1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1710-2020 English PDF (YYT1710-2020)

YY/T 1710-2020 English PDF (YYT1710-2020)

Regular price

$245.00 USD

Regular price

Sale price

$245.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY/T 1710-2020

Historical versions: YY/T 1710-2020

Preview True-PDF (Reload/Scroll if blank)

YY/T 1710-2020: Disposable abdominal trocars

YY/T 1710-2020

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.30

C 31

Disposable Abdominal Trocars

ISSUED ON: FEBRUARY 26, 2020

IMPLEMENTED ON: MARCH 1, 2021

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Structure and Materials ... 5

4 Requirements... 7

5 Test Methods ... 10

6 Type Inspection ... 13

7 Labeling and Instruction Manual ... 13

8 Packaging ... 14

Appendix A (normative) Test Method for Air Chocking and Sealing Performance

... 15

Appendix B (informative) Evaluation and Test Method for Puncturing

Performance ... 17

Appendix C (informative) Evaluation and Test Method for Plugging / Unplugging

Performance ... 19

Disposable Abdominal Trocars

1 Scope

This Standard specifies the structure, materials, requirements, test methods, type

inspection, labeling, instruction manual and packaging of disposable abdominal trocars.

This Standard is applicable to disposable abdominal trocars (hereinafter referred to as

trocars) that puncture human abdominal wall tissues during laparoscopic surgery to

establish artificial pneumoperitoneum and operate surgical instrument channel.

2 Normative References

The following documents are indispensable to the application of this document. In

terms of references with a specified date, only versions with a specified date are

applicable to this document. In terms of references without a specified date, the latest

version (including all the modifications) is applicable to this document.

GB/T 1220 Stainless Steel Bars

GB/T 1962.2 Conical Fittings with a 6% (Luer) Taper for Syringes, Needles and Certain

Other Medical Equipment - Part 2: Lock Fittings

GB/T 3280 Cold Rolled Stainless Steel Plate, Sheet and Strip

GB/T 4340.1 Metallic Materials - Vickers Hardness Test - Part 1: Test Method

GB/T 6682-2008 Water for Analytical Laboratory Use - Specification and Test Methods

GB/T 12672 Acrylonitrile-butadiene-styrene (ABS) Resin

GB/T 14233.1-2008 Test Methods for Infusion, Transfusion, Injection Equipment for

Medical Use - Part 1: Chemical Analysis Methods

GB/T 16886 (all parts) Biological Evaluation of Medical Devices

YY/T 0149-2006 Medical Instruments of Stainless Steel - Test Methods of Corrosion

Resistance

YY/T 0466.1 Medical Devices - Symbols to be Used with Medical Device Labels,

Labelling and Information to be Supplied - Part 1: General Requirements

YY/T 0806 Polycarbonate Material for Manufacture of Infusion, Transfusion and

Injection Equipment for Medical Use and Other Medical Devices

4 Requirements

4.1 Appearance

4.1.1 The outer surface of the trocars shall be smooth and clean. There shall be no

defects, such as: burrs, bubbles, impurities, cracks and sintered substances, etc.

4.1.2 The surface of the trocars shall not have visible accumulation of lubricant.

4.1.3 The specification marking on the body of the trocars shall be clearly visible.

4.1.4 If there is a puncturing knife at the tip of the puncturing lever, then, the puncturing

knife shall be flat, and there shall be no rust, sharp edges, burrs or obvious pitting. The

cutting edge of the puncturing knife shall be free of nicks, white edges, wire edges and

cracks, etc.

