1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1556-2017 English PDF (YY/T1556-2017)

YY/T 1556-2017 English PDF (YY/T1556-2017)

Regular price

$170.00 USD

Regular price

Sale price

$170.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 1556-2017 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1556-2017

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1556-2017: Test methods for particle contamination of infusion, transfusion and injection equipment for medical use

YY/T 1556-2017

Test methods for particle contamination of infusion, transfusion and injection equipments for medical use

ICS 11.040.20

C31

People's Republic of China Pharmaceutical Industry Standard

Medical infusion, blood transfusion, injecting equipment

Particle contamination test method

Published on.2017-03-28

2018-04-01 implementation

State Food and Drug Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some of the contents of this document may involve patents. The issuing organization of this document is not responsible for identifying these patents.

This standard was proposed by the State Food and Drug Administration.

This standard is under the jurisdiction of the National Technical Committee for Standardization of Medical Infusion Devices (SAC/TC106).

This standard was drafted. Shandong Medical Device Product Quality Inspection Center, Shandong Xinhua Ande Medical Products Co., Ltd., Guangdong Lily

Medical Technology Co., Ltd.

The main drafters of this standard. Yao Xiujun, Nie Jiaqi, Nie Yucai, Huang Huizhen.

introduction

Infusion, blood transfusion, injection process, some insoluble particles enter the human body, causing harm to patients, this standard is for the infusion device particulate pollution

The test provides a common test method.

There are three kinds of rinsing liquids to choose from in this standard. purified water, isopropyl alcohol and a certain concentration of Tween-80 solution.

The purified water is suitable for the test sample which has not been silicified, and the isopropyl alcohol and Tween-80 solution are suitable for the siliconized test sample. but

It is easy to foam in the Tween-80 solution during shaking or stirring. It is not suitable for the particle counter method. Isopropanol has a large volatility and has a

To be toxic, it is recommended to provide the necessary protection when using it. Product standards are superior to method standards when selecting test methods.

Medical infusion, blood transfusion, injecting equipment

Particle contamination test method

1 Scope

This standard specifies the method for testing the particulate contamination of intravenous infusion, blood transfusion, and injecting.

This standard applies to the inspection of particulate contamination of intravenous infusion devices. Refer to this standard for particle contamination testing methods for other products.

This standard does not apply to syringes for intramuscular injection with a nominal capacity of 1 mL or less.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only the dated version applies to this article.

Pieces. For undated references, the latest edition (including all amendments) applies to this document.

GB/T 6682-2008 Analytical laboratory water specifications and test methods (ISO 3696.1987, MOD)

GB/T 25915.1-2010 Clean rooms and related controlled environments - Part 1. Air cleanliness level (ISO 14644-1.

1999, IDT)

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Flushing fluid forwashing

A liquid that has not been contacted with the test sample and is used to elute the particles contained in the test sample.

3.2

Eluent fluidsafterwashing

After the rinsing liquid is in contact with the test sample, the particles contained in the sample have been eluted into the rinsing liquid.

3.3

Blank test blanktest

Inspection of granules, glass containers, and particles contained in test equipment.

3.4

Pipeline tubings

In vitro use, a hose that directly or indirectly contacts the inner surface with human blood, such as an infusion set, a blood transfusion device, and the like.

3.5

Intravascular catheter type intravascularcatheters

A hose inserted into a blood vessel of a human body, such as a central venous catheter, a contrast catheter, or the like.

3.6

Syringe class injectiondevices

A device consisting at least of a piston and a sheath, such as a hypodermic syringe, a high pressure contrast syringe, and the like.

3.7

Container class containers

A device with a large internal cavity and direct or indirect contact with the human blood on the inner surface, such as a liquid storage bag/bottle, a blood separation cup, and the like.

Note. Containers with tubing, by container.

3.8

Entity class smalentries

Instruments that directly or indirectly contact the outer surface of the product with human blood during use, such as syringe plungers, guide wires, etc.

3.9

Puncture device class piercingdevices

Instruments that provide infusion channels to human tissue, such as intravenous infusion needles, intravenous indwelling needles, and the like.

