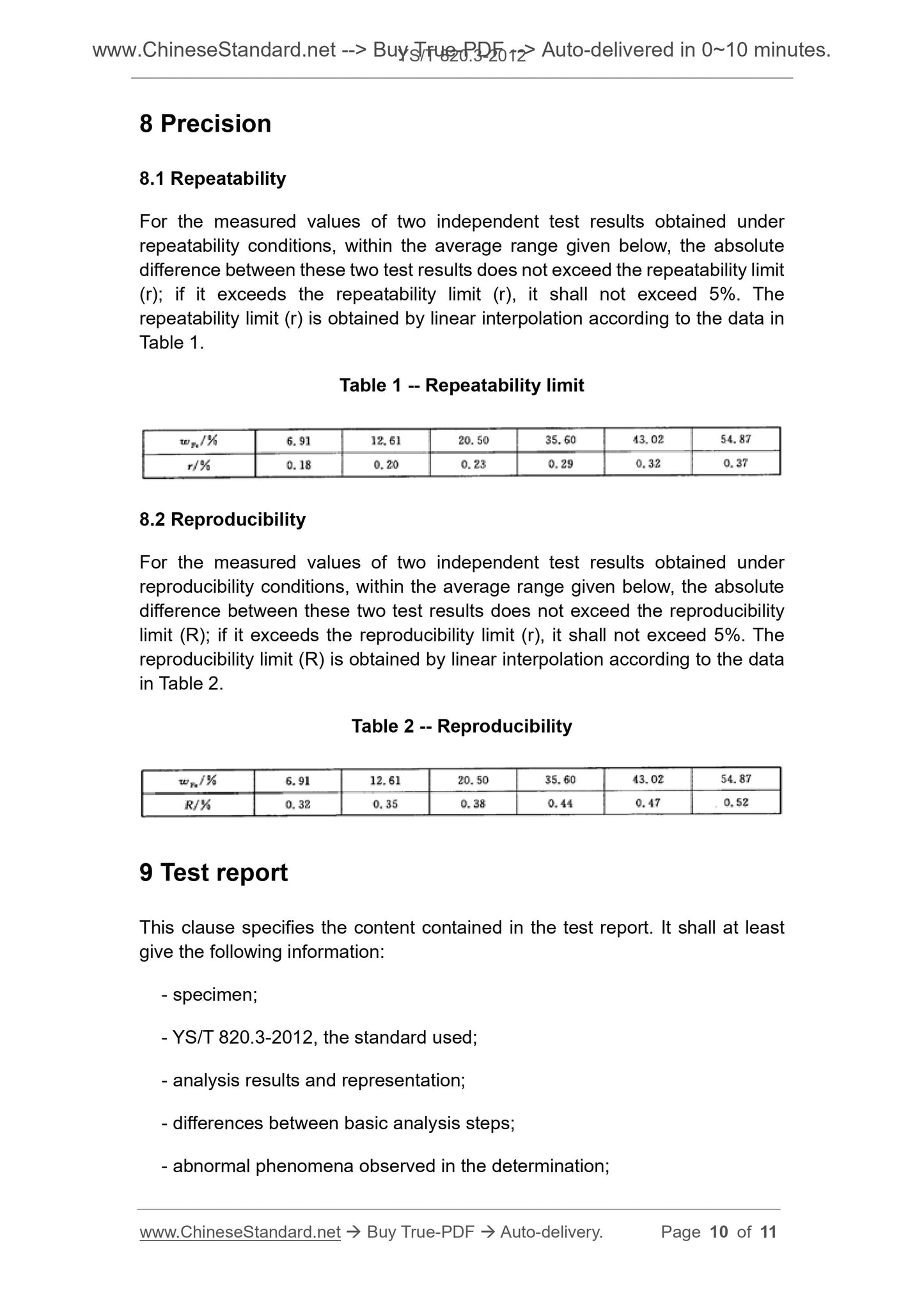

8 Precision

8.1 Repeatability

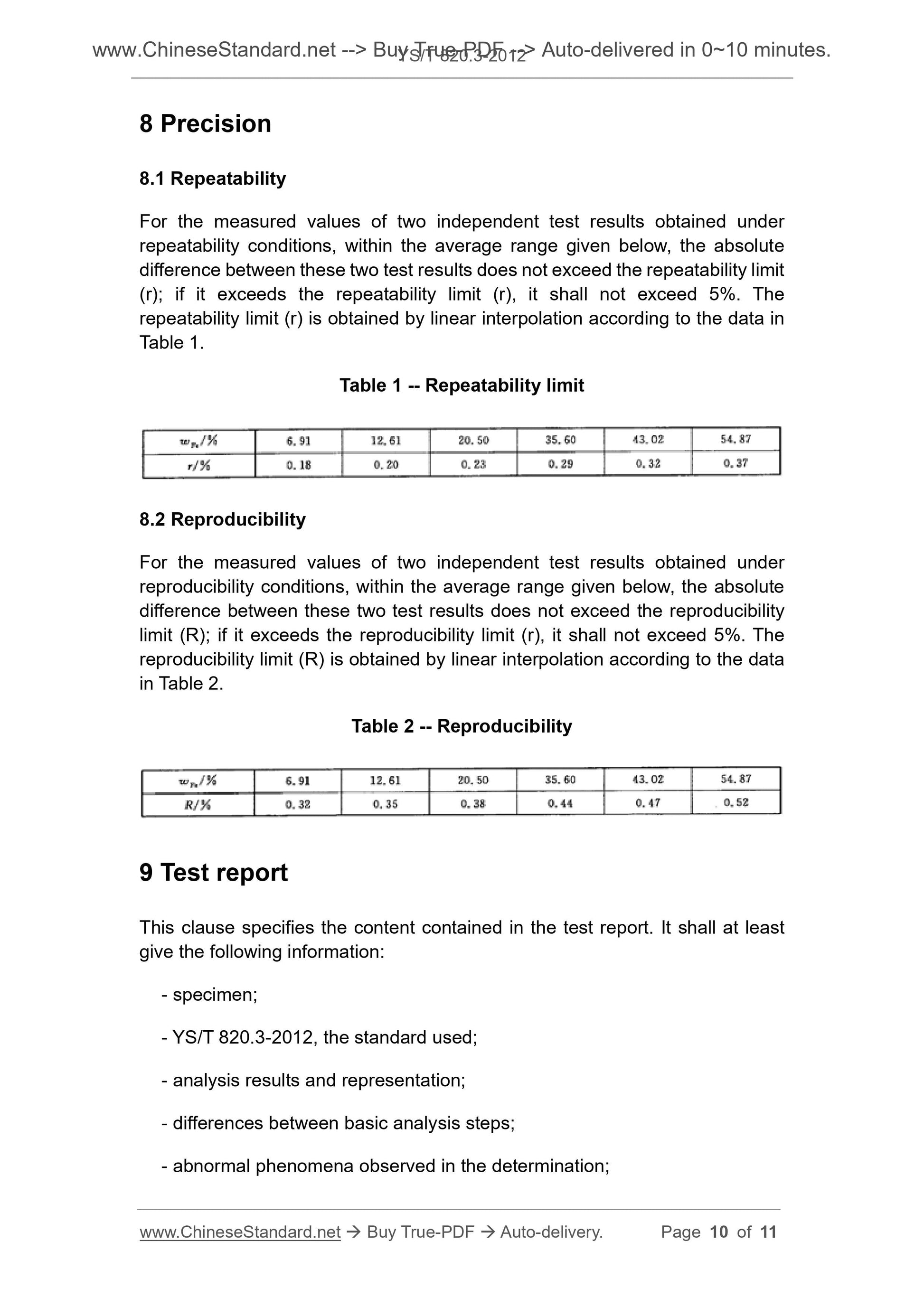

For the measured values of two independent test results obtained under

repeatability conditions, within the average range given below, the absolute

difference between these two test results does not exceed the repeatability limit

(r); if it exceeds the repeatability limit (r), it shall not exceed 5%. The

repeatability limit (r) is obtained by linear interpolation according to the data in

Table 1.

Table 1 -- Repeatability limit

8.2 Reproducibility

For the measured values of two independent test results obtained under

reproducibility conditions, within the average range given below, the absolute

difference between these two test results does not exceed the reproducibility

limit (R); if it exceeds the reproducibility limit (r), it shall not exceed 5%. The

reproducibility limit (R) is obtained by linear interpolation according to the data

in Table 2.

Table 2 -- Reproducibility

9 Test report

This clause specifies the content contained in the test report. It shall at least

give the following information.

