1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY 0174-2019 English PDF

YY 0174-2019 English PDF

Regular price

$230.00 USD

Regular price

Sale price

$230.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY 0174-2019 (Self-service in 1-minute)

Historical versions (Master-website): YY 0174-2019

Preview True-PDF (Reload/Scroll-down if blank)

YY 0174-2019: [YY/T 0174-2019] Scalpel blade

YY 0174-2019

Scalpel blade

ICS 11.040.30

C31

People's Republic of China Pharmaceutical Industry Standards

Replace YY 0174-2005

Surgical blade

2019-05-31 released

2020-06-01 Implementation

Issued by the National Medical Products Administration

Preface

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces YY 0174-2005 "Surgery Blade".

Compared with YY 0174-2005, the main changes of this standard are as follows.

---Revised the scope of application (see Chapter 1, Chapter 1 of the.2005 edition);

---Revised manufacturing materials (see 3.3, 3.2 of the.2005 edition);

---Added the blade identification requirements (see 3.4);

---Revised the hardness requirements (see 4.4, 4.4.1 of the.2005 edition);

---Added anti-rust performance requirements (see 4.6);

---Added ethylene oxide residue requirements (see 4.8);

---Added requirements for packaging labels and instructions (see 4.9);

---Revised the surface roughness test method (see 5.2.1, 5.2.1 of the.2005 edition);

---Revised the cutting edge sharpness test method (see 5.3, 5.3 of the.2005 edition);

---Revised the type inspection (see Chapter 6, Chapter 6 of the.2005 edition);

---Revised the labeling and instructions requirements (see Chapter 7, Chapter 7 of the.2005 edition);

---Revised the packaging, transportation and storage requirements (see Chapter 8, Chapter 8 of the.2005 edition).

Please note that some of the contents of this document may involve patents, and the issuing agency of this document does not bear the responsibility for identifying these patents.

This standard was proposed by the State Drug Administration.

This standard is under the jurisdiction of the National Technical Committee for Standardization of Surgical Instruments (SAC/TC94).

Drafting organizations of this standard. Shanghai Pudong Jinhuan Medical Products Co., Ltd., Shanghai Medical Device Testing Institute, Huaiyin Medical Devices Co., Ltd.

Limited company.

The main drafters of this standard. Zhang Yanqing, Wang Zewei, Gao Bai, Wang Fengcai, Huang Shuze, Lu Guangheng, Lu Lidong.

The previous versions of the standard replaced by this standard are as follows.

---WS2/Z45~WS2/Z46-1982;

---GB n210-1983;

---GB 2544-1988;

---YY/T 0174-1994, YY 0293-1997;

---YY 0174-2005.

Surgical blade

1 Scope

This standard specifies the classification and identification, requirements, test methods, type inspection, labeling and instructions, packaging, transportation, and storage of surgical blades.

And expiry date.

This standard applies to surgical blades (hereinafter referred to as blades) installed on the scalpel handle for cutting soft tissues.

2 Normative references

The following documents are indispensable for the application of this document. For dated reference documents, only the dated version applies to this article

Pieces. For undated reference documents, the latest version (including all amendments) is applicable to this document.

GB/T 191 Packaging, storage and transportation pictorial signs

GB/T 1299 Tool and Die Steel

GB/T 4340.1 Vickers hardness test of metallic materials Part 1.Test method

GB 8662 Matching size of scalpel blade and scalpel handle

GB/T 9969 General Rules for the Use of Industrial Products

GB/T 14233.1 Medical infusion, blood transfusion, and injection equipment inspection methods Part 1.Chemical analysis methods

YY 0167-2005 Non-absorbable surgical suture

YY/T 0294.1 Metallic materials for surgical instruments Part 1.Stainless steel

YY/T 0466.1 Medical devices are used for medical device labeling, marking and providing information symbols. Part 1.General requirements

YY/T 1052 Surgical instrument mark

Pharmacopoeia of the People's Republic of China (2015 Edition·Fourth Edition)

3 Classification and identification

3.1 Delivery status

The blade has two delivery states. aseptic and non-sterile (hereinafter referred to as sterile blade and non-sterile blade).

