1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY 0900-2013 English PDF (YY0900-2013)

YY 0900-2013 English PDF (YY0900-2013)

Regular price

$150.00 USD

Regular price

Sale price

$150.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY 0900-2013

Historical versions: YY 0900-2013

Preview True-PDF (Reload/Scroll if blank)

YY 0900-2013: Walk training platform with suspension

YY 0900-2013

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.60

C 42

Walk Training Platform with Suspension

减重步行训练台

ISSUED ON. OCTOBER 21, 2013

IMPLEMENTED ON. OCTOBER 1, 2014

Issued by. China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Classification ... 5

5 Requirements... 5

6 Test Methods ... 8

7 Inspection Rules ... 11

8 Marking and Operation Instruction ... 12

9 Packaging, Transportation and Storage ... 14

Walk Training Platform with Suspension

1 Scope

This Standard specifies the terms, definitions, classification, requirements, test

methods, inspection rules, marking, operation instruction, packaging, transportation

and storage of walk training platform with suspension (hereinafter referred to as

equipment).

This Standard is applicable to equipment stipulated in 3.1.

2 Normative References

The following documents are indispensable to the application of this Standard. In terms

of references with a specified date, only versions with a specified date are applicable

to this Standard. The latest version (including all the modifications) of references

without a specified date is also applicable to this Standard.

GB/T 191 Packaging - Pictorial Marking for Handling of Goods

GB 9706.1-2007 Medical Electrical Equipment - Part 1. General Requirements for

Safety

GB 9706.15 Medical Electrical Equipment - Part 1. General Requirements for

Safety - 1. Collateral Standard. Safety Requirements for Medical Electrical

Systems

GB/T 14710 Environmental Requirement and Test Methods for Medical Electrical

Equipment

GB/T 16886.1 Biological Evaluation of Medical Devices - Part 1. Evaluation and

Testing within a Risk Management Process

GB 17498.6-2008 Stationary Training Equipment - Part 6. Treadmills - Additional

Specific Safety Requirements and Test Methods

YY/T 0466.1 Medical Devices - Symbols to be Used with Medical Device Labels,

Labeling and Information to be Supplied - Part 1. General Requirements

3 Terms and Definitions

Those defined in GB 9706.1-2007 AND the following terms and definitions are

applicable to this document.

5.1.5 Suspension belt

5.1.5.1 Adjustment and locking

The suspension belt shall be equipped with adjustment and locking device, and easily

operable. Locking shall be safe and reliable; easily recognizable and safely operated.

It shall be manually operated without the help of any instruments.

5.1.5.2 Width

The suspension belt shall be reasonably designed. The suspension belt that contacts

the buttock shall use soft materials; the edges shall be smooth; the width shall not be

less than 80 mm.

5.2 Walk Training Platform

5.2.1 Timing setting

The walk training platform shall have timing function; the timing error shall not be more

than ± 1% of the set value, and not more than ± 1 min at the maximum.

5.2.2 Speed setting

The walk training platform shall have the function of speed control. Speed output shall

guarantee accuracy and uniformity. The deviation of accuracy shall not exceed ± 5%;

the deviation of uniformity shall not exceed 1 m/s. Speed shall be continuously

adjustable within the range stipulated by the manufacturer; the lowest speed shall not

exceed 0.5 km/h.

5.2.3 Gradient setting

In terms of walk training platform which has the function of gradient adjustment,

gradient shall be continuously adjustable. It shall also have the function of adjustment

indication; the deviation of gradient indication shall not exceed ± 10%.

5.2.4 Static load

The walk training platform shall be able to maintain intact after supporting 6 times of

the normal load stipulated by the manufacturer.

5.2.5 Safety of unexpected power outage

As power supply recovers after unexpected power outage, the walk training platform

would not automatically operate.

5.2.6 Emergency stop device

Except from the power switch, the equipment shall also provide an emergency stop

button, which can stop the training program at any time. This button shall take effect

6.2.4 Static load

Conduct the test in accordance with the requirement in 6.6 in GB 17498.6-2008; it shall

comply with the requirement in 5.2.4.

6.2.5 Safety of unexpected power outage

Conduct the test in practical operation; it shall comply with the requirement in 5.2.5.

6.2.6 Emergency stop device

Conduct the test in visual inspection and practical operation; it shall comply with the

requirement in 5.2.6.

