1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 0245-2008 English PDF (YYT0245-2008)

YY/T 0245-2008 English PDF (YYT0245-2008)

Regular price

$120.00 USD

Regular price

Sale price

$120.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 0245-2008 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0245-2008

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0245-2008: General specifications for stapler

YY/T 0245-2008

General specifications for stapler

ICS 11.040.30

C31

People's Republic of China Pharmaceutical Industry Standard

YY/T 0245-2008

Replacing YY/T 0245.1-1997

General technical conditions for kiss (seam)

Released on.2008-04-25

2009-06-01 implementation

State Food and Drug Administration released

Foreword

This standard replaces YY/T 0245.1-1997 "General Technical Conditions for Kiss (Sew) Couplings".

The main differences between this standard and YY/T 0245.1-1997.

--- The standard has expanded the scope of application, that is, for reusable kiss (sew) and disposable kiss (sew);

--- The requirements in the original standard have been re-arranged according to their characteristics, and the level is more distinct in the content;

--- The hardness requirements for the main components of the kiss (seam) joint are directly specified in this standard;

--- The pressure resistance index of the kiss (seam) combiner is also directly included in this standard, unified assessment;

--- Increase the content of Appendix B "Peel Strength Test Method".

Appendix A and Appendix B of this standard are normative appendices.

This standard is proposed and managed by the National Surgical Instrument Standardization Technical Committee.

This standard was drafted by Shanghai Medical Devices (Group) Co., Ltd. Surgical Instrument Factory and Changzhou Kangdi Medical Stapler Co., Ltd.

The main drafters of this standard. Liu Weiqun, Yan Guoan.

The previous versions of the standards replaced by this standard.

---GB 8667-1988;

---YY/T 0245.1-1997.

YY/T 0245-2008

General technical conditions for kiss (seam)

1 range

This standard specifies the classification and type, requirements, test methods, inspection rules, signs, instructions for use, packaging, transportation of kiss (seam)

And storage.

This standard applies to reusable and single-use kiss (sew) combiners for the assembly of components on a kiss (seam) for round tubes

The incision anastomosis and the ring-resection anastomosis of the supraorbital mucosa or the suture closure of the stump incision closure.

2 Normative references

The terms of the following documents constitute provisions of this standard by reference to this standard. Any dated reference document, followed by

Some amendments (not including errata content) or revisions do not apply to this standard, however, parties to agreements based on this standard are encouraged to

Whether the latest version of these files can be used. For undated references, the latest edition applies to this standard.

GB/T 230.1 Metallic Rockwell hardness test - Part 1. Test methods (A, B, C, D, E, F, G, H, K, N, T scales)

(GB/T 230.1-2004, ISO 6508-1.1999, MOD)

GB/T 1220 stainless steel rod

GB/T 2828.1. Sampling procedures for sampling by sampling - Part 1 . Batch-to-batch sampling plan, searched by AQL

(GB/T 2828.1-2003, ISO 2859-1..1999, IDT)

GB/T 2829 Cycle Inspection Counting Sampling Procedures and Tables (Applicable to Inspection of Process Stability)

GB/T 4340.1 Metallic Vickers hardness test - Part 1. Test methods (GB/T 4340.1-1999, eqv ISO

6507-1.1997)

GB 9969.1 General guidelines for the use of industrial products

GB 12672 acrylonitrile-butadiene-styrene (ABS) resin

GB/T 13810 Surgical implants made of titanium and titanium alloy (GB/T 13810-1997, eqv ISO 5832-2.1993)

GB/T 15076 钽铌 chemical analysis method

GB/T 16886.5 Biological evaluation of medical devices - Part 5. In vitro cytotoxicity test (GB/T 16886.5-2003,

ISO 10993-5.1999, IDT)

GB/T 16886.7 Biological evaluation of medical devices - Part 7. Resin residues in ethylene oxide (GB/T 16886.7-2001,

ISO 10993-7.1995, IDT)

GB/T 16886.10 Biological evaluation of medical devices - Part 10. Stimulation and delayed hypersensitivity test

(GB/T 16886.10-2005, ISO 10993-10.2002, IDT)

YY/T 0149 Test method for corrosion resistance of stainless steel medical devices (YY/T 0149-2006, ISO 13401.1995,

MOD)

YY/T 1052 surgical instrument sign

YY 0466 Medical device for medical device labeling, marking and information providing symbols (YY 0466-2003,

ISO 15223.2000, IDT)

Chinese Pharmacopoeia (2005 Edition)