3.10

Blind/cavity products dielumens

A device with a small internal cavity and direct or indirect contact with the human blood on the inner surface, such as a heparin cap or a three-way valve.

3.11

Unit eluent unitwashingfluid

Eluent prepared from a product according to the prescribed method.

Note. The results of the unit eluent test can independently determine the particle contamination of a product.

3.12

Pooled eluent colectedfluid

The eluate prepared from the plurality of products is collected into a unitary eluate according to a prescribed method.

Note. The pooled eluent cannot make an independent determination of the particulate contamination of a product, and can only make an overall determination of particulate contamination of multiple products.

4 General

4.1 The test shall be carried out under laminar flow purification conditions [in accordance with ISO 5 (100) purification workbench in GB/T 25915.1-2010],

Testers should wear appropriate clean clothes, gloves, test equipment and other required supplies should be clean and free of particles to ensure that the test environment is not

Foreign pollution will be introduced to affect the test results.

4.2 Before the start of the test, the rinse solution was tested in the same manner as the corresponding test eluent for the blank test. Blank test should meet 500mL

The particle contamination index of the rinsing liquid is not more than 9. If the rinsing liquid required for the test is other volume, it should be in accordance with the volume of the rinsing liquid and a multiple of 500mL.

The relationship is converted to its pollution index.

4.3 For each test, the eluents were classified and counted according to Table 1. The pollution index was calculated according to Chapter 12.

