1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1511-2017 English PDF (YYT1511-2017)

YY/T 1511-2017 English PDF (YYT1511-2017)

Regular price

$140.00 USD

Regular price

Sale price

$140.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 1511-2017 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1511-2017

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1511-2017: Collagen Sponge

YY/T 1511-2017

Collagen sponge

ICS 11.120.20

C48

People's Republic of China Pharmaceutical Industry Standard

Collagen sponge

Colagensponge

Published by.2017-05-02

2018-04-01 implementation

State Food and Drug Administration issued

Foreword

This standard is written in accordance with the rules given in GB/T 1.1-2009.

Please note that some of the contents of this document may involve patents. Publication of this document

The organization is not responsible for identifying these patents.

This standard was proposed by the State Food and Drug Administration.

This standard is under the jurisdiction of Jinan Medical Device Quality Supervision and Inspection Center of the State Food and Drug Administration.

This standard is mainly drafted by. Shanghai Qisheng Biological Preparation Co., Ltd., Shandong Province Medical Device Product Quality Inspection Center.

Participated in the drafting of this standard. Wuxi Beidi Biological Engineering Co., Ltd., Beijing Korode Biological Products Technology Development Co., Ltd., Shaoxing

Zhende Medical Dressing Co., Ltd.

The main drafters of this standard. Jiang Lixia, Liu Lili, Wei Changzheng, Huang Chao, Ren Weiye, Li Kang, Zhang Rui.

introduction

Collagen sponge raw materials are mainly from animal tissues, used for surgical wound filling, hemostasis, and wound healing.

Desorption.

The YY/T 0771 series of standards gives requirements for risk control of animal-derived medical devices.

Collagen sponge

1 Scope

This standard specifies the performance requirements and test methods for collagen sponges.

This standard applies to sterile collagen sponges.

This standard does not apply to sponges prepared with genetically engineered collagen and collagen sponges containing other materials.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article.

Pieces. For undated references, the latest edition (including all amendments) applies to this document.

GB/T 6682 Analytical laboratory water specifications and test methods

GB/T 16886.1 Biological evaluation of medical devices - Part 1. Evaluation and testing in the process of risk management

YY/T 0466.1 Medical devices for use in medical devices - Labels, markings and information provided - Part 1 . General requirements

YY/T 0615.1 Requirements for "sterile" medical devices - Part 1 . Requirements for terminally sterilized medical devices

The Pharmacopoeia of the People's Republic of China (2010 Edition)

ISO 11607-1.2006 Packaging of terminally sterilized medical devices - Part 1 . Materials, sterile barrier systems, packaging systems

1) (PackagingforterminalysterilizedmedicaldevicesPart 1.Materials,sterilebarriersystemsand

Packagingsystems)

1) The ISO standard corresponding to ISO 11607-1 is GB 19633. The latest version has been submitted for approval. Please pay attention to the standard release.

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Collagen sponge colagensponge

Collagen extracted from animal tissue, purified, cross-linked (if any), freeze-dried, sterilized, etc.

dressing.

4 requirements

4.1 traits

Visually, the collagen sponge should be a white or light yellow, loose sponge.

4.2 Loss on drying

When tested in accordance with 6.2, the mass loss of the sample shall not exceed 15.0%.

4.3 Liquid absorption

When tested in accordance with 6.3, the sample should absorb no less than 20 times its own weight.

4.4 pH

When tested in accordance with 6.4, the pH should be 4.0 to 7.0.

4.5 Sulphate ash

When tested in accordance with 6.5, the sulphated ash should be no more than 2.0%.

4.6 Heavy metals

When tested in accordance with 6.6, the heavy metal should be no more than 10 mg/kg.

Note. Heavy metal elements may be introduced during the production process of collagen sponge. For example, 316L stainless steel reactor may release elements such as chromium and iron. manufacturer

Risk analysis and possible control of heavy metal elements that may be introduced are required.

4.7 Protein content

When testing according to Appendix A, the protein content of the collagen sponge should be not less than 90% according to the dry product.

4.8 Hydroxyproline content

When tested according to Appendix B, the hydroxyproline content in the collagen sponge should be no less than 9% of the total protein content.

4.9 Tensile properties

When tested according to 6.7, the 1 cm wide collagen strip was able to withstand 0.5 N tensile force and did not break for 1 min.

4.10 Residual agent residue

Manufacturers who use chemical reagents for cross-linking should establish crosslinker residue limits and test methods.

