1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 0291-2016 English PDF (YY/T0291-2016)

YY/T 0291-2016 English PDF (YY/T0291-2016)

Regular price

$140.00 USD

Regular price

Sale price

$140.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 0291-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0291-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0291-2016: Environmental requirements and test methods for medical X-ray equipment

YY/T 0291-2016

Environmental requirements and test methods for medical X-ray equipment

ICS 11.040.50

C43

People's Republic of China Pharmaceutical Industry Standard

Replacing YY/T 0291-2007

Medical X-ray equipment environmental requirements and test methods

Published on.2016-03-23

2017-01-01 Implementation

The State Food and Drug Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Compared with YY/T 0291-2007, the main technical changes in this standard are as follows.

--- Added JTGB 01-2014 highway engineering technical standards in the normative references;

--- Added terms and definitions section;

--- Revised the expression of the environmental grouping (see 4, see 3 of.2007 edition);

--- Modify the expression of the requirement (see 5, see version 4.1, 4.2 and 4.3 of the.2007 edition);

--- Modify the expression of special circumstances (see 6.3, see the.2007 version 5.1);

--- Modify the expression of the test sequence (see 6.1.2, see 5.2.2 of the.2007 edition);

--- Modify the expression of the test content (see 6.2, see version 5.2.3 of the.2007 edition);

--- Modify the expression of the environmental test method (see 6.2, see 5.3 in.2007 edition);

--- Modify the requirements of the recovery time and the requirements of the power adaptability requirements (see Table A.1, see Table A.1 of the.2007 edition);

--- Added Appendix B of the environmental test sequence chart is an informative appendix.

Please note that some of the contents of this document may involve patents. The issuing agency of this document does not assume responsibility for identifying these patents.

This standard is proposed by the State Food and Drug Administration.

This standard consists of the National Medical Electrotechnical Standardization Technical Committee Medical X-ray Equipment and Appliances Standardization Subcommittee (SAC/

TC10/SC1) centralized.

This standard was drafted by. Liaoning Provincial Medical Device Inspection Institute, Shanghai Siemens Medical Devices Co., Ltd.

The main drafters of this standard. Jin Yubo, Zhao Jin, Liu Congzhi, Mei Weiming.

The previous versions of the standards replaced by this standard are.

---YY/T 0291-1997, YY/T 0291-2007.

Medical X-ray equipment environmental requirements and test methods

1 Scope

This standard specifies the environmental grouping, requirements, and test methods for medical X-ray equipment (hereinafter referred to as equipment).

This standard applies to medical X-ray equipment.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB 9706.1-2007 Medical electrical equipment Part 1. General requirements for safety

GB 9706.3-2000 Medical electrical equipment - Part 2. Particular requirements for the safety of high voltage generators for diagnostic X-ray generators

GB 9706.18-2006 Medical electrical equipment - Part 2. Particular requirements for the safety of X-ray computed tomography equipment

GB 9706.24-2005 Medical electrical equipment Part 2-45. Mammography X-ray photography equipment and breast stereotaxic device safety

Special requirements

GB/T 10149-1988 medical X-ray equipment terms and symbols

GB/T 14710-2009 Environmental requirements and test methods for medical electrical appliances

JTGB 01-2014 Highway Engineering Technical Standards

3 Terms and Definitions

The terms and definitions defined in GB/T 10149-1988 apply to this document.

4 Environment Grouping

4.1 Climate Environment Grouping

Equipment is divided into two groups according to the conditions of use.

a) Group I. Used in a good environment, usually referring to equipment used in controlled environments with air-conditioning and other equipment, see

3.1a) of GB/T 14710-2009;

b) Group II. used in a general environment, usually refers to the equipment used in a heating and ventilation environment, see GB/T 14710-

2009b).