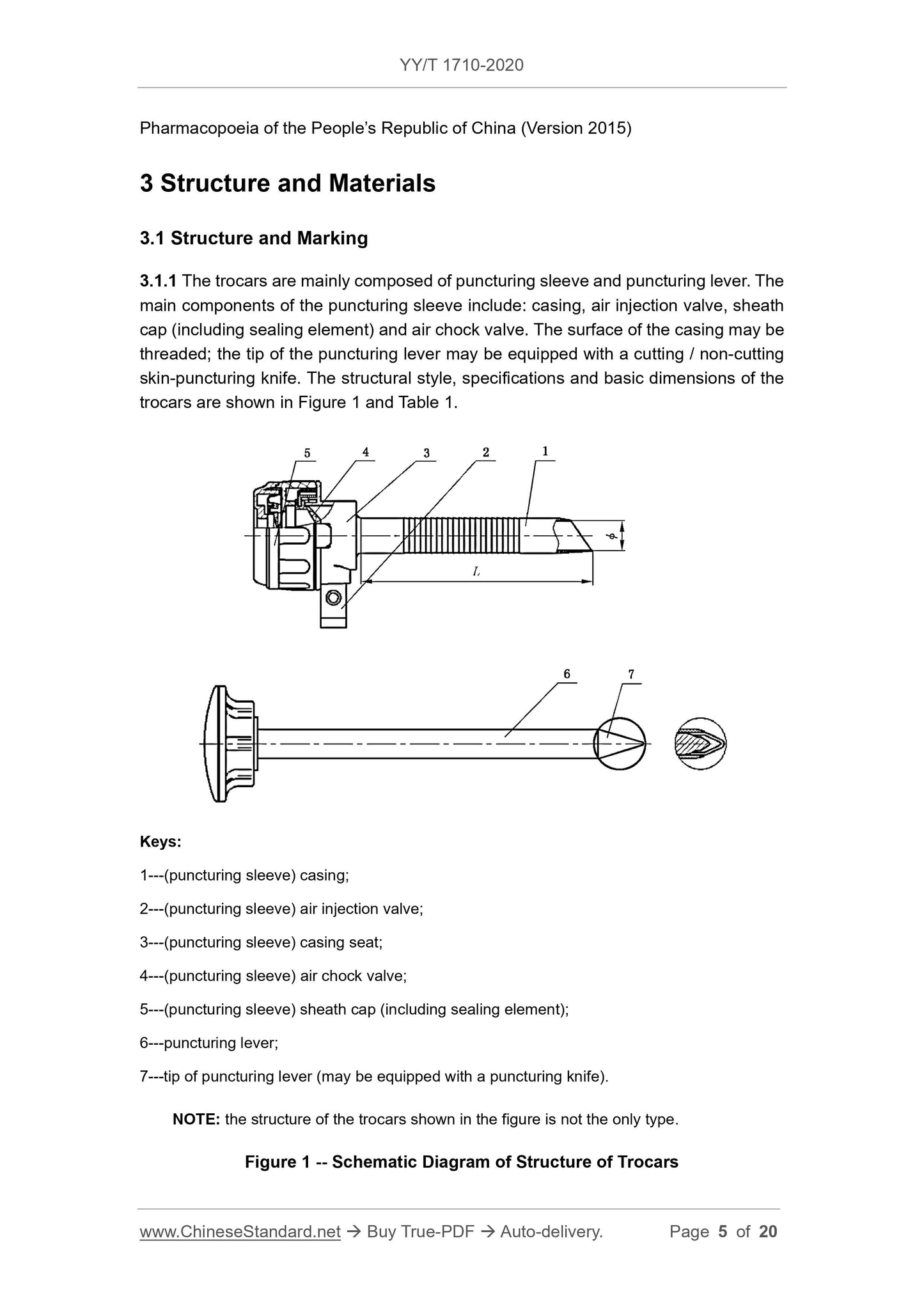

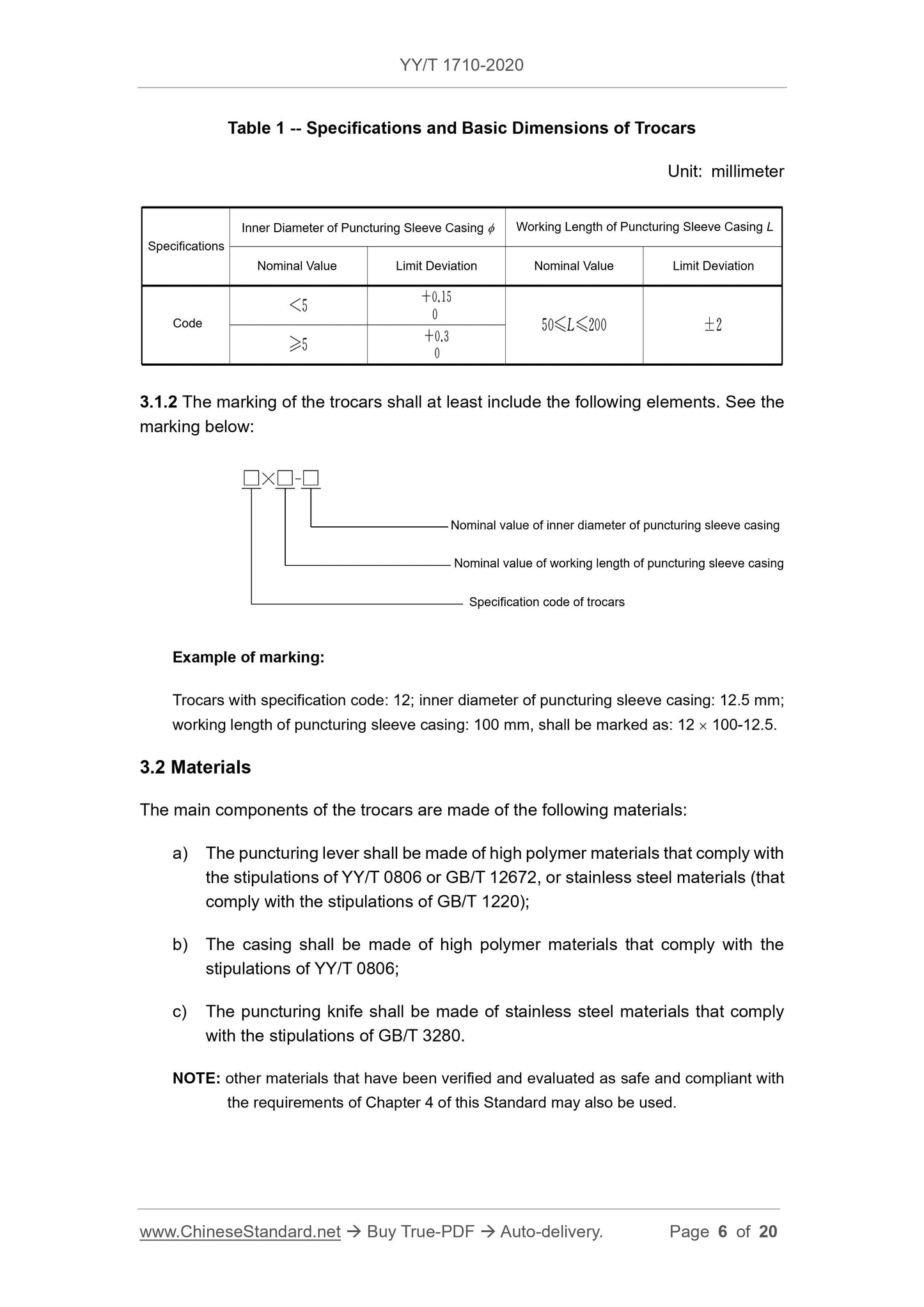

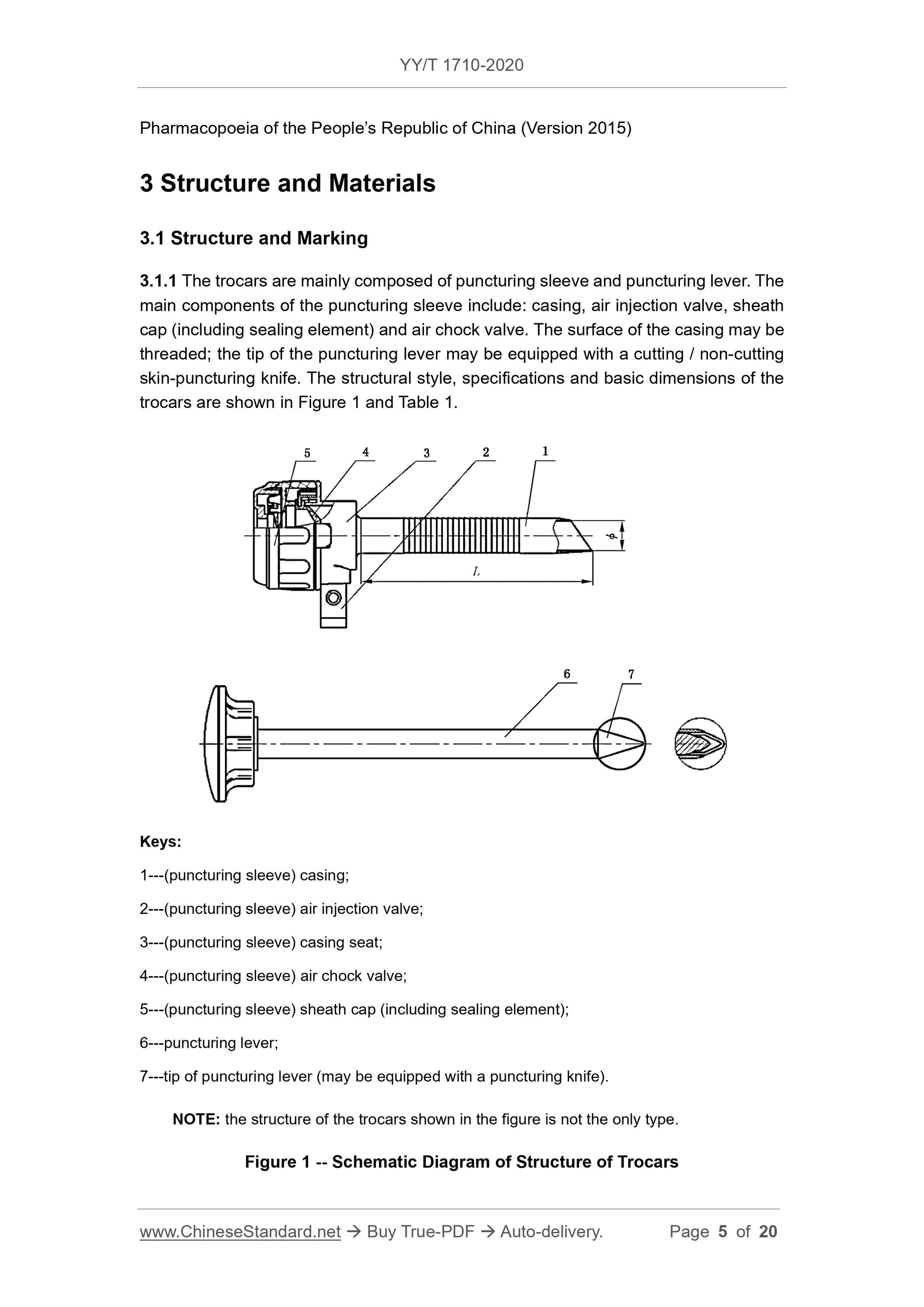

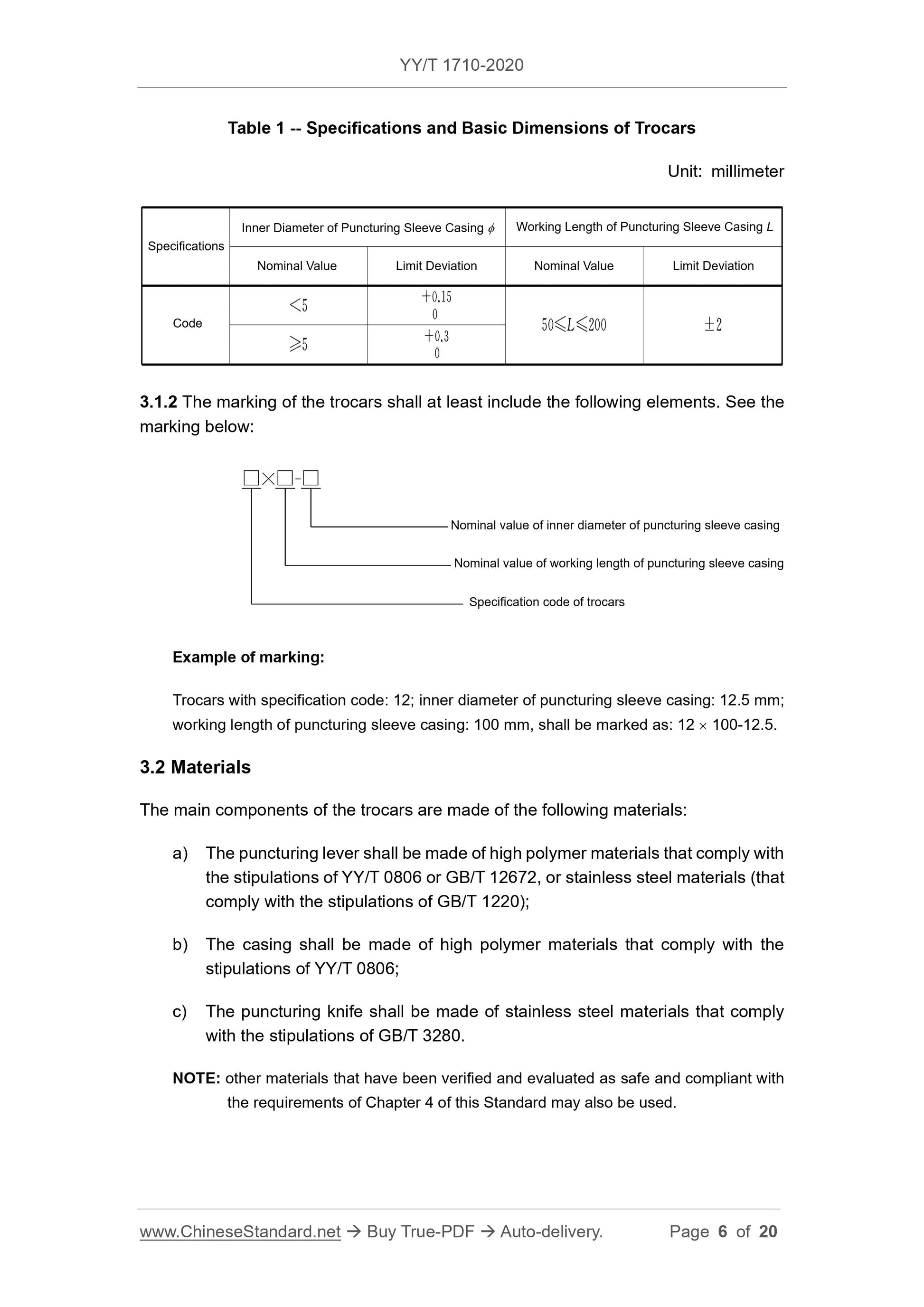

4.2 Dimensions

The inner diameter and working length L of the puncturing sleeve casing of the

trocars shall comply with the stipulations of Table 1.

4.3 Surface Roughness

If there is a puncturing knife at the tip of the puncturing lever, then, the surface

roughness of the cutting edge surface of the puncturing knife Ra ≤ 0.8 μm.

4.4 Hardness

If there is a skin-puncturing knife at the tip of the puncturing lever, then, the puncturing

knife shall receive thermal treatment; its hardness shall be not less than 650HV10.

4.5 Flexibility