3.2 Specifications

Please refer to Appendix A for the specifications and dimensions of the blade, and the assembly specifications of the knife handle.

3.3 Materials

The manufacturing material of the blade should be made of non-alloy tool steel that meets the requirements of GB/T 1299 or martensite that meets the requirements of YY/T 0294.1

Stainless steel, or other applicable metal materials that meet the requirements of Chapter 4.

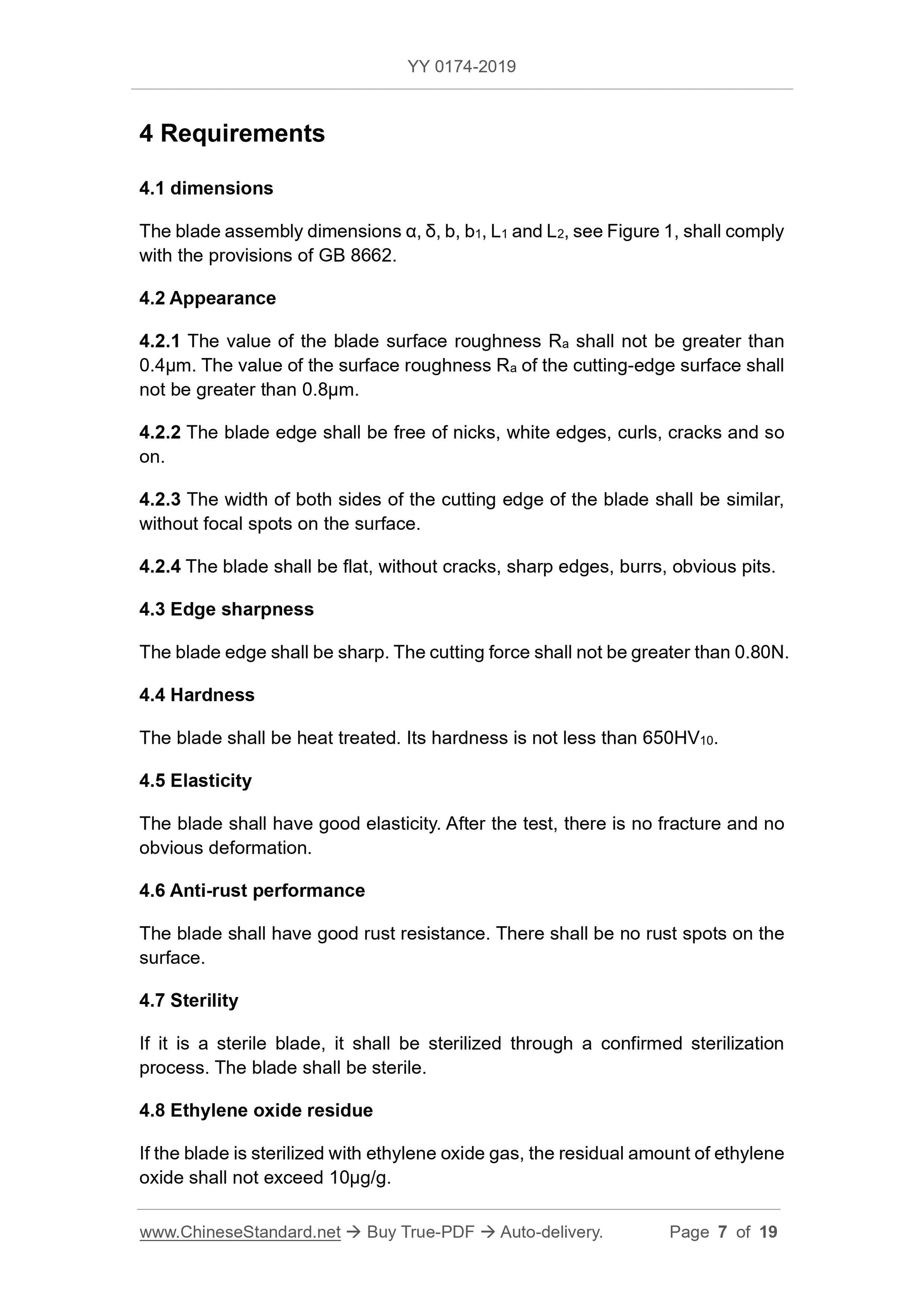

3.4 Marking requirements

According to the provisions of YY/T 1052, the surface of the blade should at least be marked with the manufacturer code, material code (non-alloy tool steel, marking default) and specification.