4.2 Mechanical Environment Grouping

Equipment is divided into two groups according to transportation and circulation conditions.

a) Group I. Careful operation, equipment that can be subjected to slight vibration and shock during transportation and circulation. Generally refers to fixed, position is rarely moved

For moving equipment, see 3.2a) of GB/T 14710-2009; for example. medical X-ray computed tomography equipment, medium and large-sized medical doctors

Use X-ray machines, medical X-ray image intensifier TV systems and other fixed installation X-ray equipment;

b) Group II. Devices that are allowed to receive general vibration and shock during use, generally refer to devices that are convenient to move, see GB/T 14710-

3.2b) in.2009; for example. mobile X-ray machines, portable X-ray machines, etc.

5 requirements

5.1 Test Environment

5.1.1 Benchmark test conditions The reference value or range and tolerance requirements are shown in Table 2 of GB/T 14710-2009. When no doubt arises,

At 10 °C ~ 40 °C, relative humidity 30% ~ 75%, voltage fluctuation is less than rated value ± 10%, power supply frequency fluctuation is not more than ± 2%

Under conditions. At the same time, the power supply network shall meet the requirements of 10.2.2 a) of GB 9706.1-2007 and the corresponding GB 9706.3-2000 of the equipment.

The requirements of 10.2.2 a) in 10.2.2 a), 10.2.2 a) in GB 9706.18-2006 and 10.2.2 a) in GB 9706.24-2005.