3 Classification and type

3.1 The type and basic dimensions of the kiss (sew) combiner shall be in accordance with the relevant product standards.

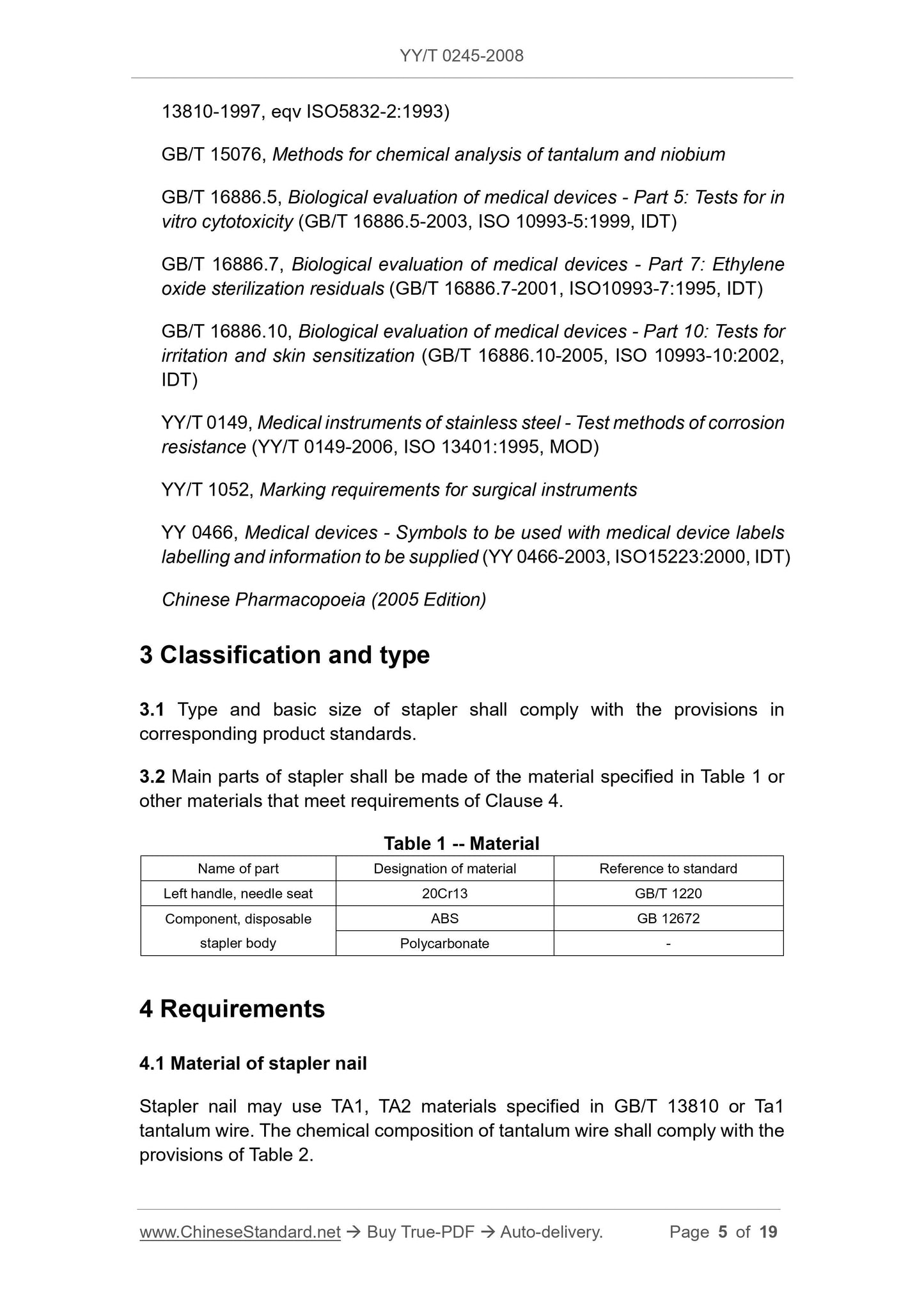

3.2 The main parts of the kiss (seam) joints shall be made of materials that meet the requirements of Table 1 or other materials that meet the requirements of Chapter 4.

