1

/

of

11

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1304.2-2015 English PDF (YY/T1304.2-2015)

YY/T 1304.2-2015 English PDF (YY/T1304.2-2015)

Regular price

$140.00 USD

Regular price

Sale price

$140.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 1304.2-2015 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1304.2-2015

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1304.2-2015: Detection system of time-resolved fluoroimmunoassay - Part 2: Quantitative reagent (kit) for time-resolved fluoroimmunoassay

YY/T 1304.2-2015

Detection system of time-resolved fluoroimmunoassay.Part 2.Quantitative reagent (kit) for time-resolved fluoroimmunoassay

ICS 11.100

C44

People's Republic of China Pharmaceutical Industry Standard

Time-resolved fluorescence immunodetection system. Part 2.

Time-resolved fluorescence immunoassay quantitative determination reagent (kit)

2015-03-02 released

2016-01-01 Implementation

Issued by the State Food and Drug Administration

Foreword

YY/T 1304 "Time-Resolved Fluorescence Immunoassay System" is planned to be published in parts. Currently, the following parts are planned to be published.

---Part 1.Semi-automatic time-resolved fluorescence immunoassay analyzer;

---Part 2.Time-resolved fluorescence immunoassay quantitative determination reagent (kit);

---Part 3.Fully automatic time-resolved fluorescence immunoassay analyzer.

This part is part 2 of YY/T 1304.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some content of this document may involve patents. The issuer of this document does not assume responsibility for identifying these patents.

This part is proposed by the State Food and Drug Administration.

This part is under the jurisdiction of the National Medical Clinical Laboratory and the Standardization Technical Committee of In Vitro Diagnostic Systems (SAC/TC136).

The main drafters of this part. Beijing Medical Device Inspection Institute, Suzhou Xinbo Biotechnology Co., Ltd., Guangzhou Dari Antibody Project

Technology Co., Ltd.

The main drafters of this section. Zhang Xinmei, Tu Xianju, Wu Yingsong, Du Haiou.

Time-resolved fluorescence immunodetection system. Part 2.

Time-resolved fluorescence immunoassay quantitative determination reagent (kit)

1 Scope

This part of YY/T 1304 specifies the terms of time-resolved fluorescence immunoassay quantitative determination reagent (kit) (hereinafter referred to as kit)

And definitions, requirements and test methods, labels, labels and instructions for use, packaging, transportation and storage.

This section applies to single-label time-resolved fluorescence immunoassay.

This section does not apply to dual-label and multi-label time-resolved fluorescence immunoassays.

2 Normative references

The following documents are essential for the application of this document. For dated reference documents, only the dated version applies to this article

Pieces. For the cited documents without date, the latest version (including all amendments) applies to this document.

GB/T 21415 In-vitro diagnostic medical device biological sample measurement calibrator and control substance assignment of metrological traceability

Source

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Time-resolved fluoroimmunoassay; TRFIA

Combining time-resolved fluorescence and immunoassay, using rare earth ions and their chelates as tracers, labeling antigens or antibodies to be tested

The substance undergoes a series of immune reactions, and the fluorescence intensity of the final product is determined to obtain the analytical technique for the concentration of the analyte.

4 requirements

4.1 Appearance

Should meet the following requirements.

a) The components of the kit should be complete and complete, with no leakage of liquid;

b) The Chinese packaging label should be clear and free of wear.

4.2 Linear

In the linear interval specified by the manufacturer, the linear correlation coefficient (|r|) of the kit should not be less than 0.9900.

4.3 Blank limit

The manufacturer shall specify the requirements for the blank limits.

4.4 Repeatability

Repeat the test 10 times with samples of at least 2 concentration levels, then the coefficient of variation (CV) of the repeatability results should be consistent with.

CV< 10.0%.

Note. The concentration level of the sample should be close to the product's critical value or medically determined level.

4.5 Difference between batches

To test the same sample with three batch kits, the coefficient of variation (CV) between batches of the three batch kits should meet.

CV< 15.0%.

Note. The concentration level of the sample should be close to the product's critical value or medically determined level.

4.6 Accuracy

The accuracy should meet one of the following conditions.

a) A certain concentration of certified reference material (or other recognized reference material) is tested as a sample, and the relative measurement results

The deviation should be within ±10%;

b) Add corresponding substances of known concentration to blood matrix or other body fluid components, the recovery rate should be in the range of 85%~115%

Inside.

Note 1.The concentration level of the certified reference substance should be close to the product's critical value or medically determined level.

Note 2.When there is a certified reference substance (including national reference substance or international reference substance) in the test substance, a) is used for testing.

Note 3.When there is no certified reference substance (including national reference substance or international reference substance) in the test substance, b) is used for testing.

4.7 Specificity

Specific requirements should be specified.

4.8 Stability

The following methods can be selected for detection.

a) Expiration date stability. The manufacturer should specify the expiration date of the kit. Take a batch of kits to be tested within a certain time after the expiration date

4.2~4.4, should meet the corresponding requirements.

b) Thermal stability. After placing a batch of kits within the validity period for 7 days at 37℃, the test is 4.2~4.4, which should meet the phase

by request.