4.4 The particle counter used should be calibrated at least once a year.

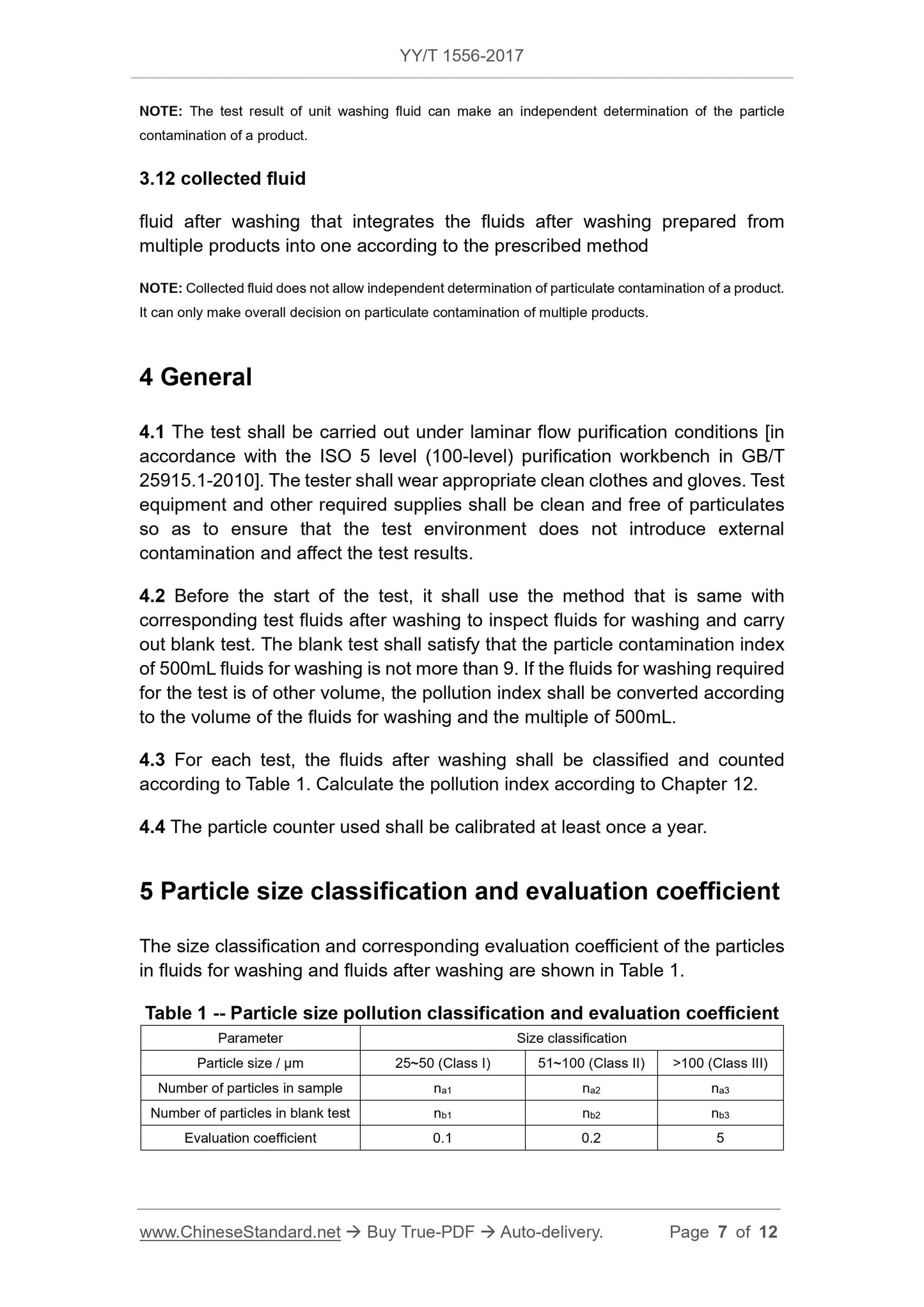

5 particle size classification and evaluation coefficient

The size classification and corresponding evaluation coefficients of the granules in the rinsing liquid and the eluent are shown in Table 1.

Table 1 Classification and evaluation coefficients of particle size pollution

Parameter size classification

Particle size/μm 25~50 (Class I) 51~100 (Class II) >100 (Class III)

The number of particles in the sample is na1 na2 na3

Number of particles in the blank test nb1 nb2 nb3

Evaluation coefficient 0.1 0.2 5

6 Principle

Rinse the sample in the eluent (3.2) by using a suitable rinse solution, rinsing the test piece by the specified method, and using a suitable counting method.

Class and count.

7 Instruments and materials

7.1 Flushing fluid

7.1.1 Rinsing solution A. Purified water, filtered through a membrane having a pore size of not more than 0.22 μm.

7.1.2 Rinsing solution B. Isopropanol, analytically pure, filtered through a membrane not larger than 0.22 μm.

7.1.3 rinsing liquid C. Tween-80 solution, 10L of pure water (in accordance with GB/T 6682-2008 grade 1 or 2) dissolve 3g high on the market

The concentration of polysorbate 80 (Tween-80) was obtained.

7.2 Vacuum filter

The pore size is 0.45 μm.

7.3 Erlenmeyer flask

The volume is 300 mL.

7.4 Ultrasonic cleaner

The frequency is 40 kHz.

7.5 Oscillation equipment

It is moved at a frequency of 300 times/min to 350 times/min on a horizontal circular path having a diameter of 12 mm ± 1 mm.

7.6 Particle Counter

The extinction (light shading or light blocking) principle is employed, and the particles in the eluate can be classified and counted according to the categories defined in Table 1.

7.7 microscope

The magnification is about 50 times, with proper direct illumination from 0 to 10 degrees from the microscope stage.

8 choice of rinse

Purified water (7.1.1) can be selected as the rinsing liquid for products that are not siliconized; isopropyl alcohol should be selected for the siliconized product.

(7.1.2) or Tween-80 solution (7.1.3) as a rinse solution.

Note. Isopropanol is highly volatile and has certain toxicity. It is recommended to provide necessary protection when using it.

9 counting method selection

The eluent prepared by using purified water (7.1.1) and isopropanol (7.1.2) as a rinsing liquid may be selected by a microparticle counting method or a microscopic method;

Use Tween-80 solution (7.1.3) as the eluent prepared by the rinsing solution, which is affected by the easy blistering during the oscillation process (7.6)

The judgment should be based on the microscope.

10 eluent preparation

10.1 Pipeline products

Take 10 test samples in the state of supply, under the static head of 1m, flush the inner cavity with 500mL of washing liquid according to the maximum flow rate.

10 parts each of 500 mL of unit eluent.

