1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 0079-2016 English PDF (YYT0079-2016)

YY/T 0079-2016 English PDF (YYT0079-2016)

Regular price

$130.00 USD

Regular price

Sale price

$130.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 0079-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0079-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0079-2016: Metallic clip

YY/T 0079-2016

Metallic clip

ICS 11.040.30

C36

People's Republic of China Pharmaceutical Industry Standard

Replacing YY/T 0079-2006

Medical metal clip

Metalicclip

Published on.2016-03-23

2017-01-01 Implementation

The State Food and Drug Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces YY/T 0079-2006 "Surgical Implant Metal Clips."

The main differences between this standard and YY/T 0079-2006 are as follows.

--- Changed the name of the standard, changed from "Surgical implant metal clip" to "medical metal clip";

--- Revised structural style and size requirements;

--- Revised the material grade and hardness range of titanium metal clips;

--- Delete enamel metal clips and related content;

--- Increased clamping performance, corrosion resistance and package sealing requirements and test methods;

--- Increase the requirements of microbiological indicators and test methods;

--- Improve biocompatibility requirements and test methods.

Please note that some of the contents of this document may involve patents. The issuing agency of this document does not assume responsibility for identifying these patents.

This standard was proposed and managed by the National Surgical Instruments Standardization Technical Committee (SAC/TC94).

This standard was drafted by. Hangzhou Tonglu Medical Optical Instrument Factory, Shanghai Medical Device Testing Institute, Johnson and Johnson (Shanghai) Medical Equipment Co., Ltd.

Limited company.

Participants in this standard. Xinhua Surgical Instruments Co., Ltd.

Drafters of this standard. Shen Tuyuhua, Zheng Qiang, Shi Wanxia, Huang Shuze, Yu Rong.

The previous versions of the standards replaced by this standard are.

---WSZ-196-1975;

---YY 0079.1-1992;

---YY/T 0079-2006.

Medical metal clip

1 Scope

This standard specifies the type and basic dimensions of metal clips, requirements, test methods, inspection rules, markings, operating instructions, packaging, transportation,

Storage requirements.

This standard applies to silver clips that clamp the capillaries of the brain and titanium clips that clamp the abdominal tubular tissue. The following are referred to as (metal clips).

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 4135 Silver Bar

GB/T 4340.1 Vickers hardness test of metallic materials Part 1. Test methods

GB/T 6682 Analysis Laboratory Water Specifications and Test Methods

GB/T 13810-2007 titanium and titanium alloys for surgical implants

GB/T 14233.2-2005 Methods for the examination of medical infusions, blood transfusions and syringes - Part 2. Biological methods

GB/T 16886.3-2008 Biological evaluation of medical devices - Part 3. Genetic toxicity, carcinogenicity and reproductive toxicity tests

GB/T 16886.5-2003 Biological evaluation of medical devices Part 5. In vitro cytotoxicity test

GB/T 16886.6-1997 Biological evaluation of medical devices - Part 6. Local response test after implantation

GB/T 16886.7 Biological evaluation of medical devices. Part 7. Ethylene oxide sterilization residue

GB/T 16886.10-2005 Biological evaluation of medical devices - Part 10. Stimulation and delayed type hypersensitivity tests

GB/T 16886.11-2011 Biological evaluation of medical devices Part 11. Systemic toxicity test

YY/T 0149-2006 Test Method for Corrosion Resistance of Stainless Steel Medical Devices

YY/T 0171-2008 Surgical device packaging, signs and instructions

YY/T 0466.1 Medical Devices Symbols for Labeling, Marking, and Providing Information on Medical Devices Part 1. General Requirements

YY/T 0597-2006 Application clamp

YY/T 0681.4 Test methods for packaging sterile medical devices. Part 4. Dyeing fluid penetration method for leak detection of leaks in breathable packages

Pharmacopoeia of the People's Republic of China (2010 Edition, Part 2)

