1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY 0341.1-2020 English PDF

YY 0341.1-2020 English PDF

Regular price

$245.00 USD

Regular price

Sale price

$245.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY 0341.1-2020 (Self-service in 1-minute)

Historical versions (Master-website): YY 0341.1-2020

Preview True-PDF (Reload/Scroll-down if blank)

YY 0341.1-2020: Non-active surgical implants - Osteosynthesis and spinal implants - Part 1: Particular requirements for osteosynthesis implants

YY 0341.1-2020

Non-active surgical implants - Osteosynthesis and spinal implants - Part 1.Particular requirements for osteosynthesis implants

ICS 11.040.40

C35

People's Republic of China Pharmaceutical Industry Standard

Replacing YY 0341-2009

Passive surgical implant bone joint and spinal implant

Part 1.Special requirements for osteosynthetic implants

2020-09-27 release

2022-06-01 implementation

Issued by the State Drug Administration

Table of contents

Foreword Ⅰ

1 Scope 1

2 Normative references 1

3 Terms and definitions 1

4 Requirements 2

5 Test method 3

6 Manufacturing 4

7 Sterilization 4

8 Packaging 4

9 Information provided by the manufacturer 4

Appendix A (informative appendix) Relevant standards for osteosynthetic implants that have been proven acceptable for clinical use 6

Appendix B (informative appendix) Relevant material standards for clinical use certification 8

Appendix C (informative appendix) List of approved method standards for chemical analysis 10

Appendix D (informative appendix) Relevant standards related to design evaluation and testing 11

Preface

All technical content of this standard is mandatory.

YY 0341 "Passive Surgical Implant Bone Joint and Spinal Implant" standard is divided into the following two parts.

---Part 1.Special requirements for bone joint implants;

---Part 2.Special requirements for spinal implants.

This part is part 1 of YY 0341.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

"Passive surgical implant bone joint and spinal implants" replace YY 0341-2009 "passive surgical metal implants for bone joint

Technical Conditions of Use. The main technical differences between this part and YY 0341-2009 are as follows.

--- Split the original standard into two parts. "bone joint implant" and "spine implant";

---Modify the scope of application, it is no longer only applicable to passive surgical implants made of metal materials, and the non-applicable in YY 0341.1

The scope was amended to "coated part of bone joint implant with surface coating" (see Chapter 1, Chapter 1 of the.2009 edition);

---Add related terms and definitions, such as "anodization of titanium and titanium alloys" (see 3.3);

--- Modify the "appearance" requirements (see 4.5.3, 4.4.3 of the.2009 edition);

---Add "anodized surface treatment" requirements (see 4.5.4);

---Add "cooperating performance" requirements (see 4.7);

--- Increase the requirement of "Ethylene oxide residue" (see 4.8);

--- Delete the original Chapter 6 "Inspection Rules", merge the regulations on the number of test samples into Chapter 5 "Test Methods", delete the original Chapter 7 "Use

Instruction Manual", original Chapter 10 "Transport and Storage", original Chapter 11 "Requirements for Use", add "manufacturing" and "information provided by the manufacturer"

And other chapters.

Please note that certain contents of this document may involve patents. The issuing agency of this document is not responsible for identifying these patents.

This part was proposed by the State Drug Administration.

This part is organized by the Orthopedic Implant Sub-Technical Committee of the National Standardization Technical Committee for Surgical Implants and Orthopedic Devices (SAC/TC110/

SC1) Centralized.

Drafting organizations of this section. Tianjin Medical Device Quality Supervision and Inspection Center, Medical Device Technology Review under the State Drug Administration

Xin, Beijing Natong Technology Group Co., Ltd.

The main drafters of this section. Jiang Xi, Zhang Lu, Fu Ruizhi, Song Duo, Liu Bin, Liu Yinghui, Li Renyao, Zhao Wenwen.

The previous versions of the standards replaced by this part are as follows.

---YY 0341-2002,YY 0341-2009.

Passive surgical implant bone joint and spinal implant

Part 1.Special requirements for osteosynthetic implants

1 Scope

This part of YY 0341 specifies the special requirements of passive surgical implants for osteosynthesis (hereinafter referred to as "osseous implants"), including

The terms and definitions, requirements, test methods, manufacturing, sterilization, packaging, and information provided by the manufacturer of the osteosynthetic implant.