10.2 Endovascular catheter products

Take three catheters in supply and insert each catheter tube into an Erlenmeyer flask (7.3), leaving only the catheter holder outside, using 100 mL

The rinsing liquid is divided into three equal portions to flush the lumens of the respective catheters. Cut and discard the catheter adapter and immerse the body part of the catheter in the flask (7.3)

In the liquid. The mixture was shaken on an oscillating device (7.5) for 20 s to collect the eluent.

10.3 Syringe products

10.3.1 For a test syringe with a nominal capacity of less than or equal to 10 mL, take 10 syringes, each of which draws a nominal volume of rinse solution.

The cone joint is sealed and soaked for 5 minutes; the cone is placed vertically downward into the ultrasonic cleaner (7.4) container, so that the water in the washer is submerged to the nominal

Above the volume, but do not submerge the syringe, elute for 2 min; push all the syringe conical joints out of the eluent to the counter's sampling cup

in. If the eluent is less than 100 mL, repeat the above steps for the same 10 syringes, and collect the eluates from each time to obtain at least 100 mL.

The eluents were pooled.

10.3.2 For syringes with a nominal capacity greater than 10 mL and less than or equal to 100 mL, take 5 syringes, each with a nominal capacity of one.

Half of the rinsing solution, pump the piston to the nominal capacity, shake it on the oscillating device (7.5) for 20 s, and collect the eluent from each syringe into one

If the eluent is less than 100 mL, repeat the above steps for the same 5 syringes, and collect the eluates from each time to obtain 100 mL pool.

Eluent.

10.3.3 For the test syringe with a nominal capacity greater than 100mL, take 3 syringes, each pump 100mL rinse solution, move the piston to

At the nominal capacity, the cone was shaken down on an oscillating device (7.5) for 20 s to obtain 3 parts of 100 mL unit eluent.

10.4 Container products

Take 3 containers in the state of supply, fill the filling line with the nominal capacity of the flushing liquid, close the container, and wash it with an ultrasonic cleaner.

After 2 min off, the eluate was pooled into a sampling cup to obtain 3 parts of the eluate of the nominal volume of the test sample.

10.5 Small entity products

Take 10 products to be tested, place them in an Erlenmeyer flask (7.3), add 100 mL of rinse solution, and seal with aluminum foil (or other suitable material).

Cover the top of the conical flask with the bottle cap and shake it in an oscillating device (7.5) for 20 s to obtain 100 mL of the eluent.

10.6 Puncture equipment products

Take 5 test samples, and under the static head of 1m, let the rinse liquid flow through each of the 5 test samples, 100mL each, and collect 500mL of sinks.

Collect the eluent.

10.7 Small blind/cavity products

Take 10 test products in the state of use, under the static head of 1m, flush the inner cavity with 50mL of washing liquid according to the maximum flow rate.

500 mL pooled eluate.

11 particle counting method

11.1 Particle Counter Method

The number of particles in the eluate was measured by a particle counter, and stirred on a particle counter (7.6) for 1 min, and the sample amount was not less than the unit eluent.

Or pool 50% of the eluent. Calculate the total number of particles in each of the three types of particles based on the total amount of eluent.

11.2 Microscopy

After completion of the sonication or shaking, the resulting unit eluate or collection eluate is quickly filtered through a filter membrane (7.2). Transfer filter to microscopy

Mirror (7.7) to avoid contamination. The particles on the filter are sorted and counted.

12 results indicate

The particle counts classified by the three dimensions of the test piece are used as the analysis results, and then multiplied by their evaluation coefficients, and the results are added to obtain the test.

The number of particles in the piece, Na. Then multiply the number of particles classified by each size in the blank test by the evaluation coefficient, and add the results to each other.

The number of particles in the test, Nb. The calculated particle contamination index in the unit eluent or pooled eluate was used as the contamination index of the test sample.

Na minus Nb gives the pollution index.

Number of particles in the eluent.

Na=na1·0.1 na2·0.2 na3·5

Number of particles in the blank test.

Nb=nb1·0.1 nb2·0.2 nb3·5

pollution index.

N=Na-Nb

13 test report

The test report shall include at least the following.

a) identification of test samples;

b) the number of test samples;

c) the selected rinse solution;

d) particle counting method;

e) the number of types of particles in the blank test;

f) the ...