4.11 Digestibility

The manufacturer can test according to 6.8 and evaluate the in vitro degradation of the product with the average digestion time.

4.12 Sterile

Collagen sponges should be supplied sterile and meet the requirements of YY/T 0615.1.

5 Biocompatibility

Biological evaluation of collagen sponges in accordance with GB/T 16886.1, the results should indicate no unacceptable biology

harm.

6 Test methods

6.1 General

All tests should be performed in the final form of the material.

Unless otherwise specified, the reagents used shall be of analytical grade and the test water shall meet the requirements for secondary water as specified in GB/T 6682.

6.2 Dry weight loss test

Take about 0.5g of the sample and test according to the VIIIL dry weight loss determination method of the Second Pharmacopoeia of the People's Republic of China (2010 edition).

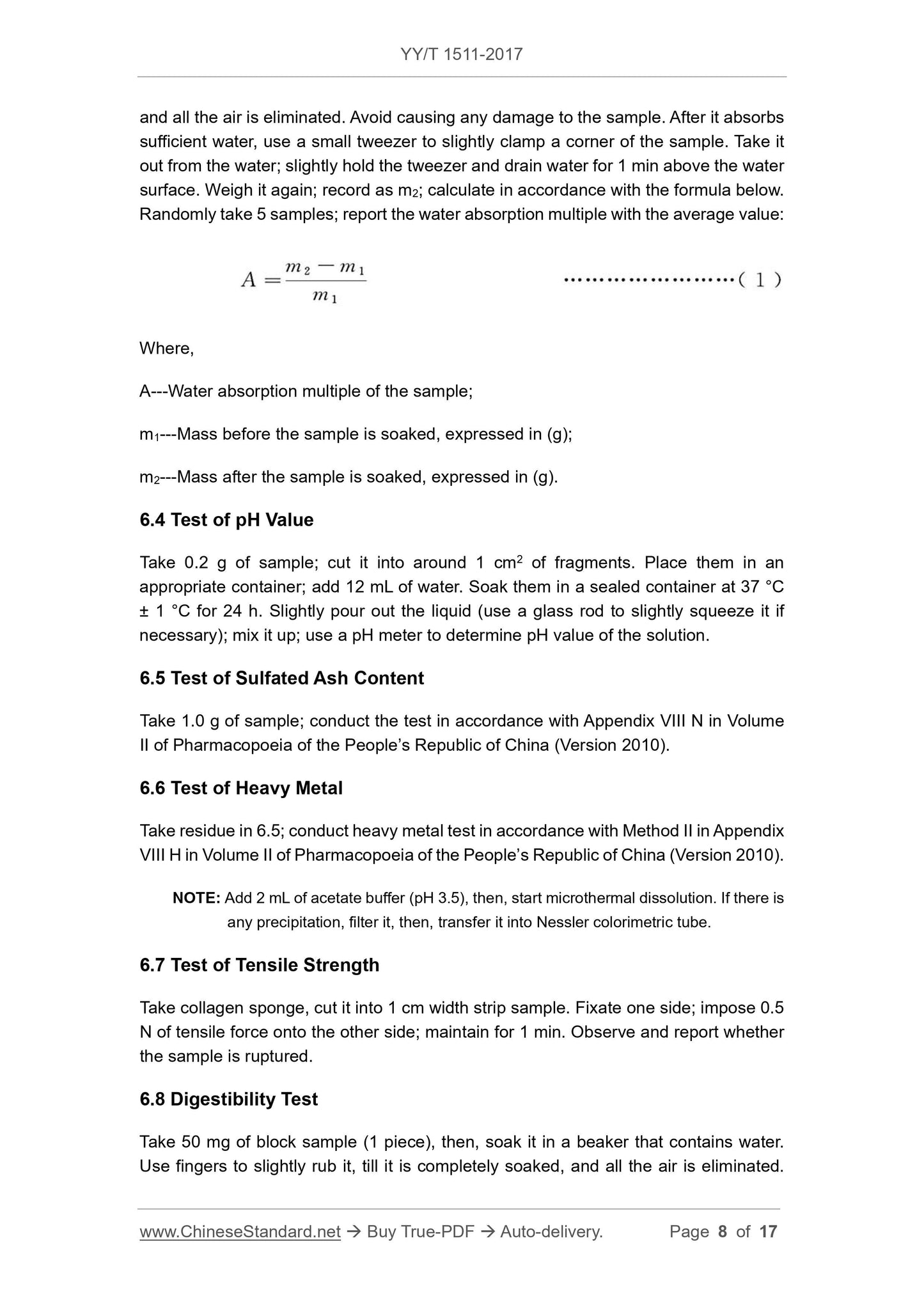

6.3 Liquid absorption test

A sample having a mass of about 20 mg was taken and accurately weighed and recorded as m1. Dip into a beaker containing 20 ° C ± 1 ° C water, use your fingers to straighten