Note 1.According to product characteristics, any combination of a) and b) methods can be selected, but the selected method should be able to verify the stability of the product to ensure that the product is within the validity period

Can meet the corresponding requirements.

Note 2.In general, when the validity period of the kit is specified to be 12 months, it is advisable to select a kit with an expiration date not exceeding 1 month for stability testing; when specified

When the validity period of the kit is 6 months, it is advisable to select products whose expiration date does not exceed half a month for stability testing, and so on. But you can also use the system

The expiration date verified in the stability report provided by the manufacturer.

Note 3.Thermal stability can not be used to derive the expiration date of the kit, unless it is based on the derivation formula established based on a large number of stability study data.

4.9 Traceability

The manufacturer should provide the source, evaluation process and inaccurate measurement of the standard kit used in accordance with GB/T 21415 and relevant regulations

Scale and other content.

5 Test method

5.1 Appearance

Visual inspection should meet the requirements of 4.1.

5.2 Linear

Dilute the high-value samples close to the upper limit of the linear interval to at least 5 concentrations in a certain ratio, and the low-value concentration samples must be close to linear

The lower limit of the interval. Operate according to the instructions of the reagent (kit), repeat the test for each concentration sample twice, calculate the average value, and average the results

The value and the dilution ratio are linearly fitted by the least square method, and the linear correlation coefficient |r| is calculated, which should meet the requirements of 4.2.

5.3 Blank limit

Use zero concentration calibrator or sample diluent as the sample, repeat the measurement 20 times, calculate the average value (M) of 20 fluorescence measurement results and

Standard deviation (SD), calculate the fluorescence value of M 2SD, recorded as LOB, according to the calibration curve or the concentration of the zero concentration calibrator and the adjacent calibrator

The two-point regression fitting of the degree-fluorescence value results in a linear equation, and the LOB value is brought into the above equation to find the corresponding concentration value, which is the blank

The results should meet the requirements of 4.3.