This part of YY 0341 applies to bone-engaging implants, not to the coating part of bone-engaging implants with surface coating.

2 Normative references

The following documents are indispensable for the application of this document. For dated reference documents, only the dated version applies to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 4340.1 Vickers hardness test for metallic materials Part 1.Test method

GB/T 10610 Product Geometric Technical Specification (GPS) Surface Structure Profile Method. Rules and Methods for Surface Structure Evaluation

GB/T 14233.2 Medical infusion, blood transfusion, and injection equipment inspection methods Part 2.Biological test methods

GB/T 16886.7 Biological Evaluation of Medical Devices Part 7.Residues of Ethylene Oxide Sterilization

YY/T 0343 Liquid penetration testing of surgical metal implants

YY/T 0640-2016 General requirements for passive surgical implants

YY/T 1074 Pitting potential of surgical implant stainless steel products

YY/T 1615 General requirements for titanium and titanium alloy anodic oxide films on surgical implants

3 Terms and definitions

The following terms and definitions defined in YY/T 0640-2016 apply to this document.

3.1

Passive surgical implant for osteosynthesis non-activesurgicalimplantforosteosynthesis

Passive surgical implant products used to support bone, cartilage, tendon or ligament structures.

Note. Refer to Appendix A for common types of bone-engaging implants that have been proven acceptable for clinical use.

3.2

Coating

A layer of material used to cover or partially cover the surface of an implant.

3.3

Anodizing titanium and titanium alloy anodizing titanium and titanium alloy

Electrochemical oxidation of titanium and titanium alloys. Titanium and titanium alloys are used as anodes, in the corresponding electrolyte, through the action of an external electric field,

The process of forming an oxide layer on its surface under certain process conditions.

4 requirements

4.1 Materials

Manufacturers should give priority to materials suitable for bone-engaging implants specified in international standards, national standards, and industry standards.

Note. Some material standards for osteosynthetic implants that have been proven acceptable through clinical applications can be found in the informative list given in Appendix B.

4.2 Hardness

The hardness of metal bone joint implants should meet the requirements of the corresponding product standards.

4.3 Static and/or dynamic mechanical properties

The manufacturer should combine the characteristics of the bone-engaging implant and its clinical use to specify its static and/or dynamic mechanical properties. If there are related products

Product standards, the mechanical properties of bone-engaged implants should meet the requirements of the corresponding standards. Due to the different characteristics of osteosynthetic implants, the test targets

The standards may not yet exist or the existing test standards may be modified as needed.

4.4 Corrosion resistance

The pitting potential (Eb) on the surface of the final product of the stainless steel bone-engaging implant should not be less than 800mV.

4.5 Surface quality

4.5.1 Surface defects

The surface of the non-coated metal bone joint implant shall not have any discontinuity defects.

4.5.2 Surface roughness

The manufacturer shall specify the roughness Ra value of the main surface of the bone-engaging implant.

If there are relevant product standards, the roughness Ra value of bone-engaged implants should meet the requirements of the corresponding standards.

4.5.3 Appearance

The surface of the osteosynthetic implant should be free of defects that affect the function of the implant, as well as inlays, final processing deposits and other contaminants.

Note. Defects affecting function include oxide skin, knife marks, small nicks, scratches, cracks, depressions, sharp edges (except for cutting edges), burrs and other defects.

4.5.4 Anodized surface treatment

For bone joint implants made of titanium and titanium alloy materials, if the surface treatment is anodized, the manufacturer shall deal with the relevant properties of the anodized film

Make regulations.

4.6 Dimensions of important parts

The manufacturer shall specify the dimensions of the important parts of the bone joint implant.

If there are relevant product standards, the dimensions and tolerances of important parts of the bone-engaging implants should meet the requirements of the corresponding standards.

4.7 Fitting performance

The manufacturer shall specify the compatibility of the bone-engaging implants that need to be used together.

4.8 Sterility

Bone joint implants delivered aseptically should go through an effective and confirmed sterilization process to make the product sterile. If the product adopts

For sterilization with ethylene oxide, the manufacturer shall specify the residual amount of ethylene oxide in the product.

