1

/

of

11

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1221-2013 English PDF (YY/T1221-2013)

YY/T 1221-2013 English PDF (YY/T1221-2013)

Regular price

$170.00 USD

Regular price

Sale price

$170.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 1221-2013 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1221-2013

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1221-2013: Cardiac Troponin I (cTnI) Diagnostic Kit (Colloid Gold Method)

YY/T 1221-2013

Cardiac troponini I (cTnI) diagnostic kit (Colloid gold method)

ICS 11.100

C44

People's Republic of China Pharmaceutical Industry Standard

Cardiac Troponin I Diagnostic Kit (Box)

(Colloidal gold method)

Released on.2013-10-21

2014-10-01 implementation

Issued by the State Food and Drug Administration

Preface

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some content of this standard may involve patents, and the issuing organization of this standard does not bear the responsibility for identifying these patents.

This standard was proposed by the State Food and Drug Administration.

This standard is under the jurisdiction of the National Medical Clinical Laboratory and In Vitro Diagnostic System Standardization Technical Committee (SAC/TC136).

This standard was drafted. China Food and Drug Control Research Institute.

The main drafters of this standard. Qu Shoufang, Huang Jie, Gao Shangxian.

Cardiac Troponin I Diagnostic Kit (Box)

(Colloidal gold method)

1 Scope

This standard specifies the terms and definitions, requirements, test methods, inspections and judgments of cardiac troponin I diagnostic kits (colloidal gold method)

Specification, identification, labeling and instructions for use, packaging, transportation and storage.

This standard applies to myocardial troponin I diagnostic kit (kit) (colloidal gold method). This reagent is used for the qualitative detection of human serum or plasma

Cardiac Troponin I (cTnI).

2 Normative references

The following documents are indispensable for the application of this document. For dated reference documents, only the dated version applies to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 191 Packaging, Storage and Transportation Graphic Mark

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Colloidal Gold Technology

A labeling technique that uses colloidal gold particles as a tracer or chromogenic substance for antigen-antibody reaction or other molecular detection.

3.2

Minimum detection limit

The lowest measured value in a sample that can be declared different from zero with a certain probability.

3.3

Analysis specificity

The measurement program only measures the ability to be measured.

3.4

Quality control

Substances, materials or articles used to verify the performance characteristics of in vitro diagnostic reagents (kits).

3.5

Repeatability

Under the same measurement conditions, the consistency between the results obtained by consecutive multiple measurements on the same measured.

4 requirements

4.1 Physical properties

4.1.1 Appearance

Meet the normal appearance requirements specified by the manufacturer.

4.1.2 Film strip width

Should not be less than 2.5mm.

4.1.3 Liquid moving speed

The liquid moving speed should not be less than 10mm/min.

4.2 Accuracy

Detect cTnI positive quality control products, the results should all be positive.

4.3 Repeatability

Take 10 test strips of the same batch number and test the cTnI positive quality control products of the same concentration. The reaction results should be consistent, the color development should be uniform, and the

Is positive.

4.4 Analysis specificity

Test the cTnI specific quality control material, the reaction result should be negative.

Note. cTnI specific quality control products are normal negative plasma or serum samples, quality control products of troponin T and quality control products of troponin C.

4.5 Minimum detection limit

The sensitivity of the cTnI quality control product should not be higher than 1.0ng/mL.

4.6 Stability

Take the test paper of the same batch number and place it at 37℃ for 20 days. The result should meet the requirements of 4.2~4.5.

