1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 0243-2016 English PDF (YYT0243-2016)

YY/T 0243-2016 English PDF (YYT0243-2016)

Regular price

$150.00 USD

Regular price

Sale price

$150.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 0243-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0243-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0243-2016: Plunger seal of syringes for single use

YY/T 0243-2016

Plunger seal of syringes for single use

ICS 11.040.20

C31

People's Republic of China Pharmaceutical Industry Standard

Replacing YY/T 0243-2003

Disposable syringe piston

Published on.2016-03-23

2017-01-01 Implementation

The State Food and Drug Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces YY/T 0243-2003 "Disposable syringes for sterile syringes".

The main technical changes of this standard and YY/T 0243-2003 are as follows.

--- Added Appendix A (informative annex) material guidelines, revised biological evaluation requirements;

--- Increased UV absorbance requirements;

--- Increased ash requirements;

--- Modified yellowing test method;

--- Added Appendix C (informative annex) test method for the permanent compression rate of the piston;

--- Modified Appendix D extract preparation method.

Please note that some of the contents of this document may involve patents. The publication structure of this document does not assume responsibility for identifying these patents.

This standard is proposed by the State Food and Drug Administration.

This standard is under the jurisdiction of the National Standardization Technical Committee for Medical Injectors (needle) (SAC/TC95).

This standard is mainly drafted by. Shanghai Shuangge Industrial Co., Ltd., Shandong Jihai Medical Technology Co., Ltd., Shanghai Medical Devices

Testing institute.

Participated in the drafting of this standard. Heilongjiang Provincial Medical Device Testing Institute, Jiangsu Suyun Medical Equipment Co., Ltd., Chengdu Xinjin Scifeng Medical Co., Ltd.

Instrument Co., Ltd.

The main drafters of this standard. Yang Sanba, Chen Lei, Li Wei, Huo Dongfeng, Zhang Qingjun, Tian Xinglong.

The previous versions of the standards replaced by this standard are.

---YY/T 0243-1996, YY/T 0243-2003.

Disposable syringe piston

1 Scope

This standard specifies the terms and definitions, classifications and markings, requirements, and type inspections for single-use syringe pistons (hereinafter referred to as pistons).

Inspection, packaging, marking, transportation and storage.

This standard applies to pistons for single-use syringes. The piston can be used for disposable syringes and disposables

Use a sterile insulin syringe, etc., but it does not apply to pre-filled syringes and syringes that come with liquids.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 531.1 Test Method for Indentation Hardness of Vulcanized or Thermoplastic Rubbers - Part 1. Shore Hardness Method (Shore Hardness)

(GB/T 531.1-2008, ISO 7619-1.2004 IDT)

GB/T 3512 vulcanized rubber or thermoplastic rubber hot air accelerated aging and heat resistance test

GB/T 6682 Laboratory Water Specifications and Test Methods (GB/T 6682-2008, ISO 3696.1987 MOD)

GB/T 7759.1 Determination of compression set of vulcanized or thermoplastic rubbers - Part 1. At room and elevated temperatures

(GB 7759.1-2015, ISO 815-1.2008, IDT)

GB/T 7766-2008 Chemical analysis method for rubber products

GB/T 14233.1-2008 Medical infusion, blood transfusion, injection equipment inspection methods Part 1. Chemical analysis methods

GB/T 14233.2 Medical infusion, blood transfusion, injection equipment inspection methods Part 2. Biological test methods

GB/T 16886.1 Biological evaluation of medical devices Part 1. Evaluation and testing in risk management process (GB/T 16886.1-

2011, ISO 10993-1.2009, IDT)

GB/T 16886.5 Biological evaluation of medical devices Part 5. In vitro cytotoxicity test (GB/T 16886.5-2003,

ISO 10993-5.1999, IDT)

GB/T 16886.12 Biological evaluation of medical devices - Part 12. Sample preparation and reference samples (GB/T 16886.12-

2005, ISO 10993-12.2002, IDT)

YY/T 0681.1 Test methods for packaging sterile medical devices. Part 1. Guidelines for accelerated aging tests (ASTMF 1980.02,

MOD)