YY/T 0245-2008

Table 1 Materials

Part name material grade standard number

Left handle, needle holder 20Cr13 GB/T 1220

Component, disposable kiss (seam) body

ABS GB 12672

Polycarbonate -

4 requirements

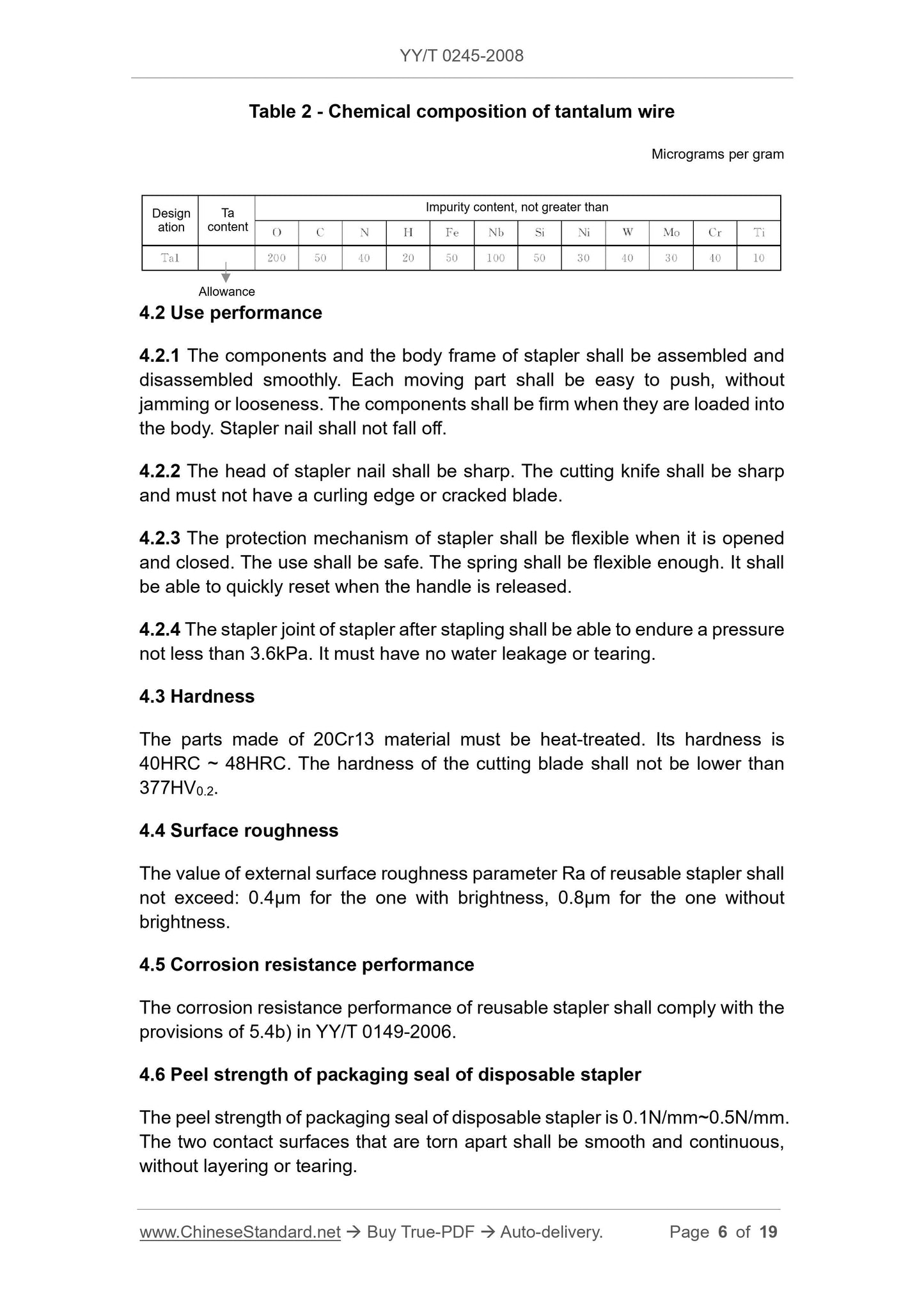

4.1 Kiss (seam) staple material

The kiss (seam) staples can be made of TA1, TA2 materials specified in GB/T 13810, or Ta1 silk materials can also be used. Silk material

The chemical composition should meet the requirements of Table 2.

Table 2 The chemical composition of silk is micrograms per gram.

Brand

Ta

content

Impurity content, not greater than

O C N H Fe Nb Si Ni W Mo Cr Ti

Ta1 balance.200 50 40 20 50 100 50 30 40 30 40 10

4.2 Performance

4.2.1 The components of the kiss (seam) and the body frame should be able to be assembled and disassembled smoothly; each moving part should be easily pushed, and there must be no jamming or looseness.

Movement phenomenon; the component loader should be strong behind the body, and the kiss (seam) staple should not fall off.

4.2.2 The end of the kiss (sew) nail should be sharp; the cutting knife should be sharp, and there must be no curling or chipping.

4.2.3 The protection mechanism of the kiss (seam) combiner should be flexible and should be used safely. The spring should be flexible enough to be quick when the handle is released

Reset.

4.2.4 Kiss (seam) joints After the kiss (seam), the kiss (seam) joint should be able to withstand a pressure of not less than 3.6 kPa, no water leakage and tearing

phenomenon.

4.3 Hardness

Parts made of 20Cr13 material shall be heat treated and have a hardness of 40HRC to 48HRC. The hardness of the cutting blade should not be lower than

377HV0.2.

4.4 Surface roughness

The value of the outer surface roughness parameter Ra of the repeated use of the kiss (sew) is not greater than. light 0.4 μm, no light 0.8 μm.

4.5 Corrosion resistance

The corrosion resistance of the repetitive kiss (sew) combiner shall be in accordance with 5.4b) of YY/T 0149-2006.

4.6 Disposable kiss (seam) seal packaging seal peel strength

The peeling strength of the disposable kiss (seam) seal is 0.1N/mm to 0.5N/mm. The two contact surfaces that are torn apart should be smooth and

Continuous uniformity without delamination or tearing.

4.7 Appearance

The shape of the kiss (sew) should be smooth and smooth with no sharp edges, burrs and cracks. The scale value or mark on the body should be clear.

4.8 size

The size of the kiss (sew) should conform to the specifications in the product standard. The error between the scale value and the head end should be no more than 0.2mm.

4.9 Sterilization

4.9.1 Disposable Kiss (Sew) The sterilizer should be sterilized by a confirmed sterilization process.

4.9.2 Ethylene oxide sterilization, the residual ethylene oxide content of its factory products should be no more than 10μg/g.

4.10 Biological evaluation

4.10.1 The cytotoxicity of the components and disposable body should not exceed level 1.

YY/T 0245-2008

4.10.2 Delayed hypersensitivity (sensitization) of components and disposable bodies shall not exceed 1 grade.

4.10.3 The score of the intradermal reaction of the component and the disposable body should be no more than 1.

5 Test methods

5.1 Material inspection

The chemical composition analysis of pure titanium materials shall be carried out in accordance with the method specified in GB/T 13810. The chemical composition analysis of the silk material shall be in accordance with

The method specified in GB/T 15076.1~15076.15 is carried out. Meet the requirements of 4.1.

5.2 Performance

5.2.1 Imitation of the action, assembly and disassembly of the components and components, and the move of the kiss (seam), the visual observation should comply with the provisions of 4.2.1.

