1

/

of

4

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1746-2020 English PDF (YYT1746-2020)

YY/T 1746-2020 English PDF (YYT1746-2020)

Regular price

$125.00 USD

Regular price

Sale price

$125.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click YY/T 1746-2020 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1746-2020

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1746-2020: Absorbable surgical suture -- Test method for breaking strength in vitro hydrolytic degradation

YY/T 1746-2020

Absorbable surgical suture - Test method for breaking strength in vitro hydrolytic degradation

People's Republic of China Pharmaceutical Industry Standards

Released on 2020-09-27

Implementation of 2021-09-01

Issued by the National Medical Products Administration

Preface

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some of the contents of this document may involve patents. Publication of this document

The agency is not responsible for identifying these patents.

This standard was proposed by the State Drug Administration.

This standard is under the jurisdiction of the National Technical Committee for Standardization of Surgical Instruments (SAC/TC94).

Drafting organizations of this standard. Shanghai Pudong Jinhuan Medical Products Co., Ltd., Shanghai Medical Device Testing Institute, Huaiyin Medical Devices Co., Ltd.

Co., Ltd., Jiangsu Medical Device Inspection Institute.

The main drafters of this standard. Wang Fengcai, Zou Fengping, Gao Bai, Hu Yuwen, Zhang Yanqing, Qian Xinyi, Lu Guangheng, Shi Yang, Zhang Lihua.

Test method for breaking strength of absorbable surgical suture after hydrolysis in vitro

1 Scope

This standard specifies the test for retention of breaking strength of absorbable surgical sutures (hereinafter referred to as sutures) in an in vitro simulated environment

method.

This standard applies to absorbable surgical sutures processed from synthetic polymers that are hydrolyzed and degraded.

2 Principle

The retention value of the suture breaking strength is tested in different time periods under the in vitro simulated environment to determine whether the suture is in the critical period of wound healing.

Can maintain sufficient tension to provide reference information.

3 Apparatus and reagents

3.1 Material testing machine

The tensile speed is 300mm/min±10mm/min, and the test gauge length is 130mm±5mm.

Note. If the length of the suture cannot meet the requirements of the specified test gauge length, the test gauge length can be adjusted according to the actual length of the suture, and the corresponding stretching speed is set as

Adjust the test gauge length of 2 times. For example, the adjusted test gauge length is set to 50mm, and the stretching speed is set to 2×50=100mm/min.

3.2 Electric heating constant temperature oscillating water tank or constant temperature oscillator

The temperature is 37°C±1°C, and the oscillation frequency. 60r/min (or other suitable oscillation methods).

The accuracy of the pH meter is not less than 0.02.

3.4 Container

Inert plastic or glass containers (such as bottles, cans and vials) can hold test samples of various materials and the required soaking liquid for the required time.

Each container should be sealed to prevent loss of solution due to evaporation and to prevent microbial contamination.

3.5 Test solution

The test solution is. phosphate buffer (pH 7.4).

Phosphate buffer is a mixture of 18.2% solution a) and 81.8% solution b) (volume fraction). The salt used to prepare the following solution should be

For analytical purity, the water used to dissolve the salt should be sterile double-distilled water.

a) 1/15mol/L potassium dihydrogen phosphate. Dissolve 9.08g potassium dihydrogen phosphate (KH2PO4) per liter of water;

b) 1/15mol/L disodium hydrogen phosphate. Dissolve 11.9 g of disodium hydrogen phosphate dihydrate (Na2HPO4.2H2O) per liter of water.

When prepared in this way, the pH value of the buffer solution is 7.4 ± 0.2.

Note. According to different physiological environments, other buffers with suitable pH values can also be used.

4 Test procedure

4.1 Preparation

Record the characteristics of the suture and set the instrument parameters (3.1 and 3.2).

4.2 Test of initial breaking strength

4.2.1 Take out the suture from the package, tie a simple knot in its middle position, and tighten the knot. Class B sutures with specifications less than 8-0 are not knotted.

4.2.2 Fix both ends of the suture on the fixing clamps of the material testing machine (3.1). The knot is located in the middle of the two fixing clamps so that the suture

Tighten, pull the suture off at the specified speed, and record the maximum force value.

Note 1.The suture can be selected according to the clinical use without knotting.

Note 2.If the suture breaks within 1cm from the fixture, the test is invalid.

4.2.3 Repeat steps 4.2.1 and 4.2.2.

4.2.4 Calculate the average of the 10 recorded force values, which is the initial breaking strength.

4.3 Test of residual breaking strength

4.3.1 Take 10 sutures of the same batch as the initial value of the test (4.2), put them into the container (3.4), make the test solution (3.5) completely immerse the sutures (test)

The ratio of the volume of the test solution to the mass of the suture is at least 10mL. 1g).