3 type and basic size

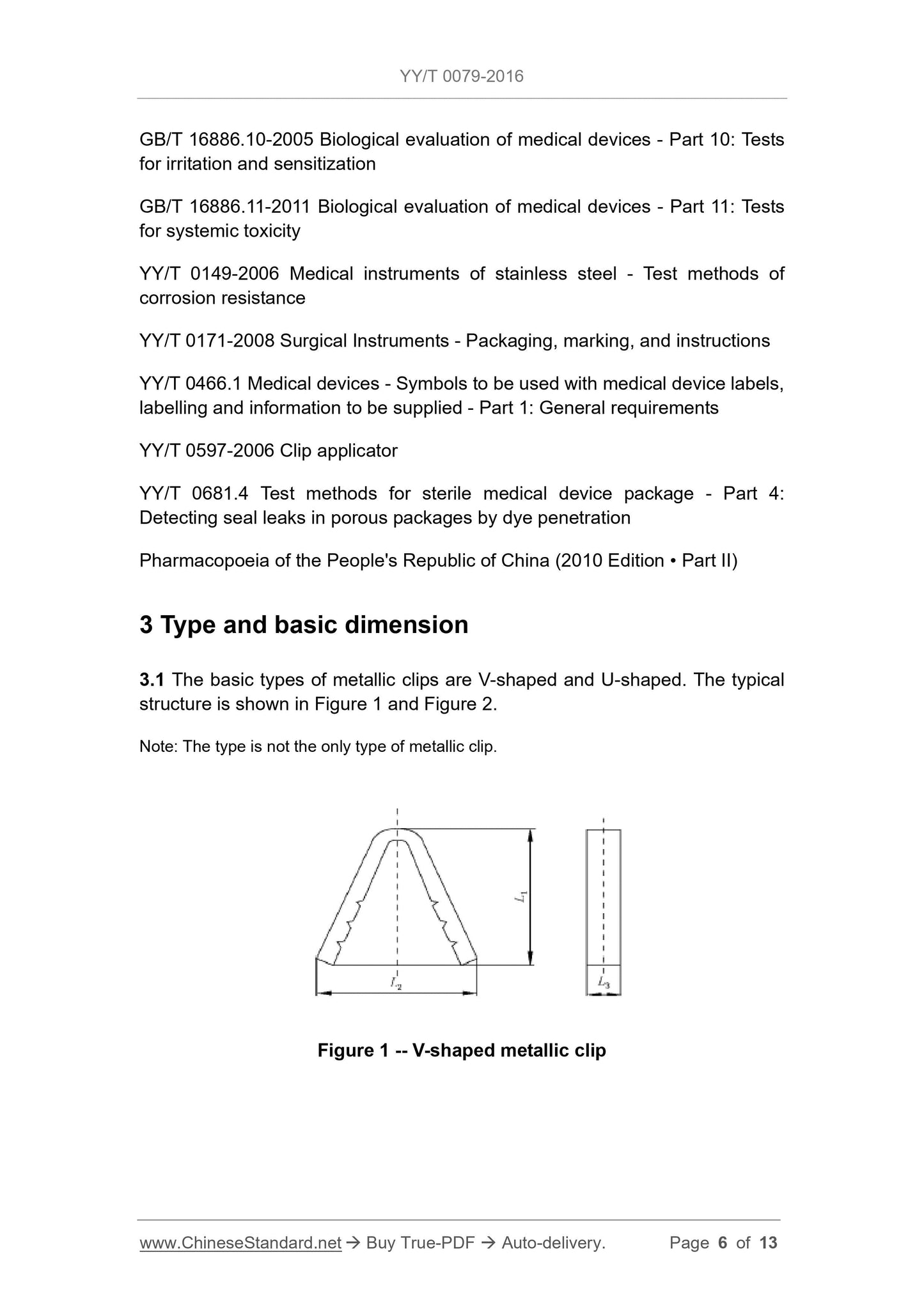

3.1 The basic types of metal clips are V-shaped and U-shaped. Their typical structures are shown in Figure 1 and Figure 2.

Note. The only type of this type of non-metallic clip.