5.2.2 imitate the use of the action, using a layer of blown paper sandwiched between a layer of sponge and a thickness of 8mm ~ 10mm sample for inspection, and

Observe with your eyesight, the kiss (sew) after the kiss (sew) should be neat, no missing needle, and into a "B" shape, the cut edge of the cut sample should be neat, in line with

4.2.2, 4.2.3 provisions.

5.2.3 Pressure test

According to the method of Appendix A, it shall comply with the provisions of 4.2.4.

5.3 hardness

According to the method specified in GB/T 230.1 or GB/T 4340.1, three points are measured on the surface of the heat treatment, and the arithmetic of each of the three points is taken.

The average value should meet the requirements of 4.3.

5.4 Surface roughness

It is carried out by the sample comparison method or the electrical measurement method, and the electrical measurement method is used for arbitration, which complies with the provisions of 4.4.

5.5 Corrosion resistance

According to the boiling water test method in YY/T 0149, it should meet the requirements of 4.5.

5.6 Seal peel strength test

Five test pieces were prepared for each batch according to the method of Appendix B. Each test piece records the maximum peel strength value of the four sides of the seal and calculates its value.

The average value, visual inspection of the seal and the surface of the material, shall be in accordance with 4.6.

5.7 Appearance

Use eyesight and hand wipes, which should meet the requirements of 4.7.

5.8 size

Measurements with general purpose or special gauges shall be in accordance with 4.8.

5.9 Aseptic and ethylene oxide residue test

5.9.1 Three samples of the same batch number shall be taken in accordance with the methods stipulated in the Pharmacopoeia, in accordance with the provisions of 4.9.1.

5.9.2 Determination of ethylene oxide residue according to the method specified in GB/T 16886.7, in accordance with the provisions of 4.9.2.

5.10 Biological evaluation

5.10.1 According to the method of 8.3 direct contact test in GB/T 16886.5-2003, it shall comply with the provisions of 4.10.1.

5.10.2 According to the method of 7.4 maximum dose test in GB/T 16886.10-2005, it shall comply with the provisions of 4.10.2.

5.10.3 According to GB/T 16886.10-2005, B. The method of the intradermal reaction test in Chapter 2 shall be in accordance with the provisions of 4.10.3.

6 Inspection rules

6.1 Acceptance

The kiss (seam) joint shall be inspected by the technical inspection department of the manufacturer, and the acceptance shall be submitted to the ordering party for acceptance.

6.2 Inspection

Kiss (sew) combiners must be submitted for inspection in batches, which are divided into batch-by-batch inspections (factory inspections) and periodic inspections (type inspections).