5 Test method

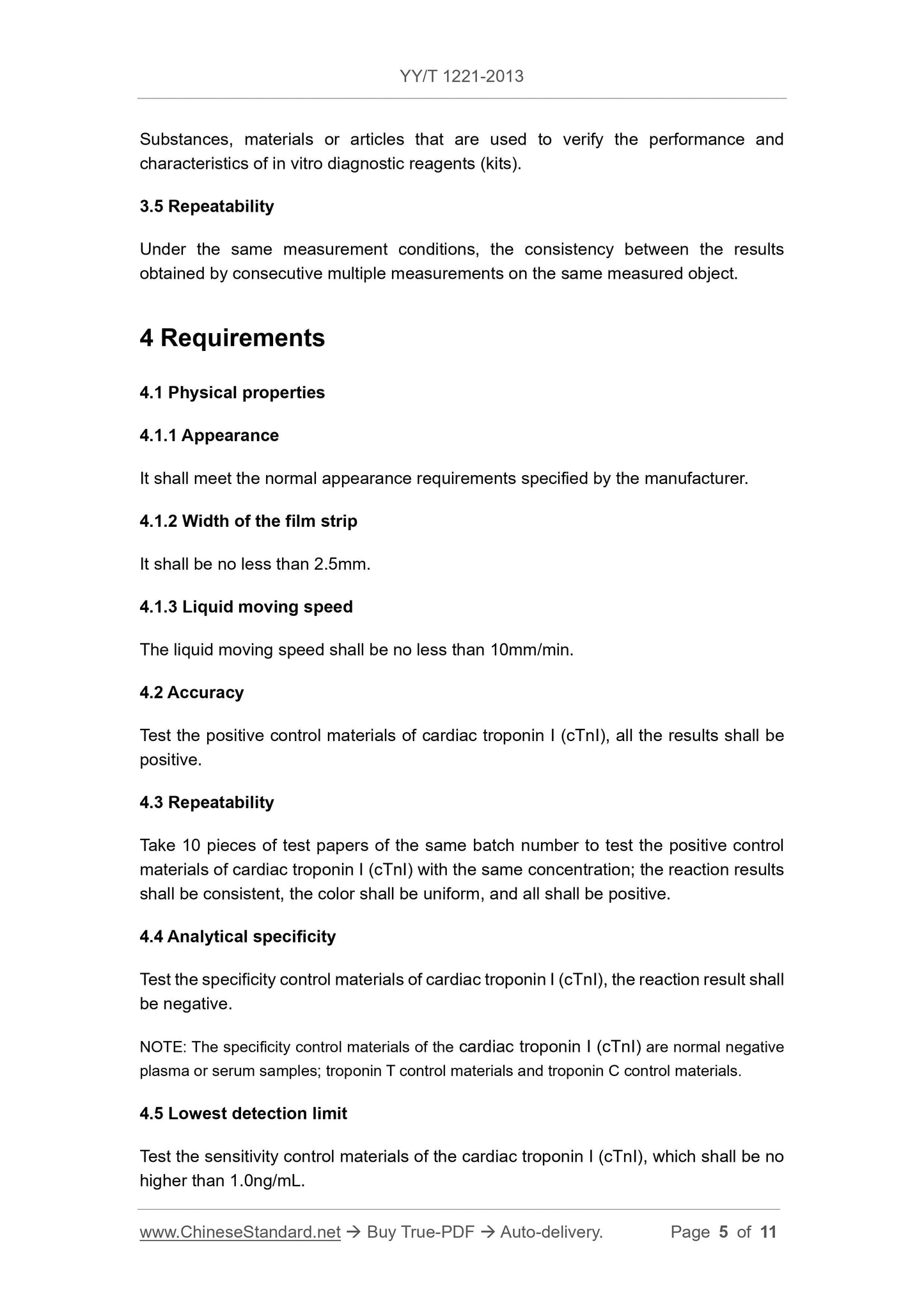

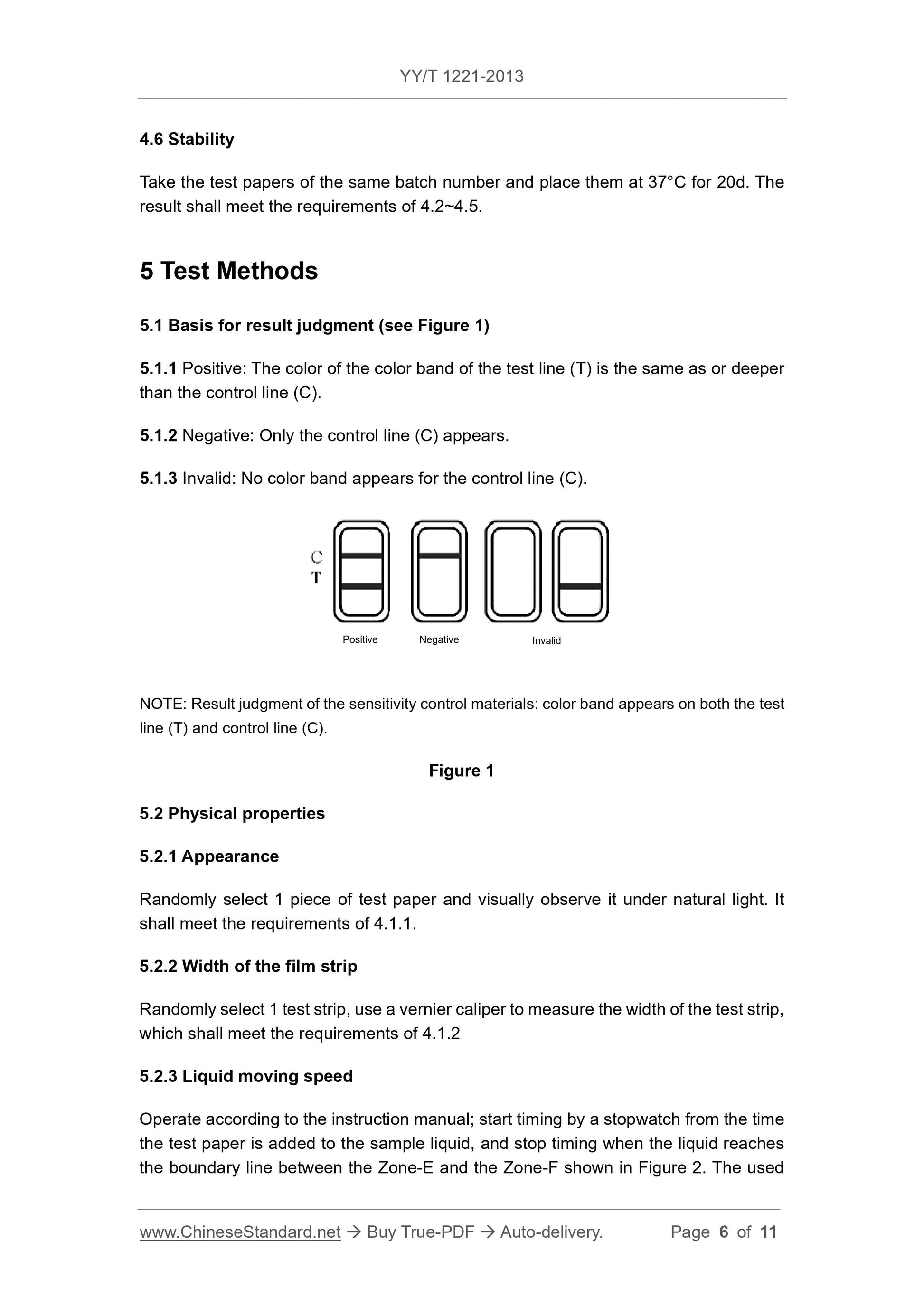

5.1 Judgment basis for results (see Figure 1)

5.1.1 Positive. The color of the color band of the detection line (T) is the same as or deeper than the quality control line (C).

5.1.2 Negative. Only the quality control line (C) appears.

5.1.3 Invalid. No ribbon appears on the quality control line (C).

Note. The result of the sensitivity quality control product is judged. the detection line (T) and the quality control line (C) have colored bands.