- specimen;

- YS/T 820.3-2012, the standard used;

- analysis results and representation;

- differences between basic analysis steps;

- abnormal phenomena observed in the determination;

YS/T 820.3-2012

YS

NONFERROUS METALLURGY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 73.060

D 04

Methods for chemical analysis of laterite nickel ores -

Part 3. Determination of total iron content -

Potassium dichromate titration

ISSUED ON. NOVEMBER 07, 2012

IMPLEMENTED ON. MARCH 01, 2013

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Method summary ... 6

4 Reagents ... 6

5 Specimen ... 8

6 Analysis steps ... 8

7 Calculation of analysis results ... 9

8 Precision ... 10

9 Test report ... 10

Foreword

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

YS/T 820-2012 “Methods for chemical analysis of laterite nickel ores” consists

of 26 parts.

- Part 1. Determination of nickel content - Flame atomic absorption

spectrometry;

- Part 2. Determination of nickel content - Dimethylglyoxime

spectrophotometry;

- Part 3. Determination of total iron content - Potassium dichromate titration;

- Part 4. Determination of phosphorus content - Phosphorus molybdenum

blue spectrophotometry;

- Part 5. Determination of cobalt content - Flame atomic absorption

spectrometry;

- Part 6. Determination of copper content - Flame atomic absorption

spectrometry;

- Part 7. Determination of calcium and magnesium content – Flame atomic

absorption spectrometry;

- Part 8. Determination of silica content - Potassium silicafluoride titrimetric

method;

- Part 9. Determination of scandium and cadmium contents - Inductively

coupled plasma mass spectrometry;

- Part 10. Determination of calcium, cobalt, copper, magnesium, manganese,

nickel, phosphate and zinc content - Inductively coupled plasma atomic

emission spectrometry;

- Part 11. Determination of fluorine and chlorine contents - Ion

chromatography;

- Part 12. Determination of manganese content - Flame atomic absorption

spectrometry;

- Part 13. Determination of lead content - Flame atomic absorption

spectrometry;

- Part 14. Determination of the zinc content - Flame atomic absorption

spectrometry;

Methods for chemical analysis of laterite nickel ores -

Part 3. Determination of total iron content -

Potassium dichromate titration

1 Scope

This Part of YS/T 820 specifies the determination method of total iron content

in laterite nickel ores.

This Part is applicable to the determination of total iron content in laterite nickel

ores. The determination range is 7.00%~55.00%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

YS/T 820.24-2012, Methods for chemical analysis of laterite nickel ores -

Part 24. Determination hygroscopic moisture content - Gravimetric method

3 Method summary

The test material is melted with sodium peroxide. Use water to leach the cooled

melt out. Then use hydrochloric acid to acidize. Most of the iron is reduced by

stannous chloride. The remaining iron is reduced by titanium trichloride. Use

potassium dichromate solution to oxidize the excess reducing agent. Use

sodium diphenylamine sulfonate as indicator. Use potassium dichromate

standard titration solution to titrate the reduced amount of iron.

4 Reagents

Unless otherwise stated, only analytically pure reagents and distilled or

deionized water or water with equivalent purity are used in the analysis.

4.1 Sodium peroxide.

4.2 Hydrochloric acid (ρ1.19 g/mL).

5 Specimen

5.1 Specimen

The granularity of the specimen shall be less than 160 µm.

5.2 Determination of wet reserved water amount

While analyzing specimen, determine the wet reserved water amount according

to YS/T 820.24-2012.

6 Analysis steps

6.1 Test material

Weigh 0.20 g of specimen, to the nearest of 0. 0001 g.

6.2 Determination frequency

Carry out the determination twice, independently. Take the mean value.

6.3 Blank test

Carry out the blank test with test material (see 6.4.4 for requirements).

6.4 Determination

6.4.1 Decomposition of test material

Place the test material (6.1) in a 30mL corundum crucible. Add 2g~3g of sodium

peroxide (4.1). Mix well. Then add 1 g of sodium peroxide (4.1) to cover. Melt

in a muffle furnace at 800°C for 8min~10min. Take out and cool for a while.

Leach in a 300mL beaker that containing 40mL of water. Add 25 mL of

hydrochloric acid (4.2). Heat on an electric furnace to near boiling.