3 Terms and Definitions

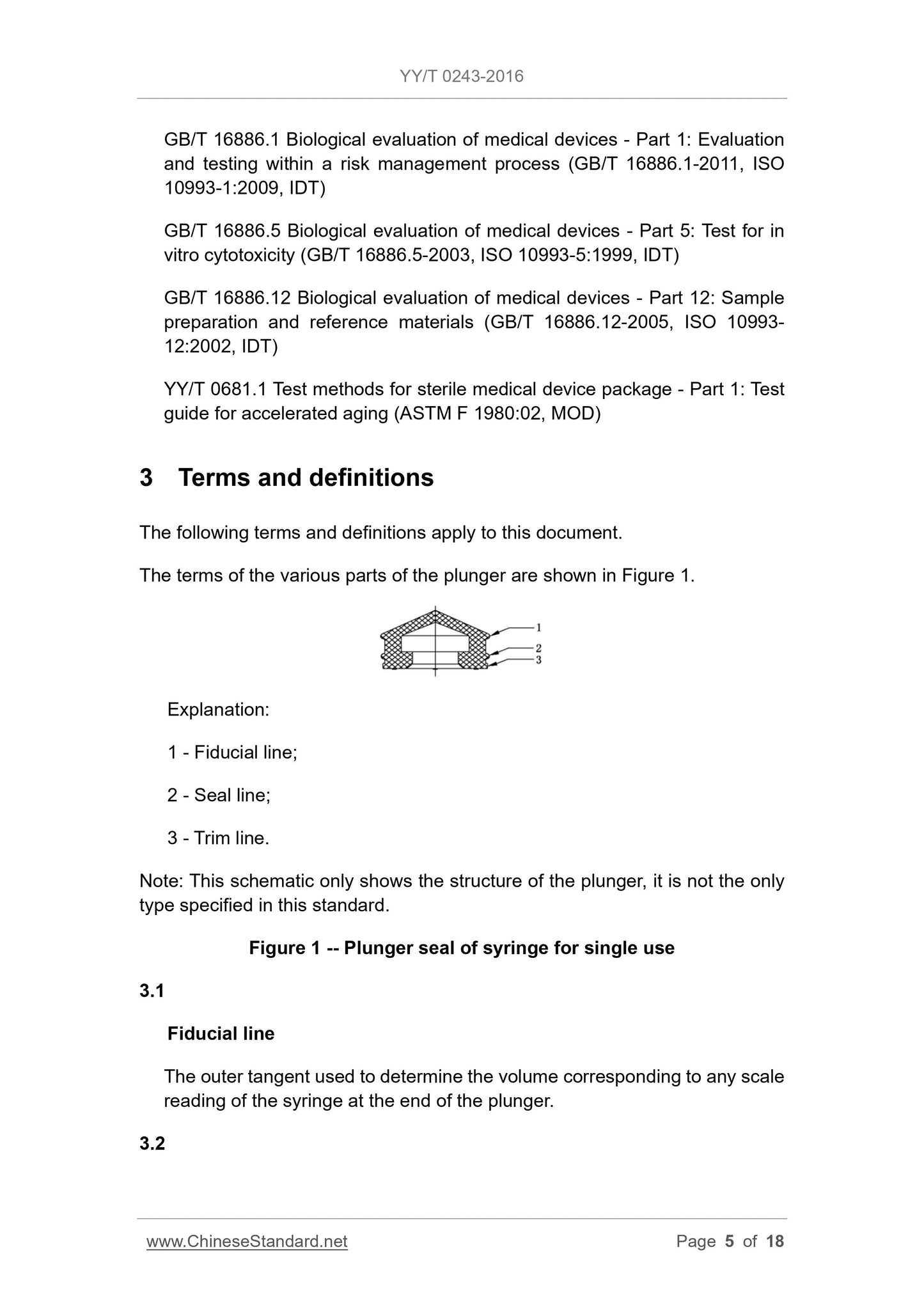

The following terms and definitions apply to this document.

The terms of the various parts of the piston are shown in Figure 1.

Explanation.

1 --- baseline;

2---Sealing ring;

3--- Trimming the line.

Note. This schematic only shows the structure of the piston and is not the only type specified for the standard.

Figure 1 Disposable syringe piston

3.1

Baseline fiducialline

The end of the piston is used to determine the outer tangent of the volume corresponding to any scale reading of the syringe.