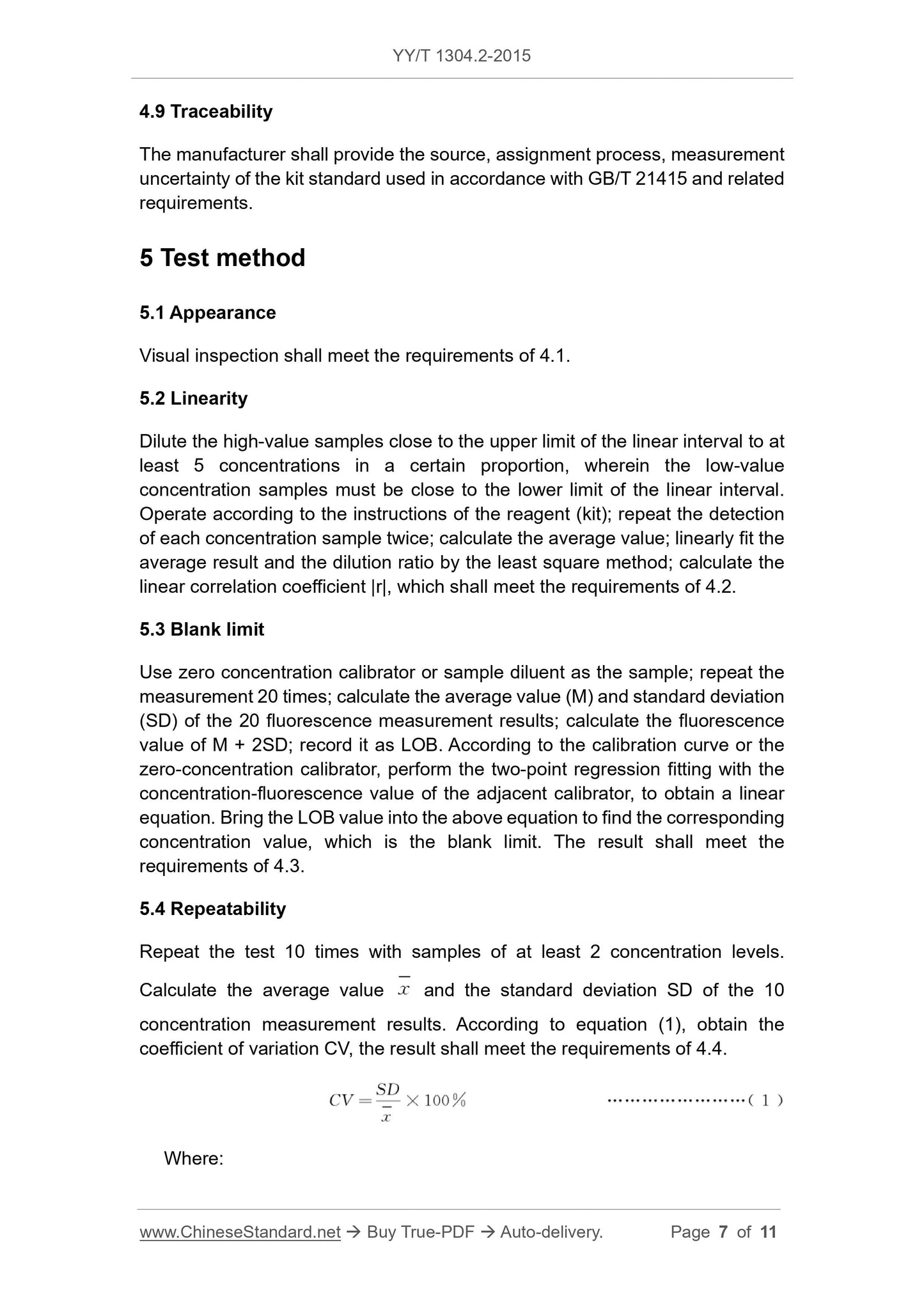

5.4 Repeatability

Repeat the test 10 times with samples of at least 2 concentration levels to calculate the average value and standard deviation of the 10 concentration measurement results

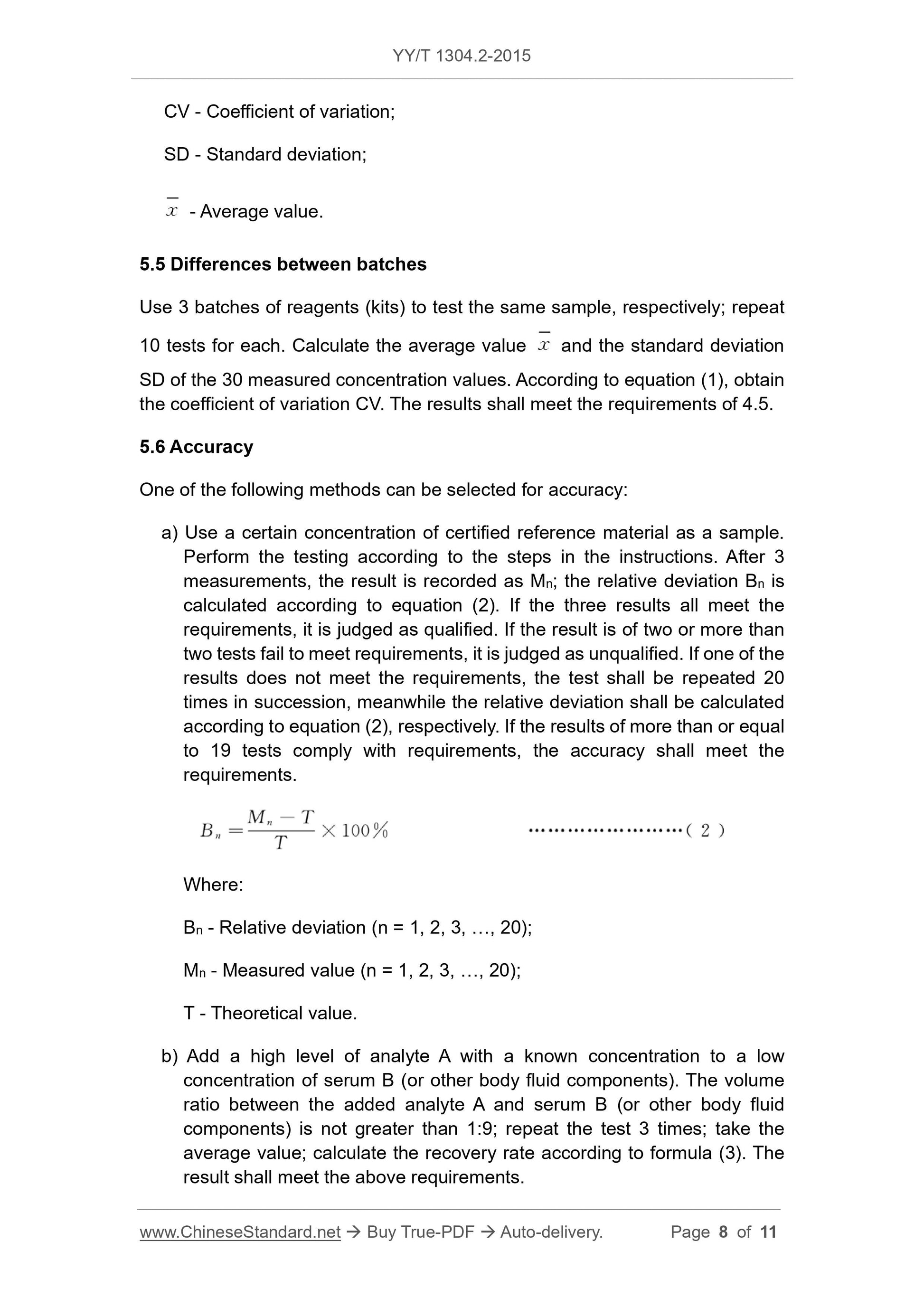

SD, according to equation (1), the coefficient of variation CV is obtained, and the result should meet the requirements of 4.4.

CV=

SD

x

×100% (1)

In the formula.

CV --- coefficient of variation;

SD --- standard deviation;

x --- average value.

5.5 Differences between batches

Test the same sample with three batches of reagents (kits), repeat 10 times each, and calculate the average value of the results of the 30 concentration measurements. x

And the standard deviation SD, according to equation (1), the coefficient of variation CV is obtained, and the result should meet the requirements of 4.5.

