1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

YY/T 0681.1-2018 English PDF (YY/T0681.1-2018)

YY/T 0681.1-2018 English PDF (YY/T0681.1-2018)

Regular price

$205.00

Regular price

Sale price

$205.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

YY/T 0681.1-2018: Test methods for sterile medical device package - Part 1: Test guide for accelerated aging

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click YY/T 0681.1-2018 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0681.1-2018

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0681.1-2018

MEDICAL INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.040

C 31

Replacing YY/T 0681.1-2009

Test methods for sterile medical device package -

Part 1: Test guide for accelerated aging

ISSUED ON: DECEMBER 20, 2018

IMPLEMENTED ON: JANUARY 01, 2020

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Meaning and application ... 8

5 Instruments ... 9

6 Accelerated aging theory ... 9

7 Accelerated aging plan ... 10

8 Post-aging test guide ... 13

9 Report ... 14

Annex A (normative) Accelerated aging of polymers ... 15

Annex B (informative) Example of shelf life test plan for sterile barrier system

... 16

Annex C (informative) Relative humidity used in aging solution ... 18

Bibliography ... 20

Foreword

YY/T 0681 “Test methods for sterile medical device package” consists of the

following 16 parts:

- Part 1: Test guide for accelerated aging;

- Part 2: Seal strength of flexible battier materials;

- Part 3: Internal pressurization failure resistance of unrestrained packages;

- Part 4: Detecting seal leaks in porous packages by dye penetration;

- Part 5: Detecting gross leaks in medical packaging by internal

pressurization (bubble test);

- Part 6: Evaluation of chemical resistance of printed inks and coatings on

flexible packaging materials;

- Part 7: Evaluating inks or coating adhesion to flexible packaging materials

using tape;

- Part 8: Coating/adhesive weight determination;

- Part 9: Burst testing of flexible package seals using internal air

pressurization weight restraining plates;

- Part 10: Test for microbial barrier ranking of porous package material;

- Part 11: Determining integrity of seals for medical packaging by visual

inspection;

- Part 12: Flex durability of flexible barrier films;

- Part 13: Slow rate penetration resistance of flexible barrier films and

laminates;

- Part 14: Breathable packaging materials for wet and dry microbial barrier

tests;

- Part 15: Performance test of transport containers and systems;

- Part 16: Packaging system climate strain capability test.

This is Part 1 of YY/T 0681.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

Test methods for sterile medical device package -

Part 1: Test guide for accelerated aging

1 Scope

This Part of YY/T 0681 specifies the guide for designed accelerated aging

solutions.

This Part applies to the rapid determination of the sterile integrity of the sterile

barrier system specified in GB/T 19633.1-2015 and the effects that physical

properties of its packaging material components are affected by the elapsed

time.

NOTE 1: Use the information in this Part of YY/T 0681 to support the expiration date of the medical device

sterile barrier system (i.e. shelf life).

This Part is not applicable to real-time aging solution.

NOTE 2: Accelerated aging test involves sterile barrier system with or without instruments. This Part does

not address the compatibility of sterile barrier system materials with instrument interactions required during

new product development or evaluation.

NOTE 3: Real-time aging test is a basic aging study used to determine the results of accelerated aging

tests.

NOTE 4: This Part does not address methods for confirmation of sterile barrier system, including effects

on mechanical processing, sterilization processes, circulation, handling and transport. The ability of the

sterile barrier system to resist transport challenges is given in YY/T 0681.15.

NOTE 5: This Part does not address the effects of extreme weather conditions that may be experienced

in a simulated transport environment. For the climatic strain capacity test of the sterile barrier system, see

YY/T 0681.16.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 4857.2, Packaging - Transport packages - Temperature and humidity

conditioning

NOTE: The term “real-time aging” is also called “actual-time aging” in GB/T 19633.1-2015.

3.8 real-time equivalent

the length of time equivalent to real-time aging estimated for a given aging

condition

3.9 zero time

start time of aging study

4 Meaning and application

4.1 Degradation of physical properties of materials over time and degradation

of materials at bonding or heat sealing over time and dynamic events during

subsequent transport and handling, may lead to loss of integrity of the sterile

barrier system.

4.2 The packaging system shall provide protection and maintain the integrity of

the sterile barrier system. The sterile barrier system shall maintain its sterility

before or during the expiration date. Stability test shall confirm that the sterile

barrier system maintains its integrity at all times. Adopt stability test of

accelerated aging solution. Sufficient evidence of the nominal expiration date

shall be considered before the actual aging study data is issued.