Figure 1 V-shaped metal clips

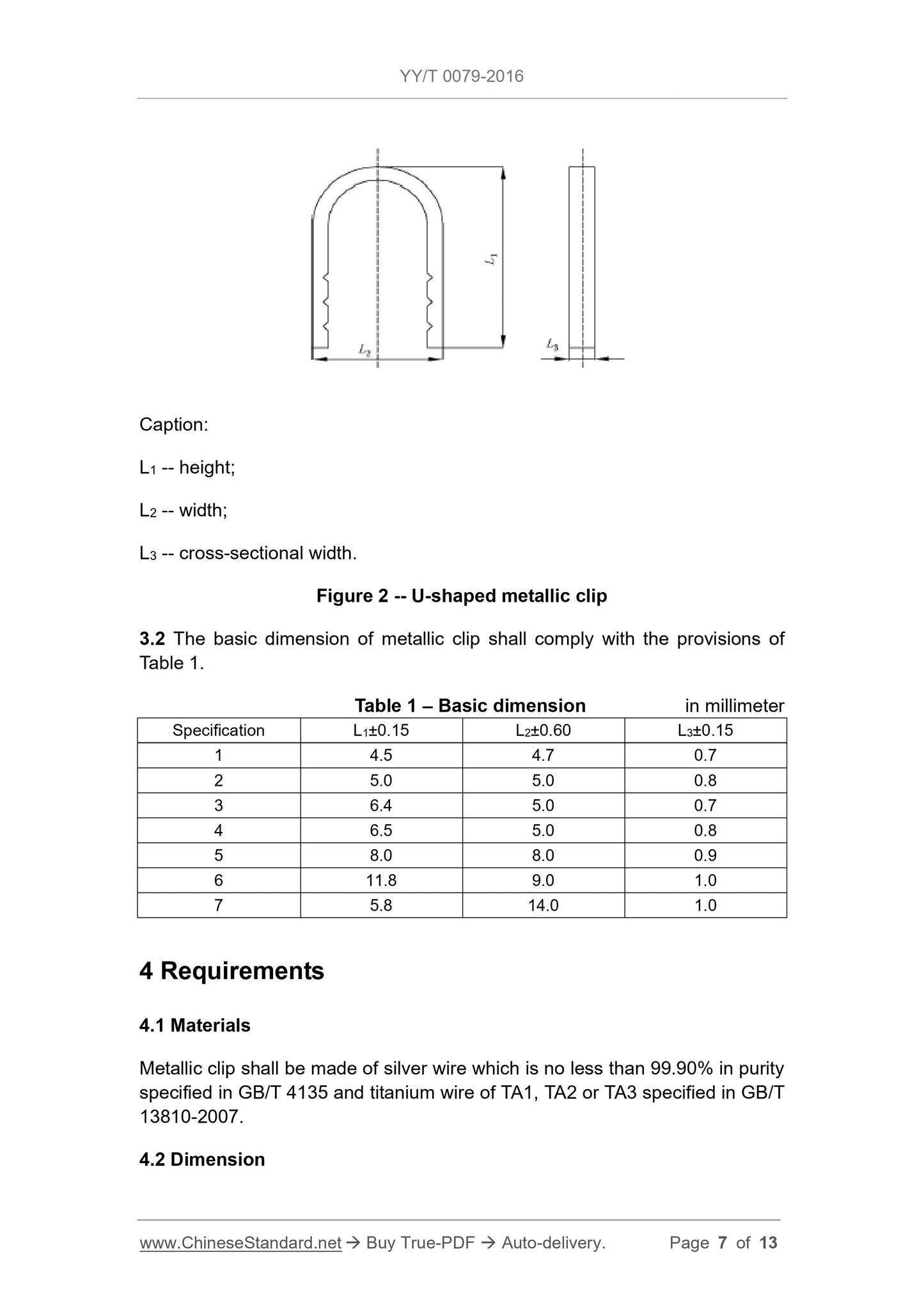

Explanation.

L1 --- height;

L2---width;

L3 - cross-sectional width.

Figure 2 U-shaped metal clips schematic

3.2 The basic dimensions of the metal clips are to comply with the requirements of Table 1.

Table 1 The basic dimensions are in millimeters

Specifications L1±0.15 L2±0.60 L3±0.15

1 4.5 4.7 0.7

2 5.0 5.0 0.8

3 6.4 5.0 0.7

4 6.5 5.0 0.8

5 8.0 8.0 0.9

6 11.8 9.0 1.0

7 5.8 14.0 1.0

4 Requirements

4.1 Materials

The metal clip shall have a purity of not less than 99.90% of the silver wire specified in GB/T 4135 and a TA1 as specified in GB/T 13810-2007.

TA2 or TA3 titanium wire material.

4.2 Size

The dimensions of the metal clips L1, L2, L3 shall comply with the provisions of 3.2.

4.3 Appearance

4.3.1 Both sides of the metal clip should be symmetrical, and the outer shape should be flat, with no defects such as sharp edges, burrs, cracks, and spots.

4.3.2 The stripes and/or grooves on the metal clip should be clear and complete, and there should be no overflow or sharp edges.

4.4 Surface roughness

The surface roughness parameter Ra of the metal clip should not exceed 0.8 μm.

4.5 Hardness

The hardness of the silver metal clip is 60HV0.1 to 100HV0.1, and the hardness of the titanium metal clip is 100HV0.2 to.200HV0.2.

4.6 Toughness

Metal clips should have good toughness and must not be cracked or broken after being clamped.

4.7 Clipping performance

The metal clamp and clamp clamp are well-matched and should have good clamping performance.

4.8 Corrosion resistance

The metal clip should have good corrosion resistance, and no trace of corrosion will be produced after the test.

4.9 Sterility

If the metal clip is delivered in a sterile state, it should be subjected to an effective, validated sterilization process to make the product sterile.

4.10 Microbiological indicators

If the metal clip is delivered in a non-sterile state, its initial contamination should be no more than 100 CFU/piece.