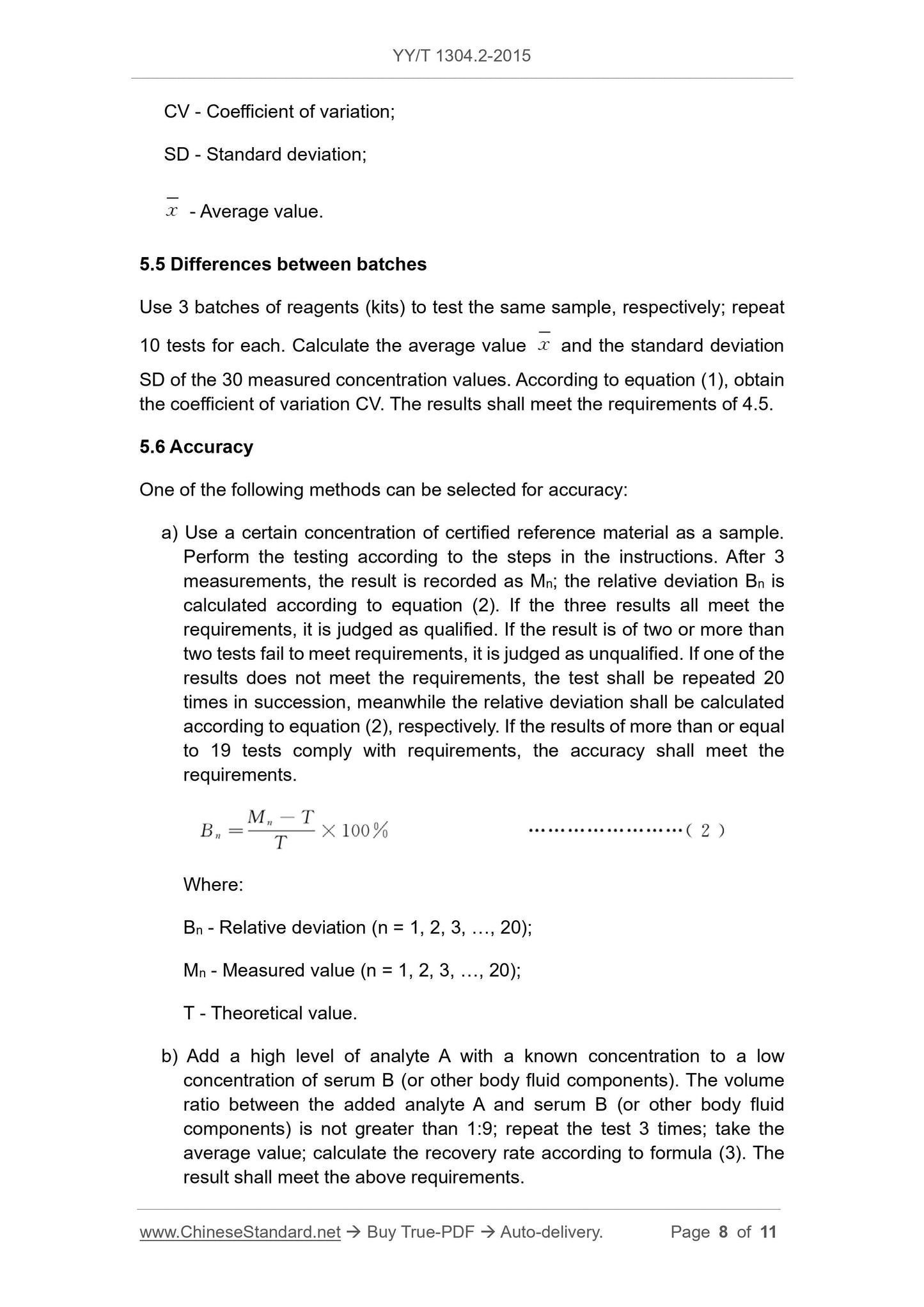

5.6 Accuracy

One of the following methods can be selected for accuracy.

a) Take a certain concentration of certified reference material as a sample, perform the test according to the steps in the instructions, and after measuring 3 times, the result is recorded as

Mn, the relative deviation Bn is calculated according to formula (2), and if all three results meet the requirements, it is judged as qualified. If greater than or equal to

If the result of two times does not match, it is judged as unqualified. If one result does not meet the requirements, the test should be repeated 20 times in a row, and

Calculate the relative deviation according to equation (2) respectively. If the results of 19 or more tests are met, the accuracy meets the requirements.

Bn=

Mn-T

T ×100%

(2)

In the formula.

Bn --- relative deviation (n=1,2,3,,20);

Mn---measured value (n=1,2,3,,20);

T ---Theoretical value.

