1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 0506.4-2016 English PDF (YYT0506.4-2016)

YY/T 0506.4-2016 English PDF (YYT0506.4-2016)

Regular price

$195.00 USD

Regular price

Sale price

$195.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 0506.4-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0506.4-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0506.4-2016: Surgical drapes, gowns and clean air suits for patients, clinical staff and equipment--Part 4: Test method for linting in the dry state

YY/T 0506.4-2016

Surgical drapes, gowns and clean air suits for patients, clinical staff and equipment--Part 4. Test method for linting in the dry state

ICS 11.140

C46

People's Republic of China Pharmaceutical Industry Standard

Replace YY/T 0506.4-2005

Surgical sheets and gowns for patients, medical staff and instruments

And clean clothes. Part 4. dry flocculation test method

(ISO 9073-10..2003, NEQ)

2016-07-29 release

2017-06-01 Implementation

Issued by the State Food and Drug Administration

Foreword

YY/T 0506 "Surgical sheets, surgical gowns and clean clothes for patients, medical staff and instruments", consists of the following parts.

--- Part 1. General requirements for manufacturers, treatment plants and products;

--- Part 2. Performance requirements and test methods;

--- Part 4. Dry flocculation test method;

--- Part 5. Test method for blocking penetration of dry microorganisms;

--- Part 6. Test method for penetration of moisture-resistant microorganisms;

--- Part 7. Cleanliness-microbiological test method.

This part is part 4 of YY/T 0506.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

This part replaces YY/T 0506.4-2005 "Surgical sheets, surgical gowns and clean clothes for patients, medical staff and instruments Part 4.

Compared with YY/T 0506.4-2005, the main dry flocculation test method is as follows.

--- Updated normative references;

--- Revised informative appendix B.

This part of YY/T 0506 refers to ISO 9073-10..2003 "Test methods for textile nonwovens-Part 10. Dry state drop

"The production of floc and other particles" is formulated, and the degree of consistency is not equivalent.

Please note that some content of this document may involve patents. The issuer of this document does not assume responsibility for identifying these patents.

This part is under the jurisdiction of the Jinan Medical Device Quality Supervision and Inspection Center of the State Food and Drug Administration.

This section was drafted by. Shandong Hengxin Testing Technology Development Center, Wenjian Industrial (Shenzhen) Co., Ltd.

The main drafters of this section. Yao Xiujun, Nie Jiaqi, Zheng Duozi.

The previous versions of the standard replaced by this part are as follows.

--- YY/T 0506.4-2005.

Surgical sheets and gowns for patients, medical staff and instruments

And clean clothes. Part 4. dry flocculation test method

1 Scope

This part of YY/T 0506 specifies the test method for measuring surgical sheets, surgical gowns and clean clothing and materials under dry conditions. The

The method is also suitable for other medical textile materials.

2 Normative references

The following documents are essential for the application of this document. For dated references, only the dated version applies to this article

Pieces. For the cited documents without date, the latest version (including all amendments) applies to this document.

GB/T 25915.1 Clean room and related controlled environment Part 1. Air cleanliness level (GB/T 25915.1-2010,

(ISO 14644-1..1999, IDT)

ISO 554 Standard Atmospheresforconditioningand/or

testing-Specifications)

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Lint

Fibers released during use.

3.2

Linting

The release of fluff and other particles during operation.

3.3

Coefficient of coefficient oflinting

The logarithm (lg) of the count of all particles or part of the particles entering the measurement channel.

4 Principle

This method describes the improved Gelbo distortion method. In this method, the sample is subjected to a combined operation of torsion and compression in the test chamber

use. During this twisting process, air was extracted from the test box, and particle counters were used to count and classify the particles in the air.

See Appendix A for general information on reproducibility.

5 Instruments

5.1 Laminar flow hood

Used to provide a clean test environment.

Note. It is also possible to use ISO 5 clean rooms in accordance with GB/T 25915.1 1).