Grid, the location of the mark is shown in Figure 1.

4 requirements

4.1 Dimensions

The blade assembly dimensions α, δ, b, b1, L1 and L2, see Figure 1, should meet the requirements of GB 8662.

4.2 Appearance

4.2.1 The value of the surface roughness Ra of the insert should not be greater than 0.4μm, and the value of the surface roughness Ra of the cutting edge surface should not be greater than

0.8μm.

4.2.2 The cutting edge of the blade should be free of nicks, white edges, curls, cracks, etc.

4.2.3 The width of both sides of the cutting edge of the blade should be similar, and the surface should be free of focal spots.

4.2.4 The blade should be flat, and there should be no cracks, sharp edges, burrs, or obvious pitting.

4.3 Cutting edge sharpness

The cutting edge of the blade should be sharp, and its cutting force should not be greater than 0.80N.

4.4 Hardness

The blade should be heat treated, and its hardness is not less than 650HV10.

4.5 Flexibility

The blade should have good elasticity, and there should be no fracture and no obvious deformation after the test.

4.6 Anti-rust performance

The blade should have good anti-rust performance and there should be no rust spots on the surface.

4.7 Sterility

If it is a sterile blade, it should be sterilized through a confirmed sterilization process, and the blade should be sterile.

4.8 Residual ethylene oxide

If the blade is sterilized with ethylene oxide gas, the residual amount of ethylene oxide should not exceed 10μg/g.

4.9 Packaging labels and instructions

The packaging label should be clear and comply with the provisions of Chapter 7.The instructions should specify detailed sterilization or disinfection methods.

5 Test method

5.1 Dimensions

Measured with a universal measuring tool, it should meet the requirements of 4.1.

5.2 Appearance

5.2.1 Comparing with the surface roughness comparison sample block should meet the requirements of 4.2.1.

5.2.2 Visual observation should meet the requirements of 4.2.2, 4.2.3, and 4.2.4.

5.3 Cutting edge sharpness

The test method is shown in Appendix B, which should meet the requirements of 4.3.

5.4 Hardness

Carry out the test according to the method specified in GB/T 4340.1, measure three points on the blade, and take the arithmetic average value, which should meet the requirements of 4.4.

5.5 Flexibility

The test method is shown in Appendix C, which should meet the requirements of 4.5.

5.6 Anti-rust performance

5.6.1 Open the package, the surface of the blade should meet the requirements of 4.6.

5.6.2 Non-sterile blades are tested according to the sterilization or disinfection method specified in the instructions, and the surface of the blade should meet the requirements of 4.6.

5.7 Sterility

It should be carried out in accordance with the general rule 1101 of the "Pharmacopoeia of the People's Republic of China" (2015 Edition·Part Four) "Sterile Inspection Method", which should meet the requirements of 4.7.

5.8 Residual ethylene oxide

It should be carried out according to the method specified in GB/T 14233.1 and should meet the requirements in 4.8.

5.9 Packaging labels and instructions

By visual observation, the relevant content of the smallest package label and manual should meet the requirements of 4.9.

