1

/

of

10

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 0294.1-2016 English PDF (YYT0294.1-2016)

YY/T 0294.1-2016 English PDF (YYT0294.1-2016)

Regular price

$90.00 USD

Regular price

Sale price

$90.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 0294.1-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0294.1-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0294.1-2016: Surgical instruments--Metallic materials--Part 1: Stainless steel

YY/T 0294.1-2016

Surgical instruments--Metallic materials--Part 1. Stainless steel

ICS 11.040.30

C31

People's Republic of China Pharmaceutical Industry Standard

Replacing YY/T 0294.1-2005

Surgical instruments metal materials

Part 1. Stainless steel

Part 1. Stainlesssteel

(ISO 7153-1.1991, MOD)

Published on.2016-03-23

2017-01-01 Implementation

The State Food and Drug Administration issued

Foreword

YY/T 0294, "Surgical Instruments Metal Materials," contains the following sections.

--- Part 1. Stainless steel;

Subsequent parts will be developed one after another.

This section is Part 1 of YY/T 0294.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces YY/T 0294.1-2005 "Surgical Instruments, Metal Materials, Part 1. Stainless Steel."

The main differences between this section and YY/T 0294.1-2005 are as follows.

--- Add Chapter 2 normative references;

---In Table 1 and Table 2, domestic brands corresponding to various stainless steels have been added.

This section uses the translation method to modify the use of ISO 7153-1.1991 "Surgical Instruments Metal Materials Part 1. Stainless Steel" and A1.

In.1999, the main differences are as follows.

--- The scope applies to "surgical instruments";

--- Delete the normative references of international standards, because ISO 683-13.1986 and ISO 4957.1980 have been repealed;

---In Table 1 and Table 2, domestic brands corresponding to various stainless steels have been added.

Please note that some of the contents of this document may involve patents. The issuing agency of this document does not assume responsibility for identifying these patents.

This part is proposed and managed by the National Surgical Instruments Standardization Technical Committee (SAC/TC94).

This section drafted by. Shanghai Medical Device Testing, Shanghai Medical Devices (Group) Co., Ltd. surgical instruments factory.

The main drafters of this section. Lu Hao, Huang Lili, Pan Weirong, and Wang Zexi.

The previous versions of the standards replaced in this section were.

---YY/T 0294.1-1997, YY/T 0294.1-2005.

Surgical instruments metal materials

Part 1. Stainless steel

1 Scope

This part of YY/T 0294 is for the selection of stainless steel materials when designing and manufacturing surgical instruments.

Note. When manufacturing stainless steel materials for surgical instruments, if it is necessary for the design of the instrument, it is allowed to use materials other than this part. Therefore, the content of this part is not applicable.

The only basis for making materials. Manufacturers should also consider materials that meet the relevant surgical instrument standards when selecting stainless steel materials and respond to selected materials.

Be responsible for.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 20878-2007 Stainless Steel and Heat Resistant Steel Grades and Chemical Composition