6.4.2 Reduction

Immediately drop stannous chloride solution (4.9), reduced iron (III). Keep

stirring the crucible and solution till the solution becomes light yellow. Clean the

inner wall of the beaker with small amount of water. Cool with running water to

room temperature. Add 15 drops of sodium tungstate solution (4.13) as indicator.

Reduce the remaining iron (III) with titanium trichloride solution. Keep stirring

till the solution becomes blue.

6.4.3 Titration

While stirring, drop the potassium dichromate solution (4.8) till colorless. Add

8 Precision

8.1 Repeatability

For the measured values of two independent test results obtained under

repeatability conditions, within the average range given below, the absolute

difference between these two test results does not exceed the repeatability limit

(r); if it exceeds the repeatability limit (r), it shall not exceed 5%. The

repeatability limit (r) is obtained by linear interpolation according to the data in

Table 1.

Table 1 -- Repeatability limit

8.2 Reproducibility

For the measured values of two independent test results obtained under

reproducibility conditions, within the average range given below, the absolute

difference between these two test results does not exceed the reproducibility

limit (R); if it exceeds the reproducibility limit (r), it shall not exceed 5%. The

reproducibility limit (R) is obtained by linear interpolation according to the data

in Table 2.

Table 2 -- Reproducibility

9 Test report

This clause specifies the content contained in the test report. It shall at least

give the following information.

- specimen;

- YS/T 820.3-2012, the standard used;

- analysis results and representation;

- differences between basic analysis steps;

- abnormal phenomena observed in the determination;

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click YS/T 820.3-2012 (Self-service in 1-minute)

Historical versions (Master-website): YS/T 820.3-2012

Preview True-PDF (Reload/Scroll-down if blank)

YS/T 820.3-2012

YS

NONFERROUS METALLURGY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 73.060

D 04

Methods for chemical analysis of laterite nickel ores -

Part 3. Determination of total iron content -

Potassium dichromate titration

ISSUED ON. NOVEMBER 07, 2012

IMPLEMENTED ON. MARCH 01, 2013

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Method summary ... 6

4 Reagents ... 6

5 Specimen ... 8

6 Analysis steps ... 8

7 Calculation of analysis results ... 9

8 Precision ... 10

9 Test report ... 10

Foreword

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

YS/T 820-2012 “Methods for chemical analysis of laterite nickel ores” consists

of 26 parts.

- Part 1. Determination of nickel content - Flame atomic absorption

spectrometry;

- Part 2. Determination of nickel content - Dimethylglyoxime

spectrophotometry;

- Part 3. Determination of total iron content - Potassium dichromate titration;

- Part 4. Determination of phosphorus content - Phosphorus molybdenum

blue spectrophotometry;

- Part 5. Determination of cobalt content - Flame atomic absorption

spectrometry;

- Part 6. Determination of copper content - Flame atomic absorption

spectrometry;

- Part 7. Determination of calcium and magnesium content – Flame atomic

absorption spectrometry;

- Part 8. Determination of silica content - Potassium silicafluoride titrimetric

method;

- Part 9. Determination of scandium and cadmium contents - Inductively

coupled plasma mass spectrometry;

- Part 10. Determination of calcium, cobalt, copper, magnesium, manganese,

nickel, phosphate and zinc content - Inductively coupled plasma atomic

emission spectrometry;

- Part 11. Determination of fluorine and chlorine contents - Ion

chromatography;

- Part 12. Determination of manganese content - Flame atomic absorption

spectrometry;

- Part 13. Determination of lead content - Flame atomic absorption

spectrometry;

- Part 14. Determination of the zinc content - Flame atomic absorption

spectrometry;

Methods for chemical analysis of laterite nickel ores -

Part 3. Determination of total iron content -

Potassium dichromate titration

1 Scope

This Part of YS/T 820 specifies the determination method of total iron content

in laterite nickel ores.

This Part is applicable to the determination of total iron content in laterite nickel

ores. The determination range is 7.00%~55.00%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

YS/T 820.24-2012, Methods for chemical analysis of laterite nickel ores -

Part 24. Determination hygroscopic moisture content - Gravimetric method

3 Method summary

The test material is melted with sodium peroxide. Use water to leach the cooled

melt out. Then use hydrochloric acid to acidize. Most of the iron is reduced by

stannous chloride. The remaining iron is reduced by titanium trichloride. Use

potassium dichromate solution to oxidize the excess reducing agent. Use

sodium diphenylamine sulfonate as indicator. Use potassium dichromate

standard titration solution to titrate the reduced amount of iron.