4.11 Ethylene oxide residue

If the metal clip is sterilized with ethylene oxide gas, the residual amount should not exceed 10 μg/g.

4.12 Packaging Seal

Aseptically packaged metal clips should be sealed in a single package and have good resistance to bacteria.

4.13 Biocompatibility

4.13.1 The cytotoxicity of metal clips should not be greater than grade 1.

4.13.2 The metal clamp sensitization reaction should not be greater than 1.

4.13.3 The internal reaction of the metal clip should not be greater than 1.

4.13.4 Metal clips should have no acute systemic toxicity.

4.13.5 Metal clips should have no subchronic toxicity.

4.13.6 Metal clips should have no genetic toxicity.

4.13.7 Metal clips should have no implant reaction.

4.13.8 Bacterial endotoxin in aseptically packaged silver clips should not exceed 2.15 EU/piece.

5 test methods

5.1 Material Inspection

Chemical composition analysis method of silver metal clips is carried out according to the method specified in GB/T 4135, chemical composition analysis method for titanium metal clips

According to the method specified in GB/T 13810-2007, it shall comply with the provisions of 4.1.

5.2 Inspection of dimensions

Testing with universal gauges should meet the requirements of 4.2.

5.3 appearance inspection

Under conditions of 5x to 10x magnification, normal or corrected visual acuity should meet the requirements of 4.3.1 and 4.3.2.

5.4 Surface roughness test

The surface roughness of the metal clip is tested by the sample comparison method and compared with the sample under magnification of 5 to 10 times, using normal or corrected

Visual inspection should comply with the provisions of 4.4.

5.5 Hardness

According to the provisions of GB/T 4340.1, measuring 3 points on the metal clip, calculate the arithmetic mean, should comply with the provisions of 4.5.

5.6 Toughness test

After clamping the metal clamp with a clamp clamp that matches the metal clamp and conforms to YY/T 0597-2006, use a 5x to 10x magnifying glass.

Observations should meet the requirements of 4.6.

5.7 Clamping performance test

According to the provisions in Table 2 of YY/T 0597-2006, select test materials, match with metal clips, in line with YY/T 0597-2006

The clamps are clamped and the clamps are clamped onto the suspended test material. Loosen the clamp jaws. The metal clamp should be able to be fixed on the test material. No relative

Displacement shall meet the requirements of 4.7.

5.8 Corrosion resistance test

Silver clips were tested according to YY/T 0149-2006 sodium chloride solution test method.

Titanium clip, using sodium hydroxide 0.005g, plus three test water 250mL in accordance with GB/T 6682, the solution temperature is 20 °C ±

5°C, stir well. It was immersed in the solution and kept for 48 h and dried.

Use a 5x to 10x magnifier to check that the test results meet the requirements of 4.8.

5.9 Sterility test

According to the Pharmacopoeia of the People's Republic of China (2010 Edition, Part II) in the inspection of Appendix XI H sterility test, should meet the 4.9

Claim.

5.10 Microbial indicators

According to the "Chinese Pharmacopoeia" (2010 Edition, Part II) in the Appendix XIJ microbial limit test method for inspection, shall comply with 4.10

Provisions.

5.11 Ethylene Oxide Residue

Detection according to the method specified in GB/T 16886.7, shall comply with the provisions of 4.11.

Preparation of the test solution. The metal clips and the test water were configured in a ratio of 1.0 g.5 mL, and sealed and equilibrated at a temperature of 60° C.±1° C. for 40 minutes.

5.12 Packaging Seal Inspection

According to the method specified in YY/T 0681.4, it shall comply with the provisions of 4.12.

5.13 Biocompatibility

5.13.1 Cytotoxicity Test

According to GB/T 16886.5-2003 8.2 (extract liquid test) prescribed method, should meet the requirements of 4.13.1.

5.13.2 Sensitization, intradermal reaction test

According to the methods specified in 7.4 (maximum dose test) and Appendix B.2 (intradermal reaction test) in GB/T 16886.10-2005,

Meet the requirements of 4.13.2 and 4.13.3.

5.13.3 Assessment of Systemic and Subchronic Toxicity

According to GB/T 16886.11-2011 in Chapter 5 and Chapter 6 methods for evaluation, should meet the requirements of 4.13.4 and 4.13.5.

5.13.4 Genetic toxicity assessment

According to GB/T 16886.3-2008 4.4 provisions of the method of evaluation, should meet the requirements of 4.13.6.

5.13.5 Evaluation of Implantation Response

Evaluation according to the method specified in 3.4 of GB/T 16886.6-1997 shall meet the requirements of 4.13.7.