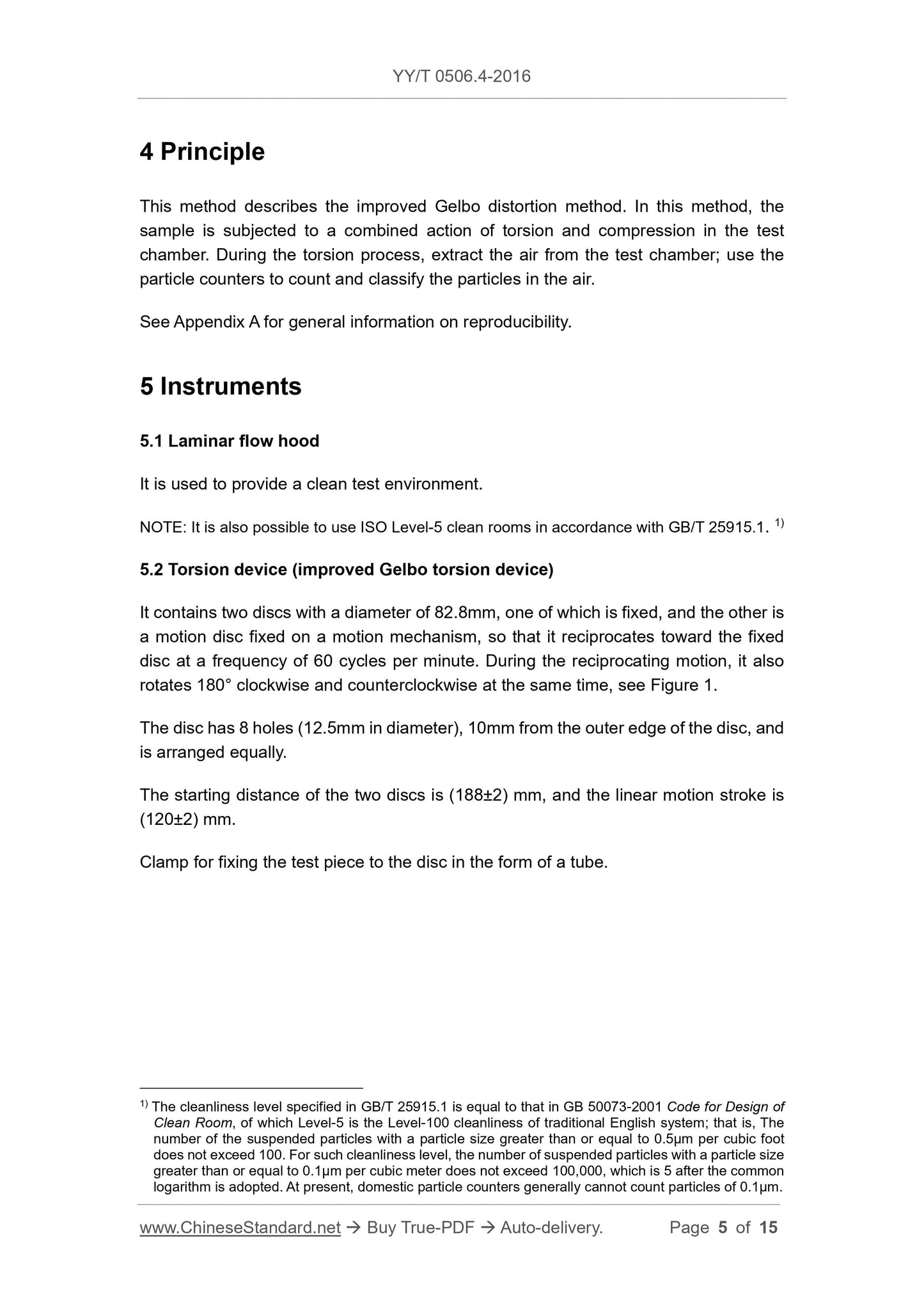

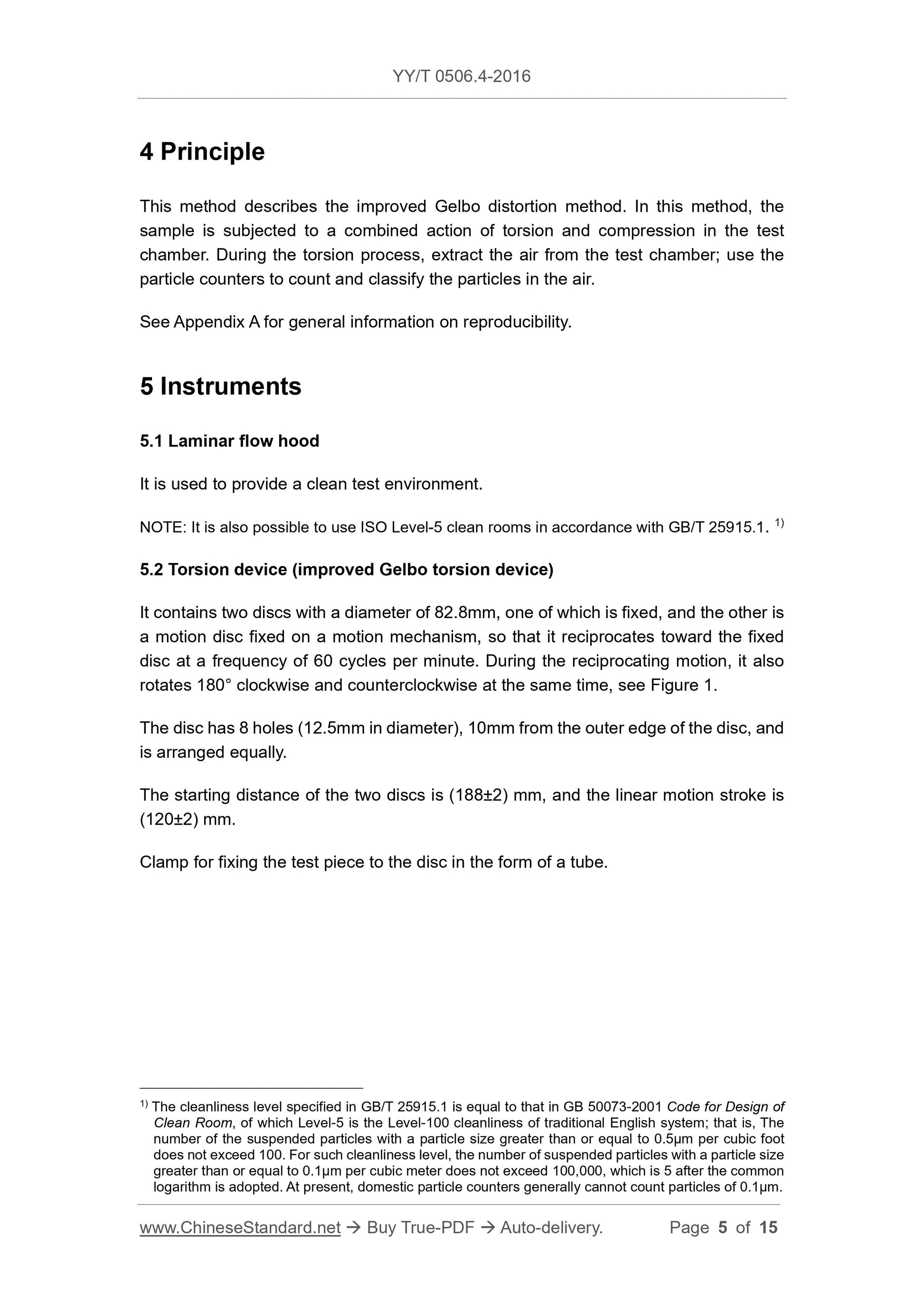

5.2 Twisting device (improved Gelbo twisting device)

Contains two discs with a diameter of 82.8mm, one of which is fixed and the other is a motion disc fixed on a motion mechanism to make it

The reciprocating motion is performed at a frequency of 60 cycles per minute toward the fixed disk. During the reciprocating motion, it also rotates clockwise and counterclockwise at the same time

180 °, see Figure 1.

The disc has 8 holes (12.5mm in diameter), 10mm from the outer edge of the disc, and is arranged equally.

The starting distance between the two discs is (188 ± 2) mm, and the linear motion stroke is (120 ± 2) mm.

A jig used to fix the test piece to the disc in the form of a tube.

Explanation.

1 --- Test box;

2 --- Particle counter;

3 --- Test piece.