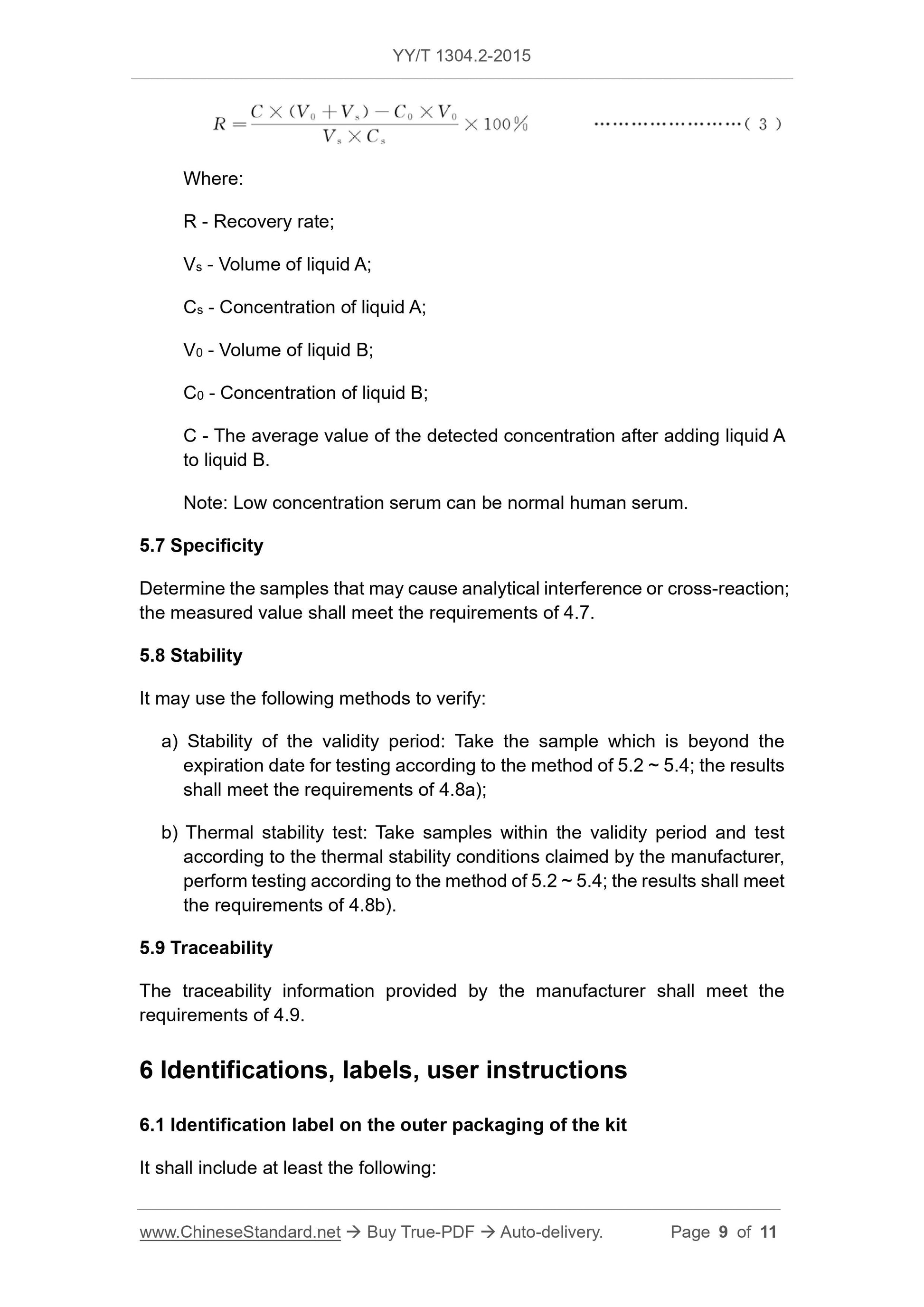

b) Add a high level of test substance A with a known concentration to a low concentration of serum (or other body fluid components) B. The added test substance A and

The volume ratio between serum (or other body fluid components) B is not more than 1.9, and each test is repeated 3 times, and the average value is calculated according to formula (3)