5 Test method

5.1 Materials

The chemical composition and microstructure of metal materials for bone-synthetic implants, and the physical and chemical properties of polymer materials are tested according to the selected material standards

The specified method or refer to Appendix C recommended method for inspection.

Note. If the final product cannot be sampled due to structure or size, the same batch of raw materials through the same manufacturing process can also be used.

5.2 Hardness

According to the method of GB/T 4340.1.

Note. Other validated methods are also acceptable.

5.3 Static and/or dynamic mechanical properties

When using static and/or dynamic load tests to evaluate bone-engaging implants, existing inspection standards can be used (see Appendix D for related information)

Or adopt a customized test model that takes into account the characteristics of the implant. The number of samples required for the test should be determined according to the selected test method standard.

Note 1.The test method can be selected according to different test levels.

Note 2.Preclinical evaluation should take into account existing data of similar implants or design characteristics.

Note 3.Tests can be performed on specific implants under specific loads and/or specific environmental conditions to evaluate their performance.

5.4 Corrosion resistance

According to the method specified in YY/T 1074, the number of samples should be no less than 3 pieces.

Note. If the final product cannot be sampled due to structure (such as locking screw) or size, the same batch of raw materials and samples of the same manufacturing process can also be used.

5.5 Surface quality

5.5.1 Surface defects

According to the method specified in YY/T 0343, the number of samples should be no less than 3 pieces.

Note. Other validated methods are also acceptable.

5.5.2 Surface roughness

The sample comparison method or the electrical measurement method specified in GB/T 10610 is adopted. The electrical measurement method is the arbitration inspection method, and the number of samples should not be less than

3 pieces.

5.5.3 Appearance

For normal or corrected vision inspection, the number of samples should be no less than 3 pieces.

5.5.4 Anodized surface treatment

According to the method specified in YY/T 1615, at least the qualitative analysis and cytotoxicity of the surface elements of the anodic oxide film should be tested.

Note. Other validated methods are also acceptable.

5.6 Dimensions of important parts

Use general measuring tools or special inspection tools to measure, and the number of samples should be no less than 3 pieces.

5.7 Coordination performance

The action can be imitated or other methods can be used to test the matching performance.

5.8 Sterility

5.8.1 The sterility test shall be carried out according to the method specified in GB/T 14233.2.

Note. Other validated methods are also acceptable.

5.8.2 The residual amount of ethylene oxide shall be carried out according to the method specified in GB/T 16886.7.

Note. Other validated methods are also acceptable.

6 Manufacturing

It shall meet the requirements of Chapter 8 in YY/T 0640-2016.

7 Sterilization

It shall meet the requirements of Chapter 9 in YY/T 0640-2016.

8 packaging

It should meet the requirements of Chapter 10 in YY/T 0640-2016.

9 Information provided by the manufacturer

9.1 General

Chapter 11 of YY/T 0640-2016 and the following specific terms apply.

9.2 Manual

Should comply with the provisions of 11.3 in YY/T 0640-2016, the manufacturer should also provide the following information.

Restrictions on any modification after delivery of the implant. size, shape, surface condition.

9.3 Marking

9.3.1 11.5, 11.6 or the following clauses in YY/T 0640-2016 apply.