5.1.2 The test chamber (room) shall meet the requirements of 10.1 of GB/T 14710-2009.

5.2 Environmental test conditions

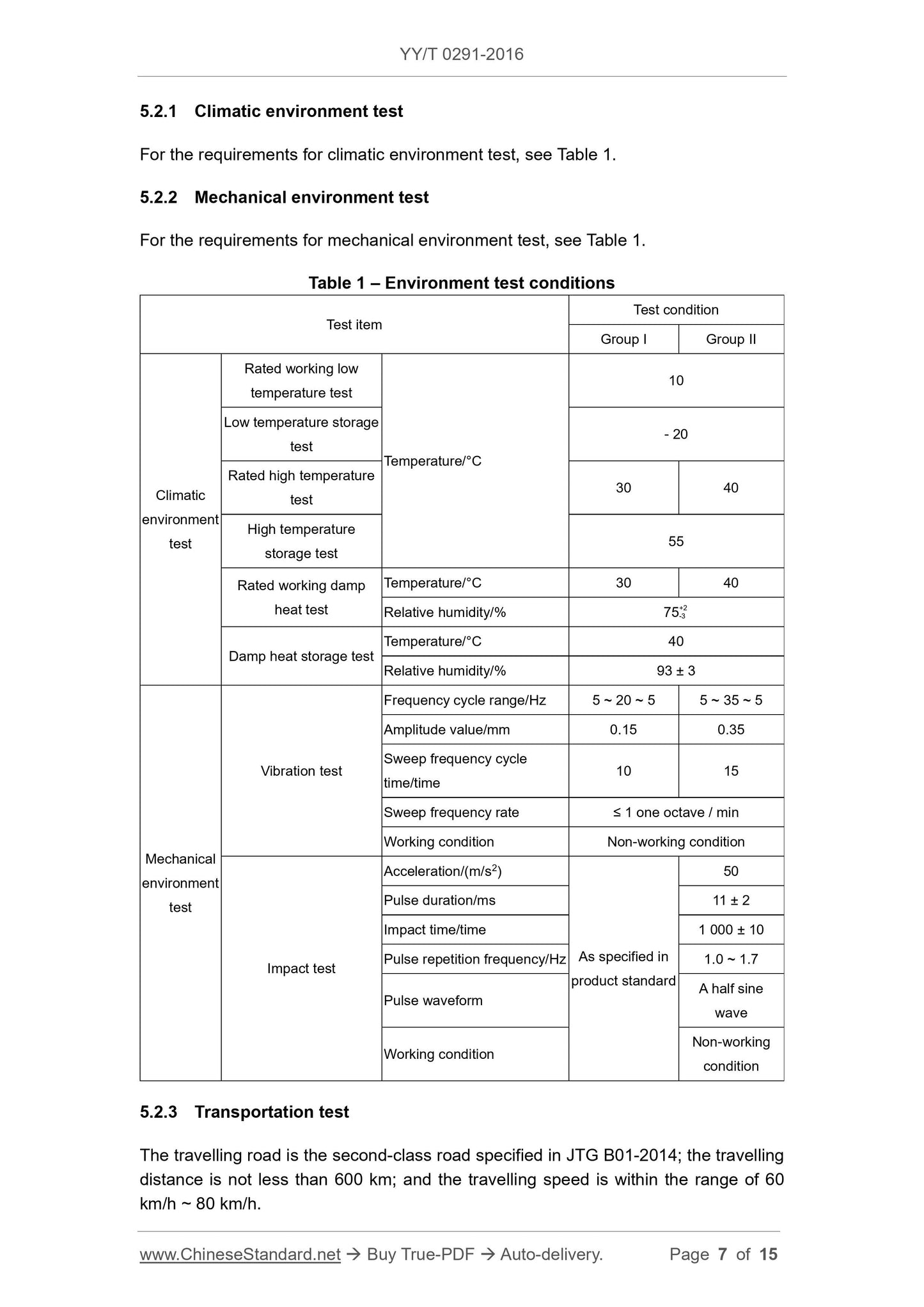

5.2.1 climatic environment test

The climatic and environmental test requirements are shown in Table 1.

5.2.2 Mechanical Environmental Test

Mechanical environmental test requirements are shown in Table 1.

Table 1 Environmental test conditions

Pilot projects

Test conditions

Group I Group II

Rated working low temperature test

Low temperature storage test

Rated high temperature test

High temperature storage test

Rated working damp heat test

Hygrothermal storage test

Temperature/°C

Temperature/°C

Relative humidity/%

Temperature/°C

Relative humidity/%

-20

75 2-3

93±3

Vibration test

Crash test

Frequency cycle range/Hz

Amplitude/mm

Sweep cycle times/time

Sweep rate

Work status

Acceleration/(m/s2)

Pulse duration/ms

Number of collisions/time

Pulse repetition frequency/Hz

Pulse waveform

Work status

5~20~5 5~35~5

0.15 0.35

≤ 1 octave/minute

Non-working state

By product

standard regulation

11±2

1000±10

1.0~1.7

Half sine wave

Non-working state

5.2.3 Transport Test

The road surface is secondary road specified in the standard JTGB 01-2014, the driving distance is not less than 600km, and the driving speed is 60km/h~

80km/h range.

After the test, the fasteners of the equipment shall be free from loosening and tested in accordance with the test items specified in the product standards.

5.2.4 Adaptability to Power Supply

5.2.4.1 Set the equipment supply voltage to 110% and 90% of the rated operating voltage respectively. The frequency of the power supply is 50Hz±1Hz (if necessary

To), and after testing the product for at least 15 minutes, test the relevant test items specified in the product standard.

5.2.4.2 For equipment with special requirements for power supply frequency and supply voltage, the frequency and voltage operating range may be separately specified in the product standard.

Provisions.

6 Test methods

6.1 Test Procedure and Test Sequence

6.1.1 Test procedure

Each trial usually includes the following procedures.

a) Pretreatment (if necessary);

b) initial testing (if necessary);

c) test;

d) intermediate tests (if necessary);

e) recovery (if necessary);

f) Last test.

6.1.2 Test Sequence

When multiple tests are performed on the same equipment in sequence, the test is generally performed in the following order.

a) rated working low temperature test;

b) cryogenic storage test;

c) rated high temperature test;

d) high temperature storage test;

e) Rated working damp heat test;

f) wet heat storage test;

g) vibration test;

h) collision test;

i) Transport trials.

If the test sequence is adjusted, follow the product standard.

6.2 Test content

6.2.1 climatic environment test

6.2.1.1 rated low temperature test, according to the provisions of GB/T 14710-2009 11.1 implementation.

6.2.1.2 cryogenic storage test, according to GB/T 14710-2009 in the provisions of 11.2 implementation.

6.2.1.3 rated high temperature test, according to the provisions of GB/T 14710-2009 11.3 of the implementation.

6.2.1.4 high temperature storage test, according to GB/T 14710-2009 provisions of 11.4 implementation.