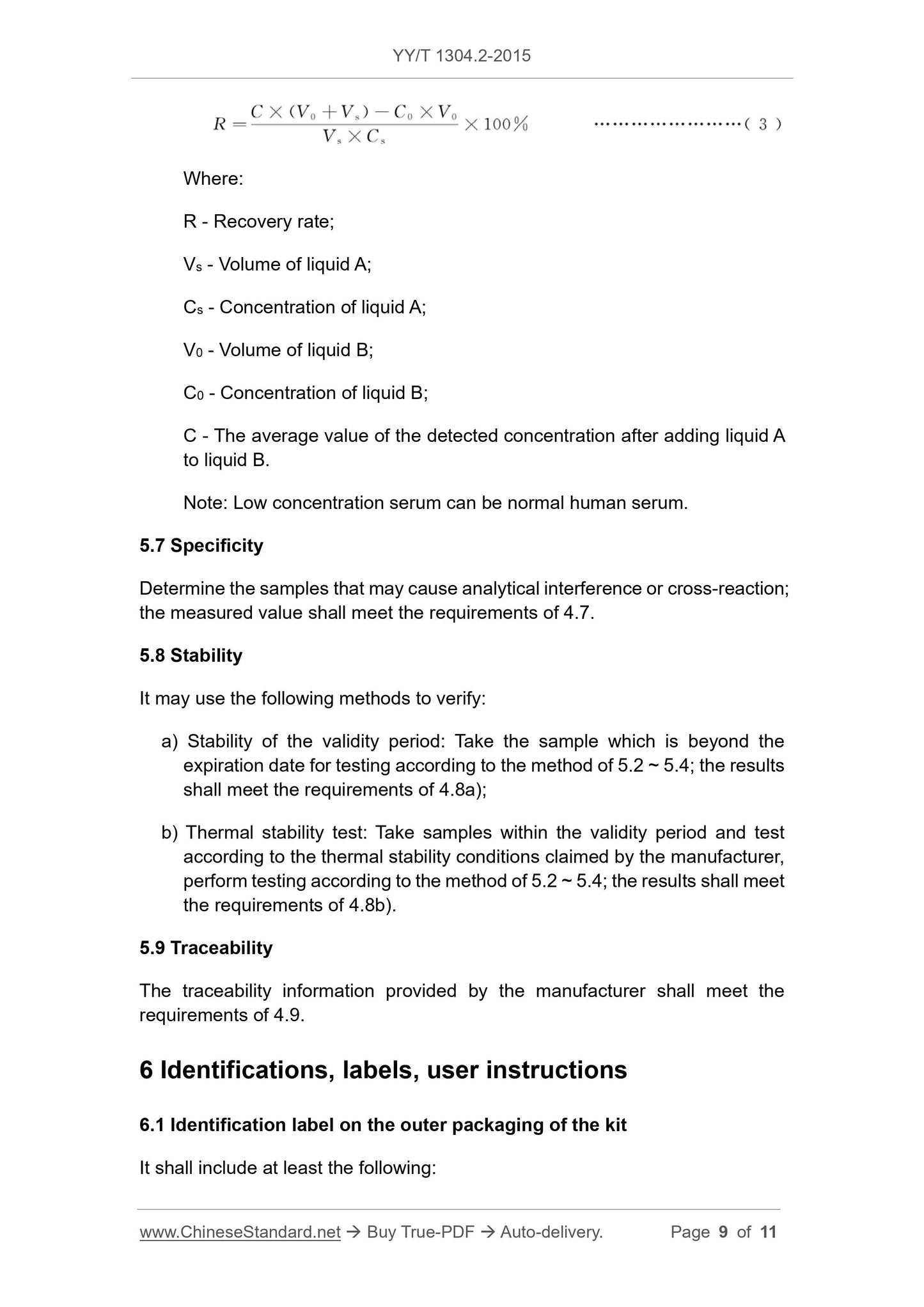

The recovery rate should meet the above requirements.

R=

C×(V0 Vs)-C0×V0

Vs×Cs ×

100% (3)

Trial.

R --- recovery rate;

Vs ---A liquid volume;

Cs ---A liquid concentration;

V0 ---B liquid volume;

C0 ---B liquid average value;

C --- The average value of the detected concentration after adding liquid A to liquid B.

Note. Low concentration serum can be normal human serum.

5.7 Specificity

Determination of samples that may cause analytical interference or cross-reaction, the measured value should meet the requirements of 4.7.

5.8 Stability

You can use the following methods to verify.

a) Stability of the validity period. the samples after the validity period are tested according to the methods of 5.2 to 5.4, and should meet the requirements of 4.8a);

b) Thermal stability test. take samples within the validity period according to the thermal stability conditions claimed by the manufacturer, and follow the methods of 5.2~5.4

The test shall meet the requirements of 4.8b).

5.9 Traceability

The traceability information provided by the manufacturer shall meet the requirements of 4.9.

6 Logos, labels and operating instructions

6.1 Identification label on the outer packaging of the kit

It should include at least the following.

a) The name and address of the manufacturer;

b) Product name and specifications;

c) storage conditions;

d) Production batch number and validity period;

e) Medical device registration certificate number and product standard number.

6.2 Instruction manual of the kit

It should include at least the following.

a) Product name;

b) Packaging specifications;

c) Intended use;

d) Applicable instruments;

e) Inspection principle;

f) The main components;

g) Storage conditions and expiration date;

h) sample requirements;

i) Inspection method;

j) Interpretation of test results;

k) Reference value (reference range);

l) Limitations of inspection methods;

m) Product performance indicators;

n) matters needing attention;

o) Production company name and address;

p) Medical device manufacturing enterprise license number (only applicable to domestic medical device manufacturing enterprises);

q) Medical device registration certificate number;

r) Product standard number;

s) Date of approval and revision of the manual.

7 Packaging, transportation and storage

7.1 Packaging and transportation

Products should be packed and transported in accordance with the prescribed conditions.

7.2 Storage

Products should be stored in accordance with specified conditions.

Get Quotation: Click YY/T 1304.2-2015 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1304.2-2015

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1304.2-2015: Detection system of time-resolved fluoroimmunoassay - Part 2: Quantitative reagent (kit) for time-resolved fluoroimmunoassay

YY/T 1304.2-2015

Detection system of time-resolved fluoroimmunoassay.Part 2.Quantitative reagent (kit) for time-resolved fluoroimmunoassay

ICS 11.100

C44

People's Republic of China Pharmaceutical Industry Standard

Time-resolved fluorescence immunodetection system. Part 2.