3.2

Sealing line sealline

The outer side of the piston, which cooperates with the jacket of the syringe to achieve the purpose of sealing.

3.3

Trimming line trimline

The front end of the piston is used to cut the outer tangent of the process.

4 Classification and marking

4.1 Classification

The piston is divided into natural rubber pistons and synthetic rubber pistons according to manufacturing materials.

Note. A guide to the material is given in Appendix A.

4.2 Marking

The piston is marked according to the matching syringe capacity, for example 0.3mL, 0.5mL, 1mL, 2mL, 5mL, 10mL, 20mL, 30mL, 50mL,

100mL and so on.

5 requirements

5.1 Appearance requirements

5.1.1 The surface of the piston should be clean, free from glue, rubber and foreign matter, and should not be exposed to frost.

5.1.2 The piston surface should not have obvious air bubbles, defects or cracks.

5.1.3 The piston end should have a clear baseline and should be complete.

5.1.4 The side of the piston should have a complete seal.

5.1.5 The diameter of the piston trim line should not be greater than the diameter of the piston seal.

5.1.6 If lubricant is applied to the surface of the piston, no obvious lubricant convergence should be seen under normal or corrected to normal vision.

5.1.7 Anti-yellowing test according to the test method of Appendix B. Under the condition of aging at 70°C for 14 days, the color of the piston before and after aging should not be obvious.

Variety.

5.2 Physical and mechanical properties of the material

5.2.1 Hardness (shoreA)

Testing according to the method specified in GB/T 531.1 shall comply with the hardness agreed by the manufacturer of the piston or the manufacturer of the single-use syringe.

The difference should not exceed the nominal value of ±5. Unproven hardness should meet 60 5-3.

5.2.2 Compression set

Test according to the method specified in GB/T 7759.1, aging test at 40±1°C and 120 0-2h, permanent compression of the piston

The shape should not exceed 40%.

NOTE. Appendix C gives the test method for the permanent compression of the finished piston.

5.2.3 rate of change in tensile strength

According to the method specified in GB/T 3512, the rate of change of tensile strength before and after piston aging should not be changed under conditions of aging at 70°C for 72 hours.

More than ±20%.

5.2.4 Change in elongation at break

According to the test method specified in GB/T 3512, the change rate of elongation at break of the piston before and after aging under the condition of aging at 70°C for 72 hours shall not be

More than ±20%.

5.3 Chemical properties

5.3.1 pH

When using a laboratory pH meter and a general-purpose electrode, the difference between the pH of the leach solution prepared according to Appendix D and the pH of the blank solution should be

Must not exceed 1.0.

5.3.2 extractable metal content

The extract prepared according to Appendix D was tested using an approved microanalytical method (eg, atomic absorption method).

The sum of tin, zinc, and iron content should not exceed 5 mg/L, and the cadmium content should be less than 0.1 mg/L.

5.3.3 Reducing substances

Take the extract prepared in accordance with Appendix D and use a 20-mL leach solution for 1 h, according to the rules in 5.2.2 of GB/T 14233.1-2008.

For the method, the difference between the volume of the potassium permanganate solution that consumes 0.002 mol/L of extract solution should not be greater than that of the same volume of blank control solution.

More than 0.4 mL.

5.3.4 UV absorbance

Take the extract prepared in accordance with Appendix D, according to the method specified in GB/T 14233.1-2008, in the 220nm ~ 360nm, extraction

Liquid UV absorbance should not exceed 0.2.

5.3.5 Ash Content

Take an appropriate amount of piston to cut, take 1.0g, put it in a muffle furnace at 550°C±25°C and weigh it to a constant weight. Weigh it accurately to

0.1mg, slowly flaring to complete carbonization (to prevent the sample from catching fire), and then move the crucible into a muffle furnace at 550 °C ± 25 °C to complete ignition

For full ashing, remove the crucible and cool it slightly. Transfer it to a desiccator, continue cooling to room temperature, and weigh until constant weight. Residual residue should not exceed

Over 60%.

5.4 Biological Requirements

5.4.1 Heat source

Test according to the method specified in GB/T 16886.12, choose 0.2g/mL extraction ratio to prepare the extract, according to GB/T 14233.2

For the method test, the piston should be pyrogen free.