6.3 Batch inspection

6.3.1 Batch-by-batch inspection shall be carried out in accordance with the provisions of GB/T 2828.1.

YY/T 0245-2008

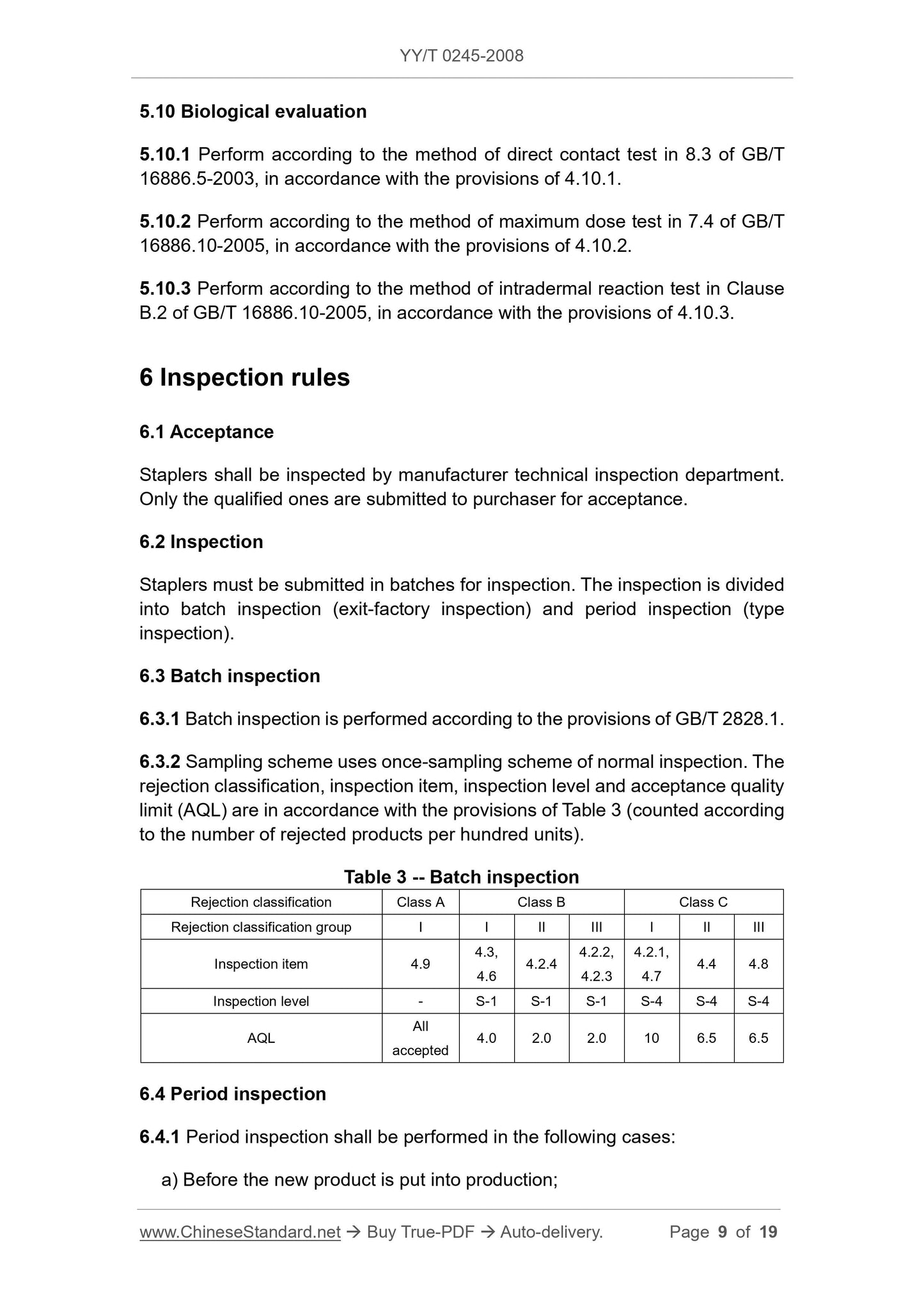

6.3.2 Sampling plan adopts the normal inspection one sampling plan, its unqualified classification, inspection items, inspection level and acceptance quality limit

(AQL) According to the provisions of Table 3 (calculated according to the number of unqualified products per hundred units).

Table 3 Batch inspection

Unqualified classification class A, class B, class C

Unqualified classification group I I II III I II III

Check item 4.9 4.3, 4.6 4.2.4 4.2.2, 4.2.3 4.2.1, 4.7 4.4 4.8

Inspection level - S-1 S-1 S-1 S-4 S-4 S-4

AQL all qualified 4.0 2.0 2.0 10 6.5 6.5

6.4 Cycle check

6.4.1 Periodic inspection should be carried out under the following circumstances.

a) before the new product is put into production;

b) when it is put into production at intervals of more than one year;

c) when there are major changes in the design, process, and materials;

d) When the national quality supervision and inspection agency conducts supervision and inspection of product quality.

6.4.2 The inspection items and sampling methods for periodic inspection shall be carried out in accordance with the provisions of Table 4. In any of the following cases, the provisions of 4.10 shall be added.

Biological evaluation (no exemption in the following cases).

a) when the source of material or technical conditions used to manufacture the product changes;

b) when the product formulation, process, primary packaging or sterilization changes;

c) any changes in the final product during the storage period;

d) when the use of the product changes;

e) There are indications that the product will have an adverse effect when applied to the human body.