5.2 Physical properties

5.2.1 Appearance

1 piece of test paper is randomly selected and observed under natural light. It should meet the requirements of 4.1.1

5.2.2 Film strip width

One test strip is randomly selected, and the width of the test strip is measured with a vernier caliper, which should meet the requirements of 4.1.2.

5.2.3 Liquid moving speed

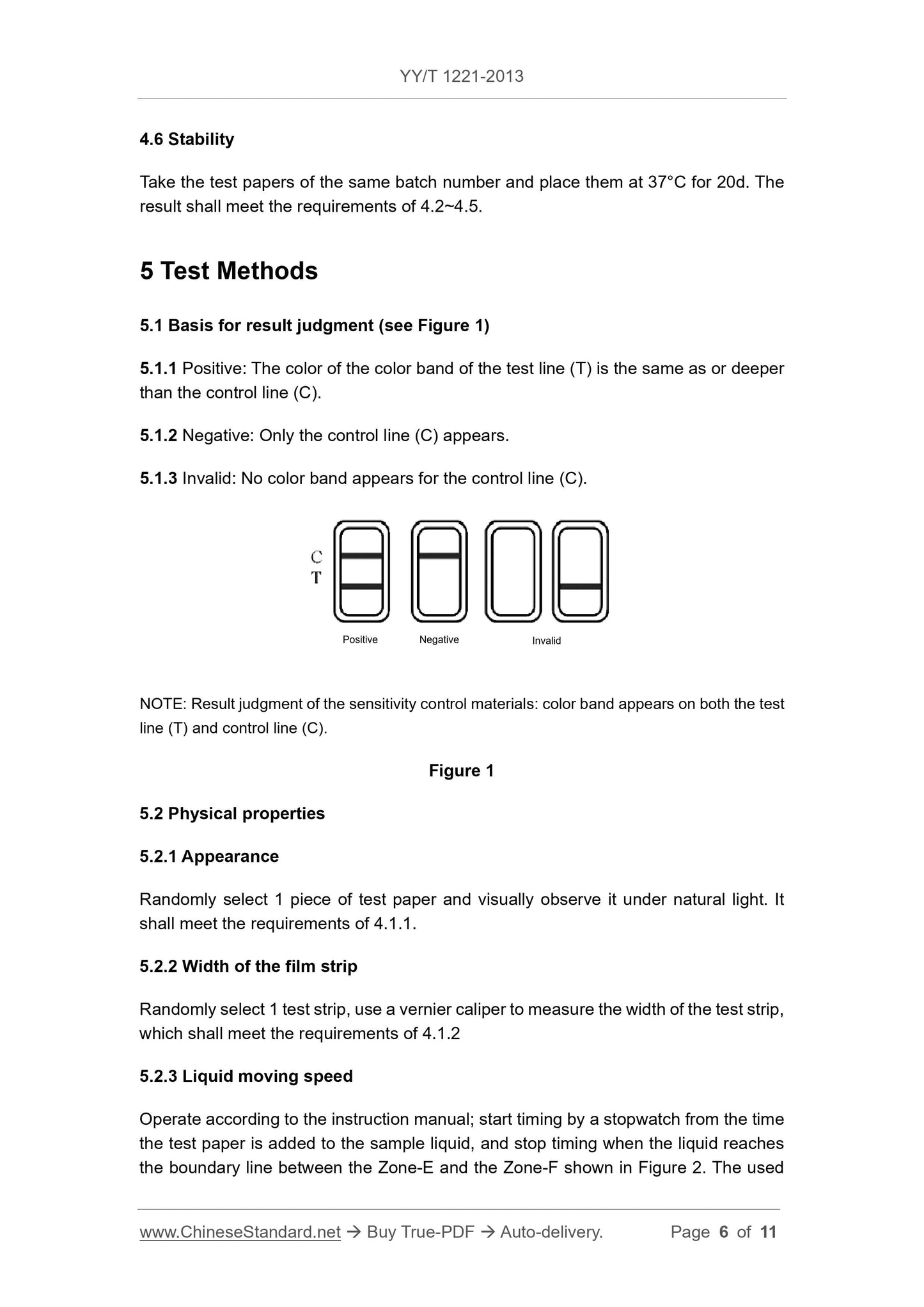

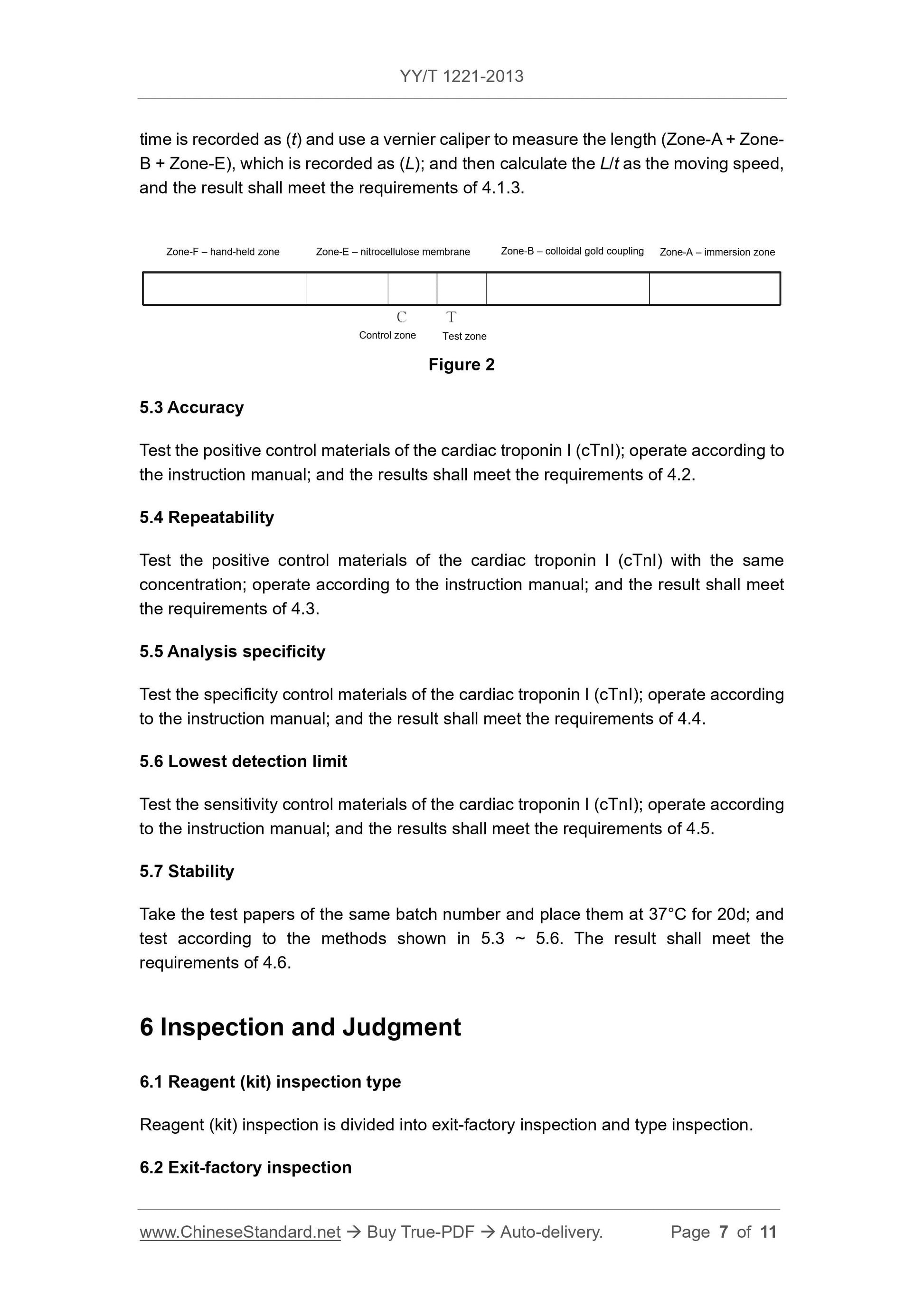

Operate according to the instructions, start timing with a stopwatch from the time the test paper is added to the sample liquid, until the liquid reaches between the E zone and the F zone shown in Figure 2.