4.3 Real-time aging procedures provide the best data to ensure that sterile

barrier system materials and sterile barrier system integrity do not degrade over

time. However, in the market conditions where product updates are fast, new

products need to be put into the market in the shortest possible time. But real-

time aging study cannot meet this purpose. Accelerated aging study provides

another alternative method. To ensure that accelerated aging study truly

represents real-time aging effects, real-time aging study shall be synchronized

with accelerated aging study. Real-time aging study shall be carried out to the

product's nominal shelf life and up to completion.

4.4 If there is a lack of understanding of the material of the sterile barrier system

being evaluated, a conservative accelerated aging factor shall be used. More

realistic accelerated aging factors can be used. But use documented evidence

to show the relationship between real-time aging and accelerated aging.

4.5 When accelerating the aging process to establish a nominal shelf life, it shall

be recognized that the data obtained from the study is based on a simulation of

the aging effect of the material. The established expiration date or shelf life is

based on the use of conservatively estimated aging factors (e.g. Q10). It is only

temporary before the real-time aging study of the sterile barrier system is

completed.

sterile barrier system. This shall be carried out separately and has nothing to

do with the aging of the material.

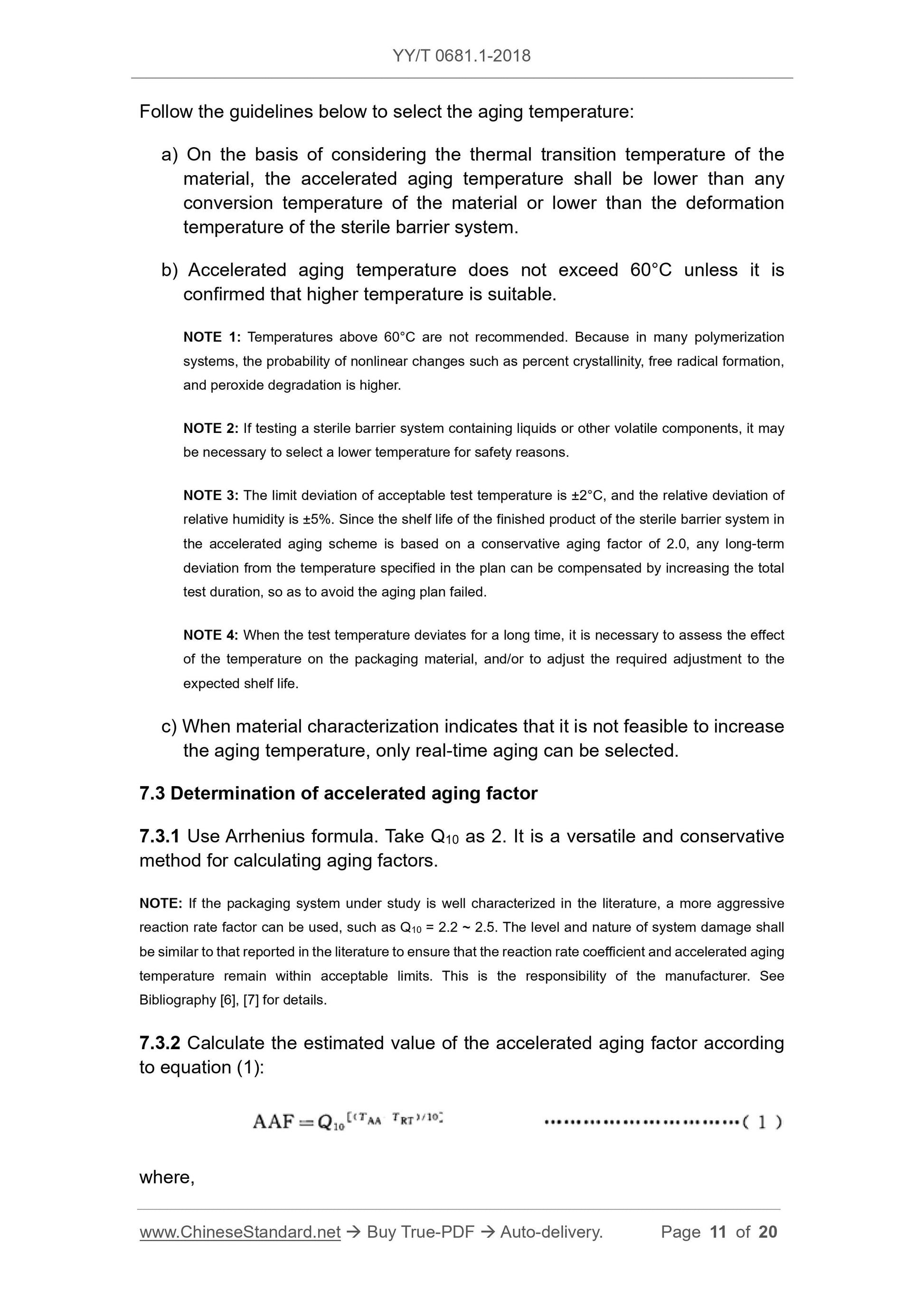

7 Accelerated aging plan

7.1 Material characterization

Accelerated aging theory and its application are directly related to the

composition of packaging materials. Material properties that may affect the

results of accelerated aging study include:

a) composition;

b) morphology (glassy, amorphous, semi-crystalline, highly crystalline,

percent crystallinity, etc.);

c) thermal conversion temperature (Tm, Tg, Tα);

NOTE: Tm: Melting temperature of material; Tg: Glass transition temperature; Tα: Alpha

temperature, heat distortion temperature.

d) additives, process aids, catalysts, lubricants, residual solvents, corrosive

gases and fillers.

7.2 Design guide for accelerated aging plan

7.2.1 Temperature limits shall be considered on the basis of material

characterization of medical device and sterile barrier system so as to ensure

that the initial conservative aging factor is appropriate. The temperature used

in the test shall be determined based on the characterization of the packaging

material and the expected storage conditions. Material characterization and

composition are factors in establishing accelerated aging temperature limits.

Temperature selection shall avoid any physical transformation of the material.

7.2.2 Choose a room temperature or ambient temperature that represents the

actual product storage and use conditions.