Note. In determining the absence of material heating of the piston, conventional tests use the bacterial endotoxin test given in GB/T 14233.2 to control endotoxin contamination.

The resulting pyrogen. The bacterial endotoxin content of each piston should not exceed 20 EU. In routine tests, exceeding this limit can be considered as not complying with 5.4.1.

Claim.

5.4.2 Cytotoxicity

According to the provisions of GB/T 16886.5, choose 0.2g/mL extraction ratio to prepare the extract, according to the method specified in GB/T 14233.2

Test, the piston cytotoxicity should not be greater than 2.

5.4.3 Hemolysis

According to the provisions of GB/T 16886.12, choose 0.2g/mL extraction ratio to prepare the extract, according to the method specified in GB/T 14233.2

Test, the hemolytic rate of the piston should be less than 5%.

5.4.4 Intradermal stimulation

Test according to the method specified in GB/T 14233.2, the piston should be no stimulus response.

5.4.5 Sensitization

Test according to the method specified in GB/T 14233.2, the piston should not be sensitized.

5.4.6 Acute systemic toxicity

According to the provisions of GB/T 16886.12, choose 0.2g/mL extraction ratio to prepare the extract, according to the method specified in GB/T 14233.2

Test, the piston should have no acute systemic toxicity.

6 type inspection

6.1 Type inspection is a full performance test.

6.2 In the type inspection, the inspection item is all the requirements of Chapter 5. If there is no special provision, the physical requirements of each random sample of 5 sets, other requirements by

The standard regulations proceed.

6.3 If all inspection items are qualified, they will pass the type inspection. If the type test fails, mass production may not be carried out.

7 Packaging

7.1 Initial packaging

Double plastic bags should be used to seal the package.

The packaged material should not have harmful effects on the contents. The material and design of this package should ensure.

a) The contents contain minimal risk of contamination when removed from the packaging;

b) Full protection of the contents during normal handling, transportation and storage.

7.2 Outer packaging

One or more primary packagings should be included in an outer packaging.

During normal handling, transportation and storage, the outer packaging should be able to protect the contents fully and effectively.

8 signs

8.1 Initial packaging mark

The following packaging should have at least the following signs.

a) Description of the contents, including product name, model or specification, piston material hardness, piston material name;

b) the name and address of the manufacturer or supplier;

c) quantity;

d) production lot number or date;

e) Expiration date.

8.2 Outer Packaging Marking

The outer packaging should have at least the following signs.

a) Description of the contents, including product name, model or specification, piston material hardness, piston material name;

b) the name and address of the manufacturer or supplier;

c) quantity;

d) production lot number or date;

e) expiration date;

f) Requirements for handling, storage and transportation.

9 Transportation and Storage

9.1 Transportation

Avoid direct sunlight and rain and snow soaking when transporting.

9.2 Storage

Pistons should be stored in a non-corrosive atmosphere and in a well-ventilated room with adequate protection for the piston.

Appendix A

(Informative Appendix)

Material guide

The material used to make the piston should be compatible with the sterilization process of a suitable syringe.

The material used to make the piston must not be physically or chemically harmful during the routine use of syringes for injection preparations.

influences.

The material used to make the piston uses a high quality natural or synthetic rubber polymer. The gel content should not be less than 40%, according to

GB/T 7766-2008 Section 4.4 "rubber polymer content" or Chapter 5 "determination of rubber polymer" for testing. Natural rubber and non-

The differentiation of natural rubber can be detected according to the test method of “Nitrogen Content, Measured by Protein” in Section 4.10.7 of GB/T 7766-2008.

This standard does not limit technological progress. If thermoplastic elastomers or other polymer materials are used, manufacturers should refer to this standard and related standards.

Qualifications and regulations are evaluated.

The surface of the piston can optionally use dimethyl silicone oil as a lubricant in accordance with the Chinese National Pharmacopoeia.

The piston should not release any substances that have side effects on the human body. When the new product is put into production, materials and production processes have major changes, it should be

According to GB/T 16886.1 its biological evaluation, the basic evaluation test is.

a) pyrogen should be pyrogen free;

b) cytotoxicity (relative proliferation should not be greater than 2);

c...