5.13.6 Bacterial endotoxin

According to the method specified in GB/T 14233.2-2005, it shall comply with the provisions of 4.13.8.

6 Inspection Rules

Type inspection items are those specified in Chapter 4, 7.1.1, and 7.1.2.

If there is no special provision, the items to be inspected shall be randomly sampled by 3 and all shall be qualified.

7 Signs, Instruction Manual

7.1 Logo

7.1.1 Ordinary single package shall have at least the material code specified in Table 3 and the mark specified in 4.1.1 of YY/T 0171-2008.

7.1.2 Sterile single package shall have at least the material code specified in Table 3 and the mark specified in 4.1.3 of YY/T 0171-2008.

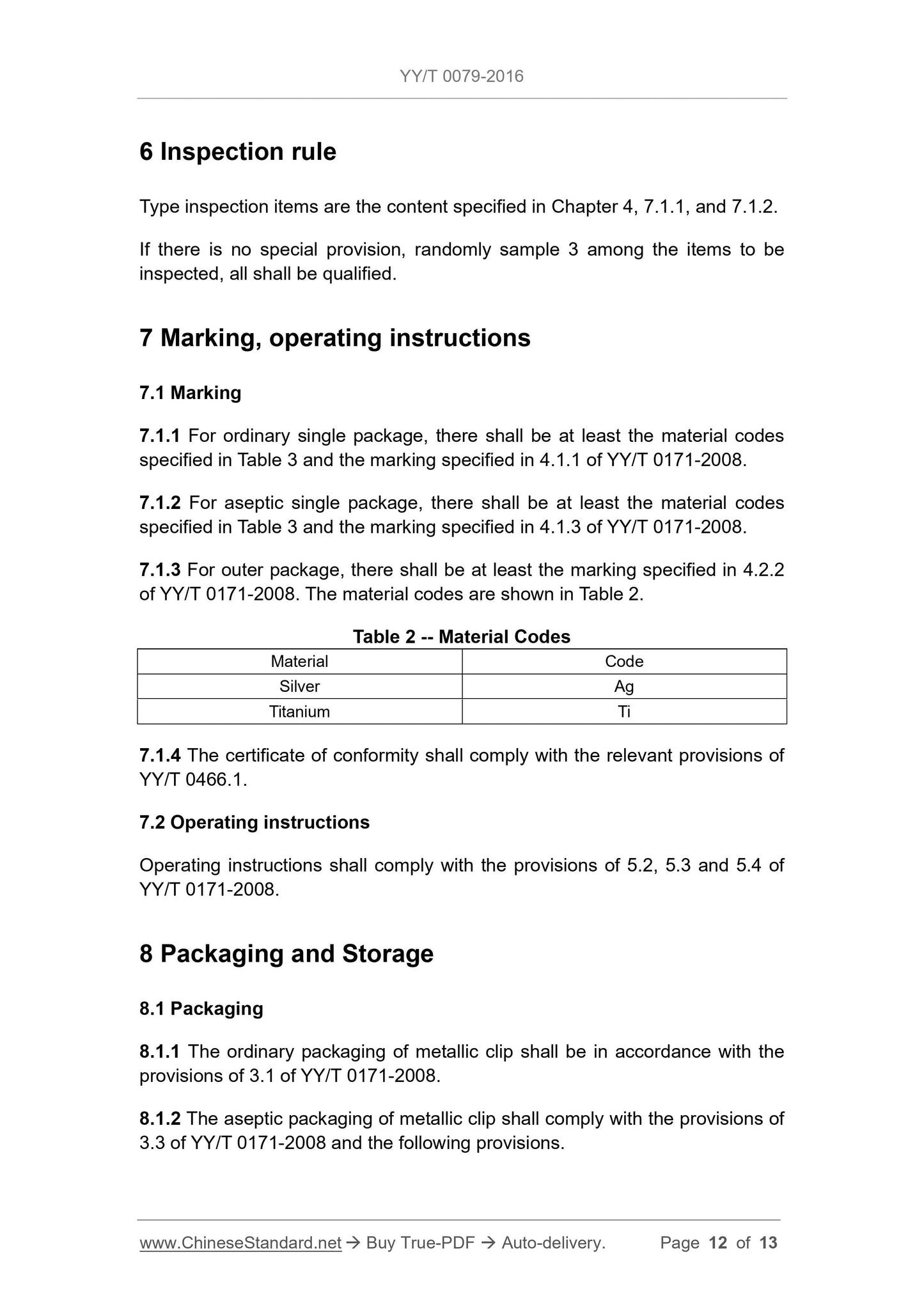

7.1.3 The outer package shall have at least the mark specified in 4.2.2 of YY/T 0171-2008. The material code is shown in Table 2.