NOTE: This temperature is usually between 20°C~25°C. A temperature of 25°C is considered a

conservative value.

7.2.3 Select accelerated aging temperature based on material characterization.

The higher the accelerated aging temperature, the greater the accelerated

aging factor, and the shorter the time to accelerate aging. It shall be noted that

the accelerated aging temperature cannot be reduced in an uncontrolled

manner to shorten the time for accelerated aging. Excessive temperatures may

affect the material's real-time temperature or room temperature (see Annex A).

7.4.7 Define material properties, seal strength and seal integrity testing, sample

size and acceptance criteria for sterile barrier system.

7.4.8 Accelerate aging to sample under accelerated aging temperature. At the

same time, perform real-time aging of sample under real-time aging conditions

(ambient temperature).

7.4.9 Evaluate the performance of the sterile barrier system after accelerated

aging and the initial sterile barrier system requirements, such as packaging seal

strength, package integrity.

7.4.10 Evaluate whether the sterile barrier system meets its original design

requirements after real-time aging.

NOTE: The early accelerated aging factor method is a simple and conservative technique for evaluating

the long-term effects of aging on materials and seals. However, as with all accelerated aging techniques,

the estimated shelf life of the aging test is determined by real-time aging data.

8 Post-aging test guide

8.1 Evaluate physical properties and integrity of sterile barrier systems after

aging (e.g., accelerated aging and real-time aging).

8.2 The test selected for evaluation shall be able to challenge the most critical

function of the material or package or the function that is most likely to fail due

to aging.

8.3 It is advisable to evaluate the constituent materials and all seals or closures

of the equipment-free sterile barrier system that is subject to aging. Evaluate

various reductions in strength characteristics and ability to maintain integrity.

8.4 Aging test or stability test and performance test are two different tests.

Performance tests evaluate the interaction between packaging systems and

products caused by stresses imposed by the production, sterilization process,

and handling, storage, and transport environment. The aging of a particular

sterile barrier system is not affected by its physical structure or contents. As

long as the sterile barrier system is subjected to the same sterilization process,

regardless of its physical structure and contents, the material and seal are

expected to undergo the same aging.

8.5 If the packaging system has documented acceptable limits for performance

such as seal strength, puncture or impact resistance that meet the requirements

of the intended packaging system, then the specified physical test data shall be

complete.