Until it is completely wet, and all the air is removed, be careful not to break it. After the water is absorbed, use a small tweezers to gently clamp a corner and take it from the water.

Out, lightly hold the dice on the water for 1 min, then weigh again, denoted as m2, and calculate according to the following formula. A total of 5 samples were randomly selected and averaged

Report water absorption multiples.

A=

M2-m1

M1

(1)

In the formula.

A --- sample water absorption multiple;

M1 --- the mass of the sample before wetting, in grams (g);

M2 --- The mass of the sample after wetting, in grams (g).

6.4 pH test

0.2g sample, cut into pieces of about 1cm2, put into a suitable container, add 12mL water, in a closed container at 37 °C ± 1 °C

After soaking for 24 hours, pour out the liquid (slightly squeeze with a glass rod if necessary), mix, and measure the pH of the solution with a pH meter.

6.5 Sulphate ash test

Take 1.0g sample and test according to Appendix VIII N of the Second Edition of the Pharmacopoeia of the People's Republic of China (2010 Edition).

6.6 Heavy metal test

Take 6.5 residue and carry out heavy metal test according to the second method of Appendix VIII H of the Second Edition of the Pharmacopoeia of the People's Republic of China (2010 Edition).

Note. Add 2mL of acetate buffer (pH3.5), add it to the Nessler colorimetric tube if it is precipitated, filtered, and then filtered.

6.7 Tensile performance test

The collagen sponge was cut into strips of 1 cm width, one end was fixed, and the other was applied with a pulling force of 0.5 N for 1 min.

Tell if the sample is broken.

6.8 Digestibility test

Take a 50mg block sample, immerse it in a water-filled beaker, gently rub it with your fingers until it is completely wet, and all air is removed.

Do not break. Remove, remove excess water with filter paper, and place the wet sample in a 150 mL stoppered flask.

100mL pre-heated to 37 ° C ± 1 ° C mass fraction of 1% pepsin (vigorous about 3000U/mg) of hydrochloric acid solution [c (HCl) =

0.1 mol/L]. Gently shake at 37 ° C ± 1 ° C, about 150r/min until complete digestion. Repeat the operation twice. Report three times completely

The average of the time.

7 signs

7.1 General

The symbols specified in YY/T 0466.1 can be used to meet the requirements of 7.2 and 7.3.

7.2 single package

a) the name and specification of the contents;

b) sterility and sterilization methods;

c) information such as one-time use, packaging damage, and use;

d) the year of failure;

e) manufacturer's name and address;

f) Production lot number or date.

7.3 Shelf packaging

At least the following information should be included in the shelf packaging.

a) the name and specification of the contents;

b) sterility and sterilization methods;

c) information such as one-time use, packaging damage, and use;

d) the year of failure;

e) manufacturer's name and address;

f) Production lot number or date.

8 packaging

8.1 The manufacturer shall be able to provide proof that the packaging after loading the collagen sponge meets the requirements of ISO 11607-1.2006.

8.2 The design of the single package should be convenient for the contents to be taken aseptically, and the opened trace should be left after the package is opened.

Appendix A

(normative appendix)

Determination of protein content in Kjeldahl method

A.1 Principle

Calculate by measuring the total nitrogen content of the test sample and the non-protein content in the filtrate of the test article for removing protein by tungstic acid precipitation.

The protein content.

A.2 Instruments and equipment

Analytical balance, nitrogen analyzer, Kjeldahl digestive tract, digestion furnace, fume hood equivalent equipment.