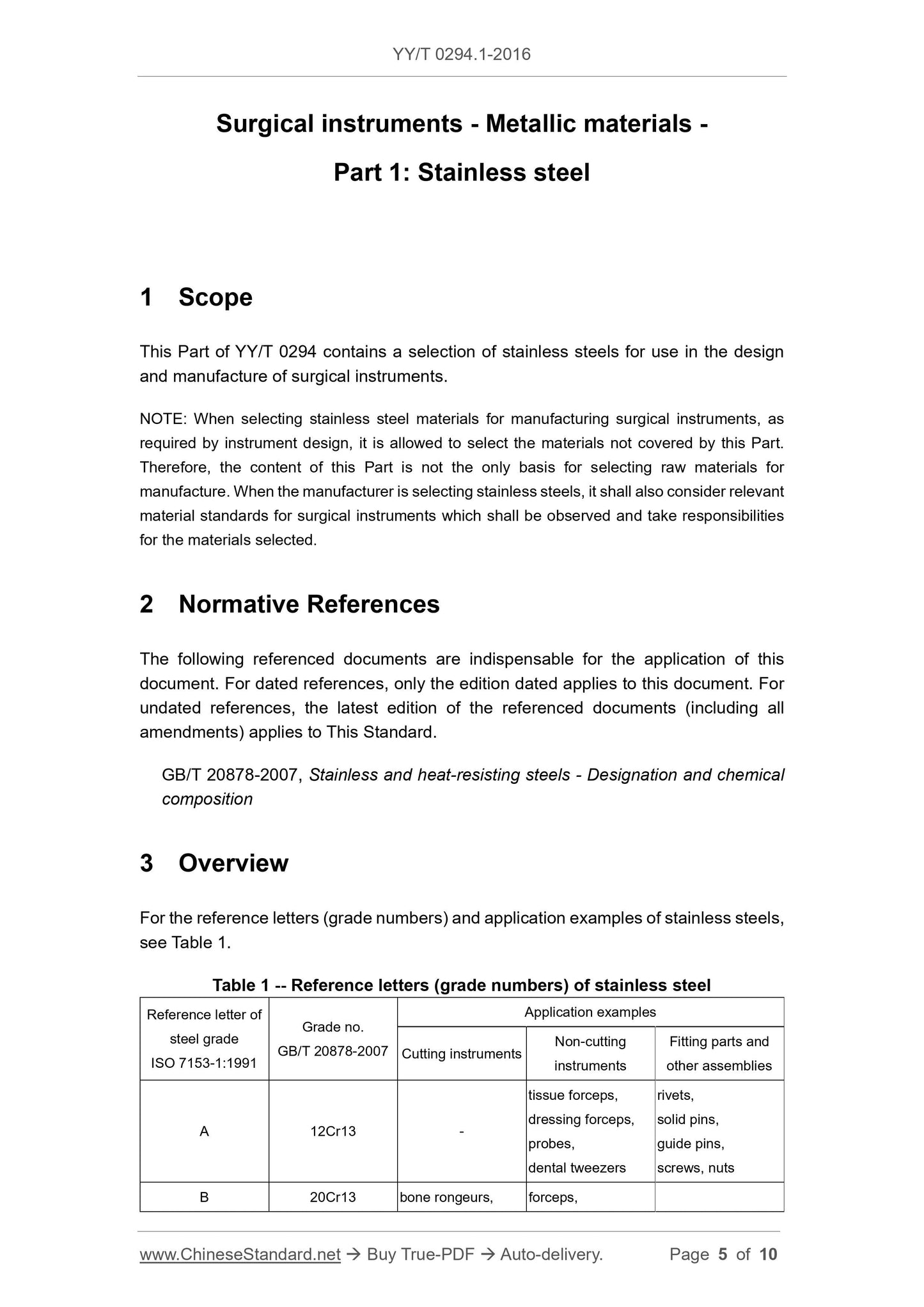

3 Overview

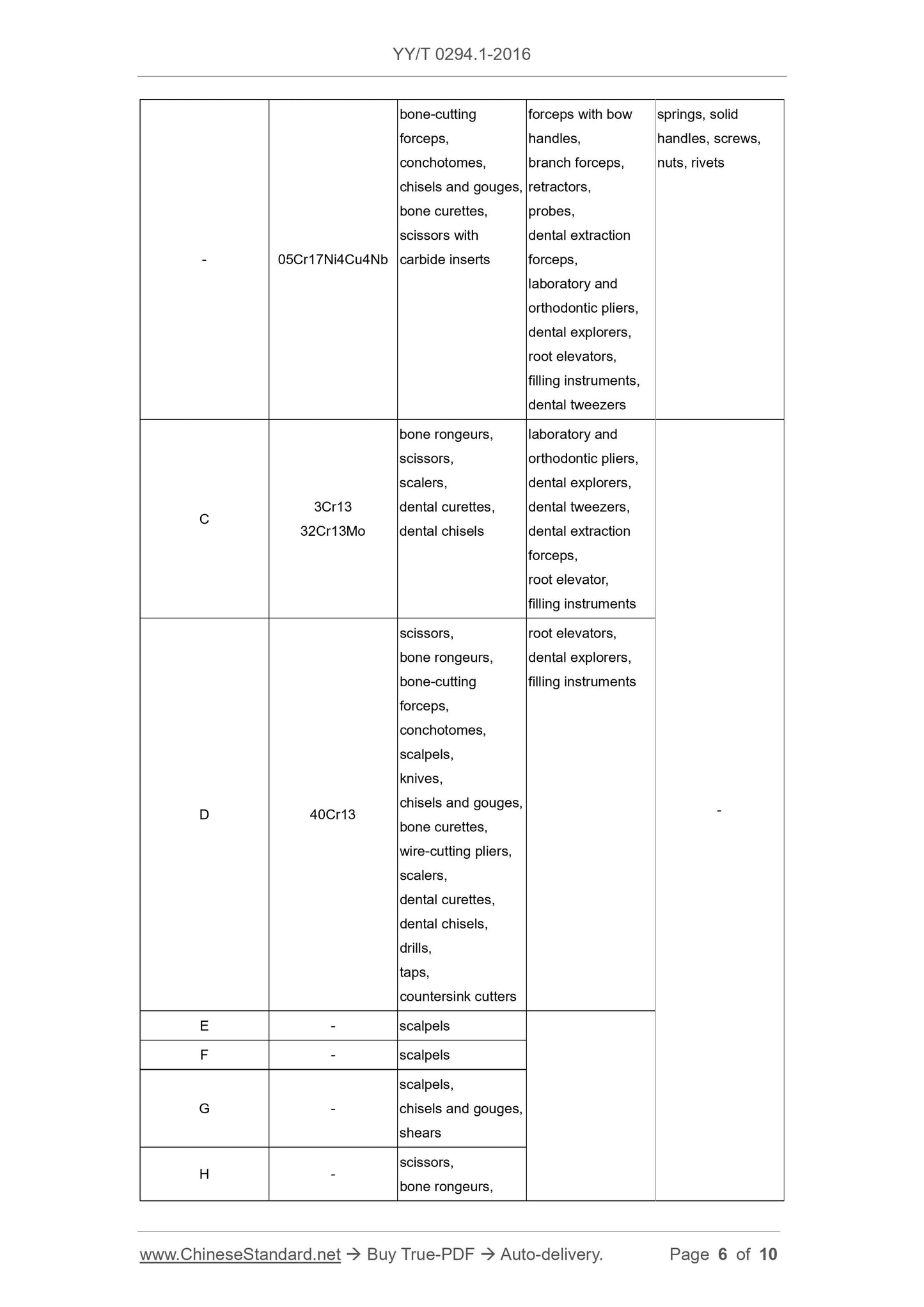

Stainless steel material code (plate number) and applicable examples, see Table 1.

Table 1 Stainless Steel Code (Grade)