8.6 Sometimes, packaging performance test can be performed on an aged

Annex B

(informative)

Example of shelf life test plan for sterile barrier system

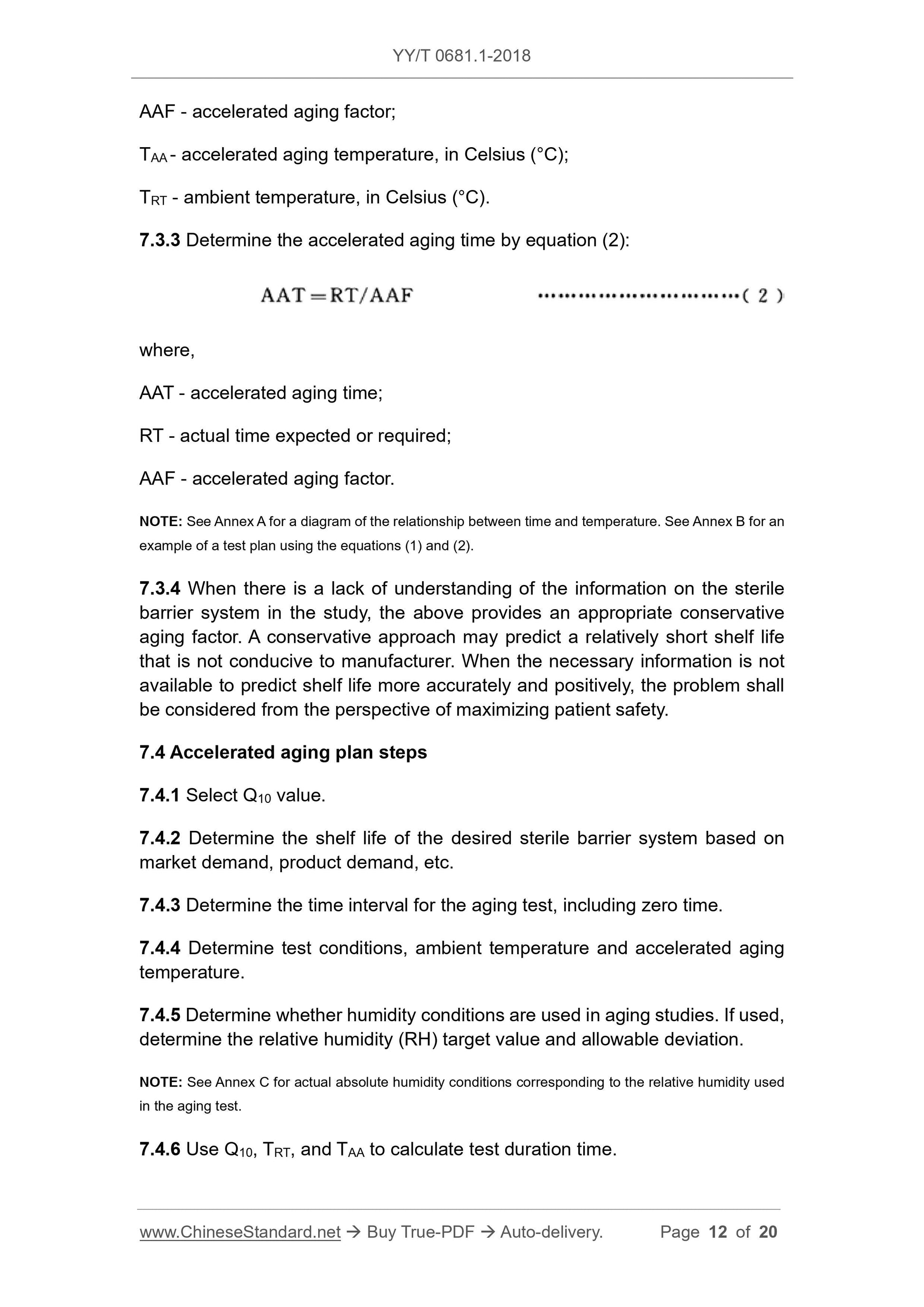

B.1 Selection of Q10 value

Select conservative estimate of accelerated aging factor, such as Q10=2 (see

Figure A.1).

B.2 Determination of time interval

Determine the aging time point corresponding to the expected shelf life, such

as 2 years and 3 years.

