1

/

of

7

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1555.1-2017 English PDF (YY/T1555.1-2017)

YY/T 1555.1-2017 English PDF (YY/T1555.1-2017)

Regular price

$110.00 USD

Regular price

Sale price

$110.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 1555.1-2017 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1555.1-2017

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1555.1-2017: Particular requirement of silicone gel filled breast implant—Performance requirement of silicone gel filler—Part 1: Limitation requirement of volatile substances

YY/T 1555.1-2017

Particular requirement of silicone gel filled breast implant-Performance requirement of silicone gel filler-Part 1.Limitation requirement of volatile substances

ICS 11.040.30

C30

People's Republic of China Pharmaceutical Industry Standards

Specific requirements for silicone gel-filled breast implants

Silicon gel filling performance requirements

Part 1.Limit requirements for volatile substances

2017-03-28 released

2018-04-01 implementation

Issued by the State Food and Drug Administration

Table of contents

Foreword Ⅰ

1 Scope 1

2 Terms and definitions 1

3 Samples and equipment 1

4 Test method 2

5 Result calculation 2

6 Limit requirements 2

Reference 3

Specific requirements for silicone gel-filled breast implants

Silicon gel filling performance requirements

Part 1.Limit requirements for volatile substances

1 Scope

This part of YY/T 1555 specifies the testing methods for volatile substances of silicone gel filled breast implants and

Limited requirements.

2 Terms and definitions

The following terms and definitions apply to this document.

2.1

Breast implant

An implant with a shell used to increase breast volume or replace breasts, which can be filled into the shell by the manufacturer or surgeon

Charge objects.

[YY 0647-2008, definition 3.5]

2.2

Volatile substances

Substances that can be vaporized by heating at a temperature of (150±2)℃ for 4h.

2.3

Filler filer

The contents of the implant.

2.4

Silicone gel

A type of low modulus gel material composed of low-degree cross-linked polysiloxane.

3 Samples and equipment

3.1 Sample

Silicone gel fills breast implants.

3.2 Equipment

3.2.1 Constant temperature blast drying oven.

3.2.2 Electronic balance (precision 0.1mg).

3.2.3 Weighing bottle (recommended diameter 60mm).

3.2.4 Dryer.

4 Test method

4.1 Principle

The silicone gel sample is heated at a certain temperature, and the mass loss of the sample after heating is calculated as the percentage of the initial mass of the sample, which is the silica gel

The mass fraction of volatile substances in the glue.

4.2 Test procedure

Take 2g~3g of silicone gel sample and spread it flatly in a constant weight (m0) diameter of about 60mm in a constant temperature blast drying oven at (150±2)℃.

In the weighing bottle, weigh (m1) to the nearest 0.0001g, place it in a constant temperature blast drying oven at (150±2)℃ for 4h, then take it out and place it in a dry

Weigh (m2) after cooling to room temperature in the desiccator. Two samples were tested in parallel, and the results were expressed as the average of the results of the two parallel samples.

Note. The test procedure refers to ASTMF703-07.