Table 2 Material Codes

Material code

Silver Ag

Titanium Ti

7.1.4 The certificate shall comply with the relevant provisions of YY/T 0466.1.

7.2 Instruction Manual

The instructions for use shall comply with 5.2, 5.3 and 5.4 of YY/T 0171-2008.

8 Packaging and Storage

8.1 Packaging

8.1.1 Metal clips are generally packaged in accordance with 3.1 of YY/T 0171-2008.

8.1.2 Aseptic packaging of metal clips shall comply with 3.3 of YY/T 0171-2008 and the following provisions.

a) The metal clips are aseptically packaged and should remain sterile during the storage period.

b) The metal clips are aseptically packaged and should be left open after opening.

8.1.3 Single packaging into the box should be accompanied by instruction manual and certificate of conformity.

8.2 Transport, Storage and Validity

8.2.1 The outer packaging of the metal clip should be able to guarantee no damage under normal conditions of transportation and storage.

8.2.2 The words or signs on the outer packaging should ensure that it should not be long and ambiguous.

8.2.3 The metal clip after packaging should be stored in a room with a relative humidity of no more than 80%, no corrosive gas and good ventilation. Metal clips from sterilization

The date of validity shall be not less than two years.

Get Quotation: Click YY/T 0079-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0079-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0079-2016: Metallic clip

YY/T 0079-2016

Metallic clip

ICS 11.040.30

C36

People's Republic of China Pharmaceutical Industry Standard

Replacing YY/T 0079-2006

Medical metal clip

Metalicclip

Published on.2016-03-23

2017-01-01 Implementation

The State Food and Drug Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces YY/T 0079-2006 "Surgical Implant Metal Clips."

The main differences between this standard and YY/T 0079-2006 are as follows.

--- Changed the name of the standard, changed from "Surgical implant metal clip" to "medical metal clip";

--- Revised structural style and size requirements;

--- Revised the material grade and hardness range of titanium metal clips;

--- Delete enamel metal clips and related content;

--- Increased clamping performance, corrosion resistance and package sealing requirements and test methods;

--- Increase the requirements of microbiological indicators and test methods;

--- Improve biocompatibility requirements and test methods.

Please note that some of the contents of this document may involve patents. The issuing agency of this document does not assume responsibility for identifying these patents.

This standard was proposed and managed by the National Surgical Instruments Standardization Technical Committee (SAC/TC94).

This standard was drafted by. Hangzhou Tonglu Medical Optical Instrument Factory, Shanghai Medical Device Testing Institute, Johnson and Johnson (Shanghai) Medical Equipment Co., Ltd.

Limited company.

Participants in this standard. Xinhua Surgical Instruments Co., Ltd.

Drafters of this standard. Shen Tuyuhua, Zheng Qiang, Shi Wanxia, Huang Shuze, Yu Rong.

The previous versions of the standards replaced by this standard are.

---WSZ-196-1975;

---YY 0079.1-1992;

---YY/T 0079-2006.

Medical metal clip

1 Scope

This standard specifies the type and basic dimensions of metal clips, requirements, test methods, inspection rules, markings, operating instructions, packaging, transportation,

Storage requirements.

This standard applies to silver clips that clamp the capillaries of the brain and titanium clips that clamp the abdominal tubular tissue. The following are referred to as (metal clips).

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 4135 Silver Bar

GB/T 4340.1 Vickers hardness test of metallic materials Part 1. Test methods

GB/T 6682 Analysis Laboratory Water Specifications and Test Methods

GB/T 13810-2007 titanium and titanium alloys for surgical implants

GB/T 14233.2-2005 Methods for the examination of medical infusions, blood transfusions and syringes - Part 2. Biological methods

GB/T 16886.3-2008 Biological evaluation of medical devices - Part 3. Genetic toxicity, carcinogenicity and reproductive toxicity tests

GB/T 16886.5-2003 Biological evaluation of medical devices Part 5. In vitro cytotoxicity test

GB/T 16886.6-1997 Biological evaluation of medical devices - Part 6. Local response test after implantation

GB/T 16886.7 Biological evaluation of medical devices. Part 7. Ethylene oxide sterilization residue

GB/T 16886.10-2005 Biological evaluation of medical devices - Part 10. Stimulation and delayed type hypersensitivity tests

GB/T 16886.11-2011 Biological evaluation of medical devices Part 11. Systemic toxicity test

YY/T 0149-2006 Test Method for Corrosion Resistance of Stainless Steel Medical Devices

YY/T 0171-2008 Surgical device packaging, signs and instructions

YY/T 0466.1 Medical Devices Symbols for Labeling, Marking, and Providing Information on Medical Devices Part 1. General Requirements

YY/T 0597-2006 Application clamp

YY/T 0681.4 Test methods for packaging sterile medical devices. Part 4. Dyeing fluid penetration method for leak detection of leaks in breathable packages

Pharmacopoeia of the People's Republic of China (2010 Edition, Part 2)

3 type and basic size

3.1 The basic types of metal clips are V-shaped and U-shaped. Their typical structures are shown in Figure 1 and Figure 2.