NOTE: Trend analysis is often used to characterize the effects of aging on the properties of material and

sterile barrier system. At least one accelerated aging time point is set. But there must be a point in time

that corresponds to the expected shelf life (expected shelf life divided by the aging factor). However, when

using only one acceleration time point, there is such a risk. That is, it is unable to draw an early warning

from the previous accelerated aging time point, resulting in a test failure. Trend analysis shall consider at

least three time points.

B.3 Sample preparation

Prepare test samples according to the confirmed production process.

NOTE: Sterile barrier system for zero time, sterilization and accelerated aging, can be packaged with or

without analog products.

B.4 Sterilization

Sterilize the sterile barrier system with a validated sterilization process.

Sterilization process may affect the stability of materials or sterile barrier system.

Material and sterile barrier system shall be subjected to the most stringent

sterilization process conditions or cycles of prior use prior to aging studies.

B.5 State conditioning

Perform sample state conditioning according to GB/T 4857.2.

NOTE: When the device is in a protective package, the sterile barrier system performance test can be

performed as part of the aging protocol, so as to determine the long-term effects of transport, handling

and storage on sterile barrier system. Whether the performance test is performed before or after aging, it

shall depend on whether the study is transported first and then stored in the hospital shelf or simulated

before being stored in the manufacturer's shelf and then transported. But there may be situations where

YY/T 0681.1-2018

MEDICAL INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.040

C 31

Replacing YY/T 0681.1-2009

Test methods for sterile medical device package -

Part 1: Test guide for accelerated aging

ISSUED ON: DECEMBER 20, 2018

IMPLEMENTED ON: JANUARY 01, 2020

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Meaning and application ... 8

5 Instruments ... 9

6 Accelerated aging theory ... 9

7 Accelerated aging plan ... 10

8 Post-aging test guide ... 13

9 Report ... 14

Annex A (normative) Accelerated aging of polymers ... 15

Annex B (informative) Example of shelf life test plan for sterile barrier system

... 16

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click YY/T 0681.1-2018 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 0681.1-2018

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 0681.1-2018

MEDICAL INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.040

C 31

Replacing YY/T 0681.1-2009

Test methods for sterile medical device package -

Part 1: Test guide for accelerated aging

ISSUED ON: DECEMBER 20, 2018

IMPLEMENTED ON: JANUARY 01, 2020

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Meaning and application ... 8

5 Instruments ... 9

6 Accelerated aging theory ... 9

7 Accelerated aging plan ... 10

8 Post-aging test guide ... 13

9 Report ... 14

Annex A (normative) Accelerated aging of polymers ... 15

Annex B (informative) Example of shelf life test plan for sterile barrier system

... 16

Annex C (informative) Relative humidity used in aging solution ... 18

Bibliography ... 20

Foreword

YY/T 0681 “Test methods for sterile medical device package” consists of the

following 16 parts:

- Part 1: Test guide for accelerated aging;

- Part 2: Seal strength of flexible battier materials;

- Part 3: Internal pressurization failure resistance of unrestrained packages;

- Part 4: Detecting seal leaks in porous packages by dye penetration;

- Part 5: Detecting gross leaks in medical packaging by internal

pressurization (bubble test);

- Part 6: Evaluation of chemical resistance of printed inks and coatings on

flexible packaging materials;

- Part 7: Evaluating inks or coating adhesion to flexible packaging materials

using tape;

- Part 8: Coating/adhesive weight determination;

- Part 9: Burst testing of flexible package seals using internal air

pressurization weight restraining plates;

- Part 10: Test for microbial barrier ranking of porous package material;

- Part 11: Determining integrity of seals for medical packaging by visual

inspection;

- Part 12: Flex durability of flexible barrier films;

- Part 13: Slow rate penetration resistance of flexible barrier films and

laminates;

- Part 14: Breathable packaging materials for wet and dry microbial barrier

tests;

- Part 15: Performance test of transport containers and systems;

- Part 16: Packaging system climate strain capability test.

This is Part 1 of YY/T 0681.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

Test methods for sterile medical device package -

Part 1: Test guide for accelerated aging

1 Scope

This Part of YY/T 0681 specifies the guide for designed accelerated aging

solutions.

This Part applies to the rapid determination of the sterile integrity of the sterile

barrier system specified in GB/T 19633.1-2015 and the effects that physical

properties of its packaging material components are affected by the elapsed

time.