Code number

ISO 7153-1.1991

Grade

GB/T 20878-2007

Applicable example

Cutting instruments Non-cutting instrument connectors or other accessories

A 12Cr13 -

Organization, accessories, retraction

, probe, dental file

Rivets, solid handles, positioning pins,

Screws, nuts

B 20Cr13

- 05Cr17Ni4Cu4Nb

Bone rongeur, scissors, turbinate

Pliers, chisels and gouges, bone curettes,

Carbide Scissors

Pliers, finger ring pliers, instrument pliers,

Retractor, probe, extraction forceps,

Technician Orthodontic Forceps, Probing

Needles, Stiffeners, Fillers, Teeth

Branch forceps

Spring, solid handle, screw, screw

Caps and Rivets

30Cr13

32Cr13Mo

Bone rongeurs, scissors, scrapers, teeth

Curettes, dental chisels

Technician Orthodontic Forceps, Probing

Needle, dental forceps, tooth extraction forceps, teeth

Ting, stuffer

D 40Cr13

Scissors, rongeurs, scissors,

Nasal clamp, scalpel, knife, chisel

And round chisel, bone curette, steel wire

Clamp, scraper, dental curette, dental

Chisels, drill bits, taps, buried

Drill

Stiffeners, tooth probes, fillers -

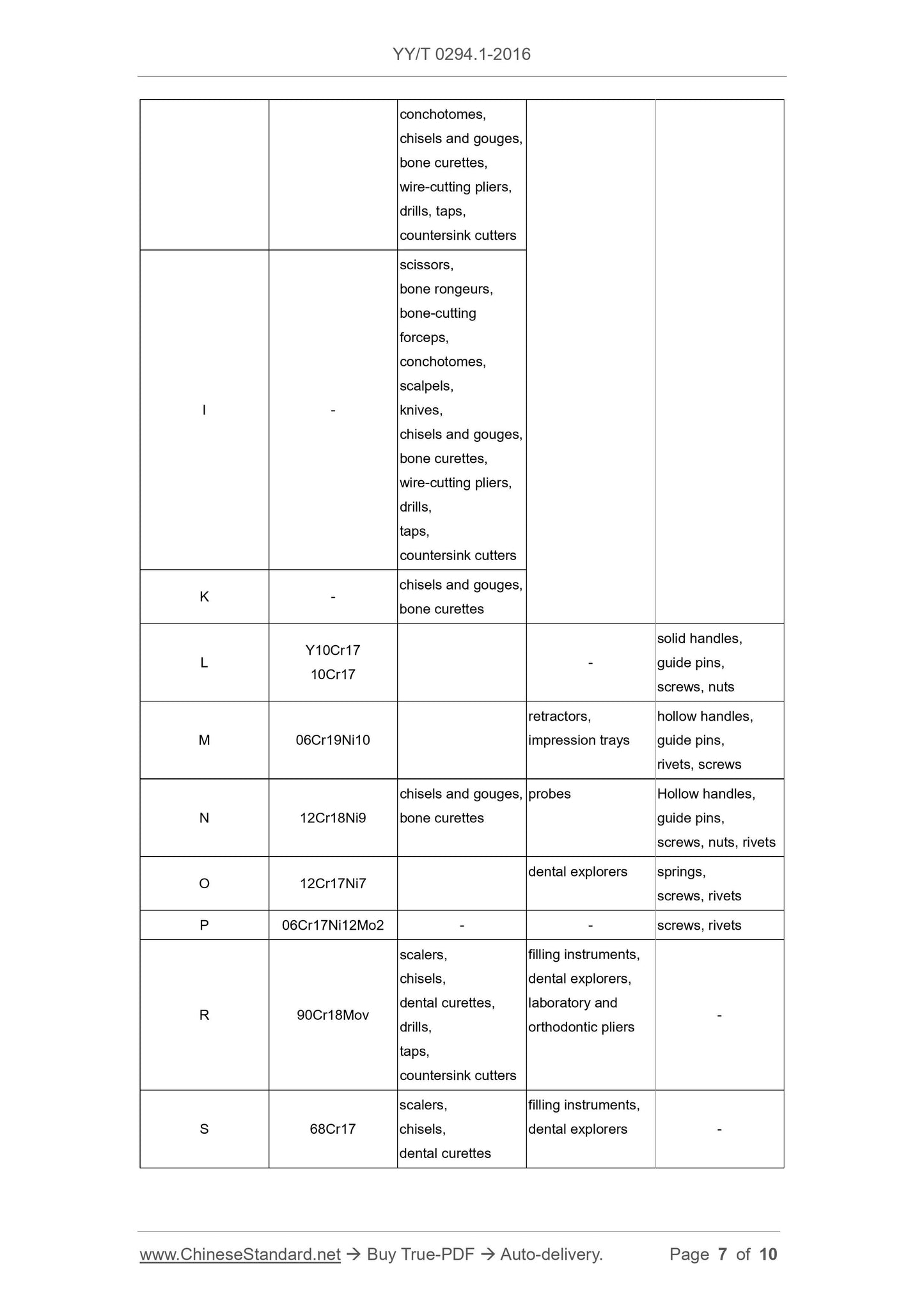

Table 1 (continued)