Figure 1 Gelbo twisted dry particle generator

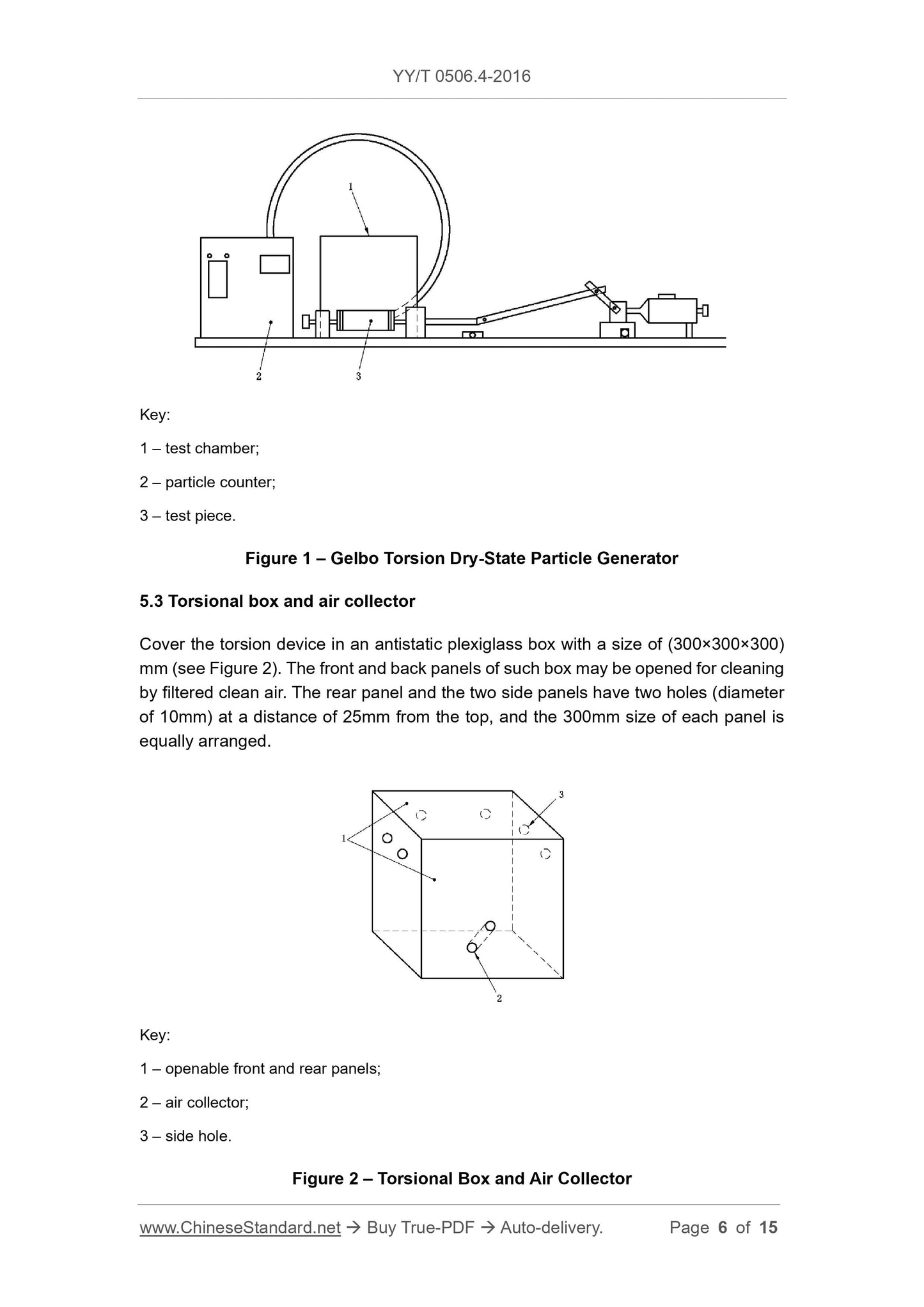

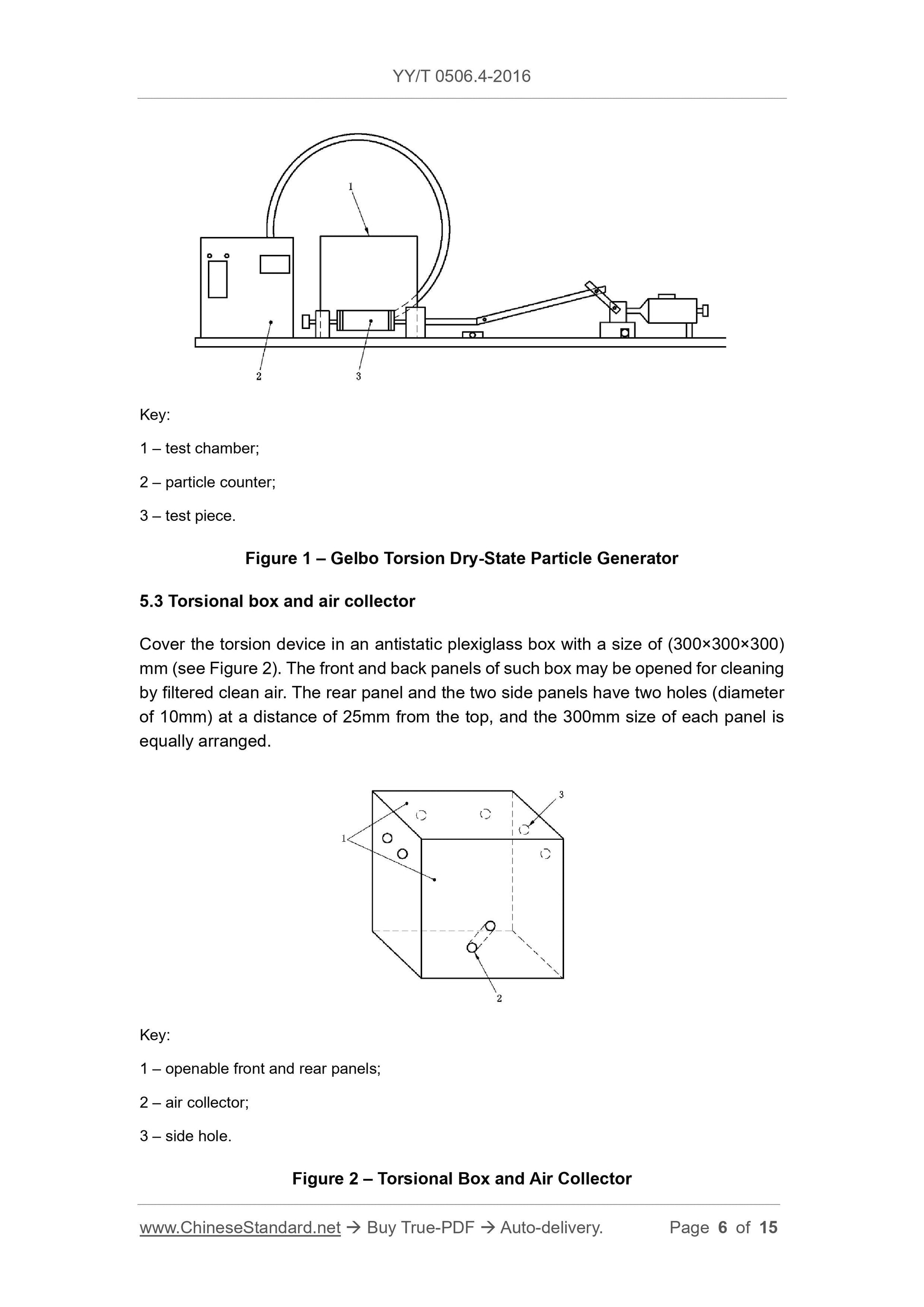

5.3 Twist box and air collector

Cover the twisting device in an antistatic plexiglass box with a size of (300 × 300 × 300) mm (see Figure 2), the front and back of the box

The board can be opened for easy cleaning with filtered clean air. The rear panel and the two side panels have two holes (diameter is

10mm), equally divide the 300mm size of each board.

1) The cleanliness level specified in GB/T 25915.1 is equivalent to the level in GB 50073-2001 "Design Code for Clean Workshops", of which 5 levels are the

The 100-degree cleanliness of the British system means that the number of suspended particles with a particle size greater than or equal to 0.5 μm per cubic foot does not exceed 100. The cleanliness

The number of suspended particles with a particle size greater than or equal to 0.1 μm per cubic meter of the grade does not exceed 100,000.

Clarity level 5 depends on this. At present, domestic particle counters cannot generally count particles of 0.1 μm.

Explanation.

1 --- Openable front and rear panels;

2 --- Air collector;

3 --- Side hole.