NOTE 1: Use the information in this Part of YY/T 0681 to support the expiration date of the medical device

sterile barrier system (i.e. shelf life).

This Part is not applicable to real-time aging solution.

NOTE 2: Accelerated aging test involves sterile barrier system with or without instruments. This Part does

not address the compatibility of sterile barrier system materials with instrument interactions required during

new product development or evaluation.

NOTE 3: Real-time aging test is a basic aging study used to determine the results of accelerated aging

tests.

NOTE 4: This Part does not address methods for confirmation of sterile barrier system, including effects

on mechanical processing, sterilization processes, circulation, handling and transport. The ability of the

sterile barrier system to resist transport challenges is given in YY/T 0681.15.

NOTE 5: This Part does not address the effects of extreme weather conditions that may be experienced

in a simulated transport environment. For the climatic strain capacity test of the sterile barrier system, see

YY/T 0681.16.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 4857.2, Packaging - Transport packages - Temperature and humidity

conditioning

NOTE: The term “real-time aging” is also called “actual-time aging” in GB/T 19633.1-2015.

3.8 real-time equivalent

the length of time equivalent to real-time aging estimated for a given aging

condition

3.9 zero time

start time of aging study

4 Meaning and application

4.1 Degradation of physical properties of materials over time and degradation

of materials at bonding or heat sealing over time and dynamic events during

subsequent transport and handling, may lead to loss of integrity of the sterile

barrier system.

4.2 The packaging system shall provide protection and maintain the integrity of

the sterile barrier system. The sterile barrier system shall maintain its sterility

before or during the expiration date. Stability test shall confirm that the sterile

barrier system maintains its integrity at all times. Adopt stability test of

accelerated aging solution. Sufficient evidence of the nominal expiration date

shall be considered before the actual aging study data is issued.

4.3 Real-time aging procedures provide the best data to ensure that sterile

barrier system materials and sterile barrier system integrity do not degrade over

time. However, in the market conditions where product updates are fast, new

products need to be put into the market in the shortest possible time. But real-

time aging study cannot meet this purpose. Accelerated aging study provides

another alternative method. To ensure that accelerated aging study truly

represents real-time aging effects, real-time aging study shall be synchronized

with accelerated aging study. Real-time aging study shall be carried out to the

product's nominal shelf life and up to completion.

4.4 If there is a lack of understanding of the material of the sterile barrier system

being evaluated, a conservative accelerated aging factor shall be used. More

realistic accelerated aging factors can be used. But use documented evidence

to show the relationship between real-time aging and accelerated aging.

4.5 When accelerating the aging process to establish a nominal shelf life, it shall

be recognized that the data obtained from the study is based on a simulation of

the aging effect of the material. The established expiration date or shelf life is

based on the use of conservatively estimated aging factors (e.g. Q10). It is only

temporary before the real-time aging study of the sterile barrier system is

completed.

sterile barrier system. This shall be carried out separately and has nothing to

do with the aging of the material.

7 Accelerated aging plan

7.1 Material characterization

Accelerated aging theory and its application are directly related to the

composition of packaging materials. Material properties that may affect the

results of accelerated aging study include:

a) composition;

b) morphology (glassy, amorphous, semi-crystalline, highly crystalline,

percent crystallinity, etc.);

c) thermal conversion temperature (Tm, Tg, Tα);

NOTE: Tm: Melting temperature of material; Tg: Glass transition temperature; Tα: Alpha

temperature, heat distortion temperature.

d) additives, process aids, catalysts, lubricants, residual solvents, corrosive

gases and fillers.

7.2 Design guide for accelerated aging plan

7.2.1 Temperature limits shall be considered on the basis of material

characterization of medical device and sterile barrier system so as to ensure

that the initial conservative aging factor is appropriate. The temperature used

in the test shall be determined based on the characterization of the packaging

material and the expected storage conditions. Material characterization and

composition are factors in establishing accelerated aging temperature limits.

Temperature selection shall avoid any physical transformation of the material.

7.2.2 Choose a room temperature or ambient temperature that represents the

actual product storage and use conditions.

NOTE: This temperature is usually between 20°C~25°C. A temperature of 25°C is considered a

conservative value.

7.2.3 Select accelerated aging temperature based on material characterization.

The higher the accelerated aging temperature, the greater the accelerated

aging factor, and the shorter the time to accelerate aging. It shall be noted that

the accelerated aging temperature cannot be reduced in an uncontrolled

manner to shorten the time for accelerated aging. Excessive temperatures may

affect the material's real-time temperature or room temperature (see Annex A).