Get Quotation: Click YY/T 0243-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0243-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0243-2016: Plunger seal of syringes for single use

YY/T 0243-2016

Plunger seal of syringes for single use

ICS 11.040.20

C31

People's Republic of China Pharmaceutical Industry Standard

Replacing YY/T 0243-2003

Disposable syringe piston

Published on.2016-03-23

2017-01-01 Implementation

The State Food and Drug Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces YY/T 0243-2003 "Disposable syringes for sterile syringes".

The main technical changes of this standard and YY/T 0243-2003 are as follows.

--- Added Appendix A (informative annex) material guidelines, revised biological evaluation requirements;

--- Increased UV absorbance requirements;

--- Increased ash requirements;

--- Modified yellowing test method;

--- Added Appendix C (informative annex) test method for the permanent compression rate of the piston;

--- Modified Appendix D extract preparation method.

Please note that some of the contents of this document may involve patents. The publication structure of this document does not assume responsibility for identifying these patents.

This standard is proposed by the State Food and Drug Administration.

This standard is under the jurisdiction of the National Standardization Technical Committee for Medical Injectors (needle) (SAC/TC95).

This standard is mainly drafted by. Shanghai Shuangge Industrial Co., Ltd., Shandong Jihai Medical Technology Co., Ltd., Shanghai Medical Devices

Testing institute.

Participated in the drafting of this standard. Heilongjiang Provincial Medical Device Testing Institute, Jiangsu Suyun Medical Equipment Co., Ltd., Chengdu Xinjin Scifeng Medical Co., Ltd.

Instrument Co., Ltd.

The main drafters of this standard. Yang Sanba, Chen Lei, Li Wei, Huo Dongfeng, Zhang Qingjun, Tian Xinglong.

The previous versions of the standards replaced by this standard are.

---YY/T 0243-1996, YY/T 0243-2003.

Disposable syringe piston

1 Scope

This standard specifies the terms and definitions, classifications and markings, requirements, and type inspections for single-use syringe pistons (hereinafter referred to as pistons).

Inspection, packaging, marking, transportation and storage.

This standard applies to pistons for single-use syringes. The piston can be used for disposable syringes and disposables

Use a sterile insulin syringe, etc., but it does not apply to pre-filled syringes and syringes that come with liquids.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 531.1 Test Method for Indentation Hardness of Vulcanized or Thermoplastic Rubbers - Part 1. Shore Hardness Method (Shore Hardness)

(GB/T 531.1-2008, ISO 7619-1.2004 IDT)

GB/T 3512 vulcanized rubber or thermoplastic rubber hot air accelerated aging and heat resistance test

GB/T 6682 Laboratory Water Specifications and Test Methods (GB/T 6682-2008, ISO 3696.1987 MOD)

GB/T 7759.1 Determination of compression set of vulcanized or thermoplastic rubbers - Part 1. At room and elevated temperatures

(GB 7759.1-2015, ISO 815-1.2008, IDT)

GB/T 7766-2008 Chemical analysis method for rubber products

GB/T 14233.1-2008 Medical infusion, blood transfusion, injection equipment inspection methods Part 1. Chemical analysis methods

GB/T 14233.2 Medical infusion, blood transfusion, injection equipment inspection methods Part 2. Biological test methods

GB/T 16886.1 Biological evaluation of medical devices Part 1. Evaluation and testing in risk management process (GB/T 16886.1-

2011, ISO 10993-1.2009, IDT)

GB/T 16886.5 Biological evaluation of medical devices Part 5. In vitro cytotoxicity test (GB/T 16886.5-2003,

ISO 10993-5.1999, IDT)

GB/T 16886.12 Biological evaluation of medical devices - Part 12. Sample preparation and reference samples (GB/T 16886.12-

2005, ISO 10993-12.2002, IDT)

YY/T 0681.1 Test methods for packaging sterile medical devices. Part 1. Guidelines for accelerated aging tests (ASTMF 1980.02,

MOD)

3 Terms and Definitions

The following terms and definitions apply to this document.

The terms of the various parts of the piston are shown in Figure 1.

Explanation.

1 --- baseline;

2---Sealing ring;

3--- Trimming the line.

Note. This schematic only shows the structure of the piston and is not the only type specified for the standard.

Figure 1 Disposable syringe piston

3.1

Baseline fiducialline

The end of the piston is used to determine the outer tangent of the volume corresponding to any scale reading of the syringe.