Code number

ISO 7153-1.1991

Grade

GB/T 20878-2007

Applicable example

Cutting instruments Non-cutting instrument connectors or other accessories

E - Scalpel - -

F - Scalpel - -

G -

Scalpels, chisels and gouges,

scissors

- - -

H -

Scissors, rongeurs, turbinates,

Chisels and gouges, bone curettes, steel

Wire clamps, drill bits, taps, buried

Drill

- - -

I -

Scissors, rongeurs, scissors,

Nasal clamp, scalpel, knife, chisel

And round chisel, bone curette, steel wire

Pliers, drill bits, taps, countersink

- - -

K - Chisels and Gouges, Bone Curettes - -

Y10Cr17

10Cr17

- - -

Solid handles, guide pins, screws,

Nuts

M 06Cr19Ni10 - Retractor, impression tray

Hollow handles, guide pins, rivets,

Screws

N 12Cr18Ni9 chisels and gouges, bone scraper probes

Hollow handle, guide pin, screw, screw

Caps and Rivets

O 12Cr17Ni7 - Dental Probe Springs, Screws, Rivets

P 06Cr17Ni12Mo2 - - Screws, Rivets

R 90Cr18MoV

Scraper, chisel, tooth curette, drill

Head, tap, countersink

Filler, dental probe, mechanic

Orthodontic pliers

S 68Cr17 Scraper, Chisel, Scraper, Dental Probe -

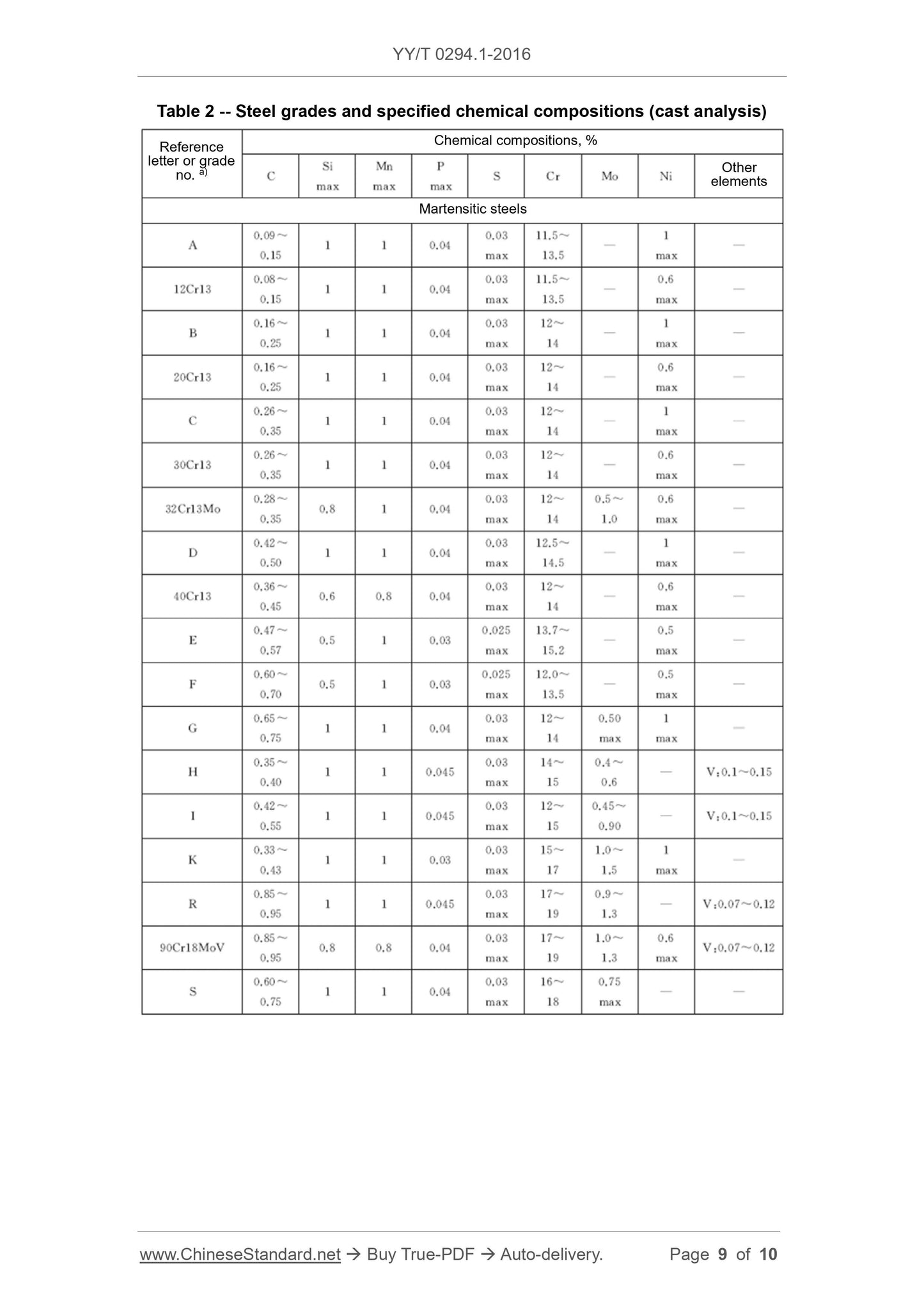

4 Chemical composition

The chemical composition of stainless steel is shown in Table 2.

Except for the purpose of completing the smelting, the elements not listed in Table 2 shall not be arbitrarily added to the stainless steel without the buyer’s consent. Should take one

Take reasonable measures to prevent the addition of elements from scrap steel or other materials used in the manufacturing process to stainless steel to avoid affecting the stainless steel

Hardenability, mechanical properties and application range.

Table 2 Chemical composition of stainless steel (cast sample analysis)

Code or brand a)