6.4.3 The periodic inspection shall be carried out in accordance with the provisions of GB/T 2829.

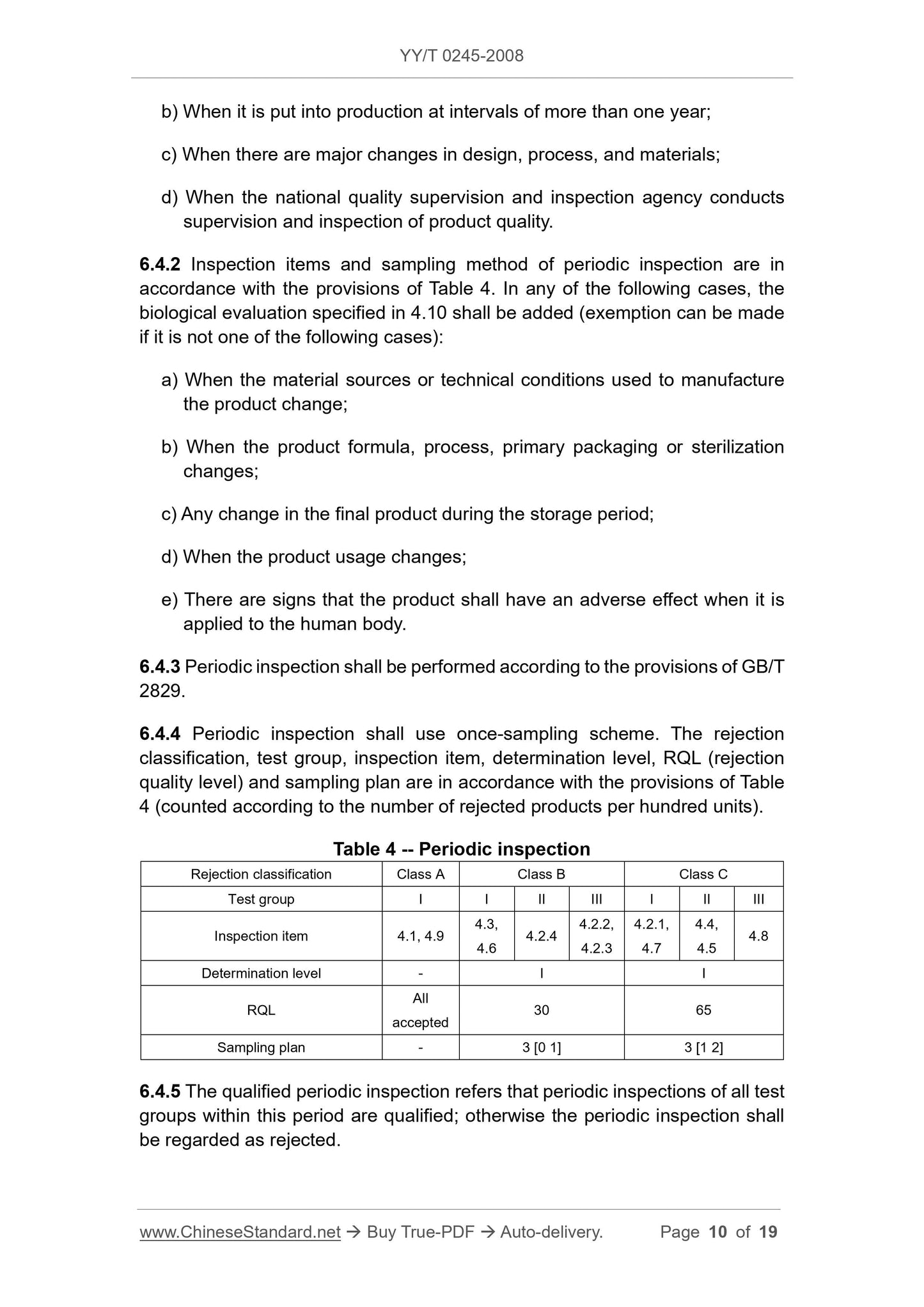

6.4.4 Periodic inspection adopts a sampling plan, its unqualified classification, test group, inspection items, discriminating level, RQL (unqualified quality water)

The sampling plan and the sampling plan are as specified in Table 4 (calculated according to the number of unqualified products per hundred units).

Table 4 Cycle check

Unqualified classification class A, class B, class C

Test group I I II III I II III

Check items 4.1, 4.9 4.3, 4.6 4.2.4 4.2.2, 4.2.3 4.2.1, 4.7 4.4, 4.5 4. 8

Discriminating level - I I

RQL all qualified 30 65

Sampling plan - 3[01] 3[12]

6.4.5 If the cycle inspection is qualified, it shall be that all the test groups in the cycle are qualified in the cycle inspection, otherwise the cycle inspection is considered unqualified.

7 logo, instruction manual

7.1 mark

7.1.1 Each kiss (sew) clutch or component shall have the following markings as specified in YY/T 1052.

a) manufacturer's code or trademark;

b) the date of production (the last two words);

c) Material marking.

7.1.2 The following signs shall be on the box.

a) manufacturer's name, address, trademark;

YY/T 0245-2008

b) product name;

c) quantity, specification;

d) product standard number;

e) Product registration number.

7.1.3 The followi...

Get Quotation: Click YY/T 0245-2008 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0245-2008

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0245-2008: General specifications for stapler

YY/T 0245-2008

General specifications for stapler

ICS 11.040.30

C31

People's Republic of China Pharmaceutical Industry Standard

YY/T 0245-2008

Replacing YY/T 0245.1-1997

General technical conditions for kiss (seam)

Released on.2008-04-25

2009-06-01 implementation

State Food and Drug Administration released

Foreword

This standard replaces YY/T 0245.1-1997 "General Technical Conditions for Kiss (Sew) Couplings".

The main differences between this standard and YY/T 0245.1-1997.

--- The standard has expanded the scope of application, that is, for reusable kiss (sew) and disposable kiss (sew);

--- The requirements in the original standard have been re-arranged according to their characteristics, and the level is more distinct in the content;

--- The hardness requirements for the main components of the kiss (seam) joint are directly specified in this standard;

--- The pressure resistance index of the kiss (seam) combiner is also directly included in this standard, unified assessment;

--- Increase the content of Appendix B "Peel Strength Test Method".

Appendix A and Appendix B of this standard are normative appendices.

This standard is proposed and managed by the National Surgical Instrument Standardization Technical Committee.

This standard was drafted by Shanghai Medical Devices (Group) Co., Ltd. Surgical Instrument Factory and Changzhou Kangdi Medical Stapler Co., Ltd.

The main drafters of this standard. Liu Weiqun, Yan Guoan.

The previous versions of the standards replaced by this standard.

---GB 8667-1988;

---YY/T 0245.1-1997.

YY/T 0245-2008

General technical conditions for kiss (seam)

1 range

This standard specifies the classification and type, requirements, test methods, inspection rules, signs, instructions for use, packaging, transportation of kiss (seam)

And storage.

This standard applies to reusable and single-use kiss (sew) combiners for the assembly of components on a kiss (seam) for round tubes

The incision anastomosis and the ring-resection anastomosis of the supraorbital mucosa or the suture closure of the stump incision closure.

2 Normative references

The terms of the following documents constitute provisions of this standard by reference to this standard. Any dated reference document, followed by

Some amendments (not including errata content) or revisions do not apply to this standard, however, parties to agreements based on this standard are encouraged to

Whether the latest version of these files can be used. For undated references, the latest edition applies to this standard.