7.4.7 Define material properties, seal strength and seal integrity testing, sample

size and acceptance criteria for sterile barrier system.

7.4.8 Accelerate aging to sample under accelerated aging temperature. At the

same time, perform real-time aging of sample under real-time aging conditions

(ambient temperature).

7.4.9 Evaluate the performance of the sterile barrier system after accelerated

aging and the initial sterile barrier system requirements, such as packaging seal

strength, package integrity.

7.4.10 Evaluate whether the sterile barrier system meets its original design

requirements after real-time aging.

NOTE: The early accelerated aging factor method is a simple and conservative technique for evaluating

the long-term effects of aging on materials and seals. However, as with all accelerated aging techniques,

the estimated shelf life of the aging test is determined by real-time aging data.

8 Post-aging test guide

8.1 Evaluate physical properties and integrity of sterile barrier systems after

aging (e.g., accelerated aging and real-time aging).

8.2 The test selected for evaluation shall be able to challenge the most critical

function of the material or package or the function that is most likely to fail due

to aging.

8.3 It is advisable to evaluate the constituent materials and all seals or closures

of the equipment-free sterile barrier system that is subject to aging. Evaluate

various reductions in strength characteristics and ability to maintain integrity.

8.4 Aging test or stability test and performance test are two different tests.

Performance tests evaluate the interaction between packaging systems and

products caused by stresses imposed by the production, sterilization process,

and handling, storage, and transport environment. The aging of a particular

sterile barrier system is not affected by its physical structure or contents. As

long as the sterile barrier system is subjected to the same sterilization process,

regardless of its physical structure and contents, the material and seal are

expected to undergo the same aging.

8.5 If the packaging system has documented acceptable limits for performance

such as seal strength, puncture or impact resistance that meet the requirements

of the intended packaging system, then the specified physical test data shall be

complete.

8.6 Sometimes, packaging performance test can be performed on an aged

Annex B

(informative)

Example of shelf life test plan for sterile barrier system

B.1 Selection of Q10 value

Select conservative estimate of accelerated aging factor, such as Q10=2 (see

Figure A.1).

B.2 Determination of time interval

Determine the aging time point corresponding to the expected shelf life, such

as 2 years and 3 years.

NOTE: Trend analysis is often used to characterize the effects of aging on the properties of material and

sterile barrier system. At least one accelerated aging time point is set. But there must be a point in time

that corresponds to the expected shelf life (expected shelf life divided by the aging factor). However, when

using only one acceleration time point, there is such a risk. That is, it is unable to draw an early warning

from the previous accelerated aging time point, resulting in a test failure. Trend analysis shall consider at

least three time points.

B.3 Sample preparation

Prepare test samples according to the confirmed production process.

NOTE: Sterile barrier system for zero time, sterilization and accelerated aging, can be packaged with or

without analog products.

B.4 Sterilization

Sterilize the sterile barrier system with a validated sterilization process.

Sterilization process may affect the stability of materials or sterile barrier system.

Material and sterile barrier system shall be subjected to the most stringent

sterilization process conditions or cycles of prior use prior to aging studies.

B.5 State conditioning

Perform sample state conditioning according to GB/T 4857.2.

NOTE: When the device is in a protective package, the sterile barrier system performance test can be

performed as part of the aging protocol, so as to determine the long-term effects of transport, handling

and storage on sterile barrier system. Whether the performance test is performed before or after aging, it

shall depend on whether the study is transported first and then stored in the hospital shelf or simulated

before being stored in the manufacturer's shelf and then transported. But there may be situations where

YY/T 0681.1-2018

MEDICAL INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.040

C 31

Replacing YY/T 0681.1-2009

Test methods for sterile medical device package -

Part 1: Test guide for accelerated aging

ISSUED ON: DECEMBER 20, 2018

IMPLEMENTED ON: JANUARY 01, 2020

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Meaning and application ... 8

5 Instruments ... 9

6 Accelerated aging theory ... 9

7 Accelerated aging plan ... 10

8 Post-aging test guide ... 13

9 Report ... 14

Annex A (normative) Accelerated aging of polymers ... 15

Annex B (informative) Example of shelf life test plan for sterile barrier system

... 16

Share