Get Quotation: Click YY/T 1556-2017 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1556-2017

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1556-2017: Test methods for particle contamination of infusion, transfusion and injection equipment for medical use

YY/T 1556-2017

Test methods for particle contamination of infusion, transfusion and injection equipments for medical use

ICS 11.040.20

C31

People's Republic of China Pharmaceutical Industry Standard

Medical infusion, blood transfusion, injecting equipment

Particle contamination test method

Published on.2017-03-28

2018-04-01 implementation

State Food and Drug Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some of the contents of this document may involve patents. The issuing organization of this document is not responsible for identifying these patents.

This standard was proposed by the State Food and Drug Administration.

This standard is under the jurisdiction of the National Technical Committee for Standardization of Medical Infusion Devices (SAC/TC106).

This standard was drafted. Shandong Medical Device Product Quality Inspection Center, Shandong Xinhua Ande Medical Products Co., Ltd., Guangdong Lily

Medical Technology Co., Ltd.

The main drafters of this standard. Yao Xiujun, Nie Jiaqi, Nie Yucai, Huang Huizhen.

introduction

Infusion, blood transfusion, injection process, some insoluble particles enter the human body, causing harm to patients, this standard is for the infusion device particulate pollution

The test provides a common test method.

There are three kinds of rinsing liquids to choose from in this standard. purified water, isopropyl alcohol and a certain concentration of Tween-80 solution.

The purified water is suitable for the test sample which has not been silicified, and the isopropyl alcohol and Tween-80 solution are suitable for the siliconized test sample. but

It is easy to foam in the Tween-80 solution during shaking or stirring. It is not suitable for the particle counter method. Isopropanol has a large volatility and has a

To be toxic, it is recommended to provide the necessary protection when using it. Product standards are superior to method standards when selecting test methods.

Medical infusion, blood transfusion, injecting equipment

Particle contamination test method

1 Scope

This standard specifies the method for testing the particulate contamination of intravenous infusion, blood transfusion, and injecting.

This standard applies to the inspection of particulate contamination of intravenous infusion devices. Refer to this standard for particle contamination testing methods for other products.

This standard does not apply to syringes for intramuscular injection with a nominal capacity of 1 mL or less.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only the dated version applies to this article.

Pieces. For undated references, the latest edition (including all amendments) applies to this document.

GB/T 6682-2008 Analytical laboratory water specifications and test methods (ISO 3696.1987, MOD)

GB/T 25915.1-2010 Clean rooms and related controlled environments - Part 1. Air cleanliness level (ISO 14644-1.

1999, IDT)

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Flushing fluid forwashing

A liquid that has not been contacted with the test sample and is used to elute the particles contained in the test sample.

3.2

Eluent fluidsafterwashing

After the rinsing liquid is in contact with the test sample, the particles contained in the sample have been eluted into the rinsing liquid.

3.3

Blank test blanktest

Inspection of granules, glass containers, and particles contained in test equipment.

3.4

Pipeline tubings

In vitro use, a hose that directly or indirectly contacts the inner surface with human blood, such as an infusion set, a blood transfusion device, and the like.

3.5

Intravascular catheter type intravascularcatheters

A hose inserted into a blood vessel of a human body, such as a central venous catheter, a contrast catheter, or the like.

3.6

Syringe class injectiondevices

A device consisting at least of a piston and a sheath, such as a hypodermic syringe, a high pressure contrast syringe, and the like.

3.7

Container class containers

A device with a large internal cavity and direct or indirect contact with the human blood on the inner surface, such as a liquid storage bag/bottle, a blood separation cup, and the like.

Note. Containers with tubing, by container.

3.8

Entity class smalentries

Instruments that directly or indirectly contact the outer surface of the product with human blood during use, such as syringe plungers, guide wires, etc.

3.9

Puncture device class piercingdevices

Instruments that provide infusion channels to human tissue, such as intravenous infusion needles, intravenous indwelling needles, and the like.

3.10

Blind/cavity products dielumens

A device with a small internal cavity and direct or indirect contact with the human blood on the inner surface, such as a heparin cap or a three-way valve.

3.11

Unit eluent unitwashingfluid

Eluent prepared from a product according to the prescribed method.