Time-resolved fluorescence immunoassay quantitative determination reagent (kit)

2015-03-02 released

2016-01-01 Implementation

Issued by the State Food and Drug Administration

Foreword

YY/T 1304 "Time-Resolved Fluorescence Immunoassay System" is planned to be published in parts. Currently, the following parts are planned to be published.

---Part 1.Semi-automatic time-resolved fluorescence immunoassay analyzer;

---Part 2.Time-resolved fluorescence immunoassay quantitative determination reagent (kit);

---Part 3.Fully automatic time-resolved fluorescence immunoassay analyzer.

This part is part 2 of YY/T 1304.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some content of this document may involve patents. The issuer of this document does not assume responsibility for identifying these patents.

This part is proposed by the State Food and Drug Administration.

This part is under the jurisdiction of the National Medical Clinical Laboratory and the Standardization Technical Committee of In Vitro Diagnostic Systems (SAC/TC136).

The main drafters of this part. Beijing Medical Device Inspection Institute, Suzhou Xinbo Biotechnology Co., Ltd., Guangzhou Dari Antibody Project

Technology Co., Ltd.

The main drafters of this section. Zhang Xinmei, Tu Xianju, Wu Yingsong, Du Haiou.

Time-resolved fluorescence immunodetection system. Part 2.

Time-resolved fluorescence immunoassay quantitative determination reagent (kit)

1 Scope

This part of YY/T 1304 specifies the terms of time-resolved fluorescence immunoassay quantitative determination reagent (kit) (hereinafter referred to as kit)

And definitions, requirements and test methods, labels, labels and instructions for use, packaging, transportation and storage.

This section applies to single-label time-resolved fluorescence immunoassay.

This section does not apply to dual-label and multi-label time-resolved fluorescence immunoassays.

2 Normative references

The following documents are essential for the application of this document. For dated reference documents, only the dated version applies to this article

Pieces. For the cited documents without date, the latest version (including all amendments) applies to this document.

GB/T 21415 In-vitro diagnostic medical device biological sample measurement calibrator and control substance assignment of metrological traceability

Source

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Time-resolved fluoroimmunoassay; TRFIA

Combining time-resolved fluorescence and immunoassay, using rare earth ions and their chelates as tracers, labeling antigens or antibodies to be tested

The substance undergoes a series of immune reactions, and the fluorescence intensity of the final product is determined to obtain the analytical technique for the concentration of the analyte.

4 requirements

4.1 Appearance

Should meet the following requirements.

a) The components of the kit should be complete and complete, with no leakage of liquid;

b) The Chinese packaging label should be clear and free of wear.

4.2 Linear

In the linear interval specified by the manufacturer, the linear correlation coefficient (|r|) of the kit should not be less than 0.9900.

4.3 Blank limit

The manufacturer shall specify the requirements for the blank limits.

4.4 Repeatability

Repeat the test 10 times with samples of at least 2 concentration levels, then the coefficient of variation (CV) of the repeatability results should be consistent with.

CV< 10.0%.

Note. The concentration level of the sample should be close to the product's critical value or medically determined level.

4.5 Difference between batches

To test the same sample with three batch kits, the coefficient of variation (CV) between batches of the three batch kits should meet.

CV< 15.0%.

Note. The concentration level of the sample should be close to the product's critical value or medically determined level.

4.6 Accuracy

The accuracy should meet one of the following conditions.

a) A certain concentration of certified reference material (or other recognized reference material) is tested as a sample, and the relative measurement results

The deviation should be within ±10%;

b) Add corresponding substances of known concentration to blood matrix or other body fluid components, the recovery rate should be in the range of 85%~115%

Inside.

Note 1.The concentration level of the certified reference substance should be close to the product's critical value or medically determined level.

Note 2.When there is a certified reference substance (including national reference substance or international reference substance) in the test substance, a) is used for testing.

Note 3.When there is no certified reference substance (including national reference substance or international reference substance) in the test substance, b) is used for testing.

4.7 Specificity

Specific requirements should be specified.

4.8 Stability

The following methods can be selected for detection.

a) Expiration date stability. The manufacturer should specify the expiration date of the kit. Take a batch of kits to be tested within a certain time after the expiration date

4.2~4.4, should meet the corresponding requirements.

b) Thermal stability. After placing a batch of kits within the validity period for 7 days at 37℃, the test is 4.2~4.4, which should meet the phase

by request.

Note 1.According to product characteristics, any combination of a) and b) methods can be selected, but the selected method should be able to verify the stability of the product to ensure that the product is within the validity period

Can meet the corresponding requirements.

Note 2.In general, when the validity period of the kit is specified to be 12 months, it is advisable to select a kit with an expiration date not exceeding 1 month for stability testing; when specified

When the validity period of the kit is 6 months, it is advisable to select products whose expiration date does not exceed half a month for stability testing, and so on. But you can also use the system

The expiration date verified in the stability report provided by the manufacturer.

Note 3.Thermal stability can not be used to derive the expiration date of the kit, unless it is based on the derivation formula established based on a large number of stability study data.