4 Reagents

Unless otherwise stated, only analytically pure reagents and distilled or

deionized water or water with equivalent purity are used in the analysis.

4.1 Sodium peroxide.

4.2 Hydrochloric acid (ρ1.19 g/mL).

5 Specimen

5.1 Specimen

The granularity of the specimen shall be less than 160 µm.

5.2 Determination of wet reserved water amount

While analyzing specimen, determine the wet reserved water amount according

to YS/T 820.24-2012.

6 Analysis steps

6.1 Test material

Weigh 0.20 g of specimen, to the nearest of 0. 0001 g.

6.2 Determination frequency

Carry out the determination twice, independently. Take the mean value.

6.3 Blank test

Carry out the blank test with test material (see 6.4.4 for requirements).

6.4 Determination

6.4.1 Decomposition of test material

Place the test material (6.1) in a 30mL corundum crucible. Add 2g~3g of sodium

peroxide (4.1). Mix well. Then add 1 g of sodium peroxide (4.1) to cover. Melt

in a muffle furnace at 800°C for 8min~10min. Take out and cool for a while.

Leach in a 300mL beaker that containing 40mL of water. Add 25 mL of

hydrochloric acid (4.2). Heat on an electric furnace to near boiling.

6.4.2 Reduction

Immediately drop stannous chloride solution (4.9), reduced iron (III). Keep

stirring the crucible and solution till the solution becomes light yellow. Clean the

inner wall of the beaker with small amount of water. Cool with running water to

room temperature. Add 15 drops of sodium tungstate solution (4.13) as indicator.

Reduce the remaining iron (III) with titanium trichloride solution. Keep stirring

till the solution becomes blue.

6.4.3 Titration

While stirring, drop the potassium dichromate solution (4.8) till colorless. Add

8 Precision

8.1 Repeatability

For the measured values of two independent test results obtained under

repeatability conditions, within the average range given below, the absolute

difference between these two test results does not exceed the repeatability limit

(r); if it exceeds the repeatability limit (r), it shall not exceed 5%. The

repeatability limit (r) is obtained by linear interpolation according to the data in

Table 1.

Table 1 -- Repeatability limit

8.2 Reproducibility

For the measured values of two independent test results obtained under

reproducibility conditions, within the average range given below, the absolute

difference between these two test results does not exceed the reproducibility

limit (R); if it exceeds the reproducibility limit (r), it shall not exceed 5%. The

reproducibility limit (R) is obtained by linear interpolation according to the data

in Table 2.

Table 2 -- Reproducibility

9 Test report

This clause specifies the content contained in the test report. It shall at least

give the following information.

- specimen;

- YS/T 820.3-2012, the standard used;

- analysis results and representation;

- differences between basic analysis steps;

- abnormal phenomena observed in the determination;

YS/T 820.3-2012

YS

NONFERROUS METALLURGY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 73.060

D 04

Methods for chemical analysis of laterite nickel ores -

Part 3. Determination of total iron content -

Potassium dichromate titration

ISSUED ON. NOVEMBER 07, 2012

IMPLEMENTED ON. MARCH 01, 2013

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Method summary ... 6

4 Reagents ... 6

5 Specimen ... 8

6 Analysis steps ... 8

7 Calculation of analysis results ... 9

8 Precision ... 10

9 Test report ... 10

Foreword

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

YS/T 820-2012 “Methods for chemical analysis of laterite nickel ores” consists

of 26 parts.

- Part 1. Determination of nickel content - Flame atomic absorption

spectrometry;

- Part 2. Determination of nickel content - Dimethylglyoxime

spectrophotometry;

- Part 3. Determination of total iron content - Potassium dichromate titration;

- Part 4. Determination of phosphorus content - Phosphorus molybdenum

blue spectrophotometry;

- Part 5. Determination of cobalt content - Flame atomic absorption

spectrometry;

- Part 6. Determination of copper content - Flame atomic absorption

spectrometry;

- Part 7. Determination of calcium and magnesium content – Flame atomic

absorption spectrometry;

- Part 8. Determination of silica content - Potassium silicafluoride titrimetric

method;