A.3 Chemical reagents

a) Concentrated sulfuric acid. analytically pure, with a relative density of 1.84.

b) Digestive agent. Weigh 10 g of copper sulfate (CuSO4·5H2O) and 100 g of potassium sulfate, place them in a mortar, and grind together and mix.

c) 50% sodium hydroxide solution. Take 500g of sodium hydroxide in a volumetric flask, add distilled water to 1000mL, and shake well.

d) Mixed indicator. 5 parts of 0.2% bromocresol green ethanol solution and 2 parts of 0.1% methyl red ethanol solution are mixed and formulated.

e) 2% boric acid absorption solution. weigh 20g of boric acid into a volumetric flask, add distilled water to dissolve it into 1000mL, add d) mixed indicator

10mL, shake well.

f) Sulfuric acid titration solution [c(H2SO4)=0.05mol/L]. Take 3mL of sulfuric acid, slowly inject into appropriate amount of water, cool to room temperature, add water thin

Release to 1000 mL and shake well. Take the reference anhydrous sodium carbonate which is dried to constant weight at 270 ° C ~ 300 ° C about 0.15g, accurately called

Set, add 50mL of water to dissolve, add 10 drops of methyl red-bromocresol chlorine mixed indicator, use this droplet to set the solution to change from green

When it is purple, it is boiled for 2 min, cooled to room temperature, and the titration is continued until the solution changes from green to dark purple. Titration per 1 mL of sulfuric acid

The liquid corresponds to 5.30 mg of anhydrous sodium carbonate. According to the consumption of the liquid and the amount of anhydrous sodium carbonate, the concentration of the liquid is calculated.

Degree, that is.

g) Sulfuric acid titration solution [c(H2SO4)=0.005mol/L]. Precision measurement of sulfuric acid titration solution f) 100mL, placed in a 1000mL volumetric flask

Dilute to the mark with water and shake well.

A.4 operation

A.4.1 Digestion of samples

Accurately weigh about 10mg of sample, (about equivalent to nitrogen content 1.0mg~2.0mg) collagen sponge, recorded as m1, placed in digestion

In the tube, add 0.3g of digestive agent, add 2.0mL of concentrated sulfuric acid, set on the electric heat digestion stove, digest in the fume hood to clear, blue-green, continue to digest

60min. At the same time, do a blank digestion control.

A.4.2 digestion of non-protein nitrogen

Accurately weigh about 80mg of sample, recorded as m2, soaked in 8mL of water for 30min, and filtered. Take 2mL of solution and add 14mL of water.

2mL sodium tungstate solution 2mL, sulfuric acid solution (1.86 → 100) 2mL, shake well, let stand for 30min filtration, accurately measure the filtrate 5mL, set

In the tube, digestion is carried out according to the self-added digestive agent in A.4.1.

A.4.3 Determination

Take 10 mL of 2% boric acid absorption solution into a 150 mL Erlenmeyer flask, and immerse the end of the nitrogen analyzer condensation tube in the boric acid absorption liquid. Will digest

A good sample (m1) is transferred into the fixed nitrogen tube, and the digestive tube is washed 3~4 times with a small amount of distilled water, and the washing liquid is transferred into the fixed nitrogen tube, and then 50% is added.

10 mL of sodium hydroxide was then distilled. The total volume of the liquid to be received is about 35mL~50mL, and the end of the condensation tube is removed from the liquid surface to let the steam

Continue to simmer for about 1 min, rinse the end of the condenser with a small amount of distilled water and stop the distillation. The receiving solution is dropped with 0.005 mol/L sulfuric acid titration solution

The solution was changed from blue-green to gray-purple, and the sulfuric acid titration volume V1 consumed was recorded. Move the digested sample (m2) into the fixed nitrogen tube

The above distillation and titration steps were repeated, and the volume V2 of the sulfuric acid titration liquid consumed was recorded. Move the blank digestion control into the fixed nitrogen tube and repeat

In the above distillation and titration steps, the volume V0 of the sulfuric acid titration liquid consumed was recorded and corrected by a blank test.

A.5 Calculation of results

Calculate the total nitrogen content of the sample as follows.

W1=

(V1-V0)×c×2×14.01

M1×(1-m0)

In the formula.

W1---Total nitrogen content in the sample, %;

V1---Titration sample (m1) consumption of sulfuric acid titration volume, the unit is milliliter (mL);

V0---the volume of sulfuric acid titration solution consumed by blank, in milliliters (mL);

c --- sulfuric acid titration solution concentration in moles per liter (mol/L);

M1---sample quality in milligrams (mg);

M0---sample dry weight loss...