4.5.1 The air injection valve of the trocars shall be able to be flexibly opened and closed;

there shall be no obstruction or jamming.

4.5.2 If the sheath cap is detachable, then, its assembly and disassembly shall be

flexible and convenient; there shall be no obstruction or jamming.

4.5.3 If there is a puncturing knife at the tip of the puncturing lever, then, the puncturing

knife shall be able to be flexibly retracted; there shall be no obstruction or jamming.

4.6 Coordination Performance

4.6.1 The puncturing sleeve and the puncturing lever shall properly coordinate with

each other. There shall be no jamming when plugging or unplugging.

shall be not greater than 10 μg/g.

4.14 Dissolved Precipitates of Polymer Materials of Parts in Contact with

Patient

4.14.1 Appearance (turbidity and color)

The dissolution liquid shall be colorless and transparent, and there shall be no visible

foreign objects.

4.14.2 pH

The pH difference between the dissolution liquid and the blank control solution of the

same batch shall be ≤ 2.0.

4.14.3 Heavy metals

The total content of heavy metals that can be dissolved in the dissolution liquid shall

be ≤ 5 μg/mL.

4.14.4 Reducing substance

Compare the dissolution liquid with the same batch of blank control solution of an equal

volume; the difference in the amount of consumed potassium permanganate solution

[c (1/5KMnO4) = 0.01 mol/L] shall be ≤ 2.0 mL.

4.14.5 Evaporation residue

The total dry residue of the dissolution liquid shall be ≤ 2.0 mg.

4.15 Package Marking and Instruction Manual

4.15.1 The single package of the trocars shall have a marking that complies with the

stipulations of 3.1.2.

4.15.2 The instruction manual of the trocars shall include the specifications of devices

that can be used together with the trocars.

4.15.3 If the puncturing knife has the function of skin-puncturing, then, it shall be clearly

described in the instruction manual.

4.16 Biological Evaluation

The trocars shall receive biological evaluation in accordance with the stipulations of

the series standards of GB/T 16886, and there shall be no biocompatibility hazards.

inserted into the fit clearance. It shall comply with the stipulations of 4.6.2.