Figure 2 Twisted box and air collector

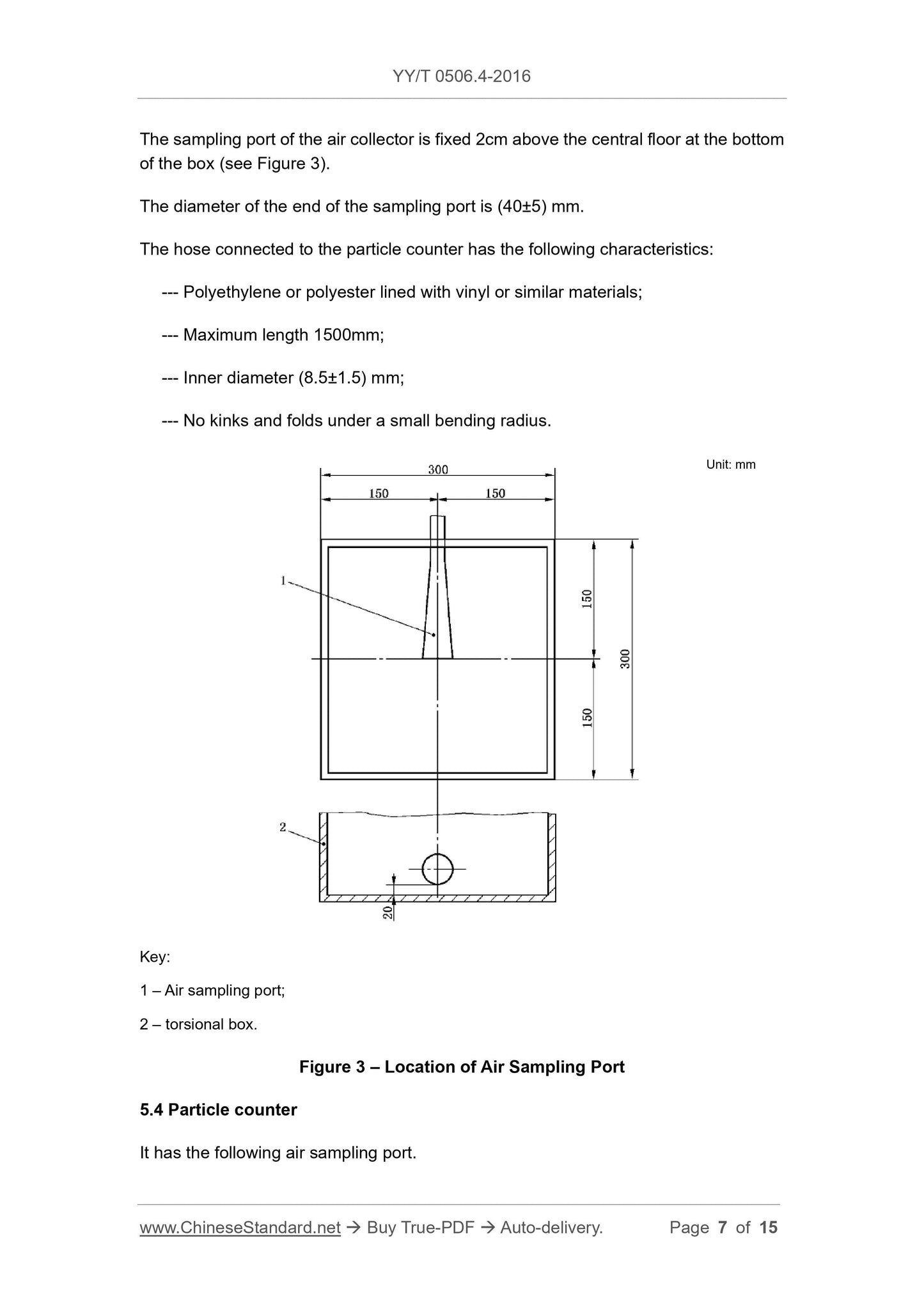

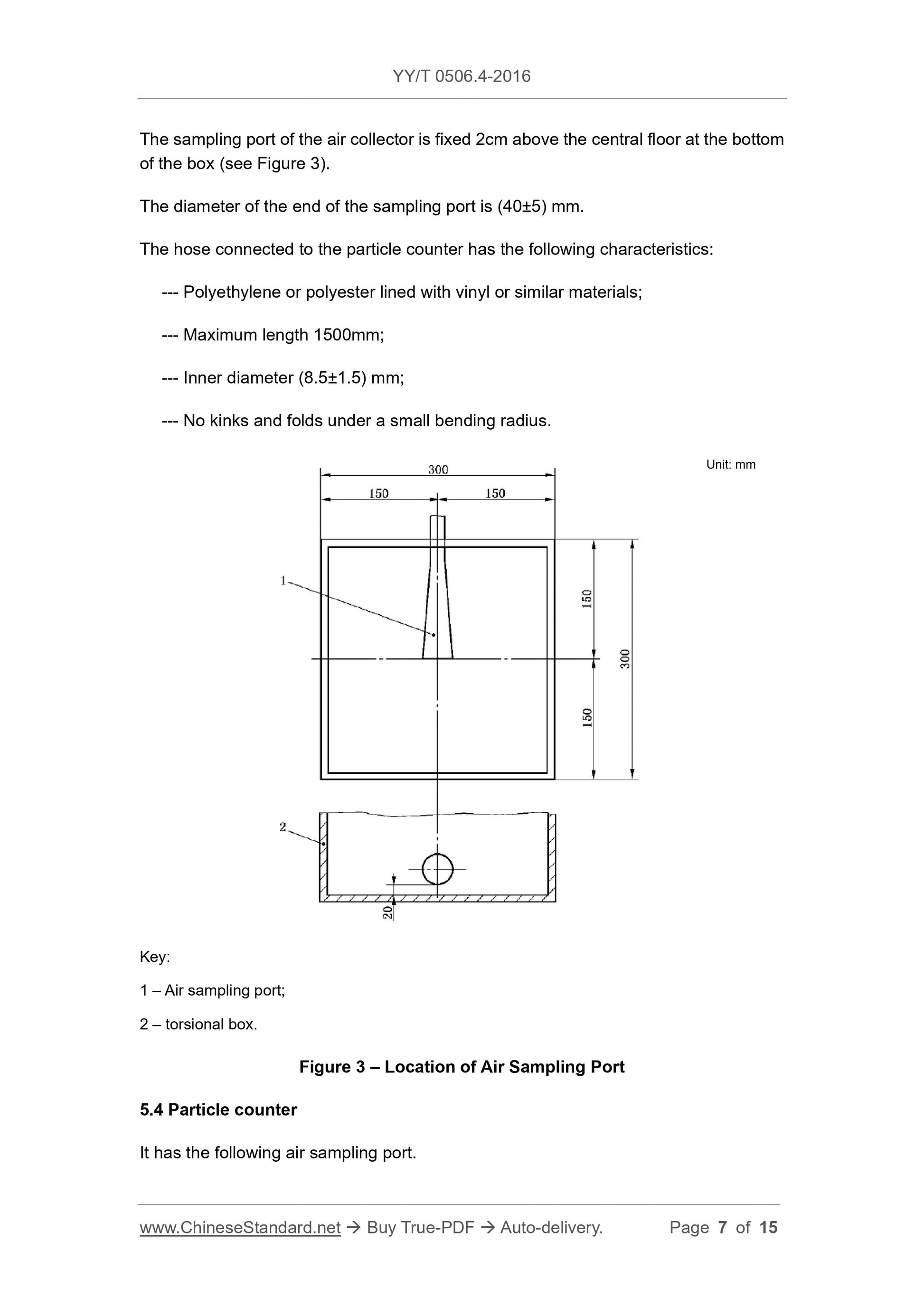

The sampling port of the air collector is fixed at 2cm above the central floor at the bottom of the box (see Figure 3).