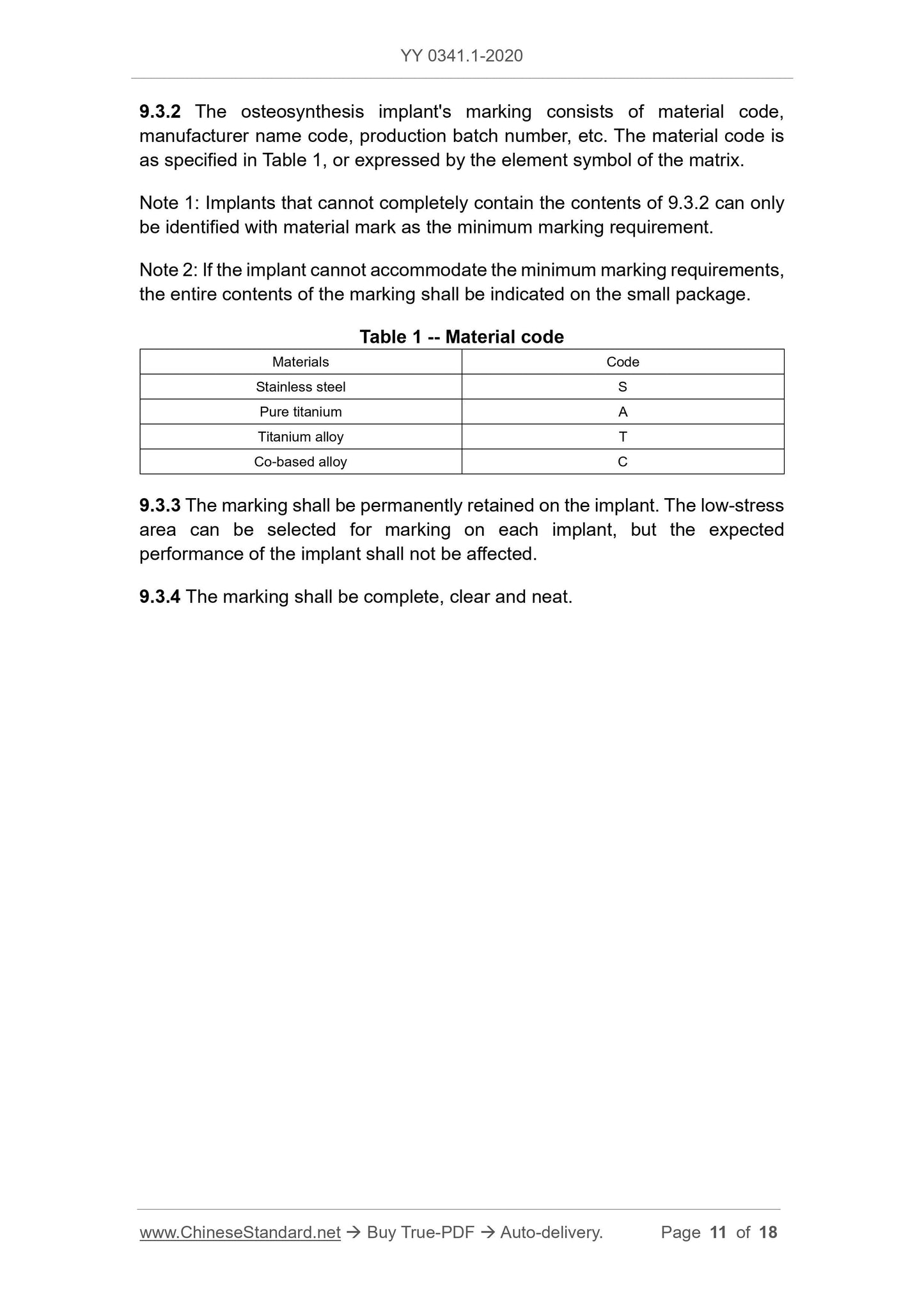

9.3.2 The osseous implant mark consists of material code, factory name code, production batch number, etc. The material code is as specified in Table 1, or based on the matrix

The symbolic representation of the element.

Note 1.Implants that cannot completely contain the contents of 9.3.2 can only be marked with material as the minimum marking requirement.

Note 2.If the implant cannot accommodate the minimum marking requirements, the entire contents of the marking should be indicated on the small package.

Appendix A

(Informative appendix)

Relevant standards for clinically acceptable bone-engaging implants

A.1 Bone nail

YY 0018 Bone joint implant metal bone screw

ISO 5835 Surgical implant asymmetric thread, spherical lower surface, hexagon socket metal bone screw size

ISO 9268 Dimensions of metal bone screws on the tapered lower surface of surgical implants

A.2 Bone Plate

YY 0017 Bone joint implant metal bone plate

YY/T 0856 Bone joint implant metal angle fixator

ISO 5836 Surgical implant metal bone plate with asymmetric thread, the corresponding hole of the spherical lower surface screw

ISO 9269 Metal bone plates for surgical implants and corresponding holes ...