5.6.3 Imitate the action of use. Conduct visual observation. It shall comply with the

stipulations of 4.6.3.

5.7 Connection Firmness Test

5.7.1 At the junction of the detachable sheath cap and the puncturing sleeve, apply an

axial static tensile force of 50 N to any component consecutively for 10 s. It shall comply

with the stipulations of 4.7.1.

5.7.2 Imitate the action of use; fix the casing; rotate and draw the casing seat. It shall

comply with the stipulations of 4.7.2.

5.7.3 At the junction of the puncturing lever, apply an axial static tensile force of 15 N

to any component consecutively for 10 s. It shall comply with the stipulations of 4.7.3.

5.8 Air Chocking and Sealing Performance Test

The test method is shown in Appendix A. It shall comply with the stipulations of 4.8.

5.9 Connector of Air Injection Valve

The Luer locking connecting of the air injection valve shall be tested in accordance

with GB/T 1962.2. It shall comply with the stipulations of 4.9.

5.10 Puncturing and Plugging / Unplugging Performance

The evaluation and test methods for the puncturing and plugging / unplugging

performance are shown in Appendix B and Appendix C.

NOTE: the method in the appendix is only a test method for the uniform evaluation of the

puncturing performance and plugging / unplugging performance of the trocars.

5.11 Corrosion Resistance

Corrosion resistanc...

Get QUOTATION in 1-minute: Click YY/T 1710-2020

Historical versions: YY/T 1710-2020

Preview True-PDF (Reload/Scroll if blank)

YY/T 1710-2020: Disposable abdominal trocars

YY/T 1710-2020

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.30

C 31

Disposable Abdominal Trocars

ISSUED ON: FEBRUARY 26, 2020

IMPLEMENTED ON: MARCH 1, 2021

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Structure and Materials ... 5

4 Requirements... 7

5 Test Methods ... 10

6 Type Inspection ... 13

7 Labeling and Instruction Manual ... 13

8 Packaging ... 14

Appendix A (normative) Test Method for Air Chocking and Sealing Performance

... 15

Appendix B (informative) Evaluation and Test Method for Puncturing

Performance ... 17

Appendix C (informative) Evaluation and Test Method for Plugging / Unplugging

Performance ... 19

Disposable Abdominal Trocars

1 Scope

This Standard specifies the structure, materials, requirements, test methods, type

inspection, labeling, instruction manual and packaging of disposable abdominal trocars.

This Standard is applicable to disposable abdominal trocars (hereinafter referred to as

trocars) that puncture human abdominal wall tissues during laparoscopic surgery to

establish artificial pneumoperitoneum and operate surgical instrument channel.

2 Normative References

The following documents are indispensable to the application of this document. In

terms of references with a specified date, only versions with a specified date are

applicable to this document. In terms of references without a specified date, the latest

version (including all the modifications) is applicable to this document.

GB/T 1220 Stainless Steel Bars

GB/T 1962.2 Conical Fittings with a 6% (Luer) Taper for Syringes, Needles and Certain

Other Medical Equipment - Part 2: Lock Fittings

GB/T 3280 Cold Rolled Stainless Steel Plate, Sheet and Strip

GB/T 4340.1 Metallic Materials - Vickers Hardness Test - Part 1: Test Method

GB/T 6682-2008 Water for Analytical Laboratory Use - Specification and Test Methods

GB/T 12672 Acrylonitrile-butadiene-styrene (ABS) Resin

GB/T 14233.1-2008 Test Methods for Infusion, Transfusion, Injection Equipment for

Medical Use - Part 1: Chemical Analysis Methods

GB/T 16886 (all parts) Biological Evaluation of Medical Devices

YY/T 0149-2006 Medical Instruments of Stainless Steel - Test Methods of Corrosion

Resistance

YY/T 0466.1 Medical Devices - Symbols to be Used with Medical Device Labels,

Labelling and Information to be Supplied - Part 1: General Requirements

YY/T 0806 Polycarbonate Material for Manufacture of Infusion, Transfusion and

Injection Equipment for Medical Use and Other Medical Devices

4 Requirements

4.1 Appearance

4.1.1 The outer surface of the trocars shall be smooth and clean. There shall be no

defects, such as: burrs, bubbles, impurities, cracks and sintered substances, etc.