The diameter of the end of the sampling port is (40 ± 5) mm.

The hose connected to the particle counter has the following characteristics.

--- Polyethylene or polyester lined with vinyl or similar materials;

--- Maximum length 1500mm;

--- Inner diameter (8.5 ± 1.5) mm;

--- No kinks and discounts under a small bending radius.

The unit is mm

Explanation.

1 --- Air sampling port;

2 --- Distorted box.

Figure 3 Location of the air sampling port

5.4 Particle Counter

With the following air sampling port.

--- 8 measurement channels;

--- Particle size measurement range. 0.3μm or 0.5μm ~ 25μm;

--- Air flow. (28.3 ± 1.4) L/min;

--- The sampling time can be selected within the range of 1s and 24h.

5.5 Glue

Used for bonding cylindrical test pieces.

5.6 Gloves

Used in ISO Class 5 clean rooms. See GB/T 25915.1.

6 steps

6.1 The operator should wear gloves to operate the test piece.

6.2 The preparation of test pieces should be carried out under clean conditions, see also the specifications specified in ISO 554.

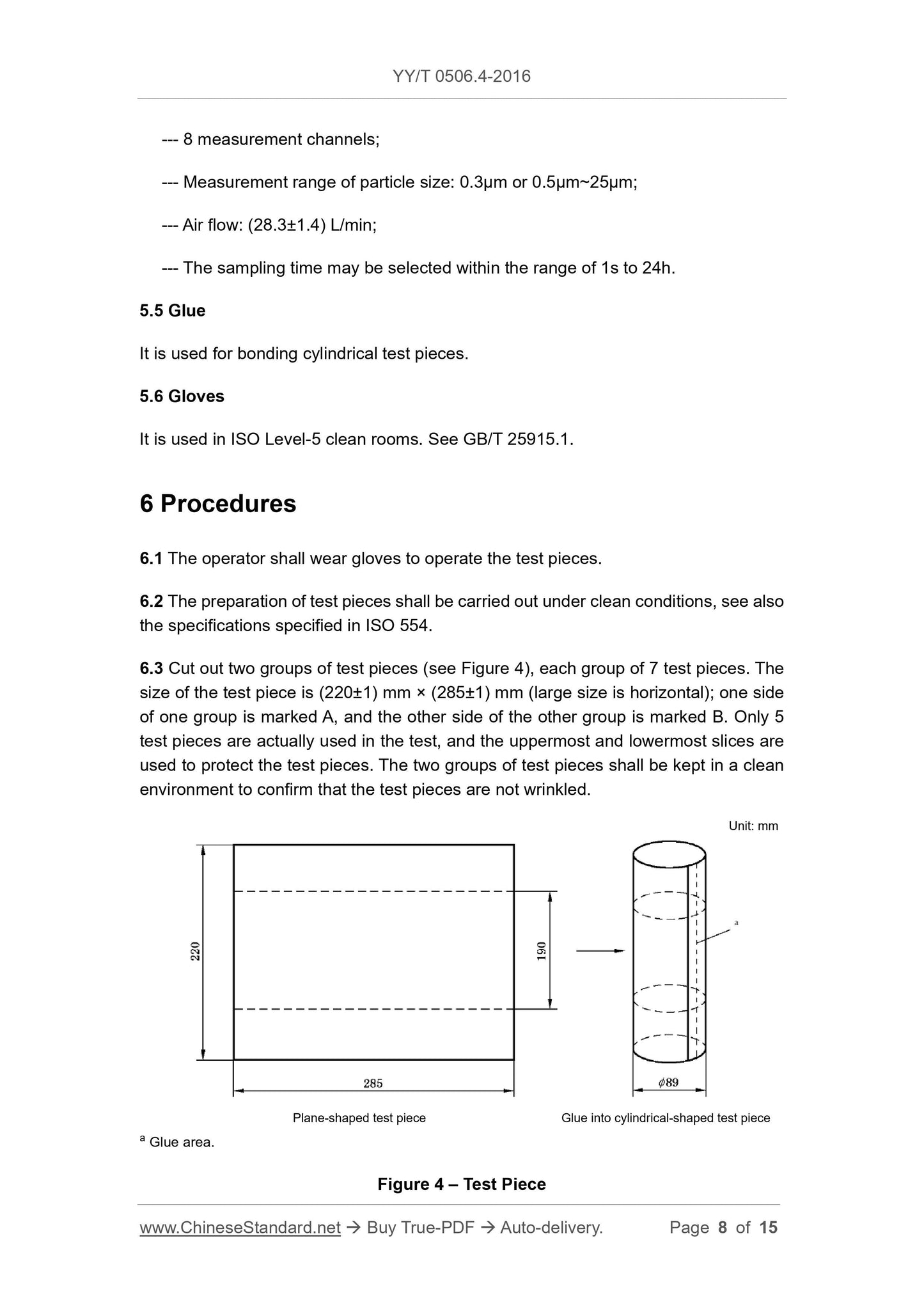

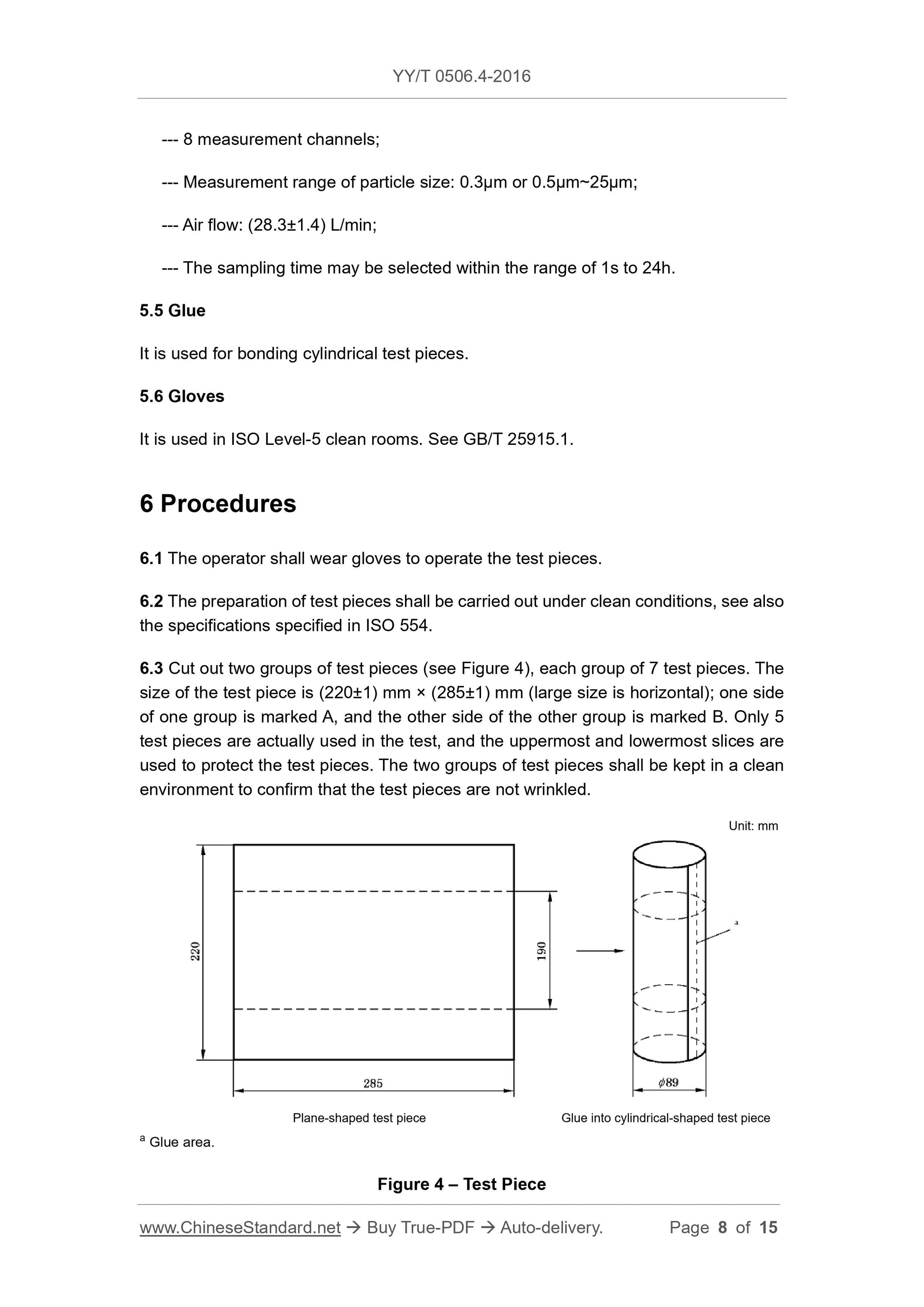

6.3 Cut out two sets of test pieces (see Figure 4), each set of 7 test pieces. The size of the test piece is (220 ± 1) mm × (285 ± 1) mm (large size is horizontal

Direction); one side of one group is marked A, and the other side of the other group is marked B. Only 5 specimens are actually used in the test, the uppermost and lowermost two

The film is used to protect the test piece. The two sets of test pieces should be kept in a clean environment to confirm that the test pieces are not wrinkled.

The unit is mm

a Glue area

Figure 4 Specimen

6.4 The test environment should be kept clean (see 5.1). Between each measurement, the twist box should be clean and the air quality in the box should be checked.

a) Open the rear panel (let clean air flow into the empty box), the bending device stops running without a test piece, perform two measurements, confirm

There are less than 100 particles with ≥0.5μm within 30s sampling time. If this requirement is not met, this step should be repeated.

b) Count the particles as follows to get the background count (C0).

1) Close the rear panel.

2) Let the twisting device run without load to 10 count stabilization periods of 30s, and record the results.

3) Add these results to get C0.

6.5 Roll the test piece into a cylindrical shape along the long dimension direction, and stick it with a suitable glue, the bonding width is 0.5cm (see Figure 4).

6.6 Adjust the disc to the starting position, separated by (188 ± 2) mm.

6.7 Carefully install the test piece on the disc and fix it with a suitable jig (such as rubber band). Touch should be minimized.

6.8 The particle counter is set to 30s counting time and 1s recounting time (operation mode).

6.9 Close the twist box.

6.10 Start the twisting device and start the particle counter at the same time until the completion of 10 consecutive 30s counts.

6.11 Stop the twisting device and counter. Remove the test piece and clean the twist box before testing the next test piece.

Note. Scrub with a clean cloth in a clean room, and then dry for the next test.

6.12 Record the particle count results of each size classification on the reading device.