4.9 Traceability

The manufacturer should provide the source, evaluation process and inaccurate measurement of the standard kit used in accordance with GB/T 21415 and relevant regulations

Scale and other content.

5 Test method

5.1 Appearance

Visual inspection should meet the requirements of 4.1.

5.2 Linear

Dilute the high-value samples close to the upper limit of the linear interval to at least 5 concentrations in a certain ratio, and the low-value concentration samples must be close to linear

The lower limit of the interval. Operate according to the instructions of the reagent (kit), repeat the test for each concentration sample twice, calculate the average value, and average the results

The value and the dilution ratio are linearly fitted by the least square method, and the linear correlation coefficient |r| is calculated, which should meet the requirements of 4.2.

5.3 Blank limit

Use zero concentration calibrator or sample diluent as the sample, repeat the measurement 20 times, calculate the average value (M) of 20 fluorescence measurement results and

Standard deviation (SD), calculate the fluorescence value of M 2SD, recorded as LOB, according to the calibration curve or the concentration of the zero concentration calibrator and the adjacent calibrator

The two-point regression fitting of the degree-fluorescence value results in a linear equation, and the LOB value is brought into the above equation to find the corresponding concentration value, which is the blank

The results should meet the requirements of 4.3.

5.4 Repeatability

Repeat the test 10 times with samples of at least 2 concentration levels to calculate the average value and standard deviation of the 10 concentration measurement results

SD, according to equation (1), the coefficient of variation CV is obtained, and the result should meet the requirements of 4.4.

CV=

SD

x

×100% (1)

In the formula.

CV --- coefficient of variation;

SD --- standard deviation;

x --- average value.

5.5 Differences between batches

Test the same sample with three batches of reagents (kits), repeat 10 times each, and calculate the average value of the results of the 30 concentration measurements. x

And the standard deviation SD, according to equation (1), the coefficient of variation CV is obtained, and the result should meet the requirements of 4.5.

5.6 Accuracy

One of the following methods can be selected for accuracy.

a) Take a certain concentration of certified reference material as a sample, perform the test according to the steps in the instructions, and after measuring 3 times, the result is recorded as

Mn, the relative deviation Bn is calculated according to formula (2), and if all three results meet the requirements, it is judged as qualified. If greater than or equal to

If the result of two times does not match, it is judged as unqualified. If one result does not meet the requirements, the test should be repeated 20 times in a row, and

Calculate the relative deviation according to equation (2) respectively. If the results of 19 or more tests are met, the accuracy meets the requirements.

Bn=

Mn-T

T ×100%

(2)

In the formula.

Bn --- relative deviation (n=1,2,3,,20);

Mn---measured value (n=1,2,3,,20);

T ---Theoretical value.

b) Add a high level of test substance A with a known concentration to a low concentration of serum (or other body fluid components) B. The added test substance A and

The volume ratio between serum (or other body fluid components) B is not more than 1.9, and each test is repeated 3 times, and the average value is calculated according to formula (3)

The recovery rate should meet the above requirements.

R=

C×(V0 Vs)-C0×V0

Vs×Cs ×

100% (3)

Trial.

R --- recovery rate;

Vs ---A liquid volume;

Cs ---A liquid concentration;

V0 ---B liquid volume;

C0 ---B liquid average value;

C --- The average value of the detected concentration after adding liquid A to liquid B.

Note. Low concentration serum can be normal human serum.

5.7 Specificity

Determination of samples that may cause analytical interference or cross-reaction, the measured value should meet the requirements of 4.7.

5.8 Stability

You can use the following methods to verify.

a) Stability of the validity period. the samples after the validity period are tested according to the methods of 5.2 to 5.4, and should meet the requirements of 4.8a);

b) Thermal stability test. take samples within the validity period according to the thermal stability conditions claimed by the manufacturer, and follow the methods of 5.2~5.4

The test shall meet the requirements of 4.8b).

5.9 Traceability

The traceability information provided by the manufacturer shall meet the requirements of 4.9.

6 Logos, labels and operating instructions

6.1 Identification label on the outer packaging of the kit

It should include at least the following.

a) The name and address of the manufacturer;

b) Product name and specifications;

c) storage conditions;

d) Production batch number and validity period;

e) Medical device registration certificate number and product standard number.

6.2 Instruction manual of the kit

It should include at least the following.

a) Product name;

b) Packaging specifications;

c) Intended use;

d) Applicable instruments;

e) Inspection principle;

f) The main components;

g) Storage conditions and expiration date;

h) sample requirements;

i) Inspection method;

j) Interpretation of test results;

k) Reference value (reference range);

l) Limitations of inspection methods;

m) Product performance indicators;

n) matters needing attention;

o) Production company name and address;

p) Medical device manufacturing enterprise license number (only applicable to domestic medical device manufacturing enterprises);

q) Medical device registration certificate number;

r) Product standard number;

s) Date of approval and revision of the manual.

7 Packaging, transportation and storage

7.1 Packaging and transportation

Products should be packed and transported in accordance with the prescribed conditions.

7.2 Storage

Products should be stored in accordance with specified conditions.

Share