Note. The results of the unit eluent test can independently determine the particle contamination of a product.

3.12

Pooled eluent colectedfluid

The eluate prepared from the plurality of products is collected into a unitary eluate according to a prescribed method.

Note. The pooled eluent cannot make an independent determination of the particulate contamination of a product, and can only make an overall determination of particulate contamination of multiple products.

4 General

4.1 The test shall be carried out under laminar flow purification conditions [in accordance with ISO 5 (100) purification workbench in GB/T 25915.1-2010],

Testers should wear appropriate clean clothes, gloves, test equipment and other required supplies should be clean and free of particles to ensure that the test environment is not

Foreign pollution will be introduced to affect the test results.

4.2 Before the start of the test, the rinse solution was tested in the same manner as the corresponding test eluent for the blank test. Blank test should meet 500mL

The particle contamination index of the rinsing liquid is not more than 9. If the rinsing liquid required for the test is other volume, it should be in accordance with the volume of the rinsing liquid and a multiple of 500mL.

The relationship is converted to its pollution index.

4.3 For each test, the eluents were classified and counted according to Table 1. The pollution index was calculated according to Chapter 12.

4.4 The particle counter used should be calibrated at least once a year.

5 particle size classification and evaluation coefficient

The size classification and corresponding evaluation coefficients of the granules in the rinsing liquid and the eluent are shown in Table 1.

Table 1 Classification and evaluation coefficients of particle size pollution

Parameter size classification

Particle size/μm 25~50 (Class I) 51~100 (Class II) >100 (Class III)

The number of particles in the sample is na1 na2 na3

Number of particles in the blank test nb1 nb2 nb3

Evaluation coefficient 0.1 0.2 5

6 Principle

Rinse the sample in the eluent (3.2) by using a suitable rinse solution, rinsing the test piece by the specified method, and using a suitable counting method.

Class and count.

7 Instruments and materials

7.1 Flushing fluid

7.1.1 Rinsing solution A. Purified water, filtered through a membrane having a pore size of not more than 0.22 μm.

7.1.2 Rinsing solution B. Isopropanol, analytically pure, filtered through a membrane not larger than 0.22 μm.

7.1.3 rinsing liquid C. Tween-80 solution, 10L of pure water (in accordance with GB/T 6682-2008 grade 1 or 2) dissolve 3g high on the market

The concentration of polysorbate 80 (Tween-80) was obtained.

7.2 Vacuum filter

The pore size is 0.45 μm.

7.3 Erlenmeyer flask

The volume is 300 mL.

7.4 Ultrasonic cleaner

The frequency is 40 kHz.

7.5 Oscillation equipment

It is moved at a frequency of 300 times/min to 350 times/min on a horizontal circular path having a diameter of 12 mm ± 1 mm.

7.6 Particle Counter

The extinction (light shading or light blocking) principle is employed, and the particles in the eluate can be classified and counted according to the categories defined in Table 1.

7.7 microscope

The magnification is about 50 times, with proper direct illumination from 0 to 10 degrees from the microscope stage.

8 choice of rinse

Purified water (7.1.1) can be selected as the rinsing liquid for products that are not siliconized; isopropyl alcohol should be selected for the siliconized product.

(7.1.2) or Tween-80 solution (7.1.3) as a rinse solution.

Note. Isopropanol is highly volatile and has certain toxicity. It is recommended to provide necessary protection when using it.

9 counting method selection

The eluent prepared by using purified water (7.1.1) and isopropanol (7.1.2) as a rinsing liquid may be selected by a microparticle counting method or a microscopic method;

Use Tween-80 solution (7.1.3) as the eluent prepared by the rinsing solution, which is affected by the easy blistering during the oscillation process (7.6)

The judgment should be based on the microscope.

10 eluent preparation

10.1 Pipeline products

Take 10 test samples in the state of supply, under the static head of 1m, flush the inner cavity with 500mL of washing liquid according to the maximum flow rate.

10 parts each of 500 mL of unit eluent.