6.13 Repeat this step for all 10 test pieces (5 test A side, 5 test B side).

7 Calculation

7.1 Background correction

7.1.1 For each test piece, subtract the C0 from the sum of 10 counts to obtain the estimated value of the material particle count. This result serves as a drop.

7.1.2 To measure the total count, no matter what kind of particle size, add all the counts, and then subtract the C0 of the corresponding size classification.

If only the particles of each size classification are required to be reported, the recorded values of the particles of this size classification are added together, and the corresponding size classification C0 is subtracted.

7.1.3 Appendix B gives a test example of total flocculation.

7.2 Results

7.2.1 Based on the results of 5 test pieces, calculate the average fall (on face A and face B, respectively). Can be classified for each size (falling), or for each

The sum of the counts (total litter), or the calculation of the litter of the selected size category.

The average value of surface A and surface B can be used to calculate the flock or total flock of surface A or B or the material.

7.2.2 The standard deviation and coefficient of variation shall be calculated for each result described in 7.2.1. The coefficient of variation is the ratio of standard deviation to litter.

7.2.3 If necessary, you can use the lg value of the total drop (see 7.2.1) to classify each face or the total surface of the material or the selected size classification

Calculate the Falling Coefficient (CL).

8 Test report

The test report shall include at least the following information.

a) Type and identification of test materials;

b) The type of particle counter used;

c) Number of test pieces;

d) The size of each surface (side A and side B) of the 5 test pieces or the fall of the selected size category is expressed as the average result;

e) If necessary, the total debris expressed by the size classification of each surface of the 5 test pieces or the sum of the average values of the selected size classifications

(See 7.2.1);

f) Total floc in the range of 3μm ~ 25μm (see 7.2.1);

g) The standard deviation and percent coefficient of variation of each reported result in items d) and e) (see 7.2.2);

h) If necessary, the results of each report in items e) and f) are taken as the flocculation coefficient expressed by lg (see 7.2.3);

i) Any deviation from the steps specified in this section.

Appendix A

(Informative appendix)

General information about reproducibility

The particles counted during the test may be debris (dust) in the air or from fabrics, stitches or other process items

Debris. When this test is used to evaluate the fibers produced by nonwoven fabrics or composites, the dust should be kept to a minimum.

It has been found that many types of nonwoven fabrics made of different materials have similar particle generation characteristics. Particles are released during twisting

Put and slowly spread to the sampling port of the counter. During the total test time of five minutes, this diffusion reached its maximum and then decayed. such

A test time of five minutes is more suitable for evaluating the characteristics of the material.