6.2.7 Fatigue test

In the test, simulate the equipment’s moving components in 100,000 times of no-load

operation. After that, the equipment’s function shall still satisfy the requirement in 5.2.7.

6.3 Overall Requirements of Equipment

6.3.1 Stability

Place the overall equipment on a flat surface; use a feeler gauge to measure the

distance between the footing and the flat surface.

In the equipment’s suspended device part, load the normal load stipulated by the

manufacturer. In accordance with the movement direction under normal training state,

or the direction which is the most unfavorable to stability, start to roll over from

horizontal. Use a protractor (precision. superior to 0.1°) to record the rolling-over angle.

The overall equipment shall be placed on a cement ground in accordance with the

requirement in the instruction. If there are trundles, lock the trundles. In the direction

of force, in the most unfavorable location at 1.5 m height of the equipment, impose 120

(1 ± 2%) N of horizontal pull or thrust; observe whether the equipment has moved.

The above test result shall comply with the requirement in 5.3.1.

6.3.2 Operating noise

Place the equipment on a hard table and at a distance of at least 3 m from the walls or

other reflectors. Under the environment where background noise is 10 dB lower than

the measuring point in the sound pressure level, operate the equipment under normal

working state where the maximum noise might be generated; measure A-weighted

sound level in the front, the back, the left, the right and the top of the host device of the

equipment; they shall all satisfy the requirement in 5.3.2. If the manufacturer stipulates

equipment’s special installation or arrangement conditions in the attached documents,