Get Quotation: Click YY/T 1511-2017 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1511-2017

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1511-2017: Collagen Sponge

YY/T 1511-2017

Collagen sponge

ICS 11.120.20

C48

People's Republic of China Pharmaceutical Industry Standard

Collagen sponge

Colagensponge

Published by.2017-05-02

2018-04-01 implementation

State Food and Drug Administration issued

Foreword

This standard is written in accordance with the rules given in GB/T 1.1-2009.

Please note that some of the contents of this document may involve patents. Publication of this document

The organization is not responsible for identifying these patents.

This standard was proposed by the State Food and Drug Administration.

This standard is under the jurisdiction of Jinan Medical Device Quality Supervision and Inspection Center of the State Food and Drug Administration.

This standard is mainly drafted by. Shanghai Qisheng Biological Preparation Co., Ltd., Shandong Province Medical Device Product Quality Inspection Center.

Participated in the drafting of this standard. Wuxi Beidi Biological Engineering Co., Ltd., Beijing Korode Biological Products Technology Development Co., Ltd., Shaoxing

Zhende Medical Dressing Co., Ltd.

The main drafters of this standard. Jiang Lixia, Liu Lili, Wei Changzheng, Huang Chao, Ren Weiye, Li Kang, Zhang Rui.

introduction

Collagen sponge raw materials are mainly from animal tissues, used for surgical wound filling, hemostasis, and wound healing.

Desorption.

The YY/T 0771 series of standards gives requirements for risk control of animal-derived medical devices.

Collagen sponge

1 Scope

This standard specifies the performance requirements and test methods for collagen sponges.

This standard applies to sterile collagen sponges.

This standard does not apply to sponges prepared with genetically engineered collagen and collagen sponges containing other materials.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article.

Pieces. For undated references, the latest edition (including all amendments) applies to this document.

GB/T 6682 Analytical laboratory water specifications and test methods

GB/T 16886.1 Biological evaluation of medical devices - Part 1. Evaluation and testing in the process of risk management

YY/T 0466.1 Medical devices for use in medical devices - Labels, markings and information provided - Part 1 . General requirements

YY/T 0615.1 Requirements for "sterile" medical devices - Part 1 . Requirements for terminally sterilized medical devices

The Pharmacopoeia of the People's Republic of China (2010 Edition)

ISO 11607-1.2006 Packaging of terminally sterilized medical devices - Part 1 . Materials, sterile barrier systems, packaging systems

1) (PackagingforterminalysterilizedmedicaldevicesPart 1.Materials,sterilebarriersystemsand

Packagingsystems)

1) The ISO standard corresponding to ISO 11607-1 is GB 19633. The latest version has been submitted for approval. Please pay attention to the standard release.

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Collagen sponge colagensponge

Collagen extracted from animal tissue, purified, cross-linked (if any), freeze-dried, sterilized, etc.

dressing.

4 requirements

4.1 traits

Visually, the collagen sponge should be a white or light yellow, loose sponge.

4.2 Loss on drying

When tested in accordance with 6.2, the mass loss of the sample shall not exceed 15.0%.

4.3 Liquid absorption

When tested in accordance with 6.3, the sample should absorb no less than 20 times its own weight.

4.4 pH

When tested in accordance with 6.4, the pH should be 4.0 to 7.0.

4.5 Sulphate ash

When tested in accordance with 6.5, the sulphated ash should be no more than 2.0%.

4.6 Heavy metals

When tested in accordance with 6.6, the heavy metal should be no more than 10 mg/kg.

Note. Heavy metal elements may be introduced during the production process of collagen sponge. For example, 316L stainless steel reactor may release elements such as chromium and iron. manufacturer

Risk analysis and possible control of heavy metal elements that may be introduced are required.

4.7 Protein content

When testing according to Appendix A, the protein content of the collagen sponge should be not less than 90% according to the dry product.

4.8 Hydroxyproline content

When tested according to Appendix B, the hydroxyproline content in the collagen sponge should be no less than 9% of the total protein content.

4.9 Tensile properties

When tested according to 6.7, the 1 cm wide collagen strip was able to withstand 0.5 N tensile force and did not break for 1 min.

4.10 Residual agent residue

Manufacturers who use chemical reagents for cross-linking should establish crosslinker residue limits and test methods.

4.11 Digestibility

The manufacturer can test according to 6.8 and evaluate the in vitro degradation of the product with the average digestion time.

4.12 Sterile

Collagen sponges should be supplied sterile and meet the requirements of YY/T 0615.1.