In general, the twisting effect only causes some of the releasable particles to be released, which can lead to results from the same sample

There is a big difference. But multiple sampling and testing can get a relatively ideal measurement of products, processes and potential lint.

Reproducibility is only for the median of each absolute number, but the ranking is very reproducible.

To calculate the 95% confidence interval of the flocculation coefficient 2), you must first calculate the standard deviation of the original particulate content, use this statistical data to

Calculate the confidence interval, report after taking the logarithm.

2) The 95% confidence limit of the flocculation coefficient = lg (total flocculation ± 1.96S), where S is the standard deviation.

Appendix B

(Informative appendix)

Test Example of Total Falling of Sample X

B.1 The first background count (the cabinet is opened)

≥0.5μm particles 0s ~ 30s. 0

30s ~ 60s. 0

These counts are used to check the cleanliness of the system and do not participate in the calculation.

B.2 Second background count

Table B.1 shows the number of particles in the range of 3μm ~ 25μm in 10 times 30s.

Table B.1 Background count of specimen X1

Period

0s ~

30s

30s ~

60s

60s ~

90s

90s ~

120s

120s ~

150s

150s ~

180s

180s ~

210s

210s ~

240s

240s ~

270s

270s ~

300s

Total background count

C0 (X1)

X1 10 1 0 0 1 0 1 0 0 0 13

B.3 Number of samples X1 (side A)

Table B.2 shows the number of particles in the range of 3μm ~ 25μm for the test piece X1 (side A) for 10 times and 30s.

Table B.2 The number of samples X...

Get Quotation: Click YY/T 0506.4-2016 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0506.4-2016

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0506.4-2016: Surgical drapes, gowns and clean air suits for patients, clinical staff and equipment--Part 4: Test method for linting in the dry state

YY/T 0506.4-2016

Surgical drapes, gowns and clean air suits for patients, clinical staff and equipment--Part 4. Test method for linting in the dry state

ICS 11.140

C46

People's Republic of China Pharmaceutical Industry Standard

Replace YY/T 0506.4-2005

Surgical sheets and gowns for patients, medical staff and instruments

And clean clothes. Part 4. dry flocculation test method

(ISO 9073-10..2003, NEQ)

2016-07-29 release

2017-06-01 Implementation

Issued by the State Food and Drug Administration

Foreword

YY/T 0506 "Surgical sheets, surgical gowns and clean clothes for patients, medical staff and instruments", consists of the following parts.

--- Part 1. General requirements for manufacturers, treatment plants and products;

--- Part 2. Performance requirements and test methods;

--- Part 4. Dry flocculation test method;

--- Part 5. Test method for blocking penetration of dry microorganisms;

--- Part 6. Test method for penetration of moisture-resistant microorganisms;

--- Part 7. Cleanliness-microbiological test method.

This part is part 4 of YY/T 0506.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

This part replaces YY/T 0506.4-2005 "Surgical sheets, surgical gowns and clean clothes for patients, medical staff and instruments Part 4.

Compared with YY/T 0506.4-2005, the main dry flocculation test method is as follows.

--- Updated normative references;

--- Revised informative appendix B.

This part of YY/T 0506 refers to ISO 9073-10..2003 "Test methods for textile nonwovens-Part 10. Dry state drop

"The production of floc and other particles" is formulated, and the degree of consistency is not equivalent.

Please note that some content of this document may involve patents. The issuer of this document does not assume responsibility for identifying these patents.

This part is under the jurisdiction of the Jinan Medical Device Quality Supervision and Inspection Center of the State Food and Drug Administration.

This section was drafted by. Shandong Hengxin Testing Technology Development Center, Wenjian Industrial (Shenzhen) Co., Ltd.

The main drafters of this section. Yao Xiujun, Nie Jiaqi, Zheng Duozi.

The previous versions of the standard replaced by this part are as follows.

--- YY/T 0506.4-2005.

Surgical sheets and gowns for patients, medical staff and instruments

And clean clothes. Part 4. dry flocculation test method

1 Scope

This part of YY/T 0506 specifies the test method for measuring surgical sheets, surgical gowns and clean clothing and materials under dry conditions. The

The method is also suitable for other medical textile materials.

2 Normative references

The following documents are essential for the application of this document. For dated references, only the dated version applies to this article

Pieces. For the cited documents without date, the latest version (including all amendments) applies to this document.

GB/T 25915.1 Clean room and related controlled environment Part 1. Air cleanliness level (GB/T 25915.1-2010,

(ISO 14644-1..1999, IDT)

ISO 554 Standard Atmospheresforconditioningand/or

testing-Specifications)

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Lint

Fibers released during use.

3.2

Linting

The release of fluff and other particles during operation.

3.3

Coefficient of coefficient oflinting

The logarithm (lg) of the count of all particles or part of the particles entering the measurement channel.

4 Principle

This method describes the improved Gelbo distortion method. In this method, the sample is subjected to a combined operation of torsion and compression in the test chamber

use. During this twisting process, air was extracted from the test box, and particle counters were used to count and classify the particles in the air.

See Appendix A for general information on reproducibility.

5 Instruments

5.1 Laminar flow hood

Used to provide a clean test environment.

Note. It is also possible to use ISO 5 clean rooms in accordance with GB/T 25915.1 1).

5.2 Twisting device (improved Gelbo twisting device)

Contains two discs with a diameter of 82.8mm, one of which is fixed and the other is a motion disc fixed on a motion mechanism to make it

The reciprocating motion is performed at a frequency of 60 cycles per minute toward the fixed disk. During the reciprocating motion, it also rotates clockwise and counterclockwise at the same time

180 °, see Figure 1.

The disc has 8 holes (12.5mm in diameter), 10mm from the outer edge of the disc, and is arranged equally.

The starting distance between the two discs is (188 ± 2) mm, and the linear motion stroke is (120 ± 2) mm.

A jig used to fix the test piece to the disc in the form of a tube.

Explanation.

1 --- Test box;

2 --- Particle counter;

3 --- Test piece.

Figure 1 Gelbo twisted dry particle generator

5.3 Twist box and air collector

Cover the twisting device in an antistatic plexiglass box with a size of (300 × 300 × 300) mm (see Figure 2), the front and back of the box

The board can be opened for easy cleaning with filtered clean air. The rear panel and the two side panels have two holes (diameter is

10mm), equally divide the 300mm size of each board.

1) The cleanliness level specified in GB/T 25915.1 is equivalent to the level in GB 50073-2001 "Design Code for Clean Workshops", of which 5 levels are the

The 100-degree cleanliness of the British system means that the number of suspended particles with a particle size greater than or equal to 0.5 μm per cubic foot does not exceed 100. The cleanliness

The number of suspended particles with a particle size greater than or equal to 0.1 μm per cubic meter of the grade does not exceed 100,000.

Clarity level 5 depends on this. At present, domestic particle counters cannot generally count particles of 0.1 μm.

Explanation.

1 --- Openable front and rear panels;

2 --- Air collector;

3 --- Side hole.