GB/T 230.1 Metallic Rockwell hardness test - Part 1. Test methods (A, B, C, D, E, F, G, H, K, N, T scales)

(GB/T 230.1-2004, ISO 6508-1.1999, MOD)

GB/T 1220 stainless steel rod

GB/T 2828.1. Sampling procedures for sampling by sampling - Part 1 . Batch-to-batch sampling plan, searched by AQL

(GB/T 2828.1-2003, ISO 2859-1..1999, IDT)

GB/T 2829 Cycle Inspection Counting Sampling Procedures and Tables (Applicable to Inspection of Process Stability)

GB/T 4340.1 Metallic Vickers hardness test - Part 1. Test methods (GB/T 4340.1-1999, eqv ISO

6507-1.1997)

GB 9969.1 General guidelines for the use of industrial products

GB 12672 acrylonitrile-butadiene-styrene (ABS) resin

GB/T 13810 Surgical implants made of titanium and titanium alloy (GB/T 13810-1997, eqv ISO 5832-2.1993)

GB/T 15076 钽铌 chemical analysis method

GB/T 16886.5 Biological evaluation of medical devices - Part 5. In vitro cytotoxicity test (GB/T 16886.5-2003,

ISO 10993-5.1999, IDT)

GB/T 16886.7 Biological evaluation of medical devices - Part 7. Resin residues in ethylene oxide (GB/T 16886.7-2001,

ISO 10993-7.1995, IDT)

GB/T 16886.10 Biological evaluation of medical devices - Part 10. Stimulation and delayed hypersensitivity test

(GB/T 16886.10-2005, ISO 10993-10.2002, IDT)

YY/T 0149 Test method for corrosion resistance of stainless steel medical devices (YY/T 0149-2006, ISO 13401.1995,

MOD)

YY/T 1052 surgical instrument sign

YY 0466 Medical device for medical device labeling, marking and information providing symbols (YY 0466-2003,

ISO 15223.2000, IDT)

Chinese Pharmacopoeia (2005 Edition)

3 Classification and type

3.1 The type and basic dimensions of the kiss (sew) combiner shall be in accordance with the relevant product standards.

3.2 The main parts of the kiss (seam) joints shall be made of materials that meet the requirements of Table 1 or other materials that meet the requirements of Chapter 4.

YY/T 0245-2008

Table 1 Materials

Part name material grade standard number

Left handle, needle holder 20Cr13 GB/T 1220

Component, disposable kiss (seam) body

ABS GB 12672

Polycarbonate -

4 requirements

4.1 Kiss (seam) staple material

The kiss (seam) staples can be made of TA1, TA2 materials specified in GB/T 13810, or Ta1 silk materials can also be used. Silk material

The chemical composition should meet the requirements of Table 2.

Table 2 The chemical composition of silk is micrograms per gram.

Brand

Ta

content

Impurity content, not greater than

O C N H Fe Nb Si Ni W Mo Cr Ti

Ta1 balance.200 50 40 20 50 100 50 30 40 30 40 10

4.2 Performance

4.2.1 The components of the kiss (seam) and the body frame should be able to be assembled and disassembled smoothly; each moving part should be easily pushed, and there must be no jamming or looseness.

Movement phenomenon; the component loader should be strong behind the body, and the kiss (seam) staple should not fall off.

4.2.2 The end of the kiss (sew) nail should be sharp; the cutting knife should be sharp, and there must be no curling or chipping.

4.2.3 The protection mechanism of the kiss (seam) combiner should be flexible and should be used safely. The spring should be flexible enough to be quick when the handle is released

Reset.

4.2.4 Kiss (seam) joints After the kiss (seam), the kiss (seam) joint should be able to withstand a pressure of not less than 3.6 kPa, no water leakage and tearing

phenomenon.

4.3 Hardness

Parts made of 20Cr13 material shall be heat treated and have a hardness of 40HRC to 48HRC. The hardness of the cutting blade should not be lower than

377HV0.2.

4.4 Surface roughness

The value of the outer surface roughness parameter Ra of the repeated use of the kiss (sew) is not greater than. light 0.4 μm, no light 0.8 μm.

4.5 Corrosion resistance

The corrosion resistance of the repetitive kiss (sew) combiner shall be in accordance with 5.4b) of YY/T 0149-2006.

4.6 Disposable kiss (seam) seal packaging seal peel strength

The peeling strength of the disposable kiss (seam) seal is 0.1N/mm to 0.5N/mm. The two contact surfaces that are torn apart should be smooth and

Continuous uniformity without delamination or tearing.

4.7 Appearance

The shape of the kiss (sew) should be smooth and smooth with no sharp edges, burrs and cracks. The scale value or mark on the body should be clear.

4.8 size

The size of the kiss (sew) should conform to the specifications in the product standard. The error between the scale value and the head end should be no more than 0.2mm.

4.9 Sterilization

4.9.1 Disposable Kiss (Sew) The sterilizer should be sterilized by a confirmed sterilization process.

4.9.2 Ethylene oxide sterilization, the residual ethylene oxide content of its factory products should be no more than 10μg/g.

4.10 Biological evaluation

4.10.1 The cytotoxicity of the components and disposable body should not exceed level 1.

YY/T 0245-2008

4.10.2 Delayed hypersensitivity (sensitization) of components and disposable bodies shall not exceed 1 grade.

4.10.3 The score of the intradermal reaction of the component and the disposable body should be no more than 1.

5 Test methods

5.1 Material inspection

The chemical composition analysis of pure titanium materials shall be carried out in accordance with the method specified in GB/T 13810. The chemical composition analysis of the silk material shall be in accordance with

The method specified in GB/T 15076.1~15076.15 is carried out. Meet the requirements of 4.1.

5.2 Performance

5.2.1 Imitation of the action, assembly and disassembly of the components and components, and the move of the kiss (seam), the visual observation should comply with the provisions of 4.2.1.