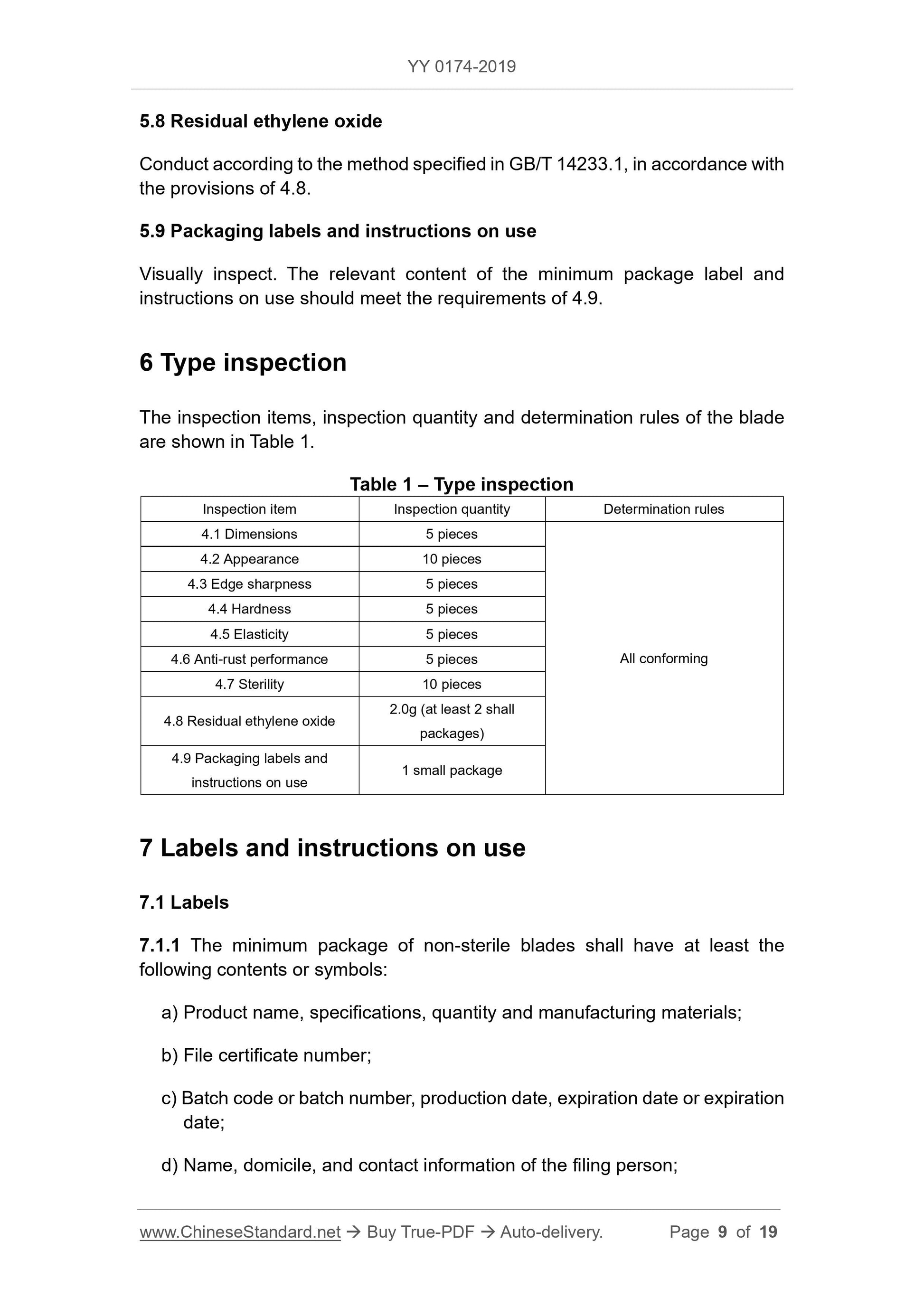

6 Type inspection

The inspection items, inspection quantity and judgment rules of the blade are shown in Table 1.

7 Labels and instructions

7.1 Label

7.1.1 The minimum package of non-sterile blades should have at least the following contents or symbols.

a) Product name, specifications, quantity and manufacturing materials;

b) The number of the filing voucher;

c) Batch code or batch number, production date, expiration date or expiration date;

d) The name, residence, and contact information of the filing person;

e) Production company name, domicile, production address, contact information and production record certificate number;

f) The words or symbols of "Other contents are detailed in the manual".