4.1.2 The surface of the trocars shall not have visible accumulation of lubricant.

4.1.3 The specification marking on the body of the trocars shall be clearly visible.

4.1.4 If there is a puncturing knife at the tip of the puncturing lever, then, the puncturing

knife shall be flat, and there shall be no rust, sharp edges, burrs or obvious pitting. The

cutting edge of the puncturing knife shall be free of nicks, white edges, wire edges and

cracks, etc.

4.2 Dimensions

The inner diameter and working length L of the puncturing sleeve casing of the

trocars shall comply with the stipulations of Table 1.

4.3 Surface Roughness

If there is a puncturing knife at the tip of the puncturing lever, then, the surface

roughness of the cutting edge surface of the puncturing knife Ra ≤ 0.8 μm.

4.4 Hardness

If there is a skin-puncturing knife at the tip of the puncturing lever, then, the puncturing

knife shall receive thermal treatment; its hardness shall be not less than 650HV10.

4.5 Flexibility

4.5.1 The air injection valve of the trocars shall be able to be flexibly opened and closed;

there shall be no obstruction or jamming.

4.5.2 If the sheath cap is detachable, then, its assembly and disassembly shall be

flexible and convenient; there shall be no obstruction or jamming.

4.5.3 If there is a puncturing knife at the tip of the puncturing lever, then, the puncturing

knife shall be able to be flexibly retracted; there shall be no obstruction or jamming.

4.6 Coordination Performance

4.6.1 The puncturing sleeve and the puncturing lever shall properly coordinate with

each other. There shall be no jamming when plugging or unplugging.

shall be not greater than 10 μg/g.

4.14 Dissolved Precipitates of Polymer Materials of Parts in Contact with

Patient

4.14.1 Appearance (turbidity and color)

The dissolution liquid shall be colorless and transparent, and there shall be no visible

foreign objects.

4.14.2 pH

The pH difference between the dissolution liquid and the blank control solution of the

same batch shall be ≤ 2.0.

4.14.3 Heavy metals

The total content of heavy metals that can be dissolved in the dissolution liquid shall

be ≤ 5 μg/mL.

4.14.4 Reducing substance

Compare the dissolution liquid with the same batch of blank control solution of an equal

volume; the difference in the amount of consumed potassium permanganate solution

[c (1/5KMnO4) = 0.01 mol/L] shall be ≤ 2.0 mL.

4.14.5 Evaporation residue

The total dry residue of the dissolution liquid shall be ≤ 2.0 mg.

4.15 Package Marking and Instruction Manual

4.15.1 The single package of the trocars shall have a marking that complies with the

stipulations of 3.1.2.

4.15.2 The instruction manual of the trocars shall include the specifications of devices

that can be used together with the trocars.

4.15.3 If the puncturing knife has the function of skin-puncturing, then, it shall be clearly

described in the instruction manual.

4.16 Biological Evaluation

The trocars shall receive biological evaluation in accordance with the stipulations of

the series standards of GB/T 16886, and there shall be no biocompatibility hazards.

inserted into the fit clearance. It shall comply with the stipulations of 4.6.2.

5.6.3 Imitate the action of use. Conduct visual observation. It shall comply with the

stipulations of 4.6.3.

5.7 Connection Firmness Test

5.7.1 At the junction of the detachable sheath cap and the puncturing sleeve, apply an

axial static tensile force of 50 N to any component consecutively for 10 s. It shall comply

with the stipulations of 4.7.1.

5.7.2 Imitate the action of use; fix the casing; rotate and draw the casing seat. It shall

comply with the stipulations of 4.7.2.

5.7.3 At the junction of the puncturing lever, apply an axial static tensile force of 15 N

to any component consecutively for 10 s. It shall comply with the stipulations of 4.7.3.

5.8 Air Chocking and Sealing Performance Test

The test method is shown in Appendix A. It shall comply with the stipulations of 4.8.

5.9 Connector of Air Injection Valve

The Luer locking connecting of the air injection valve shall be tested in accordance

with GB/T 1962.2. It shall comply with the stipulations of 4.9.

5.10 Puncturing and Plugging / Unplugging Performance

The evaluation and test methods for the puncturing and plugging / unplugging

performance are shown in Appendix B and Appendix C.

NOTE: the method in the appendix is only a test method for the uniform evaluation of the

puncturing performance and plugging / unplugging performance of the trocars.

5.11 Corrosion Resistance

Corrosion resistanc...

Share