5 Biocompatibility

Biological evaluation of collagen sponges in accordance with GB/T 16886.1, the results should indicate no unacceptable biology

harm.

6 Test methods

6.1 General

All tests should be performed in the final form of the material.

Unless otherwise specified, the reagents used shall be of analytical grade and the test water shall meet the requirements for secondary water as specified in GB/T 6682.

6.2 Dry weight loss test

Take about 0.5g of the sample and test according to the VIIIL dry weight loss determination method of the Second Pharmacopoeia of the People's Republic of China (2010 edition).

6.3 Liquid absorption test

A sample having a mass of about 20 mg was taken and accurately weighed and recorded as m1. Dip into a beaker containing 20 ° C ± 1 ° C water, use your fingers to straighten

Until it is completely wet, and all the air is removed, be careful not to break it. After the water is absorbed, use a small tweezers to gently clamp a corner and take it from the water.

Out, lightly hold the dice on the water for 1 min, then weigh again, denoted as m2, and calculate according to the following formula. A total of 5 samples were randomly selected and averaged

Report water absorption multiples.

A=

M2-m1

M1

(1)

In the formula.

A --- sample water absorption multiple;

M1 --- the mass of the sample before wetting, in grams (g);

M2 --- The mass of the sample after wetting, in grams (g).

6.4 pH test

0.2g sample, cut into pieces of about 1cm2, put into a suitable container, add 12mL water, in a closed container at 37 °C ± 1 °C

After soaking for 24 hours, pour out the liquid (slightly squeeze with a glass rod if necessary), mix, and measure the pH of the solution with a pH meter.

6.5 Sulphate ash test

Take 1.0g sample and test according to Appendix VIII N of the Second Edition of the Pharmacopoeia of the People's Republic of China (2010 Edition).

6.6 Heavy metal test

Take 6.5 residue and carry out heavy metal test according to the second method of Appendix VIII H of the Second Edition of the Pharmacopoeia of the People's Republic of China (2010 Edition).

Note. Add 2mL of acetate buffer (pH3.5), add it to the Nessler colorimetric tube if it is precipitated, filtered, and then filtered.

6.7 Tensile performance test

The collagen sponge was cut into strips of 1 cm width, one end was fixed, and the other was applied with a pulling force of 0.5 N for 1 min.

Tell if the sample is broken.

6.8 Digestibility test

Take a 50mg block sample, immerse it in a water-filled beaker, gently rub it with your fingers until it is completely wet, and all air is removed.

Do not break. Remove, remove excess water with filter paper, and place the wet sample in a 150 mL stoppered flask.

100mL pre-heated to 37 ° C ± 1 ° C mass fraction of 1% pepsin (vigorous about 3000U/mg) of hydrochloric acid solution [c (HCl) =

0.1 mol/L]. Gently shake at 37 ° C ± 1 ° C, about 150r/min until complete digestion. Repeat the operation twice. Report three times completely

The average of the time.

7 signs

7.1 General

The symbols specified in YY/T 0466.1 can be used to meet the requirements of 7.2 and 7.3.

7.2 single package

a) the name and specification of the contents;

b) sterility and sterilization methods;

c) information such as one-time use, packaging damage, and use;

d) the year of failure;

e) manufacturer's name and address;

f) Production lot number or date.

7.3 Shelf packaging

At least the following information should be included in the shelf packaging.

a) the name and specification of the contents;

b) sterility and sterilization methods;

c) information such as one-time use, packaging damage, and use;

d) the year of failure;

e) manufacturer's name and address;

f) Production lot number or date.

8 packaging

8.1 The manufacturer shall be able to provide proof that the packaging after loading the collagen sponge meets the requirements of ISO 11607-1.2006.

8.2 The design of the single package should be convenient for the contents to be taken aseptically, and the opened trace should be left after the package is opened.

Appendix A

(normative appendix)

Determination of protein content in Kjeldahl method

A.1 Principle

Calculate by measuring the total nitrogen content of the test sample and the non-protein content in the filtrate of the test article for removing protein by tungstic acid precipitation.

The protein content.

A.2 Instruments and equipment

Analytical balance, nitrogen analyzer, Kjeldahl digestive tract, digestion furnace, fume hood equivalent equipment.