Get Quotation: Click YY 0341.1-2020 (Self-service in 1-minute)

Historical versions (Master-website): YY 0341.1-2020

Preview True-PDF (Reload/Scroll-down if blank)

YY 0341.1-2020: Non-active surgical implants - Osteosynthesis and spinal implants - Part 1: Particular requirements for osteosynthesis implants

YY 0341.1-2020

Non-active surgical implants - Osteosynthesis and spinal implants - Part 1.Particular requirements for osteosynthesis implants

ICS 11.040.40

C35

People's Republic of China Pharmaceutical Industry Standard

Replacing YY 0341-2009

Passive surgical implant bone joint and spinal implant

Part 1.Special requirements for osteosynthetic implants

2020-09-27 release

2022-06-01 implementation

Issued by the State Drug Administration

Table of contents

Foreword Ⅰ

1 Scope 1

2 Normative references 1

3 Terms and definitions 1

4 Requirements 2

5 Test method 3

6 Manufacturing 4

7 Sterilization 4

8 Packaging 4

9 Information provided by the manufacturer 4

Appendix A (informative appendix) Relevant standards for osteosynthetic implants that have been proven acceptable for clinical use 6

Appendix B (informative appendix) Relevant material standards for clinical use certification 8

Appendix C (informative appendix) List of approved method standards for chemical analysis 10

Appendix D (informative appendix) Relevant standards related to design evaluation and testing 11

Preface

All technical content of this standard is mandatory.

YY 0341 "Passive Surgical Implant Bone Joint and Spinal Implant" standard is divided into the following two parts.

---Part 1.Special requirements for bone joint implants;

---Part 2.Special requirements for spinal implants.

This part is part 1 of YY 0341.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

"Passive surgical implant bone joint and spinal implants" replace YY 0341-2009 "passive surgical metal implants for bone joint

Technical Conditions of Use. The main technical differences between this part and YY 0341-2009 are as follows.

--- Split the original standard into two parts. "bone joint implant" and "spine implant";

---Modify the scope of application, it is no longer only applicable to passive surgical implants made of metal materials, and the non-applicable in YY 0341.1

The scope was amended to "coated part of bone joint implant with surface coating" (see Chapter 1, Chapter 1 of the.2009 edition);

---Add related terms and definitions, such as "anodization of titanium and titanium alloys" (see 3.3);

--- Modify the "appearance" requirements (see 4.5.3, 4.4.3 of the.2009 edition);

---Add "anodized surface treatment" requirements (see 4.5.4);

---Add "cooperating performance" requirements (see 4.7);

--- Increase the requirement of "Ethylene oxide residue" (see 4.8);

--- Delete the original Chapter 6 "Inspection Rules", merge the regulations on the number of test samples into Chapter 5 "Test Methods", delete the original Chapter 7 "Use

Instruction Manual", original Chapter 10 "Transport and Storage", original Chapter 11 "Requirements for Use", add "manufacturing" and "information provided by the manufacturer"

And other chapters.

Please note that certain contents of this document may involve patents. The issuing agency of this document is not responsible for identifying these patents.

This part was proposed by the State Drug Administration.

This part is organized by the Orthopedic Implant Sub-Technical Committee of the National Standardization Technical Committee for Surgical Implants and Orthopedic Devices (SAC/TC110/

SC1) Centralized.

Drafting organizations of this section. Tianjin Medical Device Quality Supervision and Inspection Center, Medical Device Technology Review under the State Drug Administration

Xin, Beijing Natong Technology Group Co., Ltd.

The main drafters of this section. Jiang Xi, Zhang Lu, Fu Ruizhi, Song Duo, Liu Bin, Liu Yinghui, Li Renyao, Zhao Wenwen.

The previous versions of the standards replaced by this part are as follows.

---YY 0341-2002,YY 0341-2009.

Passive surgical implant bone joint and spinal implant

Part 1.Special requirements for osteosynthetic implants

1 Scope

This part of YY 0341 specifies the special requirements of passive surgical implants for osteosynthesis (hereinafter referred to as "osseous implants"), including

The terms and definitions, requirements, test methods, manufacturing, sterilization, packaging, and information provided by the manufacturer of the osteosynthetic implant.

This part of YY 0341 applies to bone-engaging implants, not to the coating part of bone-engaging implants with surface coating.