Note. The only type of this type of non-metallic clip.

Figure 1 V-shaped metal clips

Explanation.

L1 --- height;

L2---width;

L3 - cross-sectional width.

Figure 2 U-shaped metal clips schematic

3.2 The basic dimensions of the metal clips are to comply with the requirements of Table 1.

Table 1 The basic dimensions are in millimeters

Specifications L1±0.15 L2±0.60 L3±0.15

1 4.5 4.7 0.7

2 5.0 5.0 0.8

3 6.4 5.0 0.7

4 6.5 5.0 0.8

5 8.0 8.0 0.9

6 11.8 9.0 1.0

7 5.8 14.0 1.0

4 Requirements

4.1 Materials

The metal clip shall have a purity of not less than 99.90% of the silver wire specified in GB/T 4135 and a TA1 as specified in GB/T 13810-2007.

TA2 or TA3 titanium wire material.

4.2 Size

The dimensions of the metal clips L1, L2, L3 shall comply with the provisions of 3.2.

4.3 Appearance

4.3.1 Both sides of the metal clip should be symmetrical, and the outer shape should be flat, with no defects such as sharp edges, burrs, cracks, and spots.

4.3.2 The stripes and/or grooves on the metal clip should be clear and complete, and there should be no overflow or sharp edges.

4.4 Surface roughness

The surface roughness parameter Ra of the metal clip should not exceed 0.8 μm.

4.5 Hardness

The hardness of the silver metal clip is 60HV0.1 to 100HV0.1, and the hardness of the titanium metal clip is 100HV0.2 to.200HV0.2.

4.6 Toughness

Metal clips should have good toughness and must not be cracked or broken after being clamped.

4.7 Clipping performance

The metal clamp and clamp clamp are well-matched and should have good clamping performance.

4.8 Corrosion resistance

The metal clip should have good corrosion resistance, and no trace of corrosion will be produced after the test.

4.9 Sterility

If the metal clip is delivered in a sterile state, it should be subjected to an effective, validated sterilization process to make the product sterile.

4.10 Microbiological indicators

If the metal clip is delivered in a non-sterile state, its initial contamination should be no more than 100 CFU/piece.

4.11 Ethylene oxide residue

If the metal clip is sterilized with ethylene oxide gas, the residual amount should not exceed 10 μg/g.

4.12 Packaging Seal

Aseptically packaged metal clips should be sealed in a single package and have good resistance to bacteria.

4.13 Biocompatibility

4.13.1 The cytotoxicity of metal clips should not be greater than grade 1.

4.13.2 The metal clamp sensitization reaction should not be greater than 1.

4.13.3 The internal reaction of the metal clip should not be greater than 1.

4.13.4 Metal clips should have no acute systemic toxicity.

4.13.5 Metal clips should have no subchronic toxicity.

4.13.6 Metal clips should have no genetic toxicity.

4.13.7 Metal clips should have no implant reaction.

4.13.8 Bacterial endotoxin in aseptically packaged silver clips should not exceed 2.15 EU/piece.

5 test methods

5.1 Material Inspection

Chemical composition analysis method of silver metal clips is carried out according to the method specified in GB/T 4135, chemical composition analysis method for titanium metal clips

According to the method specified in GB/T 13810-2007, it shall comply with the provisions of 4.1.

5.2 Inspection of dimensions

Testing with universal gauges should meet the requirements of 4.2.

5.3 appearance inspection

Under conditions of 5x to 10x magnification, normal or corrected visual acuity should meet the requirements of 4.3.1 and 4.3.2.

5.4 Surface roughness test

The surface roughness of the metal clip is tested by the sample comparison method and compared with the sample under magnification of 5 to 10 times, using normal or corrected

Visual inspection should comply with the provisions of 4.4.

5.5 Hardness

According to the provisions of GB/T 4340.1, measuring 3 points on the metal clip, calculate the arithmetic mean, should comply with the provisions of 4.5.

5.6 Toughness test

After clamping the metal clamp with a clamp clamp that matches the metal clamp and conforms to YY/T 0597-2006, use a 5x to 10x magnifying glass.

Observations should meet the requirements of 4.6.