chemical composition/%

Si

Max

Mn

Max

Max

S Cr Mo Ni Other elements

Martensitic stainless steel

0.09~

0.15

1 1 0.04

0.03

Max

11.5~

13.5

- 1

Max

12Cr13

0.08~

0.15

1 1 0.04

0.03

Max

11.5~

13.5

0.6

Max

0.16~

0.25

1 1 0.04

0.03

Max

12~

- 1

Max

20Cr13

0.16~

0.25

1 1 0.04

0.03

Max

12~

0.6

Max

0.26~

0.35

1 1 0.04

0.03

Max

12~

- 1

Max

30Cr13

0.26~

0.35

1 1 0.04

0.03

Max

12~

0.6

Max

32Cr13Mo

0.28~

0.35

0.8 1 0.04

0.03

Max

12~

0.5~

1.0

0.6

Max

0.42~

0.50

1 1 0.04

0.03

Max

12.5~

14.5

Max

40Cr13

0.36~

0.45

0.6 0.8 0.04

0.03

Max

12~

- 0.6

Max

0.47~

0.57

0.5 1 0.03

0.025

Max

13.7~

15.2

0.5

Max

0.60~

0.70

0.5 1 0.03

0.025

Max

12.0~

13.5

- 0.5

Max

0.65~

0.75

1 1 0.04

0.03

Max

12~

0.50

Max

Max

0.35~

0.40

1 1 0.045

0.03

Max

14~

0.4~

0.6

- V. 0.1 to 0.15

0.42~

0.55

1 1 0.045

0.03

Max

12~

0.45~

0.90

- V. 0.1 to 0.15

0.33~

0.43

1 1 0.03

0.03

Max

15~

1.0~

1.5

Max

0.85~

0.95

1 1 0.045

0.03

Max

17~

0.9~

1.3

- V. 0.07~0.12

90Cr18MoV

0.85~

0.95

0.8 0.8 0.04

0.03

Max

17~

1.0~

1.3

0.6

Max

V. 0.07~0.12

0.60~

0.75

1 1 0.04

0.03

Max

16~

0.75

Max

- - -

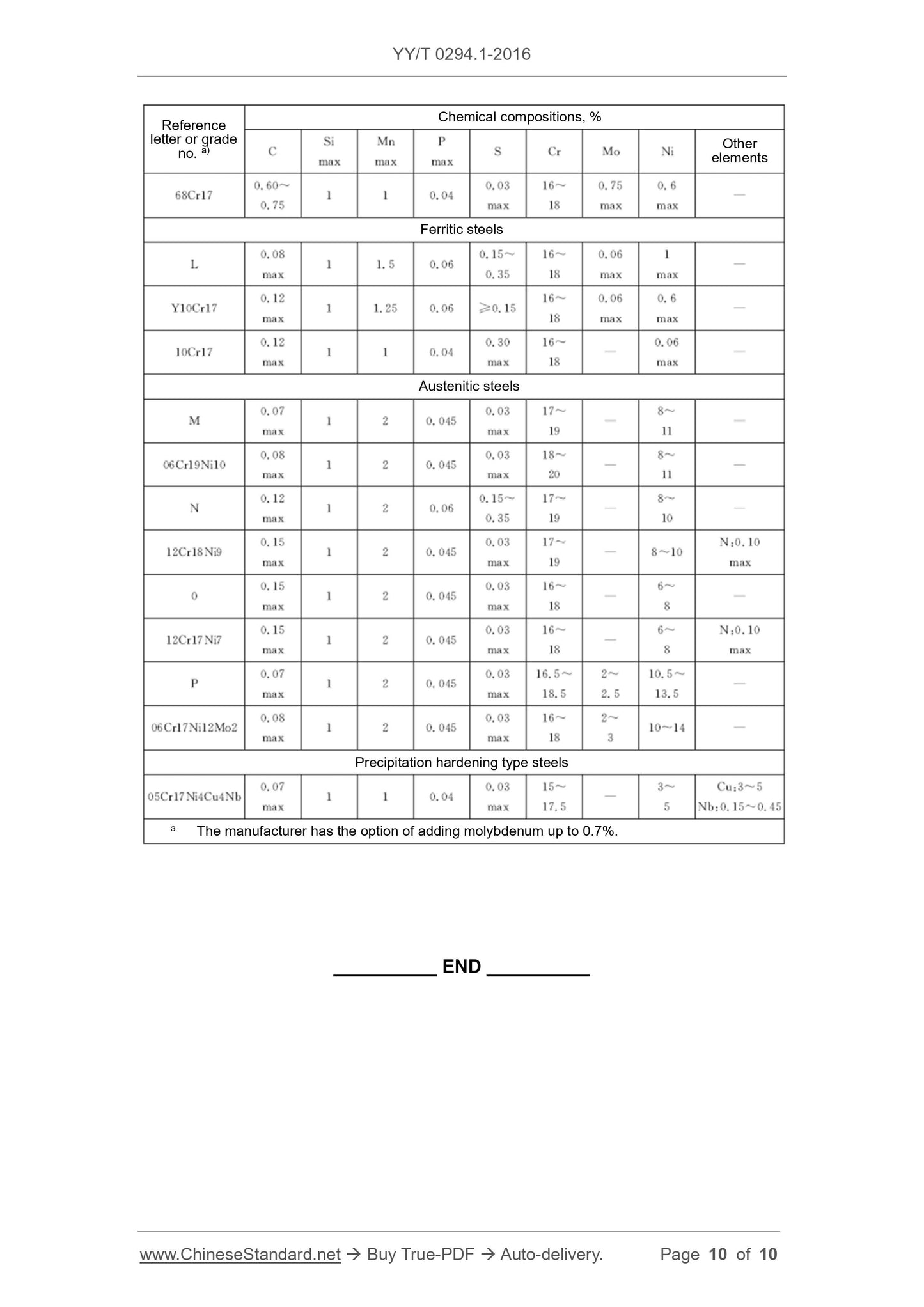

Table 2 (continued)

Code or brand a)

chemical composition/%

Si

Max

Mn

Max

Max

S Cr Mo Ni Other elements

68Cr17

0.60~

0.75

1 1 0.04

0.03

Max

16~

0.75

Max

0.6

Max

Ferritic stainless steel

0.08

Max

1 1.5 0.06

0.15~

0.35

16~

0.06

Max

Max

Y10Cr17

0.12

Max

1 1.25 0.06 ≥ 0.15

16~

0.06

Max

0.6

Max

10Cr17

0.12

Max

1 1 0.04

0.30

Max

16~

0.06

Max

Austenitic stainless steel

0.07

Max

1 2 0.045

0.03

Max

17~

- 8~

06Cr19Ni10

0.08

Max

1 2 0.045

0.03

Max

18~

8~

0.12

Max

1 2 0.06

0.15~

0.35

17~

- 8~

12Cr18Ni9

0.15

Max

1 2 0.045

0.03

Max

17~

- 8~10

N. 0.10

Max

0.15

Max

1 2 0.045

0.03

Max

16~

- 6~

12Cr17Ni7

0.15

Max

1 2 0.045

0.03

Max

16~

6~

N. 0.10

Max

0.07

Max

1 2 0.045

0.03

Max

16.5~

18.5

2~

2.5

10.5~

13.5

06Cr17Ni12Mo2

0.08

Max

1 2 0.045

0.03

Max

16~

2~

10~14 -

Precipitation hardened stainless steel

05Cr17Ni4Cu4Nb

0.07

Max

1 1 0.04

0.03

Max

15~

17.5

- 3~

Cu. 3~5

Nb. 0.15~0.45

a Manufacturers can choose to add molybdenum up to 0.7%.