6.2.1.5 The rated wet heat test is performed according to the provisions of 11.5 of GB/T 14710-2009.

6.2.1.6 The wet heat storage test shall be carried out in accordance with the provisions of 11.6 of GB/T 14710-2009.

6.2.2 Mechanical Environmental Test

6.2.2.1 The vibration test is to be carried out in accordance with the provisions of 11.7 of GB/T 14710-2009. The test part shall include at least. controller, high voltage generation

Component (without X-ray tube assembly). X-ray tube assemblies, image intensifiers, and digital detectors as otherwise specified in product standards,

Tests for this condition may not be performed.

6.2.2.2 The crash test is to be carried out in accordance with the provisions of 11.8 of GB/T 14710-2009. The test part shall include at least. the controller, high voltage generation

Component (without X-ray tube assembly). X-ray tube assemblies, image intensifiers, and digital detectors as otherwise specified in product standards,

Tests for this condition may not be performed. The direction of the test should simulate easily accessible parts in normal working position.

6.2.3 Transportation test

Under the condition that the equipment is normally shipped from the factory, the equipment should be fixed at the rear of the truck according to the position of the sign “up”.

The load should be 1/3 of the rated load.

The test can be carried out with a truck or a transport tester.

After the test is completed, whether the fasteners of the equipment are loosened and tested according to the test items specified in the product standards.

6.2.4 Test of power adaptability

This test is generally performed during the rated working low temperature test and the rated working high temperature test. During the test, the power cord of the equipment is connected to

On the adjustable power supply, the adjustable power output frequency is kept at the rated frequency of the product, and the voltage is respectively set at 110% of the rated voltage of the product and

90%, and after testing for at least 15 minutes on this voltage, test the relevant test items specified in the product standard.

6.3 Special Conditions

Consider the following situation.

a) that climatic environmental tests apply only to those parts or components that may be affected by the climatic conditions simulated by the test;

b) The equipment should be put into the test box (room) in the unpackaged, ready-to-use and normal working positions;

c) Accessories for the equipment shall be tested together with the equipment unless the annex has product standard requirements;

d) Parts that can be disassembled without tools should be disassembled and tested together with the main part;

e) Interval between treatment and test and between test and test if test is not possible without decomposition or reassembly

It can be determined according to the time of equipment handling, assembly and debugging;

f) If the equipment (such as large equipment or equipment with specific requirements for the use environment) is not suitable for certain environmental test items (eg

Such as. rated working low temperature test, rated working high temperature test, rated working damp heat test, etc., should be provided by the manufacturer for specific tests

Requirements, and explain them in product standards;

g) If the product standard has special requirements for environmental testing conditions, it shall be implemented in accordance with the product standards. When the whole test is not feasible

At that time, what key parts or components should be tested in the product standards;

h) When the working space of the test chamber (room) is not enough for the whole machine test room, if the equipment allows, it can be connected with the whole machine according to the extension type.

The system was tested separately. Test methods should be specified in product standards;

Note. This requirement can be applied to equipment for rated low temperature test, rated high temperature test, rated wet heat test.

i) When the working space of the test chamber (room) is restricted, it is allowed to divide the equipment into several parts for testing. The test method should be in production.

Product standards.

Note. This requirement can be applied to equipment that performs cryogenic storage test, high temperature storage test, and damp heat storage test.

6.4 Test results

After the end of the test, in addition to functional inspections according to product standards (initial testing, intermediate or final testing items and requirements),

Visual inspection of equipment or components should meet the following requirements.

a) No rust, cracks, peeling of the coating, etc.;

b) The words and signs should be clear;

c) The control agency should be flexible;

d) There should be no loosening of the fastening area and no spillage of the infusion.