10.2 Endovascular catheter products

Take three catheters in supply and insert each catheter tube into an Erlenmeyer flask (7.3), leaving only the catheter holder outside, using 100 mL

The rinsing liquid is divided into three equal portions to flush the lumens of the respective catheters. Cut and discard the catheter adapter and immerse the body part of the catheter in the flask (7.3)

In the liquid. The mixture was shaken on an oscillating device (7.5) for 20 s to collect the eluent.

10.3 Syringe products

10.3.1 For a test syringe with a nominal capacity of less than or equal to 10 mL, take 10 syringes, each of which draws a nominal volume of rinse solution.

The cone joint is sealed and soaked for 5 minutes; the cone is placed vertically downward into the ultrasonic cleaner (7.4) container, so that the water in the washer is submerged to the nominal

Above the volume, but do not submerge the syringe, elute for 2 min; push all the syringe conical joints out of the eluent to the counter's sampling cup

in. If the eluent is less than 100 mL, repeat the above steps for the same 10 syringes, and collect the eluates from each time to obtain at least 100 mL.

The eluents were pooled.

10.3.2 For syringes with a nominal capacity greater than 10 mL and less than or equal to 100 mL, take 5 syringes, each with a nominal capacity of one.

Half of the rinsing solution, pump the piston to the nominal capacity, shake it on the oscillating device (7.5) for 20 s, and collect the eluent from each syringe into one

If the eluent is less than 100 mL, repeat the above steps for the same 5 syringes, and collect the eluates from each time to obtain 100 mL pool.

Eluent.

10.3.3 For the test syringe with a nominal capacity greater than 100mL, take 3 syringes, each pump 100mL rinse solution, move the piston to

At the nominal capacity, the cone was shaken down on an oscillating device (7.5) for 20 s to obtain 3 parts of 100 mL unit eluent.

10.4 Container products

Take 3 containers in the state of supply, fill the filling line with the nominal capacity of the flushing liquid, close the container, and wash it with an ultrasonic cleaner.

After 2 min off, the eluate was pooled into a sampling cup to obtain 3 parts of the eluate of the nominal volume of the test sample.

10.5 Small entity products

Take 10 products to be tested, place them in an Erlenmeyer flask (7.3), add 100 mL of rinse solution, and seal with aluminum foil (or other suitable material).

Cover the top of the conical flask with the bottle cap and shake it in an oscillating device (7.5) for 20 s to obtain 100 mL of the eluent.

10.6 Puncture equipment products

Take 5 test samples, and under the static head of 1m, let the rinse liquid flow through each of the 5 test samples, 100mL each, and collect 500mL of sinks.

Collect the eluent.

10.7 Small blind/cavity products

Take 10 test products in the state of use, under the static head of 1m, flush the inner cavity with 50mL of washing liquid according to the maximum flow rate.

500 mL pooled eluate.

11 particle counting method

11.1 Particle Counter Method

The number of particles in the eluate was measured by a particle counter, and stirred on a particle counter (7.6) for 1 min, and the sample amount was not less than the unit eluent.

Or pool 50% of the eluent. Calculate the total number of particles in each of the three types of particles based on the total amount of eluent.

11.2 Microscopy

After completion of the sonication or shaking, the resulting unit eluate or collection eluate is quickly filtered through a filter membrane (7.2). Transfer filter to microscopy

Mirror (7.7) to avoid contamination. The particles on the filter are sorted and counted.

12 results indicate

The particle counts classified by the three dimensions of the test piece are used as the analysis results, and then multiplied by their evaluation coefficients, and the results are added to obtain the test.

The number of particles in the piece, Na. Then multiply the number of particles classified by each size in the blank test by the evaluation coefficient, and add the results to each other.

The number of particles in the test, Nb. The calculated particle contamination index in the unit eluent or pooled eluate was used as the contamination index of the test sample.

Na minus Nb gives the pollution index.

Number of particles in the eluent.

Na=na1·0.1 na2·0.2 na3·5

Number of particles in the blank test.

Nb=nb1·0.1 nb2·0.2 nb3·5

pollution index.

N=Na-Nb

13 test report

The test report shall include at least the following.

a) identification of test samples;

b) the number of test samples;

c) the selected rinse solution;

d) particle counting method;

e) the number of types of particles in the blank test;

f) the ...

Share