3.2

Sealing line sealline

The outer side of the piston, which cooperates with the jacket of the syringe to achieve the purpose of sealing.

3.3

Trimming line trimline

The front end of the piston is used to cut the outer tangent of the process.

4 Classification and marking

4.1 Classification

The piston is divided into natural rubber pistons and synthetic rubber pistons according to manufacturing materials.

Note. A guide to the material is given in Appendix A.

4.2 Marking

The piston is marked according to the matching syringe capacity, for example 0.3mL, 0.5mL, 1mL, 2mL, 5mL, 10mL, 20mL, 30mL, 50mL,

100mL and so on.

5 requirements

5.1 Appearance requirements

5.1.1 The surface of the piston should be clean, free from glue, rubber and foreign matter, and should not be exposed to frost.

5.1.2 The piston surface should not have obvious air bubbles, defects or cracks.

5.1.3 The piston end should have a clear baseline and should be complete.

5.1.4 The side of the piston should have a complete seal.

5.1.5 The diameter of the piston trim line should not be greater than the diameter of the piston seal.

5.1.6 If lubricant is applied to the surface of the piston, no obvious lubricant convergence should be seen under normal or corrected to normal vision.

5.1.7 Anti-yellowing test according to the test method of Appendix B. Under the condition of aging at 70°C for 14 days, the color of the piston before and after aging should not be obvious.

Variety.

5.2 Physical and mechanical properties of the material

5.2.1 Hardness (shoreA)

Testing according to the method specified in GB/T 531.1 shall comply with the hardness agreed by the manufacturer of the piston or the manufacturer of the single-use syringe.

The difference should not exceed the nominal value of ±5. Unproven hardness should meet 60 5-3.

5.2.2 Compression set

Test according to the method specified in GB/T 7759.1, aging test at 40±1°C and 120 0-2h, permanent compression of the piston

The shape should not exceed 40%.

NOTE. Appendix C gives the test method for the permanent compression of the finished piston.

5.2.3 rate of change in tensile strength

According to the method specified in GB/T 3512, the rate of change of tensile strength before and after piston aging should not be changed under conditions of aging at 70°C for 72 hours.

More than ±20%.

5.2.4 Change in elongation at break

According to the test method specified in GB/T 3512, the change rate of elongation at break of the piston before and after aging under the condition of aging at 70°C for 72 hours shall not be

More than ±20%.

5.3 Chemical properties

5.3.1 pH

When using a laboratory pH meter and a general-purpose electrode, the difference between the pH of the leach solution prepared according to Appendix D and the pH of the blank solution should be

Must not exceed 1.0.

5.3.2 extractable metal content

The extract prepared according to Appendix D was tested using an approved microanalytical method (eg, atomic absorption method).

The sum of tin, zinc, and iron content should not exceed 5 mg/L, and the cadmium content should be less than 0.1 mg/L.

5.3.3 Reducing substances

Take the extract prepared in accordance with Appendix D and use a 20-mL leach solution for 1 h, according to the rules in 5.2.2 of GB/T 14233.1-2008.

For the method, the difference between the volume of the potassium permanganate solution that consumes 0.002 mol/L of extract solution should not be greater than that of the same volume of blank control solution.

More than 0.4 mL.

5.3.4 UV absorbance

Take the extract prepared in accordance with Appendix D, according to the method specified in GB/T 14233.1-2008, in the 220nm ~ 360nm, extraction

Liquid UV absorbance should not exceed 0.2.

5.3.5 Ash Content

Take an appropriate amount of piston to cut, take 1.0g, put it in a muffle furnace at 550°C±25°C and weigh it to a constant weight. Weigh it accurately to

0.1mg, slowly flaring to complete carbonization (to prevent the sample from catching fire), and then move the crucible into a muffle furnace at 550 °C ± 25 °C to complete ignition

For full ashing, remove the crucible and cool it slightly. Transfer it to a desiccator, continue cooling to room temperature, and weigh until constant weight. Residual residue should not exceed

Over 60%.

5.4 Biological Requirements

5.4.1 Heat source

Test according to the method specified in GB/T 16886.12, choose 0.2g/mL extraction ratio to prepare the extract, according to GB/T 14233.2

For the method test, the piston should be pyrogen free.