6102-

1 4920

T/

Get Quotation: Click YY/T 0294.1-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0294.1-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0294.1-2016: Surgical instruments--Metallic materials--Part 1: Stainless steel

YY/T 0294.1-2016

Surgical instruments--Metallic materials--Part 1. Stainless steel

ICS 11.040.30

C31

People's Republic of China Pharmaceutical Industry Standard

Replacing YY/T 0294.1-2005

Surgical instruments metal materials

Part 1. Stainless steel

Part 1. Stainlesssteel

(ISO 7153-1.1991, MOD)

Published on.2016-03-23

2017-01-01 Implementation

The State Food and Drug Administration issued

Foreword

YY/T 0294, "Surgical Instruments Metal Materials," contains the following sections.

--- Part 1. Stainless steel;

Subsequent parts will be developed one after another.

This section is Part 1 of YY/T 0294.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces YY/T 0294.1-2005 "Surgical Instruments, Metal Materials, Part 1. Stainless Steel."

The main differences between this section and YY/T 0294.1-2005 are as follows.

--- Add Chapter 2 normative references;

---In Table 1 and Table 2, domestic brands corresponding to various stainless steels have been added.

This section uses the translation method to modify the use of ISO 7153-1.1991 "Surgical Instruments Metal Materials Part 1. Stainless Steel" and A1.

In.1999, the main differences are as follows.

--- The scope applies to "surgical instruments";

--- Delete the normative references of international standards, because ISO 683-13.1986 and ISO 4957.1980 have been repealed;

---In Table 1 and Table 2, domestic brands corresponding to various stainless steels have been added.

Please note that some of the contents of this document may involve patents. The issuing agency of this document does not assume responsibility for identifying these patents.

This part is proposed and managed by the National Surgical Instruments Standardization Technical Committee (SAC/TC94).

This section drafted by. Shanghai Medical Device Testing, Shanghai Medical Devices (Group) Co., Ltd. surgical instruments factory.

The main drafters of this section. Lu Hao, Huang Lili, Pan Weirong, and Wang Zexi.

The previous versions of the standards replaced in this section were.

---YY/T 0294.1-1997, YY/T 0294.1-2005.

Surgical instruments metal materials

Part 1. Stainless steel

1 Scope

This part of YY/T 0294 is for the selection of stainless steel materials when designing and manufacturing surgical instruments.

Note. When manufacturing stainless steel materials for surgical instruments, if it is necessary for the design of the instrument, it is allowed to use materials other than this part. Therefore, the content of this part is not applicable.

The only basis for making materials. Manufacturers should also consider materials that meet the relevant surgical instrument standards when selecting stainless steel materials and respond to selected materials.

Be responsible for.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 20878-2007 Stainless Steel and Heat Resistant Steel Grades and Chemical Composition

3 Overview

Stainless steel material code (plate number) and applicable examples, see Table 1.

Table 1 Stainless Steel Code (Grade)

Code number

ISO 7153-1.1991

Grade

GB/T 20878-2007

Applicable example

Cutting instruments Non-cutting instrument connectors or other accessories

A 12Cr13 -

Organization, accessories, retraction

, probe, dental file

Rivets, solid handles, positioning pins,

Screws, nuts

B 20Cr13

- 05Cr17Ni4Cu4Nb

Bone rongeur, scissors, turbinate

Pliers, chisels and gouges, bone curettes,

Carbide Scissors

Pliers, finger ring pliers, instrument pliers,

Retractor, probe, extraction forceps,

Technician Orthodontic Forceps, Probing

Needles, Stiffeners, Fillers, Teeth

Branch forceps

Spring, solid handle, screw, screw

Caps and Rivets

30Cr13

32Cr13Mo

Bone rongeurs, scissors, scrapers, teeth

Curettes, dental chisels

Technician Orthodontic Forceps, Probing

Needle, dental forceps, tooth extraction forceps, teeth

Ting, stuffer

D 40Cr13

Scissors, rongeurs, scissors,

Nasal clamp, scalpel, knife, chisel

And round chisel, bone curette, steel wire

Clamp, scraper, dental curette, dental

Chisels, drill bits, taps, buried

Drill

Stiffeners, tooth probes, fillers -

Table 1 (continued)

Code number

ISO 7153-1.1991

Grade

GB/T 20878-2007

Applicable example

Cutting instruments Non-cutting instrument connectors or other accessories

E - Scalpel - -

F - Scalpel - -

G -

Scalpels, chisels and gouges,

scissors

- - -

H -

Scissors, rongeurs, turbinates,

Chisels and gouges, bone curettes, steel

Wire clamps, drill bits, taps, buried

Drill

- - -

I -

Scissors, rongeurs, scissors,

Nasal clamp, scalpel, knife, chisel

And round chisel, bone curette, steel wire

Pliers, drill bits, taps, countersink

- - -

K - Chisels and Gouges, Bone Curettes - -

Y10Cr17

10Cr17

- - -

Solid handles, guide pins, screws,

Nuts

M 06Cr19Ni10 - Retractor, impression tray

Hollow handles, guide pins, rivets,

Screws

N 12Cr18Ni9 chisels and gouges, bone scraper probes

Hollow handle, guide pin, screw, screw

Caps and Rivets

O 12Cr17Ni7 - Dental Probe Springs, Screws, Rivets

P 06Cr17Ni12Mo2 - - Screws, Rivets

R 90Cr18MoV

Scraper, chisel, tooth curette, drill

Head, tap, countersink

Filler, dental probe, mechanic

Orthodontic pliers

S 68Cr17 Scraper, Chisel, Scraper, Dental Probe -

4 Chemical composition

The chemical composition of stainless steel is shown in Table 2.