Figure 2 Twisted box and air collector

The sampling port of the air collector is fixed at 2cm above the central floor at the bottom of the box (see Figure 3).

The diameter of the end of the sampling port is (40 ± 5) mm.

The hose connected to the particle counter has the following characteristics.

--- Polyethylene or polyester lined with vinyl or similar materials;

--- Maximum length 1500mm;

--- Inner diameter (8.5 ± 1.5) mm;

--- No kinks and discounts under a small bending radius.

The unit is mm

Explanation.

1 --- Air sampling port;

2 --- Distorted box.

Figure 3 Location of the air sampling port

5.4 Particle Counter

With the following air sampling port.

--- 8 measurement channels;

--- Particle size measurement range. 0.3μm or 0.5μm ~ 25μm;

--- Air flow. (28.3 ± 1.4) L/min;

--- The sampling time can be selected within the range of 1s and 24h.

5.5 Glue

Used for bonding cylindrical test pieces.

5.6 Gloves

Used in ISO Class 5 clean rooms. See GB/T 25915.1.

6 steps

6.1 The operator should wear gloves to operate the test piece.

6.2 The preparation of test pieces should be carried out under clean conditions, see also the specifications specified in ISO 554.

6.3 Cut out two sets of test pieces (see Figure 4), each set of 7 test pieces. The size of the test piece is (220 ± 1) mm × (285 ± 1) mm (large size is horizontal

Direction); one side of one group is marked A, and the other side of the other group is marked B. Only 5 specimens are actually used in the test, the uppermost and lowermost two

The film is used to protect the test piece. The two sets of test pieces should be kept in a clean environment to confirm that the test pieces are not wrinkled.

The unit is mm

a Glue area

Figure 4 Specimen

6.4 The test environment should be kept clean (see 5.1). Between each measurement, the twist box should be clean and the air quality in the box should be checked.

a) Open the rear panel (let clean air flow into the empty box), the bending device stops running without a test piece, perform two measurements, confirm

There are less than 100 particles with ≥0.5μm within 30s sampling time. If this requirement is not met, this step should be repeated.

b) Count the particles as follows to get the background count (C0).

1) Close the rear panel.

2) Let the twisting device run without load to 10 count stabilization periods of 30s, and record the results.

3) Add these results to get C0.

6.5 Roll the test piece into a cylindrical shape along the long dimension direction, and stick it with a suitable glue, the bonding width is 0.5cm (see Figure 4).

6.6 Adjust the disc to the starting position, separated by (188 ± 2) mm.

6.7 Carefully install the test piece on the disc and fix it with a suitable jig (such as rubber band). Touch should be minimized.

6.8 The particle counter is set to 30s counting time and 1s recounting time (operation mode).

6.9 Close the twist box.

6.10 Start the twisting device and start the particle counter at the same time until the completion of 10 consecutive 30s counts.

6.11 Stop the twisting device and counter. Remove the test piece and clean the twist box before testing the next test piece.

Note. Scrub with a clean cloth in a clean room, and then dry for the next test.

6.12 Record the particle count results of each size classification on the reading device.

6.13 Repeat this step for all 10 test pieces (5 test A side, 5 test B side).

7 Calculation

7.1 Background correction

7.1.1 For each test piece, subtract the C0 from the sum of 10 counts to obtain the estimated value of the material particle count. This result serves as a drop.

7.1.2 To measure the total count, no matter what kind of particle size, add all the counts, and then subtract the C0 of the corresponding size classification.

If only the particles of each size classification are required to be reported, the recorded values of the particles of this size classification are added together, and the corresponding size classification C0 is subtracted.

7.1.3 Appendix B gives a test example of total flocculation.

7.2 Results

7.2.1 Based on the results of 5 test pieces, calculate the average fall (on face A and face B, respectively). Can be classified for each size (falling), or for each

The sum of the counts (total litter), or the calculation of the litter of the selected size category.

The average value of surface A and surface B can be used to calculate the flock or total flock of surface A or B or the material.

7.2.2 The standard deviation and coefficient of variation shall be calculated for each result described in 7.2.1. The coefficient of variation is the ratio of standard deviation to litter.

7.2.3 If necessary, you can use the lg value of the total drop (see 7.2.1) to classify each face or the total surface of the material or the selected size classification

Calculate the Falling Coefficient (CL).

8 Test report

The test report shall include at least the following information.

a) Type and identification of test materials;

b) The type of particle counter used;

c) Number of test pieces;

d) The size of each surface (side A and side B) of the 5 test pieces or the fall of the selected size category is expressed as the average result;

e) If necessary, the total debris expressed by the size classification of each surface of the 5 test pieces or the sum of the average values of the selected size classifications

(See 7.2.1);

f) Total floc in the range of 3μm ~ 25μm (see 7.2.1);

g) The standard deviation and percent coefficient of variation of each reported result in items d) and e) (see 7.2.2);

h) If necessary, the results of each report in items e) and f) are taken as the flocculation coefficient expressed by lg (see 7.2.3);

i) Any deviation from the steps specified in this section.

Appendix A

(Informative appendix)

General information about reproducibility

The particles counted during the test may be debris (dust) in the air or from fabrics, stitches or other process items

Debris. When this test is used to evaluate the fibers produced by nonwoven fabrics or composites, the dust should be kept to a minimum.

It has been found that many types of nonwoven fabrics made of different materials have similar particle generation characteristics. Particles are released during twisting

Put and slowly spread to the sampling port of the counter. During the total test time of five minutes, this diffusion reached its maximum and then decayed. such

A test time of five minutes is more suitable for evaluating the characteristics of the material.

In general, the twisting effect only causes some of the releasable particles to be released, which can lead to results from the same sample

There is a big difference. But multiple sampling and testing can get a relatively ideal measurement of products, processes and potential lint.

Reproducibility is only for the median of each absolute number, but the ranking is very reproducible.

To calculate the 95% confidence interval of the flocculation coefficient 2), you must first calculate the standard deviation of the original particulate content, use this statistical data to

Calculate the confidence interval, report after taking the logarithm.

2) The 95% confidence limit of the flocculation coefficient = lg (total flocculation ± 1.96S), where S is the standard deviation.

Appendix B

(Informative appendix)

Test Example of Total Falling of Sample X

B.1 The first background count (the cabinet is opened)

≥0.5μm particles 0s ~ 30s. 0

30s ~ 60s. 0

These counts are used to check the cleanliness of the system and do not participate in the calculation.

B.2 Second background count

Table B.1 shows the number of particles in the range of 3μm ~ 25μm in 10 times 30s.

Table B.1 Background count of specimen X1

Period

0s ~

30s

30s ~

60s

60s ~

90s

90s ~

120s

120s ~

150s

150s ~

180s

180s ~

210s

210s ~

240s

240s ~

270s

270s ~

300s

Total background count

C0 (X1)

X1 10 1 0 0 1 0 1 0 0 0 13

B.3 Number of samples X1 (side A)

Table B.2 shows the number of particles in the range of 3μm ~ 25μm for the test piece X1 (side A) for 10 times and 30s.

Table B.2 The number of samples X...

Share