Note. In determining the absence of material heating of the piston, conventional tests use the bacterial endotoxin test given in GB/T 14233.2 to control endotoxin contamination.

The resulting pyrogen. The bacterial endotoxin content of each piston should not exceed 20 EU. In routine tests, exceeding this limit can be considered as not complying with 5.4.1.

Claim.

5.4.2 Cytotoxicity

According to the provisions of GB/T 16886.5, choose 0.2g/mL extraction ratio to prepare the extract, according to the method specified in GB/T 14233.2

Test, the piston cytotoxicity should not be greater than 2.

5.4.3 Hemolysis

According to the provisions of GB/T 16886.12, choose 0.2g/mL extraction ratio to prepare the extract, according to the method specified in GB/T 14233.2

Test, the hemolytic rate of the piston should be less than 5%.

5.4.4 Intradermal stimulation

Test according to the method specified in GB/T 14233.2, the piston should be no stimulus response.

5.4.5 Sensitization

Test according to the method specified in GB/T 14233.2, the piston should not be sensitized.

5.4.6 Acute systemic toxicity

According to the provisions of GB/T 16886.12, choose 0.2g/mL extraction ratio to prepare the extract, according to the method specified in GB/T 14233.2

Test, the piston should have no acute systemic toxicity.

6 type inspection

6.1 Type inspection is a full performance test.

6.2 In the type inspection, the inspection item is all the requirements of Chapter 5. If there is no special provision, the physical requirements of each random sample of 5 sets, other requirements by

The standard regulations proceed.

6.3 If all inspection items are qualified, they will pass the type inspection. If the type test fails, mass production may not be carried out.

7 Packaging

7.1 Initial packaging

Double plastic bags should be used to seal the package.

The packaged material should not have harmful effects on the contents. The material and design of this package should ensure.

a) The contents contain minimal risk of contamination when removed from the packaging;

b) Full protection of the contents during normal handling, transportation and storage.

7.2 Outer packaging

One or more primary packagings should be included in an outer packaging.

During normal handling, transportation and storage, the outer packaging should be able to protect the contents fully and effectively.

8 signs

8.1 Initial packaging mark

The following packaging should have at least the following signs.

a) Description of the contents, including product name, model or specification, piston material hardness, piston material name;

b) the name and address of the manufacturer or supplier;

c) quantity;

d) production lot number or date;

e) Expiration date.

8.2 Outer Packaging Marking

The outer packaging should have at least the following signs.

a) Description of the contents, including product name, model or specification, piston material hardness, piston material name;

b) the name and address of the manufacturer or supplier;

c) quantity;

d) production lot number or date;

e) expiration date;

f) Requirements for handling, storage and transportation.

9 Transportation and Storage

9.1 Transportation

Avoid direct sunlight and rain and snow soaking when transporting.

9.2 Storage

Pistons should be stored in a non-corrosive atmosphere and in a well-ventilated room with adequate protection for the piston.

Appendix A

(Informative Appendix)

Material guide

The material used to make the piston should be compatible with the sterilization process of a suitable syringe.

The material used to make the piston must not be physically or chemically harmful during the routine use of syringes for injection preparations.

influences.

The material used to make the piston uses a high quality natural or synthetic rubber polymer. The gel content should not be less than 40%, according to

GB/T 7766-2008 Section 4.4 "rubber polymer content" or Chapter 5 "determination of rubber polymer" for testing. Natural rubber and non-

The differentiation of natural rubber can be detected according to the test method of “Nitrogen Content, Measured by Protein” in Section 4.10.7 of GB/T 7766-2008.

This standard does not limit technological progress. If thermoplastic elastomers or other polymer materials are used, manufacturers should refer to this standard and related standards.

Qualifications and regulations are evaluated.

The surface of the piston can optionally use dimethyl silicone oil as a lubricant in accordance with the Chinese National Pharmacopoeia.

The piston should not release any substances that have side effects on the human body. When the new product is put into production, materials and production processes have major changes, it should be

According to GB/T 16886.1 its biological evaluation, the basic evaluation test is.

a) pyrogen should be pyrogen free;

b) cytotoxicity (relative proliferation should not be greater than 2);

c...

Share