Except for the purpose of completing the smelting, the elements not listed in Table 2 shall not be arbitrarily added to the stainless steel without the buyer’s consent. Should take one

Take reasonable measures to prevent the addition of elements from scrap steel or other materials used in the manufacturing process to stainless steel to avoid affecting the stainless steel

Hardenability, mechanical properties and application range.

Table 2 Chemical composition of stainless steel (cast sample analysis)

Code or brand a)

chemical composition/%

Si

Max

Mn

Max

Max

S Cr Mo Ni Other elements

Martensitic stainless steel

0.09~

0.15

1 1 0.04

0.03

Max

11.5~

13.5

- 1

Max

12Cr13

0.08~

0.15

1 1 0.04

0.03

Max

11.5~

13.5

0.6

Max

0.16~

0.25

1 1 0.04

0.03

Max

12~

- 1

Max

20Cr13

0.16~

0.25

1 1 0.04

0.03

Max

12~

0.6

Max

0.26~

0.35

1 1 0.04

0.03

Max

12~

- 1

Max

30Cr13

0.26~

0.35

1 1 0.04

0.03

Max

12~

0.6

Max

32Cr13Mo

0.28~

0.35

0.8 1 0.04

0.03

Max

12~

0.5~

1.0

0.6

Max

0.42~

0.50

1 1 0.04

0.03

Max

12.5~

14.5

Max

40Cr13

0.36~

0.45

0.6 0.8 0.04

0.03

Max

12~

- 0.6

Max

0.47~

0.57

0.5 1 0.03

0.025

Max

13.7~

15.2

0.5

Max

0.60~

0.70

0.5 1 0.03

0.025

Max

12.0~

13.5

- 0.5

Max

0.65~

0.75

1 1 0.04

0.03

Max

12~

0.50

Max

Max

0.35~

0.40

1 1 0.045

0.03

Max

14~

0.4~

0.6

- V. 0.1 to 0.15

0.42~

0.55

1 1 0.045

0.03

Max

12~

0.45~

0.90

- V. 0.1 to 0.15

0.33~

0.43

1 1 0.03

0.03

Max

15~

1.0~

1.5

Max

0.85~

0.95

1 1 0.045

0.03

Max

17~

0.9~

1.3

- V. 0.07~0.12

90Cr18MoV

0.85~

0.95

0.8 0.8 0.04

0.03

Max

17~

1.0~

1.3

0.6

Max

V. 0.07~0.12

0.60~

0.75

1 1 0.04

0.03

Max

16~

0.75

Max

- - -

Table 2 (continued)

Code or brand a)

chemical composition/%

Si

Max

Mn

Max

Max

S Cr Mo Ni Other elements

68Cr17

0.60~

0.75

1 1 0.04

0.03

Max

16~

0.75

Max

0.6

Max

Ferritic stainless steel

0.08

Max

1 1.5 0.06

0.15~

0.35

16~

0.06

Max

Max

Y10Cr17

0.12

Max

1 1.25 0.06 ≥ 0.15

16~

0.06

Max

0.6

Max

10Cr17

0.12

Max

1 1 0.04

0.30

Max

16~

0.06

Max

Austenitic stainless steel

0.07

Max

1 2 0.045

0.03

Max

17~

- 8~

06Cr19Ni10

0.08

Max

1 2 0.045

0.03

Max

18~

8~

0.12

Max

1 2 0.06

0.15~

0.35

17~

- 8~

12Cr18Ni9

0.15

Max

1 2 0.045

0.03

Max

17~

- 8~10

N. 0.10

Max

0.15

Max

1 2 0.045

0.03

Max

16~

- 6~

12Cr17Ni7

0.15

Max

1 2 0.045

0.03

Max

16~

6~

N. 0.10

Max

0.07

Max

1 2 0.045

0.03

Max

16.5~

18.5

2~

2.5

10.5~

13.5

06Cr17Ni12Mo2

0.08

Max

1 2 0.045

0.03

Max

16~

2~

10~14 -

Precipitation hardened stainless steel

05Cr17Ni4Cu4Nb

0.07

Max

1 1 0.04

0.03

Max

15~

17.5

- 3~

Cu. 3~5

Nb. 0.15~0.45

a Manufacturers can choose to add molybdenum up to 0.7%.

6102-

1 4920

T/

Share