the equipment can be arranged merely in accordance with the method stipulated by

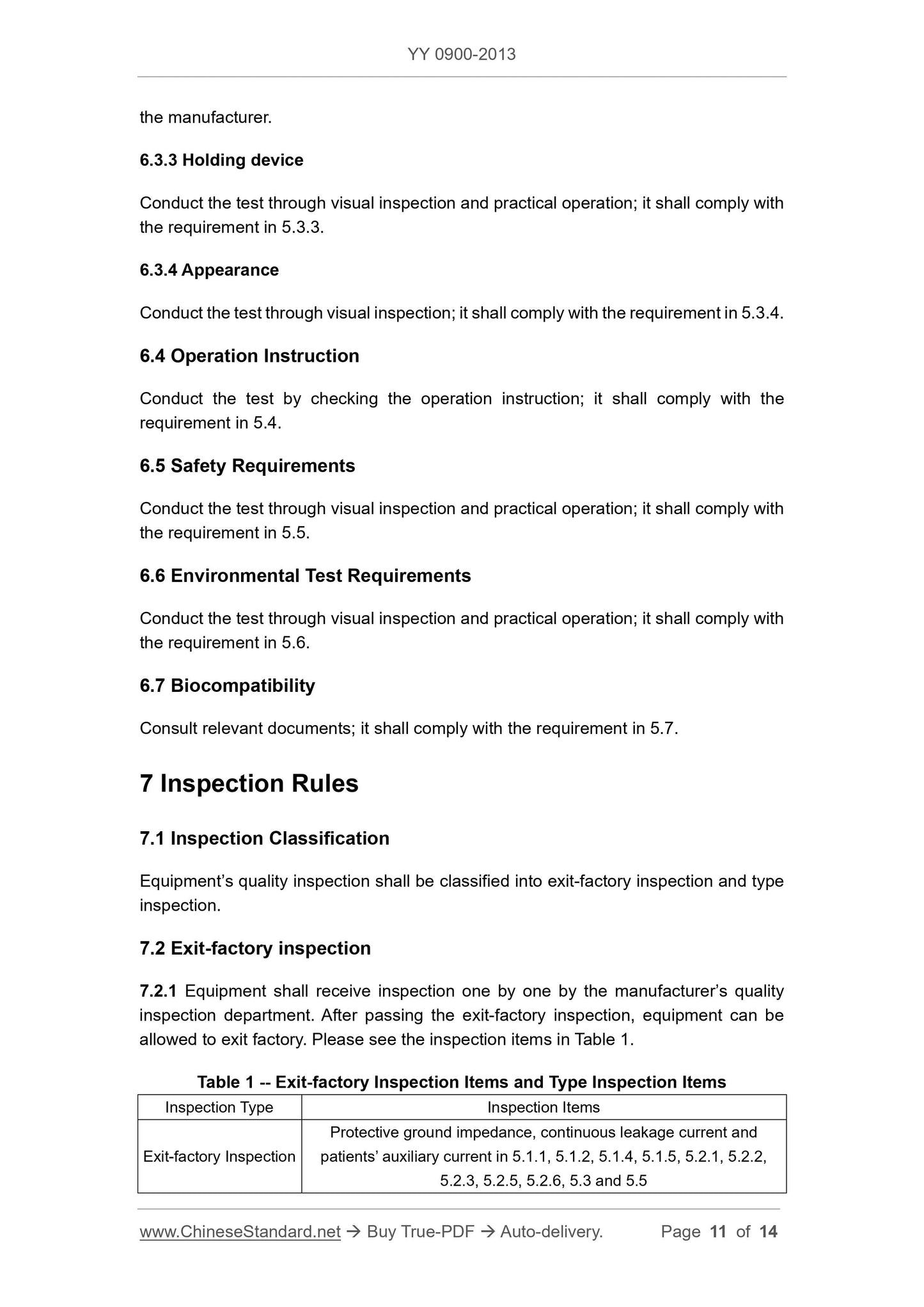

Type Inspection All items

7.2.2 Determination of exit-factory inspection. if products are qualified in all the

inspection items, then, they shall be determined as qualified in exit-factory inspection.

Otherwise, they shall be determined as unqualified in exit-factory inspection.

7.3 Type Inspection

7.3.1 Type inspection shall be conducted under one of the following circumstances.

a) Before product registration (including old products which are switched to other

production);

b) When products have been continuously produced for a certain period (generally

not more than 2 years);

c) When production is resumed after over one year of suspension;

d) When there are significant changes in product structure, materials, process or

key components;

e) When there are relatively large differences between the result of exit-factory

inspection and design requirements;

f) When national quality supervision and inspection institution requests.

7.3.2 Determination of type inspection. if products are qualified in all the inspection

items, then, they shall ...

Get QUOTATION in 1-minute: Click YY 0900-2013

Historical versions: YY 0900-2013

Preview True-PDF (Reload/Scroll if blank)

YY 0900-2013: Walk training platform with suspension

YY 0900-2013

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.60

C 42

Walk Training Platform with Suspension

减重步行训练台

ISSUED ON. OCTOBER 21, 2013

IMPLEMENTED ON. OCTOBER 1, 2014

Issued by. China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Classification ... 5

5 Requirements... 5

6 Test Methods ... 8

7 Inspection Rules ... 11

8 Marking and Operation Instruction ... 12

9 Packaging, Transportation and Storage ... 14

Walk Training Platform with Suspension

1 Scope

This Standard specifies the terms, definitions, classification, requirements, test

methods, inspection rules, marking, operation instruction, packaging, transportation

and storage of walk training platform with suspension (hereinafter referred to as

equipment).

This Standard is applicable to equipment stipulated in 3.1.

2 Normative References

The following documents are indispensable to the application of this Standard. In terms

of references with a specified date, only versions with a specified date are applicable

to this Standard. The latest version (including all the modifications) of references

without a specified date is also applicable to this Standard.

GB/T 191 Packaging - Pictorial Marking for Handling of Goods

GB 9706.1-2007 Medical Electrical Equipment - Part 1. General Requirements for

Safety

GB 9706.15 Medical Electrical Equipment - Part 1. General Requirements for

Safety - 1. Collateral Standard. Safety Requirements for Medical Electrical

Systems

GB/T 14710 Environmental Requirement and Test Methods for Medical Electrical

Equipment

GB/T 16886.1 Biological Evaluation of Medical Devices - Part 1. Evaluation and

Testing within a Risk Management Process

GB 17498.6-2008 Stationary Training Equipment - Part 6. Treadmills - Additional

Specific Safety Requirements and Test Methods

YY/T 0466.1 Medical Devices - Symbols to be Used with Medical Device Labels,

Labeling and Information to be Supplied - Part 1. General Requirements

3 Terms and Definitions

Those defined in GB 9706.1-2007 AND the following terms and definitions are

applicable to this document.

5.1.5 Suspension belt

5.1.5.1 Adjustment and locking

The suspension belt shall be equipped with adjustment and locking device, and easily

operable. Locking shall be safe and reliable; easily recognizable and safely operated.