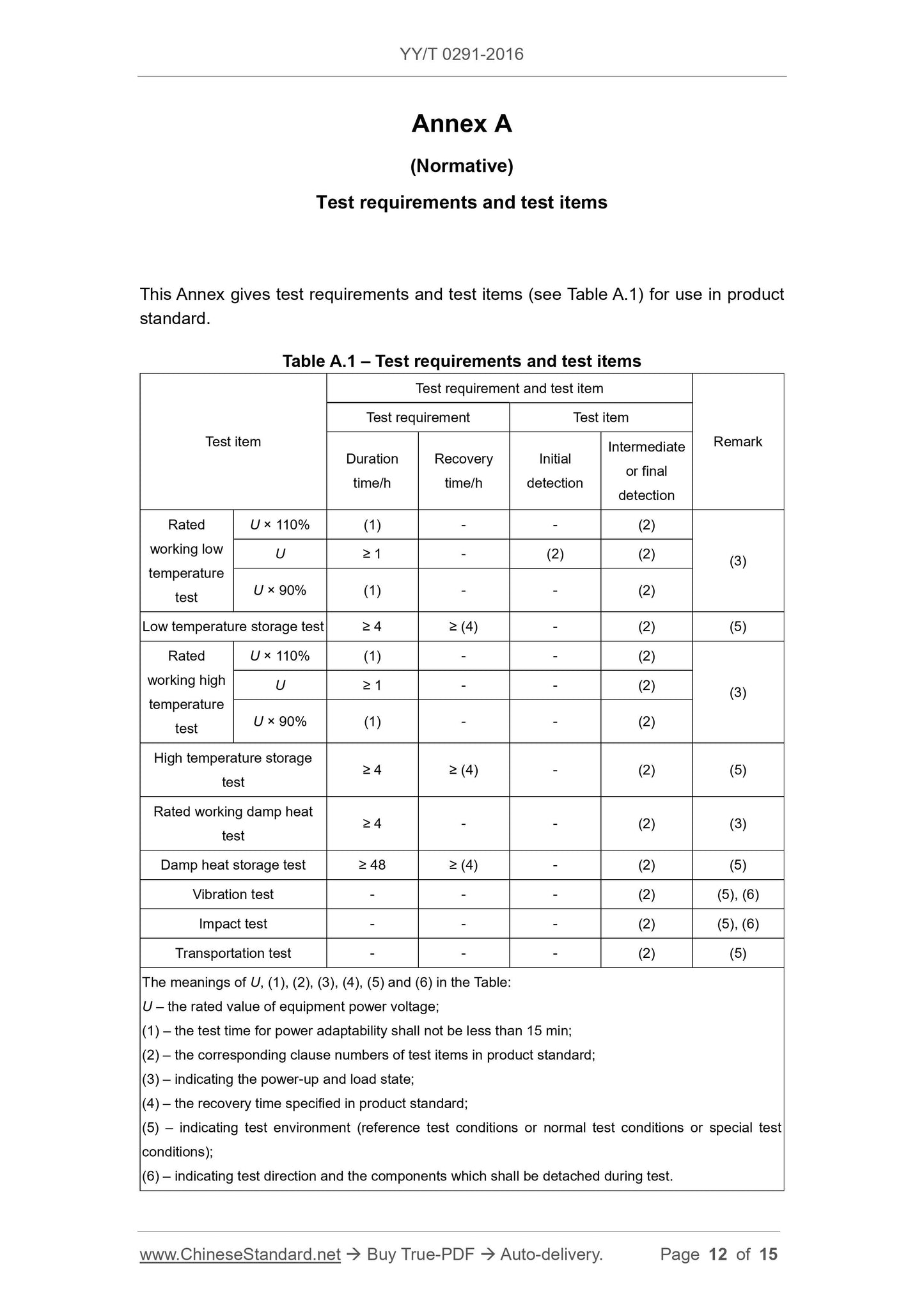

Appendix A

(Normative Appendix)

Test requirements and test items

This appendix gives test requirements and test items (see Table A.1) for product standard use.

Table A.1 Test Requirements and Test Items

Pilot projects

Test requirements and test items

Test requirements test items

Duration/h Recovery time/h Initial or middle detection

Note

Rated work

Low temperature test

U×110% (1) - - (2)

U ≥1 - (2) (2)

U×90% (1) - - (2)

(3)

Low temperature storag...