5.2.2 imitate the use of the action, using a layer of blown paper sandwiched between a layer of sponge and a thickness of 8mm ~ 10mm sample for inspection, and

Observe with your eyesight, the kiss (sew) after the kiss (sew) should be neat, no missing needle, and into a "B" shape, the cut edge of the cut sample should be neat, in line with

4.2.2, 4.2.3 provisions.

5.2.3 Pressure test

According to the method of Appendix A, it shall comply with the provisions of 4.2.4.

5.3 hardness

According to the method specified in GB/T 230.1 or GB/T 4340.1, three points are measured on the surface of the heat treatment, and the arithmetic of each of the three points is taken.

The average value should meet the requirements of 4.3.

5.4 Surface roughness

It is carried out by the sample comparison method or the electrical measurement method, and the electrical measurement method is used for arbitration, which complies with the provisions of 4.4.

5.5 Corrosion resistance

According to the boiling water test method in YY/T 0149, it should meet the requirements of 4.5.

5.6 Seal peel strength test

Five test pieces were prepared for each batch according to the method of Appendix B. Each test piece records the maximum peel strength value of the four sides of the seal and calculates its value.

The average value, visual inspection of the seal and the surface of the material, shall be in accordance with 4.6.

5.7 Appearance

Use eyesight and hand wipes, which should meet the requirements of 4.7.

5.8 size

Measurements with general purpose or special gauges shall be in accordance with 4.8.

5.9 Aseptic and ethylene oxide residue test

5.9.1 Three samples of the same batch number shall be taken in accordance with the methods stipulated in the Pharmacopoeia, in accordance with the provisions of 4.9.1.

5.9.2 Determination of ethylene oxide residue according to the method specified in GB/T 16886.7, in accordance with the provisions of 4.9.2.

5.10 Biological evaluation

5.10.1 According to the method of 8.3 direct contact test in GB/T 16886.5-2003, it shall comply with the provisions of 4.10.1.

5.10.2 According to the method of 7.4 maximum dose test in GB/T 16886.10-2005, it shall comply with the provisions of 4.10.2.

5.10.3 According to GB/T 16886.10-2005, B. The method of the intradermal reaction test in Chapter 2 shall be in accordance with the provisions of 4.10.3.

6 Inspection rules

6.1 Acceptance

The kiss (seam) joint shall be inspected by the technical inspection department of the manufacturer, and the acceptance shall be submitted to the ordering party for acceptance.

6.2 Inspection

Kiss (sew) combiners must be submitted for inspection in batches, which are divided into batch-by-batch inspections (factory inspections) and periodic inspections (type inspections).

6.3 Batch inspection

6.3.1 Batch-by-batch inspection shall be carried out in accordance with the provisions of GB/T 2828.1.

YY/T 0245-2008

6.3.2 Sampling plan adopts the normal inspection one sampling plan, its unqualified classification, inspection items, inspection level and acceptance quality limit

(AQL) According to the provisions of Table 3 (calculated according to the number of unqualified products per hundred units).

Table 3 Batch inspection

Unqualified classification class A, class B, class C

Unqualified classification group I I II III I II III

Check item 4.9 4.3, 4.6 4.2.4 4.2.2, 4.2.3 4.2.1, 4.7 4.4 4.8

Inspection level - S-1 S-1 S-1 S-4 S-4 S-4

AQL all qualified 4.0 2.0 2.0 10 6.5 6.5

6.4 Cycle check

6.4.1 Periodic inspection should be carried out under the following circumstances.

a) before the new product is put into production;

b) when it is put into production at intervals of more than one year;

c) when there are major changes in the design, process, and materials;

d) When the national quality supervision and inspection agency conducts supervision and inspection of product quality.

6.4.2 The inspection items and sampling methods for periodic inspection shall be carried out in accordance with the provisions of Table 4. In any of the following cases, the provisions of 4.10 shall be added.

Biological evaluation (no exemption in the following cases).

a) when the source of material or technical conditions used to manufacture the product changes;

b) when the product formulation, process, primary packaging or sterilization changes;

c) any changes in the final product during the storage period;

d) when the use of the product changes;

e) There are indications that the product will have an adverse effect when applied to the human body.

6.4.3 The periodic inspection shall be carried out in accordance with the provisions of GB/T 2829.

6.4.4 Periodic inspection adopts a sampling plan, its unqualified classification, test group, inspection items, discriminating level, RQL (unqualified quality water)

The sampling plan and the sampling plan are as specified in Table 4 (calculated according to the number of unqualified products per hundred units).

Table 4 Cycle check

Unqualified classification class A, class B, class C

Test group I I II III I II III

Check items 4.1, 4.9 4.3, 4.6 4.2.4 4.2.2, 4.2.3 4.2.1, 4.7 4.4, 4.5 4. 8

Discriminating level - I I

RQL all qualified 30 65

Sampling plan - 3[01] 3[12]

6.4.5 If the cycle inspection is qualified, it shall be that all the test groups in the cycle are qualified in the cycle inspection, otherwise the cycle inspection is considered unqualified.

7 logo, instruction manual

7.1 mark

7.1.1 Each kiss (sew) clutch or component shall have the following markings as specified in YY/T 1052.

a) manufacturer's code or trademark;

b) the date of production (the last two words);

c) Material marking.

7.1.2 The following signs shall be on the box.

a) manufacturer's name, address, trademark;

YY/T 0245-2008

b) product name;

c) quantity, specification;

d) product standard number;

e) Product registration number.

7.1.3 The followi...

Share