7.1.2 The minimum package of sterile blades shall have at least the following contents or symbols.

a) Product name and specifications;

b) Sterilization method, aseptic, single-use mark;

c) Product registration certificate number;

d) The words or symbols of "use if the package is damaged";

e) Batch code or batch number, production date, expiry date or expiration date;

f) The name and domicile of the registrant or manufacturer;

g) The words or symbols of "Other contents are detailed in the manual".

7.1.3 The minimum sales unit package should have at least the following contents or symbols.

a) Product name;

b) Specification and quantity;

c) Sterilization method (for sterile blades), single-use mark;

d) Batch code or batch number, production date, expiration date or expiration date;

e) Product registration certificate number or record certificate number, production license number or production record certificate number;

f) The name of the registrant or filing person, the name of the manufacturer, the address, and the contact information;

7.1.4 Each minimum sales unit shall have an inspection certificate, and the certificate shall have at least the following contents.

a) The name of the registrant or recorder or manufacturer;

b) Product technical requirement number;

c) Batch code or batch number;

d) Inspection date and inspector code.

7.1.5 The packaging, storage and transportation marks on the packaging should comply with the relevant regulations of GB/T 191 and YY/T 0466.1.

7.2 Instructions

There should be an instruction manual in each minimum sales unit, and the preparation of the instruction manual should comply with the requirements of GB/T 9969, and should at least contain the following content.

a) Product name and specifications;

b) The name, address, contact information and after-sales service information of the registrant or recorder or manufacturer.

The name, address, production license number or production record certificate number of the consigning manufacturer;

c) Product registration certificate number or record certificate number, production license number or production record certificate number;

d) Product technical requirement number;

e) Product performance, manufacturing materials, and scope of application;

f) Installation and use instructions or diagrams;

g) Storage conditions and methods;

h) One-time use, detailed sterilization or disinfection method, description of production date, expiration date or expiration date;

i) Explanation of graphics, symbols, abbreviations, etc. used in the label;

j) The date of preparation or revision of the manual;

k) Contraindications, precautions, warnings and reminders.

1) Requirements to ensure the correct and safe use of blades, and post-processing requirements for safe use;

2) Matters needing attention when the blade is used in conjunction with other instruments;

3) The sterile blade should indicate the treatment method when the smallest single package is damaged.

8 Packaging, transportation, storage and expiry date

8.1 The initial packaging consists of a single sterile blade or multiple non-sterile blades, and the initial packaging should be the smallest package.

Note. The rust-proof paper packaging of a single non-sterile blade is not regarded as the minimum packaging.

8.2 The middle package is composed of one or more small packages, and the middle package should be the smallest sales unit.

8.3 After the initial packaging of the sterile blade is opened, there should be traces of the opening.

8.4 The smallest sales unit should be accompanied by instructions and certificates.

8.5 Under the transportation conditions specified by the manufacturer, the packaging is undamaged, and the writing on the packaging label should be clear within the validity period.

8.6 The packaged blades should be stored in a room temperature, clean, well-ventilated, and non-corrosive gas environment, and the expiration date should not be less than 2 years.

B.3 Test materials

The test material adopts 3-0 uncoated 3-0 suture with twisted strands of class I silk in accordance with YY 0167-2005.

B.4 Test method

B.4.1 The surface of the sample (blade) should be cleaned of grease and care should be taken to maintain the quality of the original product.

B.4.2 Test procedure.

---Fix the sample (blade) on the fixture;

---Fix one end of the suture thread on a winding clamp, and add 100g weight to the other end of the suture thread to make the suture thread horizontal and secure

Set it on the other winding clamp, remove the weight, and prepare for the test;

---The sample moves vertically downward at a speed not greater than 10mm/s, and cuts the middle part of the suture line;

---When the suture is cut, record the test value.