2 Normative references

The following documents are indispensable for the application of this document. For dated reference documents, only the dated version applies to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 4340.1 Vickers hardness test for metallic materials Part 1.Test method

GB/T 10610 Product Geometric Technical Specification (GPS) Surface Structure Profile Method. Rules and Methods for Surface Structure Evaluation

GB/T 14233.2 Medical infusion, blood transfusion, and injection equipment inspection methods Part 2.Biological test methods

GB/T 16886.7 Biological Evaluation of Medical Devices Part 7.Residues of Ethylene Oxide Sterilization

YY/T 0343 Liquid penetration testing of surgical metal implants

YY/T 0640-2016 General requirements for passive surgical implants

YY/T 1074 Pitting potential of surgical implant stainless steel products

YY/T 1615 General requirements for titanium and titanium alloy anodic oxide films on surgical implants

3 Terms and definitions

The following terms and definitions defined in YY/T 0640-2016 apply to this document.

3.1

Passive surgical implant for osteosynthesis non-activesurgicalimplantforosteosynthesis

Passive surgical implant products used to support bone, cartilage, tendon or ligament structures.

Note. Refer to Appendix A for common types of bone-engaging implants that have been proven acceptable for clinical use.

3.2

Coating

A layer of material used to cover or partially cover the surface of an implant.

3.3

Anodizing titanium and titanium alloy anodizing titanium and titanium alloy

Electrochemical oxidation of titanium and titanium alloys. Titanium and titanium alloys are used as anodes, in the corresponding electrolyte, through the action of an external electric field,

The process of forming an oxide layer on its surface under certain process conditions.

4 requirements

4.1 Materials

Manufacturers should give priority to materials suitable for bone-engaging implants specified in international standards, national standards, and industry standards.

Note. Some material standards for osteosynthetic implants that have been proven acceptable through clinical applications can be found in the informative list given in Appendix B.

4.2 Hardness

The hardness of metal bone joint implants should meet the requirements of the corresponding product standards.

4.3 Static and/or dynamic mechanical properties

The manufacturer should combine the characteristics of the bone-engaging implant and its clinical use to specify its static and/or dynamic mechanical properties. If there are related products

Product standards, the mechanical properties of bone-engaged implants should meet the requirements of the corresponding standards. Due to the different characteristics of osteosynthetic implants, the test targets

The standards may not yet exist or the existing test standards may be modified as needed.

4.4 Corrosion resistance

The pitting potential (Eb) on the surface of the final product of the stainless steel bone-engaging implant should not be less than 800mV.

4.5 Surface quality

4.5.1 Surface defects

The surface of the non-coated metal bone joint implant shall not have any discontinuity defects.

4.5.2 Surface roughness

The manufacturer shall specify the roughness Ra value of the main surface of the bone-engaging implant.

If there are relevant product standards, the roughness Ra value of bone-engaged implants should meet the requirements of the corresponding standards.

4.5.3 Appearance

The surface of the osteosynthetic implant should be free of defects that affect the function of the implant, as well as inlays, final processing deposits and other contaminants.

Note. Defects affecting function include oxide skin, knife marks, small nicks, scratches, cracks, depressions, sharp edges (except for cutting edges), burrs and other defects.

4.5.4 Anodized surface treatment

For bone joint implants made of titanium and titanium alloy materials, if the surface treatment is anodized, the manufacturer shall deal with the relevant properties of the anodized film

Make regulations.

4.6 Dimensions of important parts

The manufacturer shall specify the dimensions of the important parts of the bone joint implant.

If there are relevant product standards, the dimensions and tolerances of important parts of the bone-engaging implants should meet the requirements of the corresponding standards.

4.7 Fitting performance

The manufacturer shall specify the compatibility of the bone-engaging implants that need to be used together.

4.8 Sterility

Bone joint implants delivered aseptically should go through an effective and confirmed sterilization process to make the product sterile. If the product adopts

For sterilization with ethylene oxide, the manufacturer shall specify the residual amount of ethylene oxide in the product.

5 Test method

5.1 Materials

The chemical composition and microstructure of metal materials for bone-synthetic implants, and the physical and chemical properties of polymer materials are tested according to the selected material standards

The specified method or refer to Appendix C recommended method for inspection.