It shall be manually operated without the help of any instruments.

5.1.5.2 Width

The suspension belt shall be reasonably designed. The suspension belt that contacts

the buttock shall use soft materials; the edges shall be smooth; the width shall not be

less than 80 mm.

5.2 Walk Training Platform

5.2.1 Timing setting

The walk training platform shall have timing function; the timing error shall not be more

than ± 1% of the set value, and not more than ± 1 min at the maximum.

5.2.2 Speed setting

The walk training platform shall have the function of speed control. Speed output shall

guarantee accuracy and uniformity. The deviation of accuracy shall not exceed ± 5%;

the deviation of uniformity shall not exceed 1 m/s. Speed shall be continuously

adjustable within the range stipulated by the manufacturer; the lowest speed shall not

exceed 0.5 km/h.

5.2.3 Gradient setting

In terms of walk training platform which has the function of gradient adjustment,

gradient shall be continuously adjustable. It shall also have the function of adjustment

indication; the deviation of gradient indication shall not exceed ± 10%.

5.2.4 Static load

The walk training platform shall be able to maintain intact after supporting 6 times of

the normal load stipulated by the manufacturer.

5.2.5 Safety of unexpected power outage

As power supply recovers after unexpected power outage, the walk training platform

would not automatically operate.

5.2.6 Emergency stop device

Except from the power switch, the equipment shall also provide an emergency stop

button, which can stop the training program at any time. This button shall take effect

6.2.4 Static load

Conduct the test in accordance with the requirement in 6.6 in GB 17498.6-2008; it shall

comply with the requirement in 5.2.4.

6.2.5 Safety of unexpected power outage

Conduct the test in practical operation; it shall comply with the requirement in 5.2.5.

6.2.6 Emergency stop device

Conduct the test in visual inspection and practical operation; it shall comply with the

requirement in 5.2.6.

6.2.7 Fatigue test

In the test, simulate the equipment’s moving components in 100,000 times of no-load

operation. After that, the equipment’s function shall still satisfy the requirement in 5.2.7.

6.3 Overall Requirements of Equipment

6.3.1 Stability

Place the overall equipment on a flat surface; use a feeler gauge to measure the

distance between the footing and the flat surface.

In the equipment’s suspended device part, load the normal load stipulated by the

manufacturer. In accordance with the movement direction under normal training state,

or the direction which is the most unfavorable to stability, start to roll over from

horizontal. Use a protractor (precision. superior to 0.1°) to record the rolling-over angle.

The overall equipment shall be placed on a cement ground in accordance with the

requirement in the instruction. If there are trundles, lock the trundles. In the direction

of force, in the most unfavorable location at 1.5 m height of the equipment, impose 120

(1 ± 2%) N of horizontal pull or thrust; observe whether the equipment has moved.

The above test result shall comply with the requirement in 5.3.1.

6.3.2 Operating noise

Place the equipment on a hard table and at a distance of at least 3 m from the walls or

other reflectors. Under the environment where background noise is 10 dB lower than

the measuring point in the sound pressure level, operate the equipment under normal

working state where the maximum noise might be generated; measure A-weighted

sound level in the front, the back, the left, the right and the top of the host device of the

equipment; they shall all satisfy the requirement in 5.3.2. If the manufacturer stipulates

equipment’s special installation or arrangement conditions in the attached documents,

the equipment can be arranged merely in accordance with the method stipulated by

Type Inspection All items

7.2.2 Determination of exit-factory inspection. if products are qualified in all the

inspection items, then, they shall be determined as qualified in exit-factory inspection.

Otherwise, they shall be determined as unqualified in exit-factory inspection.

7.3 Type Inspection

7.3.1 Type inspection shall be conducted under one of the following circumstances.

a) Before product registration (including old products which are switched to other

production);

b) When products have been continuously produced for a certain period (generally

not more than 2 years);

c) When production is resumed after over one year of suspension;

d) When there are significant changes in product structure, materials, process or

key components;

e) When there are relatively large differences between the result of exit-factory

inspection and design requirements;

f) When national quality supervision and inspection institution requests.

7.3.2 Determination of type inspection. if products are qualified in all the inspection

items, then, they shall ...

Share