B.4.3 For each blade, measure the front, middle, and back three points of the blade according to the test procedure B.4.2, and take the arithmetic average of the three-point test values as the test

Get Quotation: Click YY 0174-2019 (Self-service in 1-minute)

Historical versions (Master-website): YY 0174-2019

Preview True-PDF (Reload/Scroll-down if blank)

YY 0174-2019: [YY/T 0174-2019] Scalpel blade

YY 0174-2019

Scalpel blade

ICS 11.040.30

C31

People's Republic of China Pharmaceutical Industry Standards

Replace YY 0174-2005

Surgical blade

2019-05-31 released

2020-06-01 Implementation

Issued by the National Medical Products Administration

Preface

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces YY 0174-2005 "Surgery Blade".

Compared with YY 0174-2005, the main changes of this standard are as follows.

---Revised the scope of application (see Chapter 1, Chapter 1 of the.2005 edition);

---Revised manufacturing materials (see 3.3, 3.2 of the.2005 edition);

---Added the blade identification requirements (see 3.4);

---Revised the hardness requirements (see 4.4, 4.4.1 of the.2005 edition);

---Added anti-rust performance requirements (see 4.6);

---Added ethylene oxide residue requirements (see 4.8);

---Added requirements for packaging labels and instructions (see 4.9);

---Revised the surface roughness test method (see 5.2.1, 5.2.1 of the.2005 edition);

---Revised the cutting edge sharpness test method (see 5.3, 5.3 of the.2005 edition);

---Revised the type inspection (see Chapter 6, Chapter 6 of the.2005 edition);

---Revised the labeling and instructions requirements (see Chapter 7, Chapter 7 of the.2005 edition);

---Revised the packaging, transportation and storage requirements (see Chapter 8, Chapter 8 of the.2005 edition).

Please note that some of the contents of this document may involve patents, and the issuing agency of this document does not bear the responsibility for identifying these patents.

This standard was proposed by the State Drug Administration.

This standard is under the jurisdiction of the National Technical Committee for Standardization of Surgical Instruments (SAC/TC94).

Drafting organizations of this standard. Shanghai Pudong Jinhuan Medical Products Co., Ltd., Shanghai Medical Device Testing Institute, Huaiyin Medical Devices Co., Ltd.

Limited company.

The main drafters of this standard. Zhang Yanqing, Wang Zewei, Gao Bai, Wang Fengcai, Huang Shuze, Lu Guangheng, Lu Lidong.

The previous versions of the standard replaced by this standard are as follows.

---WS2/Z45~WS2/Z46-1982;

---GB n210-1983;

---GB 2544-1988;

---YY/T 0174-1994, YY 0293-1997;

---YY 0174-2005.

Surgical blade

1 Scope

This standard specifies the classification and identification, requirements, test methods, type inspection, labeling and instructions, packaging, transportation, and storage of surgical blades.

And expiry date.

This standard applies to surgical blades (hereinafter referred to as blades) installed on the scalpel handle for cutting soft tissues.

2 Normative references

The following documents are indispensable for the application of this document. For dated reference documents, only the dated version applies to this article

Pieces. For undated reference documents, the latest version (including all amendments) is applicable to this document.

GB/T 191 Packaging, storage and transportation pictorial signs

GB/T 1299 Tool and Die Steel

GB/T 4340.1 Vickers hardness test of metallic materials Part 1.Test method

GB 8662 Matching size of scalpel blade and scalpel handle

GB/T 9969 General Rules for the Use of Industrial Products

GB/T 14233.1 Medical infusion, blood transfusion, and injection equipment inspection methods Part 1.Chemical analysis methods

YY 0167-2005 Non-absorbable surgical suture

YY/T 0294.1 Metallic materials for surgical instruments Part 1.Stainless steel

YY/T 0466.1 Medical devices are used for medical device labeling, marking and providing information symbols. Part 1.General requirements

YY/T 1052 Surgical instrument mark

Pharmacopoeia of the People's Republic of China (2015 Edition·Fourth Edition)

3 Classification and identification

3.1 Delivery status

The blade has two delivery states. aseptic and non-sterile (hereinafter referred to as sterile blade and non-sterile blade).