- Part 9. Determination of scandium and cadmium contents - Inductively

coupled plasma mass spectrometry;

- Part 10. Determination of calcium, cobalt, copper, magnesium, manganese,

nickel, phosphate and zinc content - Inductively coupled plasma atomic

emission spectrometry;

- Part 11. Determination of fluorine and chlorine contents - Ion

chromatography;

- Part 12. Determination of manganese content - Flame atomic absorption

spectrometry;

- Part 13. Determination of lead content - Flame atomic absorption

spectrometry;

- Part 14. Determination of the zinc content - Flame atomic absorption

spectrometry;

Methods for chemical analysis of laterite nickel ores -

Part 3. Determination of total iron content -

Potassium dichromate titration

1 Scope

This Part of YS/T 820 specifies the determination method of total iron content

in laterite nickel ores.

This Part is applicable to the determination of total iron content in laterite nickel

ores. The determination range is 7.00%~55.00%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

YS/T 820.24-2012, Methods for chemical analysis of laterite nickel ores -

Part 24. Determination hygroscopic moisture content - Gravimetric method

3 Method summary

The test material is melted with sodium peroxide. Use water to leach the cooled

melt out. Then use hydrochloric acid to acidize. Most of the iron is reduced by

stannous chloride. The remaining iron is reduced by titanium trichloride. Use

potassium dichromate solution to oxidize the excess reducing agent. Use

sodium diphenylamine sulfonate as indicator. Use potassium dichromate

standard titration solution to titrate the reduced amount of iron.

4 Reagents

Unless otherwise stated, only analytically pure reagents and distilled or

deionized water or water with equivalent purity are used in the analysis.

4.1 Sodium peroxide.

4.2 Hydrochloric acid (ρ1.19 g/mL).

5 Specimen

5.1 Specimen

The granularity of the specimen shall be less than 160 µm.

5.2 Determination of wet reserved water amount

While analyzing specimen, determine the wet reserved water amount according

to YS/T 820.24-2012.

6 Analysis steps

6.1 Test material

Weigh 0.20 g of specimen, to the nearest of 0. 0001 g.

6.2 Determination frequency

Carry out the determination twice, independently. Take the mean value.

6.3 Blank test

Carry out the blank test with test material (see 6.4.4 for requirements).

6.4 Determination

6.4.1 Decomposition of test material

Place the test material (6.1) in a 30mL corundum crucible. Add 2g~3g of sodium

peroxide (4.1). Mix well. Then add 1 g of sodium peroxide (4.1) to cover. Melt

in a muffle furnace at 800°C for 8min~10min. Take out and cool for a while.

Leach in a 300mL beaker that containing 40mL of water. Add 25 mL of

hydrochloric acid (4.2). Heat on an electric furnace to near boiling.

6.4.2 Reduction

Immediately drop stannous chloride solution (4.9), reduced iron (III). Keep

stirring the crucible and solution till the solution becomes light yellow. Clean the

inner wall of the beaker with small amount of water. Cool with running water to

room temperature. Add 15 drops of sodium tungstate solution (4.13) as indicator.

Reduce the remaining iron (III) with titanium trichloride solution. Keep stirring

till the solution becomes blue.

6.4.3 Titration

While stirring, drop the potassium dichromate solution (4.8) till colorless. Add

8 Precision

8.1 Repeatability

For the measured values of two independent test results obtained under

repeatability conditions, within the average range given below, the absolute

difference between these two test results does not exceed the repeatability limit

(r); if it exceeds the repeatability limit (r), it shall not exceed 5%. The

repeatability limit (r) is obtained by linear interpolation according to the data in

Table 1.

Table 1 -- Repeatability limit

8.2 Reproducibility

For the measured values of two independent test results obtained under

reproducibility conditions, within the average range given below, the absolute

difference between these two test results does not exceed the reproducibility

limit (R); if it exceeds the reproducibility limit (r), it shall not exceed 5%. The

reproducibility limit (R) is obtained by linear interpolation according to the data

in Table 2.

Table 2 -- Reproducibility

9 Test report

This clause specifies the content contained in the test report. It shall at least

give the following information.

- specimen;

- YS/T 820.3-2012, the standard used;

- analysis results and representation;

- differences between basic analysis steps;

- abnormal phenomena observed in the determination;

Share