5.7 Clamping performance test

According to the provisions in Table 2 of YY/T 0597-2006, select test materials, match with metal clips, in line with YY/T 0597-2006

The clamps are clamped and the clamps are clamped onto the suspended test material. Loosen the clamp jaws. The metal clamp should be able to be fixed on the test material. No relative

Displacement shall meet the requirements of 4.7.

5.8 Corrosion resistance test

Silver clips were tested according to YY/T 0149-2006 sodium chloride solution test method.

Titanium clip, using sodium hydroxide 0.005g, plus three test water 250mL in accordance with GB/T 6682, the solution temperature is 20 °C ±

5°C, stir well. It was immersed in the solution and kept for 48 h and dried.

Use a 5x to 10x magnifier to check that the test results meet the requirements of 4.8.

5.9 Sterility test

According to the Pharmacopoeia of the People's Republic of China (2010 Edition, Part II) in the inspection of Appendix XI H sterility test, should meet the 4.9

Claim.

5.10 Microbial indicators

According to the "Chinese Pharmacopoeia" (2010 Edition, Part II) in the Appendix XIJ microbial limit test method for inspection, shall comply with 4.10

Provisions.

5.11 Ethylene Oxide Residue

Detection according to the method specified in GB/T 16886.7, shall comply with the provisions of 4.11.

Preparation of the test solution. The metal clips and the test water were configured in a ratio of 1.0 g.5 mL, and sealed and equilibrated at a temperature of 60° C.±1° C. for 40 minutes.

5.12 Packaging Seal Inspection

According to the method specified in YY/T 0681.4, it shall comply with the provisions of 4.12.

5.13 Biocompatibility

5.13.1 Cytotoxicity Test

According to GB/T 16886.5-2003 8.2 (extract liquid test) prescribed method, should meet the requirements of 4.13.1.

5.13.2 Sensitization, intradermal reaction test

According to the methods specified in 7.4 (maximum dose test) and Appendix B.2 (intradermal reaction test) in GB/T 16886.10-2005,

Meet the requirements of 4.13.2 and 4.13.3.

5.13.3 Assessment of Systemic and Subchronic Toxicity

According to GB/T 16886.11-2011 in Chapter 5 and Chapter 6 methods for evaluation, should meet the requirements of 4.13.4 and 4.13.5.

5.13.4 Genetic toxicity assessment

According to GB/T 16886.3-2008 4.4 provisions of the method of evaluation, should meet the requirements of 4.13.6.

5.13.5 Evaluation of Implantation Response

Evaluation according to the method specified in 3.4 of GB/T 16886.6-1997 shall meet the requirements of 4.13.7.

5.13.6 Bacterial endotoxin

According to the method specified in GB/T 14233.2-2005, it shall comply with the provisions of 4.13.8.

6 Inspection Rules

Type inspection items are those specified in Chapter 4, 7.1.1, and 7.1.2.

If there is no special provision, the items to be inspected shall be randomly sampled by 3 and all shall be qualified.

7 Signs, Instruction Manual

7.1 Logo

7.1.1 Ordinary single package shall have at least the material code specified in Table 3 and the mark specified in 4.1.1 of YY/T 0171-2008.

7.1.2 Sterile single package shall have at least the material code specified in Table 3 and the mark specified in 4.1.3 of YY/T 0171-2008.

7.1.3 The outer package shall have at least the mark specified in 4.2.2 of YY/T 0171-2008. The material code is shown in Table 2.

Table 2 Material Codes

Material code

Silver Ag

Titanium Ti

7.1.4 The certificate shall comply with the relevant provisions of YY/T 0466.1.

7.2 Instruction Manual

The instructions for use shall comply with 5.2, 5.3 and 5.4 of YY/T 0171-2008.

8 Packaging and Storage

8.1 Packaging

8.1.1 Metal clips are generally packaged in accordance with 3.1 of YY/T 0171-2008.

8.1.2 Aseptic packaging of metal clips shall comply with 3.3 of YY/T 0171-2008 and the following provisions.

a) The metal clips are aseptically packaged and should remain sterile during the storage period.

b) The metal clips are aseptically packaged and should be left open after opening.

8.1.3 Single packaging into the box should be accompanied by instruction manual and certificate of conformity.

8.2 Transport, Storage and Validity

8.2.1 The outer packaging of the metal clip should be able to guarantee no damage under normal conditions of transportation and storage.

8.2.2 The words or signs on the outer packaging should ensure that it should not be long and ambiguous.

8.2.3 The metal clip after packaging should be stored in a room with a relative humidity of no more than 80%, no corrosive gas and good ventilation. Metal clips from sterilization

The date of validity shall be not less than two years.

Share