3.2 Specifications

Please refer to Appendix A for the specifications and dimensions of the blade, and the assembly specifications of the knife handle.

3.3 Materials

The manufacturing material of the blade should be made of non-alloy tool steel that meets the requirements of GB/T 1299 or martensite that meets the requirements of YY/T 0294.1

Stainless steel, or other applicable metal materials that meet the requirements of Chapter 4.

3.4 Marking requirements

According to the provisions of YY/T 1052, the surface of the blade should at least be marked with the manufacturer code, material code (non-alloy tool steel, marking default) and specification.

Grid, the location of the mark is shown in Figure 1.

4 requirements

4.1 Dimensions

The blade assembly dimensions α, δ, b, b1, L1 and L2, see Figure 1, should meet the requirements of GB 8662.

4.2 Appearance

4.2.1 The value of the surface roughness Ra of the insert should not be greater than 0.4μm, and the value of the surface roughness Ra of the cutting edge surface should not be greater than

0.8μm.

4.2.2 The cutting edge of the blade should be free of nicks, white edges, curls, cracks, etc.

4.2.3 The width of both sides of the cutting edge of the blade should be similar, and the surface should be free of focal spots.

4.2.4 The blade should be flat, and there should be no cracks, sharp edges, burrs, or obvious pitting.

4.3 Cutting edge sharpness

The cutting edge of the blade should be sharp, and its cutting force should not be greater than 0.80N.

4.4 Hardness

The blade should be heat treated, and its hardness is not less than 650HV10.

4.5 Flexibility

The blade should have good elasticity, and there should be no fracture and no obvious deformation after the test.

4.6 Anti-rust performance

The blade should have good anti-rust performance and there should be no rust spots on the surface.

4.7 Sterility

If it is a sterile blade, it should be sterilized through a confirmed sterilization process, and the blade should be sterile.

4.8 Residual ethylene oxide

If the blade is sterilized with ethylene oxide gas, the residual amount of ethylene oxide should not exceed 10μg/g.

4.9 Packaging labels and instructions

The packaging label should be clear and comply with the provisions of Chapter 7.The instructions should specify detailed sterilization or disinfection methods.

5 Test method

5.1 Dimensions

Measured with a universal measuring tool, it should meet the requirements of 4.1.

5.2 Appearance

5.2.1 Comparing with the surface roughness comparison sample block should meet the requirements of 4.2.1.

5.2.2 Visual observation should meet the requirements of 4.2.2, 4.2.3, and 4.2.4.

5.3 Cutting edge sharpness

The test method is shown in Appendix B, which should meet the requirements of 4.3.

5.4 Hardness

Carry out the test according to the method specified in GB/T 4340.1, measure three points on the blade, and take the arithmetic average value, which should meet the requirements of 4.4.

5.5 Flexibility

The test method is shown in Appendix C, which should meet the requirements of 4.5.

5.6 Anti-rust performance

5.6.1 Open the package, the surface of the blade should meet the requirements of 4.6.

5.6.2 Non-sterile blades are tested according to the sterilization or disinfection method specified in the instructions, and the surface of the blade should meet the requirements of 4.6.

5.7 Sterility

It should be carried out in accordance with the general rule 1101 of the "Pharmacopoeia of the People's Republic of China" (2015 Edition·Part Four) "Sterile Inspection Method", which should meet the requirements of 4.7.

5.8 Residual ethylene oxide

It should be carried out according to the method specified in GB/T 14233.1 and should meet the requirements in 4.8.

5.9 Packaging labels and instructions

By visual observation, the relevant content of the smallest package label and manual should meet the requirements of 4.9.

6 Type inspection

The inspection items, inspection quantity and judgment rules of the blade are shown in Table 1.

7 Labels and instructions

7.1 Label

7.1.1 The minimum package of non-sterile blades should have at least the following contents or symbols.

a) Product name, specifications, quantity and manufacturing materials;

b) The number of the filing voucher;

c) Batch code or batch number, production date, expiration date or expiration date;

d) The name, residence, and contact information of the filing person;

e) Production company name, domicile, production address, contact information and production record certificate number;

f) The words or symbols of "Other contents are detailed in the manual".