Stop timing at the boundary line between the two, the time used is recorded as (t), use a vernier caliper to measure the length of (zone A, zone B, zone E), and mark it as (L), then

Calculating L/t is the moving speed, and the result should meet the requirements of 4.1.3.

5.3 Accuracy

Detect cTnI positive quality control products and operate according to the instructions. The results should meet the requirements of 4.2.

5.4 Repeatability

Detect the cTnI positive quality control product at the same concentration and operate according to the instructions. The result should meet the requirements of 4.3.

5.5 Analysis specificity

Detect cTnI-specific quality control products and operate according to the instructions. The results should meet the requirements of 4.4.

5.6 Minimum detection limit

Detect cTnI sensitivity quality control products, operate according to the instructions, and the results should meet the requirements of 4.5.

5.7 Stability

Take the test paper of the same batch number and place it at 37°C for 20 days, and test according to the methods shown in 5.3 to 5.6.The result should meet the requirements of 4.6.

6 Inspection and judgment

6.1 Reagent (kit) inspection type

The kit inspection is divided into factory inspection and type inspection.

6.2 Factory inspection

The factory inspection items are 4.1~4.5, and the factory can be delivered only after the inspection is qualified; if any of the inspection results does not meet the requirements, the inspection

If the re-inspection is still unqualified, the batch of products shall be determined as unqualified.

6.3 Type inspection

Type inspection items are all items, and each batch of products shall be inspected for all items according to this standard. In one of the following situations, you should enter

Line type inspection.

a) The new product is put into production;

b) Major changes in materials, processes, and formulas may affect product performance;

c) No less than once a year in continuous production;

d) Resume production after stopping production for rectification;

e) Contract regulations or departmental requirements.

All inspection items pass the type inspection; if the type inspection fails, mass production is not allowed.

7 Packaging, labeling and instructions for use

7.1 The outer packaging box of the kit should have at least the following signs.

a) Product name and specifications;

b) The name and address of the manufacturer;

c) Production batch number or production date;

d) Validity period;

e) Product standard number;

f) Production license number;

g) Product registration certificate number;

h) Storage method;

i) Matters needing attention.

7.2 The transport package of the kit should at least have the following signs.

a) Product name and specifications;

b) The name and address of the manufacturer;

c) Production batch number or production date;

d) Product registration certificate number;

e) Volume (length × width × height);

f) "Moisture-proof", "heat-proof" and other words or signs, and should comply with the relevant regulations of GB/T 191.

7.3 The product instruction manual should have the following content.

a) Product name;

b) Packaging specifications;

c) Intended use and principle;

d) Operation steps (should indicate how long the reading result is valid; if it is a test strip, indicate how long it will be placed in the sample before taking it out);

e) Results judgment;

f) storage conditions;

g) Matters needing attention;

h) The name, address and contact information of the production unit;

i) Production license number;

j) Product registration certificate number;

k) Product standard number.

8 Transportation and storage

8.1 Transportation

8.1.1 The reagent can be transported at room temperature for a short time. Corresponding protective measures should be strengthened in cold winter or hot summer to avoid freezing or prolonged high temperature.