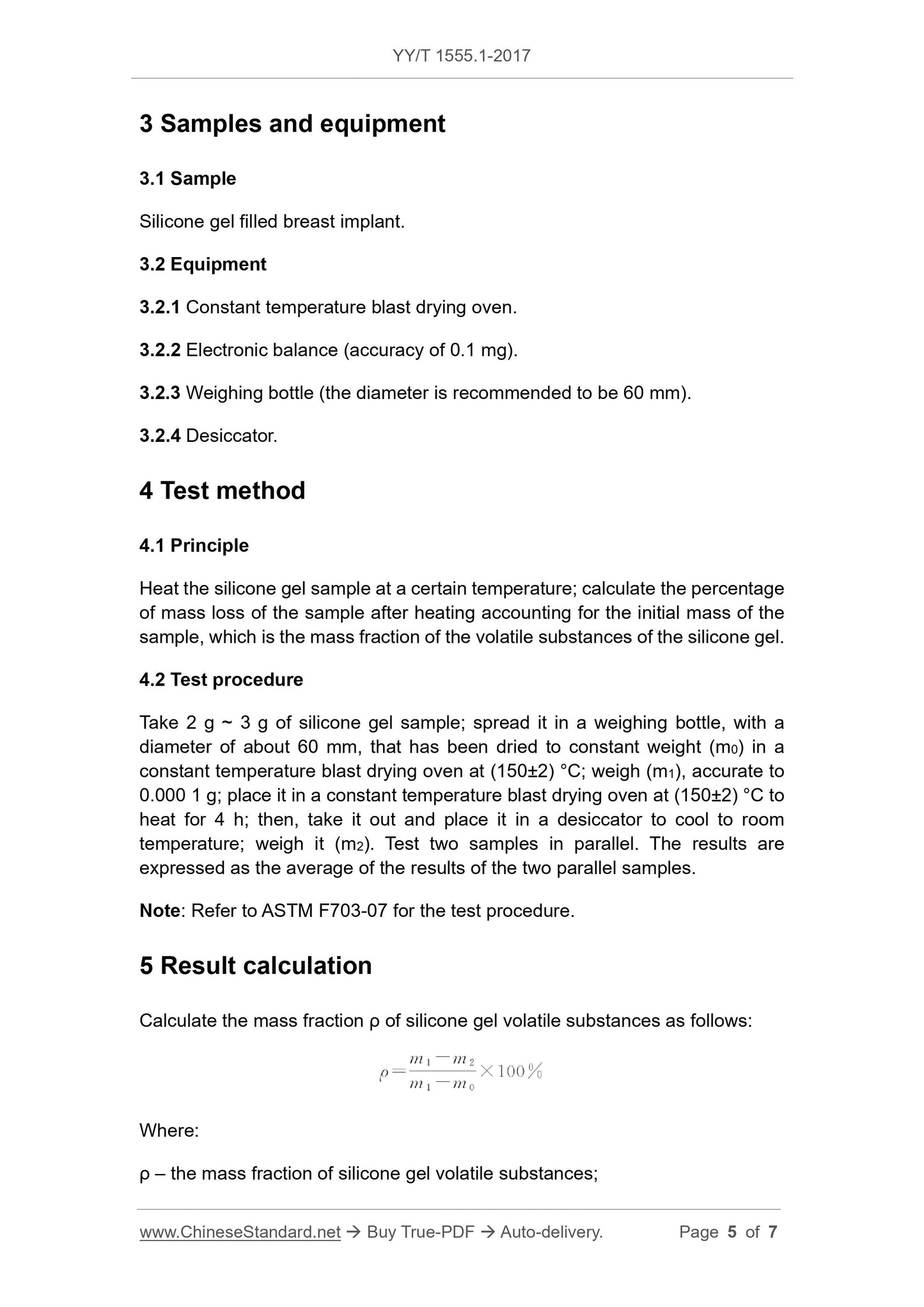

5 Result calculation

The mass fraction ρ of silicone gel volatile substances is calculated as follows.

ρ=

m1-m2

m1-m0

×100%

Where.

ρ --- Mass fraction of volatile substances in silicone gel;

m0 --- the mass of empty glassware, in grams (g);

m1 ---the mass of the empty glassware and the silicone gel sample before heating, in grams (g);

m2 --- The mass of the empty glassware and silicone gel sample after heating, in grams (g).

Note 1.The absolute difference between the measurement results of two parallel samples should not exceed 10% of their arithmetic mean.

Note 2.The test results of two parallel specimens should meet the requirements of Chapter 6.

6 Limit requirements

The total amount of volatile substances in the silicone gel filled breast implants should be ≤0.5% (mass fraction).

Get Quotation: Click YY/T 1555.1-2017 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1555.1-2017

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1555.1-2017: Particular requirement of silicone gel filled breast implant—Performance requirement of silicone gel filler—Part 1: Limitation requirement of volatile substances

YY/T 1555.1-2017

Particular requirement of silicone gel filled breast implant-Performance requirement of silicone gel filler-Part 1.Limitation requirement of volatile substances

ICS 11.040.30

C30

People's Republic of China Pharmaceutical Industry Standards

Specific requirements for silicone gel-filled breast implants

Silicon gel filling performance requirements

Part 1.Limit requirements for volatile substances

2017-03-28 released

2018-04-01 implementation

Issued by the State Food and Drug Administration

Table of contents

Foreword Ⅰ

1 Scope 1

2 Terms and definitions 1

3 Samples and equipment 1

4 Test method 2

5 Result calculation 2

6 Limit requirements 2

Reference 3

Specific requirements for silicone gel-filled breast implants

Silicon gel filling performance requirements

Part 1.Limit requirements for volatile substances

1 Scope

This part of YY/T 1555 specifies the testing methods for volatile substances of silicone gel filled breast implants and

Limited requirements.

2 Terms and definitions

The following terms and definitions apply to this document.

2.1

Breast implant

An implant with a shell used to increase breast volume or replace breasts, which can be filled into the shell by the manufacturer or surgeon

Charge objects.

[YY 0647-2008, definition 3.5]

2.2

Volatile substances

Substances that can be vaporized by heating at a temperature of (150±2)℃ for 4h.

2.3

Filler filer

The contents of the implant.

2.4

Silicone gel

A type of low modulus gel material composed of low-degree cross-linked polysiloxane.

3 Samples and equipment

3.1 Sample

Silicone gel fills breast implants.

3.2 Equipment

3.2.1 Constant temperature blast drying oven.

3.2.2 Electronic balance (precision 0.1mg).

3.2.3 Weighing bottle (recommended diameter 60mm).

3.2.4 Dryer.

4 Test method

4.1 Principle

The silicone gel sample is heated at a certain temperature, and the mass loss of the sample after heating is calculated as the percentage of the initial mass of the sample, which is the silica gel

The mass fraction of volatile substances in the glue.

4.2 Test procedure

Take 2g~3g of silicone gel sample and spread it flatly in a constant weight (m0) diameter of about 60mm in a constant temperature blast drying oven at (150±2)℃.

In the weighing bottle, weigh (m1) to the nearest 0.0001g, place it in a constant temperature blast drying oven at (150±2)℃ for 4h, then take it out and place it in a dry

Weigh (m2) after cooling to room temperature in the desiccator. Two samples were tested in parallel, and the results were expressed as the average of the results of the two parallel samples.

Note. The test procedure refers to ASTMF703-07.

5 Result calculation

The mass fraction ρ of silicone gel volatile substances is calculated as follows.

ρ=

m1-m2

m1-m0

×100%

Where.

ρ --- Mass fraction of volatile substances in silicone gel;

m0 --- the mass of empty glassware, in grams (g);

m1 ---the mass of the empty glassware and the silicone gel sample before heating, in grams (g);

m2 --- The mass of the empty glassware and silicone gel sample after heating, in grams (g).

Note 1.The absolute difference between the measurement results of two parallel samples should not exceed 10% of their arithmetic mean.

Note 2.The test results of two parallel specimens should meet the requirements of Chapter 6.

6 Limit requirements

The total amount of volatile substances in the silicone gel filled breast implants should be ≤0.5% (mass fraction).

Share