7.1.2 The minimum package of sterile blades shall have at least the following contents or symbols.

a) Product name and specifications;

b) Sterilization method, aseptic, single-use mark;

c) Product registration certificate number;

d) The words or symbols of "use if the package is damaged";

e) Batch code or batch number, production date, expiry date or expiration date;

f) The name and domicile of the registrant or manufacturer;

g) The words or symbols of "Other contents are detailed in the manual".

7.1.3 The minimum sales unit package should have at least the following contents or symbols.

a) Product name;

b) Specification and quantity;

c) Sterilization method (for sterile blades), single-use mark;

d) Batch code or batch number, production date, expiration date or expiration date;

e) Product registration certificate number or record certificate number, production license number or production record certificate number;

f) The name of the registrant or filing person, the name of the manufacturer, the address, and the contact information;

7.1.4 Each minimum sales unit shall have an inspection certificate, and the certificate shall have at least the following contents.

a) The name of the registrant or recorder or manufacturer;

b) Product technical requirement number;

c) Batch code or batch number;

d) Inspection date and inspector code.

7.1.5 The packaging, storage and transportation marks on the packaging should comply with the relevant regulations of GB/T 191 and YY/T 0466.1.

7.2 Instructions

There should be an instruction manual in each minimum sales unit, and the preparation of the instruction manual should comply with the requirements of GB/T 9969, and should at least contain the following content.

a) Product name and specifications;

b) The name, address, contact information and after-sales service information of the registrant or recorder or manufacturer.

The name, address, production license number or production record certificate number of the consigning manufacturer;

c) Product registration certificate number or record certificate number, production license number or production record certificate number;

d) Product technical requirement number;

e) Product performance, manufacturing materials, and scope of application;

f) Installation and use instructions or diagrams;

g) Storage conditions and methods;

h) One-time use, detailed sterilization or disinfection method, description of production date, expiration date or expiration date;

i) Explanation of graphics, symbols, abbreviations, etc. used in the label;

j) The date of preparation or revision of the manual;

k) Contraindications, precautions, warnings and reminders.

1) Requirements to ensure the correct and safe use of blades, and post-processing requirements for safe use;

2) Matters needing attention when the blade is used in conjunction with other instruments;

3) The sterile blade should indicate the treatment method when the smallest single package is damaged.

8 Packaging, transportation, storage and expiry date

8.1 The initial packaging consists of a single sterile blade or multiple non-sterile blades, and the initial packaging should be the smallest package.

Note. The rust-proof paper packaging of a single non-sterile blade is not regarded as the minimum packaging.

8.2 The middle package is composed of one or more small packages, and the middle package should be the smallest sales unit.

8.3 After the initial packaging of the sterile blade is opened, there should be traces of the opening.

8.4 The smallest sales unit should be accompanied by instructions and certificates.

8.5 Under the transportation conditions specified by the manufacturer, the packaging is undamaged, and the writing on the packaging label should be clear within the validity period.

8.6 The packaged blades should be stored in a room temperature, clean, well-ventilated, and non-corrosive gas environment, and the expiration date should not be less than 2 years.

B.3 Test materials

The test material adopts 3-0 uncoated 3-0 suture with twisted strands of class I silk in accordance with YY 0167-2005.

B.4 Test method

B.4.1 The surface of the sample (blade) should be cleaned of grease and care should be taken to maintain the quality of the original product.

B.4.2 Test procedure.

---Fix the sample (blade) on the fixture;

---Fix one end of the suture thread on a winding clamp, and add 100g weight to the other end of the suture thread to make the suture thread horizontal and secure

Set it on the other winding clamp, remove the weight, and prepare for the test;

---The sample moves vertically downward at a speed not greater than 10mm/s, and cuts the middle part of the suture line;

---When the suture is cut, record the test value.

B.4.3 For each blade, measure the front, middle, and back three points of the blade according to the test procedure B.4.2, and take the arithmetic average of the three-point test values as the test

Share