8.1.2 Light handling and loading and unloading should be done to avoid heavy pressure.

8.1.3 It should be waterproof, sun-proof and rain-proof.

8.2 Storage

8.2.1 Reagents should be stored at 4℃~30℃ and should not be frozen.

8.2.2 Avoid heavy pressure during storage.

8.2.3 Keep away from moisture, light and heat during storage.

Get Quotation: Click YY/T 1221-2013 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1221-2013

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1221-2013: Cardiac Troponin I (cTnI) Diagnostic Kit (Colloid Gold Method)

YY/T 1221-2013

Cardiac troponini I (cTnI) diagnostic kit (Colloid gold method)

ICS 11.100

C44

People's Republic of China Pharmaceutical Industry Standard

Cardiac Troponin I Diagnostic Kit (Box)

(Colloidal gold method)

Released on.2013-10-21

2014-10-01 implementation

Issued by the State Food and Drug Administration

Preface

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some content of this standard may involve patents, and the issuing organization of this standard does not bear the responsibility for identifying these patents.

This standard was proposed by the State Food and Drug Administration.

This standard is under the jurisdiction of the National Medical Clinical Laboratory and In Vitro Diagnostic System Standardization Technical Committee (SAC/TC136).

This standard was drafted. China Food and Drug Control Research Institute.

The main drafters of this standard. Qu Shoufang, Huang Jie, Gao Shangxian.

Cardiac Troponin I Diagnostic Kit (Box)

(Colloidal gold method)

1 Scope

This standard specifies the terms and definitions, requirements, test methods, inspections and judgments of cardiac troponin I diagnostic kits (colloidal gold method)

Specification, identification, labeling and instructions for use, packaging, transportation and storage.

This standard applies to myocardial troponin I diagnostic kit (kit) (colloidal gold method). This reagent is used for the qualitative detection of human serum or plasma

Cardiac Troponin I (cTnI).

2 Normative references

The following documents are indispensable for the application of this document. For dated reference documents, only the dated version applies to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

GB/T 191 Packaging, Storage and Transportation Graphic Mark

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Colloidal Gold Technology

A labeling technique that uses colloidal gold particles as a tracer or chromogenic substance for antigen-antibody reaction or other molecular detection.

3.2

Minimum detection limit

The lowest measured value in a sample that can be declared different from zero with a certain probability.

3.3

Analysis specificity

The measurement program only measures the ability to be measured.

3.4

Quality control

Substances, materials or articles used to verify the performance characteristics of in vitro diagnostic reagents (kits).

3.5

Repeatability

Under the same measurement conditions, the consistency between the results obtained by consecutive multiple measurements on the same measured.

4 requirements

4.1 Physical properties

4.1.1 Appearance

Meet the normal appearance requirements specified by the manufacturer.

4.1.2 Film strip width

Should not be less than 2.5mm.

4.1.3 Liquid moving speed

The liquid moving speed should not be less than 10mm/min.

4.2 Accuracy

Detect cTnI positive quality control products, the results should all be positive.

4.3 Repeatability

Take 10 test strips of the same batch number and test the cTnI positive quality control products of the same concentration. The reaction results should be consistent, the color development should be uniform, and the

Is positive.

4.4 Analysis specificity

Test the cTnI specific quality control material, the reaction result should be negative.

Note. cTnI specific quality control products are normal negative plasma or serum samples, quality control products of troponin T and quality control products of troponin C.

4.5 Minimum detection limit

The sensitivity of the cTnI quality control product should not be higher than 1.0ng/mL.

4.6 Stability

Take the test paper of the same batch number and place it at 37℃ for 20 days. The result should meet the requirements of 4.2~4.5.

5 Test method

5.1 Judgment basis for results (see Figure 1)

5.1.1 Positive. The color of the color band of the detection line (T) is the same as or deeper than the quality control line (C).

5.1.2 Negative. Only the quality control line (C) appears.

5.1.3 Invalid. No ribbon appears on the quality control line (C).

Note. The result of the sensitivity quality control product is judged. the detection line (T) and the quality control line (C) have colored bands.