Get Quotation: Click YY/T 0291-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0291-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0291-2016: Environmental requirements and test methods for medical X-ray equipment

YY/T 0291-2016

Environmental requirements and test methods for medical X-ray equipment

ICS 11.040.50

C43

People's Republic of China Pharmaceutical Industry Standard

Replacing YY/T 0291-2007

Medical X-ray equipment environmental requirements and test methods

Published on.2016-03-23

2017-01-01 Implementation

The State Food and Drug Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Compared with YY/T 0291-2007, the main technical changes in this standard are as follows.

--- Added JTGB 01-2014 highway engineering technical standards in the normative references;

--- Added terms and definitions section;

--- Revised the expression of the environmental grouping (see 4, see 3 of.2007 edition);

--- Modify the expression of the requirement (see 5, see version 4.1, 4.2 and 4.3 of the.2007 edition);

--- Modify the expression of special circumstances (see 6.3, see the.2007 version 5.1);

--- Modify the expression of the test sequence (see 6.1.2, see 5.2.2 of the.2007 edition);

--- Modify the expression of the test content (see 6.2, see version 5.2.3 of the.2007 edition);

--- Modify the expression of the environmental test method (see 6.2, see 5.3 in.2007 edition);

--- Modify the requirements of the recovery time and the requirements of the power adaptability requirements (see Table A.1, see Table A.1 of the.2007 edition);

--- Added Appendix B of the environmental test sequence chart is an informative appendix.

Please note that some of the contents of this document may involve patents. The issuing agency of this document does not assume responsibility for identifying these patents.

This standard is proposed by the State Food and Drug Administration.

This standard consists of the National Medical Electrotechnical Standardization Technical Committee Medical X-ray Equipment and Appliances Standardization Subcommittee (SAC/

TC10/SC1) centralized.

This standard was drafted by. Liaoning Provincial Medical Device Inspection Institute, Shanghai Siemens Medical Devices Co., Ltd.

The main drafters of this standard. Jin Yubo, Zhao Jin, Liu Congzhi, Mei Weiming.

The previous versions of the standards replaced by this standard are.

---YY/T 0291-1997, YY/T 0291-2007.

Medical X-ray equipment environmental requirements and test methods

1 Scope

This standard specifies the environmental grouping, requirements, and test methods for medical X-ray equipment (hereinafter referred to as equipment).

This standard applies to medical X-ray equipment.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB 9706.1-2007 Medical electrical equipment Part 1. General requirements for safety

GB 9706.3-2000 Medical electrical equipment - Part 2. Particular requirements for the safety of high voltage generators for diagnostic X-ray generators

GB 9706.18-2006 Medical electrical equipment - Part 2. Particular requirements for the safety of X-ray computed tomography equipment

GB 9706.24-2005 Medical electrical equipment Part 2-45. Mammography X-ray photography equipment and breast stereotaxic device safety

Special requirements

GB/T 10149-1988 medical X-ray equipment terms and symbols

GB/T 14710-2009 Environmental requirements and test methods for medical electrical appliances

JTGB 01-2014 Highway Engineering Technical Standards

3 Terms and Definitions

The terms and definitions defined in GB/T 10149-1988 apply to this document.

4 Environment Grouping

4.1 Climate Environment Grouping

Equipment is divided into two groups according to the conditions of use.

a) Group I. Used in a good environment, usually referring to equipment used in controlled environments with air-conditioning and other equipment, see

3.1a) of GB/T 14710-2009;

b) Group II. used in a general environment, usually refers to the equipment used in a heating and ventilation environment, see GB/T 14710-

2009b).

4.2 Mechanical Environment Grouping

Equipment is divided into two groups according to transportation and circulation conditions.

a) Group I. Careful operation, equipment that can be subjected to slight vibration and shock during transportation and circulation. Generally refers to fixed, position is rarely moved

For moving equipment, see 3.2a) of GB/T 14710-2009; for example. medical X-ray computed tomography equipment, medium and large-sized medical doctors

Use X-ray machines, medical X-ray image intensifier TV systems and other fixed installation X-ray equipment;

b) Group II. Devices that are allowed to receive general vibration and shock during use, generally refer to devices that are convenient to move, see GB/T 14710-

3.2b) in.2009; for example. mobile X-ray machines, portable X-ray machines, etc.