A.3 Chemical reagents

a) Concentrated sulfuric acid. analytically pure, with a relative density of 1.84.

b) Digestive agent. Weigh 10 g of copper sulfate (CuSO4·5H2O) and 100 g of potassium sulfate, place them in a mortar, and grind together and mix.

c) 50% sodium hydroxide solution. Take 500g of sodium hydroxide in a volumetric flask, add distilled water to 1000mL, and shake well.

d) Mixed indicator. 5 parts of 0.2% bromocresol green ethanol solution and 2 parts of 0.1% methyl red ethanol solution are mixed and formulated.

e) 2% boric acid absorption solution. weigh 20g of boric acid into a volumetric flask, add distilled water to dissolve it into 1000mL, add d) mixed indicator

10mL, shake well.

f) Sulfuric acid titration solution [c(H2SO4)=0.05mol/L]. Take 3mL of sulfuric acid, slowly inject into appropriate amount of water, cool to room temperature, add water thin

Release to 1000 mL and shake well. Take the reference anhydrous sodium carbonate which is dried to constant weight at 270 ° C ~ 300 ° C about 0.15g, accurately called

Set, add 50mL of water to dissolve, add 10 drops of methyl red-bromocresol chlorine mixed indicator, use this droplet to set the solution to change from green

When it is purple, it is boiled for 2 min, cooled to room temperature, and the titration is continued until the solution changes from green to dark purple. Titration per 1 mL of sulfuric acid

The liquid corresponds to 5.30 mg of anhydrous sodium carbonate. According to the consumption of the liquid and the amount of anhydrous sodium carbonate, the concentration of the liquid is calculated.

Degree, that is.

g) Sulfuric acid titration solution [c(H2SO4)=0.005mol/L]. Precision measurement of sulfuric acid titration solution f) 100mL, placed in a 1000mL volumetric flask

Dilute to the mark with water and shake well.

A.4 operation

A.4.1 Digestion of samples

Accurately weigh about 10mg of sample, (about equivalent to nitrogen content 1.0mg~2.0mg) collagen sponge, recorded as m1, placed in digestion

In the tube, add 0.3g of digestive agent, add 2.0mL of concentrated sulfuric acid, set on the electric heat digestion stove, digest in the fume hood to clear, blue-green, continue to digest

60min. At the same time, do a blank digestion control.

A.4.2 digestion of non-protein nitrogen

Accurately weigh about 80mg of sample, recorded as m2, soaked in 8mL of water for 30min, and filtered. Take 2mL of solution and add 14mL of water.

2mL sodium tungstate solution 2mL, sulfuric acid solution (1.86 → 100) 2mL, shake well, let stand for 30min filtration, accurately measure the filtrate 5mL, set

In the tube, digestion is carried out according to the self-added digestive agent in A.4.1.

A.4.3 Determination

Take 10 mL of 2% boric acid absorption solution into a 150 mL Erlenmeyer flask, and immerse the end of the nitrogen analyzer condensation tube in the boric acid absorption liquid. Will digest

A good sample (m1) is transferred into the fixed nitrogen tube, and the digestive tube is washed 3~4 times with a small amount of distilled water, and the washing liquid is transferred into the fixed nitrogen tube, and then 50% is added.

10 mL of sodium hydroxide was then distilled. The total volume of the liquid to be received is about 35mL~50mL, and the end of the condensation tube is removed from the liquid surface to let the steam

Continue to simmer for about 1 min, rinse the end of the condenser with a small amount of distilled water and stop the distillation. The receiving solution is dropped with 0.005 mol/L sulfuric acid titration solution

The solution was changed from blue-green to gray-purple, and the sulfuric acid titration volume V1 consumed was recorded. Move the digested sample (m2) into the fixed nitrogen tube

The above distillation and titration steps were repeated, and the volume V2 of the sulfuric acid titration liquid consumed was recorded. Move the blank digestion control into the fixed nitrogen tube and repeat

In the above distillation and titration steps, the volume V0 of the sulfuric acid titration liquid consumed was recorded and corrected by a blank test.

A.5 Calculation of results

Calculate the total nitrogen content of the sample as follows.

W1=

(V1-V0)×c×2×14.01

M1×(1-m0)

In the formula.

W1---Total nitrogen content in the sample, %;

V1---Titration sample (m1) consumption of sulfuric acid titration volume, the unit is milliliter (mL);

V0---the volume of sulfuric acid titration solution consumed by blank, in milliliters (mL);

c --- sulfuric acid titration solution concentration in moles per liter (mol/L);

M1---sample quality in milligrams (mg);

M0---sample dry weight loss...

Share