5.2 Physical properties

5.2.1 Appearance

1 piece of test paper is randomly selected and observed under natural light. It should meet the requirements of 4.1.1

5.2.2 Film strip width

One test strip is randomly selected, and the width of the test strip is measured with a vernier caliper, which should meet the requirements of 4.1.2.

5.2.3 Liquid moving speed

Operate according to the instructions, start timing with a stopwatch from the time the test paper is added to the sample liquid, until the liquid reaches between the E zone and the F zone shown in Figure 2.

Stop timing at the boundary line between the two, the time used is recorded as (t), use a vernier caliper to measure the length of (zone A, zone B, zone E), and mark it as (L), then

Calculating L/t is the moving speed, and the result should meet the requirements of 4.1.3.

5.3 Accuracy

Detect cTnI positive quality control products and operate according to the instructions. The results should meet the requirements of 4.2.

5.4 Repeatability

Detect the cTnI positive quality control product at the same concentration and operate according to the instructions. The result should meet the requirements of 4.3.

5.5 Analysis specificity

Detect cTnI-specific quality control products and operate according to the instructions. The results should meet the requirements of 4.4.

5.6 Minimum detection limit

Detect cTnI sensitivity quality control products, operate according to the instructions, and the results should meet the requirements of 4.5.

5.7 Stability

Take the test paper of the same batch number and place it at 37°C for 20 days, and test according to the methods shown in 5.3 to 5.6.The result should meet the requirements of 4.6.

6 Inspection and judgment

6.1 Reagent (kit) inspection type

The kit inspection is divided into factory inspection and type inspection.

6.2 Factory inspection

The factory inspection items are 4.1~4.5, and the factory can be delivered only after the inspection is qualified; if any of the inspection results does not meet the requirements, the inspection

If the re-inspection is still unqualified, the batch of products shall be determined as unqualified.

6.3 Type inspection

Type inspection items are all items, and each batch of products shall be inspected for all items according to this standard. In one of the following situations, you should enter

Line type inspection.

a) The new product is put into production;

b) Major changes in materials, processes, and formulas may affect product performance;

c) No less than once a year in continuous production;

d) Resume production after stopping production for rectification;

e) Contract regulations or departmental requirements.

All inspection items pass the type inspection; if the type inspection fails, mass production is not allowed.

7 Packaging, labeling and instructions for use

7.1 The outer packaging box of the kit should have at least the following signs.

a) Product name and specifications;

b) The name and address of the manufacturer;

c) Production batch number or production date;

d) Validity period;

e) Product standard number;

f) Production license number;

g) Product registration certificate number;

h) Storage method;

i) Matters needing attention.

7.2 The transport package of the kit should at least have the following signs.

a) Product name and specifications;

b) The name and address of the manufacturer;

c) Production batch number or production date;

d) Product registration certificate number;

e) Volume (length × width × height);

f) "Moisture-proof", "heat-proof" and other words or signs, and should comply with the relevant regulations of GB/T 191.

7.3 The product instruction manual should have the following content.

a) Product name;

b) Packaging specifications;

c) Intended use and principle;

d) Operation steps (should indicate how long the reading result is valid; if it is a test strip, indicate how long it will be placed in the sample before taking it out);

e) Results judgment;

f) storage conditions;

g) Matters needing attention;

h) The name, address and contact information of the production unit;

i) Production license number;

j) Product registration certificate number;

k) Product standard number.

8 Transportation and storage

8.1 Transportation

8.1.1 The reagent can be transported at room temperature for a short time. Corresponding protective measures should be strengthened in cold winter or hot summer to avoid freezing or prolonged high temperature.

8.1.2 Light handling and loading and unloading should be done to avoid heavy pressure.

8.1.3 It should be waterproof, sun-proof and rain-proof.

8.2 Storage

8.2.1 Reagents should be stored at 4℃~30℃ and should not be frozen.

8.2.2 Avoid heavy pressure during storage.

8.2.3 Keep away from moisture, light and heat during storage.

Share