5 requirements

5.1 Test Environment

5.1.1 Benchmark test conditions The reference value or range and tolerance requirements are shown in Table 2 of GB/T 14710-2009. When no doubt arises,

At 10 °C ~ 40 °C, relative humidity 30% ~ 75%, voltage fluctuation is less than rated value ± 10%, power supply frequency fluctuation is not more than ± 2%

Under conditions. At the same time, the power supply network shall meet the requirements of 10.2.2 a) of GB 9706.1-2007 and the corresponding GB 9706.3-2000 of the equipment.

The requirements of 10.2.2 a) in 10.2.2 a), 10.2.2 a) in GB 9706.18-2006 and 10.2.2 a) in GB 9706.24-2005.

5.1.2 The test chamber (room) shall meet the requirements of 10.1 of GB/T 14710-2009.

5.2 Environmental test conditions

5.2.1 climatic environment test

The climatic and environmental test requirements are shown in Table 1.

5.2.2 Mechanical Environmental Test

Mechanical environmental test requirements are shown in Table 1.

Table 1 Environmental test conditions

Pilot projects

Test conditions

Group I Group II

Rated working low temperature test

Low temperature storage test

Rated high temperature test

High temperature storage test

Rated working damp heat test

Hygrothermal storage test

Temperature/°C

Temperature/°C

Relative humidity/%

Temperature/°C

Relative humidity/%

-20

75 2-3

93±3

Vibration test

Crash test

Frequency cycle range/Hz

Amplitude/mm

Sweep cycle times/time

Sweep rate

Work status

Acceleration/(m/s2)

Pulse duration/ms

Number of collisions/time

Pulse repetition frequency/Hz

Pulse waveform

Work status

5~20~5 5~35~5

0.15 0.35

≤ 1 octave/minute

Non-working state

By product

standard regulation

11±2

1000±10

1.0~1.7

Half sine wave

Non-working state

5.2.3 Transport Test

The road surface is secondary road specified in the standard JTGB 01-2014, the driving distance is not less than 600km, and the driving speed is 60km/h~

80km/h range.

After the test, the fasteners of the equipment shall be free from loosening and tested in accordance with the test items specified in the product standards.

5.2.4 Adaptability to Power Supply

5.2.4.1 Set the equipment supply voltage to 110% and 90% of the rated operating voltage respectively. The frequency of the power supply is 50Hz±1Hz (if necessary

To), and after testing the product for at least 15 minutes, test the relevant test items specified in the product standard.

5.2.4.2 For equipment with special requirements for power supply frequency and supply voltage, the frequency and voltage operating range may be separately specified in the product standard.

Provisions.

6 Test methods

6.1 Test Procedure and Test Sequence

6.1.1 Test procedure

Each trial usually includes the following procedures.

a) Pretreatment (if necessary);

b) initial testing (if necessary);

c) test;

d) intermediate tests (if necessary);

e) recovery (if necessary);

f) Last test.

6.1.2 Test Sequence

When multiple tests are performed on the same equipment in sequence, the test is generally performed in the following order.

a) rated working low temperature test;

b) cryogenic storage test;

c) rated high temperature test;

d) high temperature storage test;

e) Rated working damp heat test;

f) wet heat storage test;

g) vibration test;

h) collision test;

i) Transport trials.

If the test sequence is adjusted, follow the product standard.

6.2 Test content

6.2.1 climatic environment test

6.2.1.1 rated low temperature test, according to the provisions of GB/T 14710-2009 11.1 implementation.

6.2.1.2 cryogenic storage test, according to GB/T 14710-2009 in the provisions of 11.2 implementation.

6.2.1.3 rated high temperature test, according to the provisions of GB/T 14710-2009 11.3 of the implementation.

6.2.1.4 high temperature storage test, according to GB/T 14710-2009 provisions of 11.4 implementation.