Note. If the final product cannot be sampled due to structure or size, the same batch of raw materials through the same manufacturing process can also be used.

5.2 Hardness

According to the method of GB/T 4340.1.

Note. Other validated methods are also acceptable.

5.3 Static and/or dynamic mechanical properties

When using static and/or dynamic load tests to evaluate bone-engaging implants, existing inspection standards can be used (see Appendix D for related information)

Or adopt a customized test model that takes into account the characteristics of the implant. The number of samples required for the test should be determined according to the selected test method standard.

Note 1.The test method can be selected according to different test levels.

Note 2.Preclinical evaluation should take into account existing data of similar implants or design characteristics.

Note 3.Tests can be performed on specific implants under specific loads and/or specific environmental conditions to evaluate their performance.

5.4 Corrosion resistance

According to the method specified in YY/T 1074, the number of samples should be no less than 3 pieces.

Note. If the final product cannot be sampled due to structure (such as locking screw) or size, the same batch of raw materials and samples of the same manufacturing process can also be used.

5.5 Surface quality

5.5.1 Surface defects

According to the method specified in YY/T 0343, the number of samples should be no less than 3 pieces.

Note. Other validated methods are also acceptable.

5.5.2 Surface roughness

The sample comparison method or the electrical measurement method specified in GB/T 10610 is adopted. The electrical measurement method is the arbitration inspection method, and the number of samples should not be less than

3 pieces.

5.5.3 Appearance

For normal or corrected vision inspection, the number of samples should be no less than 3 pieces.

5.5.4 Anodized surface treatment

According to the method specified in YY/T 1615, at least the qualitative analysis and cytotoxicity of the surface elements of the anodic oxide film should be tested.

Note. Other validated methods are also acceptable.

5.6 Dimensions of important parts

Use general measuring tools or special inspection tools to measure, and the number of samples should be no less than 3 pieces.

5.7 Coordination performance

The action can be imitated or other methods can be used to test the matching performance.

5.8 Sterility

5.8.1 The sterility test shall be carried out according to the method specified in GB/T 14233.2.

Note. Other validated methods are also acceptable.

5.8.2 The residual amount of ethylene oxide shall be carried out according to the method specified in GB/T 16886.7.

Note. Other validated methods are also acceptable.

6 Manufacturing

It shall meet the requirements of Chapter 8 in YY/T 0640-2016.

7 Sterilization

It shall meet the requirements of Chapter 9 in YY/T 0640-2016.

8 packaging

It should meet the requirements of Chapter 10 in YY/T 0640-2016.

9 Information provided by the manufacturer

9.1 General

Chapter 11 of YY/T 0640-2016 and the following specific terms apply.

9.2 Manual

Should comply with the provisions of 11.3 in YY/T 0640-2016, the manufacturer should also provide the following information.

Restrictions on any modification after delivery of the implant. size, shape, surface condition.

9.3 Marking

9.3.1 11.5, 11.6 or the following clauses in YY/T 0640-2016 apply.

9.3.2 The osseous implant mark consists of material code, factory name code, production batch number, etc. The material code is as specified in Table 1, or based on the matrix

The symbolic representation of the element.

Note 1.Implants that cannot completely contain the contents of 9.3.2 can only be marked with material as the minimum marking requirement.

Note 2.If the implant cannot accommodate the minimum marking requirements, the entire contents of the marking should be indicated on the small package.

Appendix A

(Informative appendix)

Relevant standards for clinically acceptable bone-engaging implants

A.1 Bone nail

YY 0018 Bone joint implant metal bone screw

ISO 5835 Surgical implant asymmetric thread, spherical lower surface, hexagon socket metal bone screw size

ISO 9268 Dimensions of metal bone screws on the tapered lower surface of surgical implants

A.2 Bone Plate

YY 0017 Bone joint implant metal bone plate

YY/T 0856 Bone joint implant metal angle fixator

ISO 5836 Surgical implant metal bone plate with asymmetric thread, the corresponding hole of the spherical lower surface screw

ISO 9269 Metal bone plates for surgical implants and corresponding holes ...

Share