6.2.1.5 The rated wet heat test is performed according to the provisions of 11.5 of GB/T 14710-2009.

6.2.1.6 The wet heat storage test shall be carried out in accordance with the provisions of 11.6 of GB/T 14710-2009.

6.2.2 Mechanical Environmental Test

6.2.2.1 The vibration test is to be carried out in accordance with the provisions of 11.7 of GB/T 14710-2009. The test part shall include at least. controller, high voltage generation

Component (without X-ray tube assembly). X-ray tube assemblies, image intensifiers, and digital detectors as otherwise specified in product standards,

Tests for this condition may not be performed.

6.2.2.2 The crash test is to be carried out in accordance with the provisions of 11.8 of GB/T 14710-2009. The test part shall include at least. the controller, high voltage generation

Component (without X-ray tube assembly). X-ray tube assemblies, image intensifiers, and digital detectors as otherwise specified in product standards,

Tests for this condition may not be performed. The direction of the test should simulate easily accessible parts in normal working position.

6.2.3 Transportation test

Under the condition that the equipment is normally shipped from the factory, the equipment should be fixed at the rear of the truck according to the position of the sign “up”.

The load should be 1/3 of the rated load.

The test can be carried out with a truck or a transport tester.

After the test is completed, whether the fasteners of the equipment are loosened and tested according to the test items specified in the product standards.

6.2.4 Test of power adaptability

This test is generally performed during the rated working low temperature test and the rated working high temperature test. During the test, the power cord of the equipment is connected to

On the adjustable power supply, the adjustable power output frequency is kept at the rated frequency of the product, and the voltage is respectively set at 110% of the rated voltage of the product and

90%, and after testing for at least 15 minutes on this voltage, test the relevant test items specified in the product standard.

6.3 Special Conditions

Consider the following situation.

a) that climatic environmental tests apply only to those parts or components that may be affected by the climatic conditions simulated by the test;

b) The equipment should be put into the test box (room) in the unpackaged, ready-to-use and normal working positions;

c) Accessories for the equipment shall be tested together with the equipment unless the annex has product standard requirements;

d) Parts that can be disassembled without tools should be disassembled and tested together with the main part;

e) Interval between treatment and test and between test and test if test is not possible without decomposition or reassembly

It can be determined according to the time of equipment handling, assembly and debugging;

f) If the equipment (such as large equipment or equipment with specific requirements for the use environment) is not suitable for certain environmental test items (eg

Such as. rated working low temperature test, rated working high temperature test, rated working damp heat test, etc., should be provided by the manufacturer for specific tests

Requirements, and explain them in product standards;

g) If the product standard has special requirements for environmental testing conditions, it shall be implemented in accordance with the product standards. When the whole test is not feasible

At that time, what key parts or components should be tested in the product standards;

h) When the working space of the test chamber (room) is not enough for the whole machine test room, if the equipment allows, it can be connected with the whole machine according to the extension type.

The system was tested separately. Test methods should be specified in product standards;

Note. This requirement can be applied to equipment for rated low temperature test, rated high temperature test, rated wet heat test.

i) When the working space of the test chamber (room) is restricted, it is allowed to divide the equipment into several parts for testing. The test method should be in production.

Product standards.

Note. This requirement can be applied to equipment that performs cryogenic storage test, high temperature storage test, and damp heat storage test.

6.4 Test results

After the end of the test, in addition to functional inspections according to product standards (initial testing, intermediate or final testing items and requirements),

Visual inspection of equipment or components should meet the following requirements.

a) No rust, cracks, peeling of the coating, etc.;

b) The words and signs should be clear;

c) The control agency should be flexible;

d) There should be no loosening of the fastening area and no spillage of the infusion.

Appendix A

(Normative Appendix)

Test requirements and test items

This appendix gives test requirements and test items (see Table A.1) for product standard use.

Table A.1 Test Requirements and Test Items

Pilot projects

Test requirements and test items

Test requirements test items

Duration/h Recovery time/h Initial or middle detection

Note

Rated work

Low temperature test

U×110% (1) - - (2)

U ≥1 - (2) (2)

U×90% (1) - - (2)

(3)

Low temperature storag...

Share