Note. If the length of the suture can meet the test conditions, take the same suture to test the initial breaking strength value and the residual breaking strength value.

4.3.2 Place the container in the electric heating constant temperature oscillating water tank (3.2), select the corresponding test period according to the material of the suture and the intended use, and test

During the test cycle, the pH value of the test solution in the container should be monitored as needed. If the pH value of the buffer solution drifts beyond the specified limit value (7.4±0.2), then

Adjust or replace the buffer with 0.1 mol/L sodium hydroxide solution or dilute phosphoric acid to meet the requirements (3.5).

4.3.3 At the end of the test period, take out the suture and remove the water on the surface of the suture until there is no dripping.

Note. The method of removing moisture should not affect the breaking strength of the suture.

4.3.4 Carry out the test according to the steps from 4.2.1 to 4.2.3.

4.3.5 Calculate the average of the 10 recorded force values, which is the residual fracture strength.

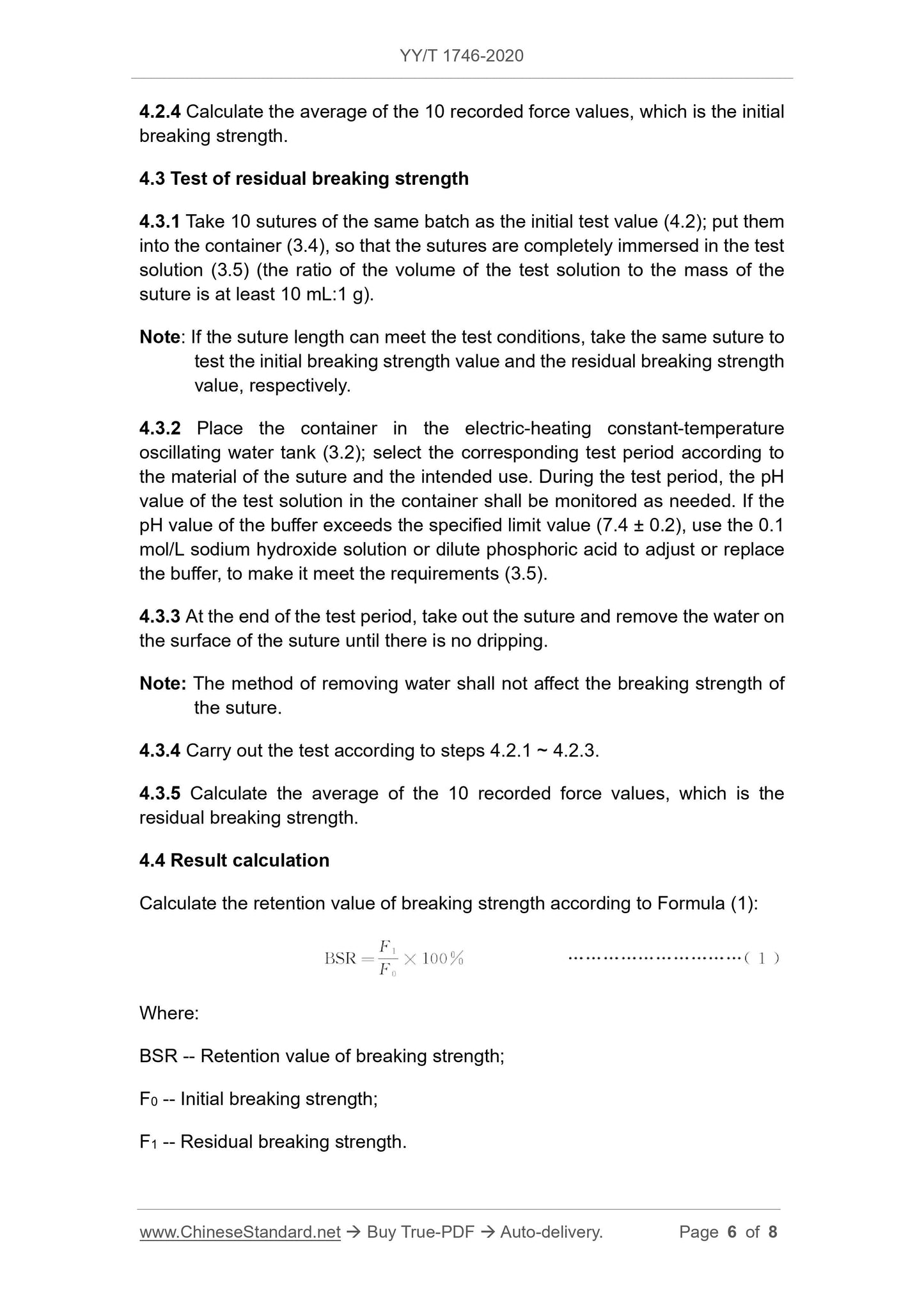

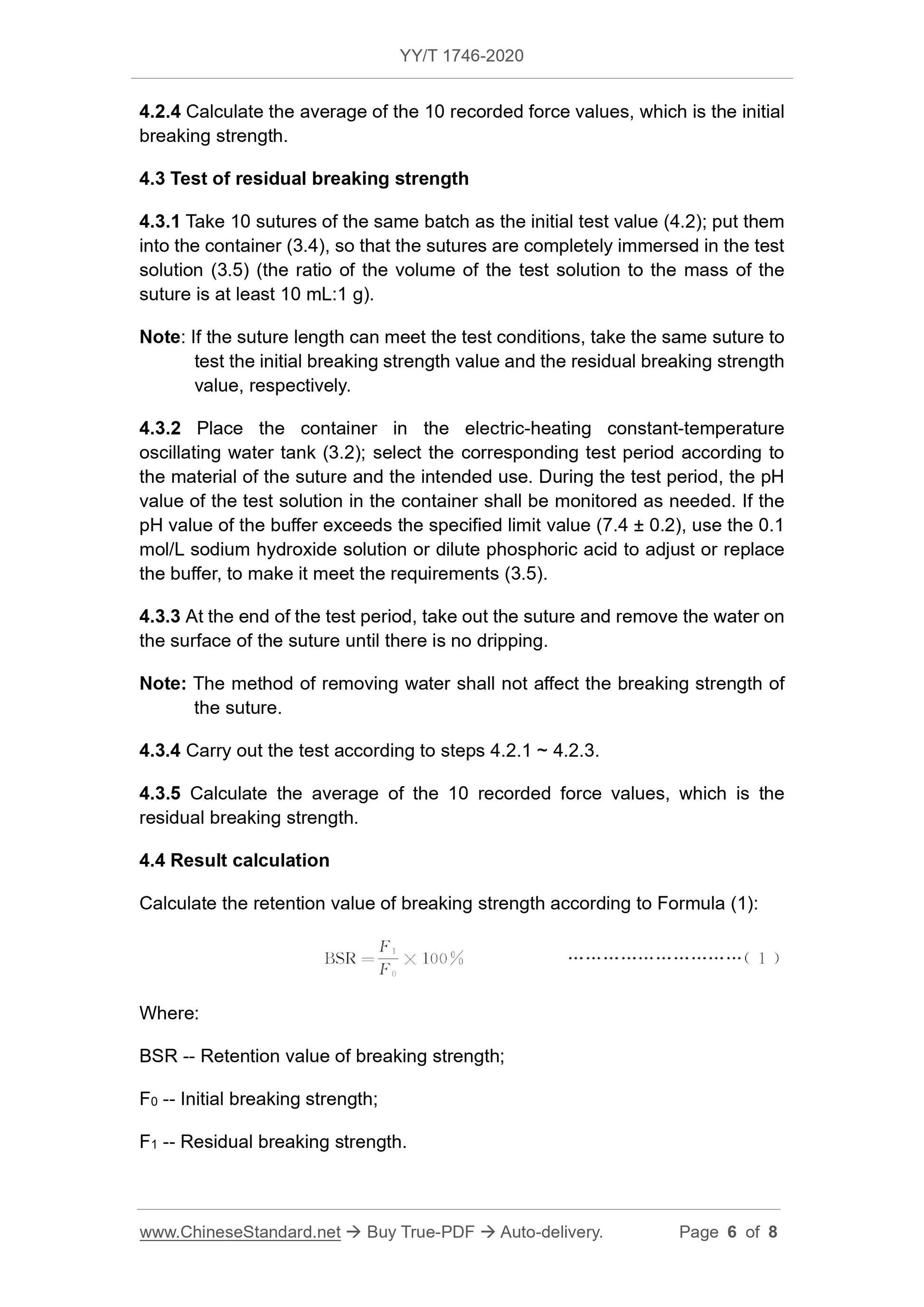

4.4 Calculation of results

The retention value of fracture strength is calculated according to formula (1).

B5 test report

The test report should include at least the following.

a) Suture material, production batch number, specification and quantity;

b) Test solution and test temperature;

c) Test period;

d) Test results (initial breaking strength, residual breaking strength and retention value of breaking strength).

Get Quotation: Click YY/T 1746-2020 (Self-service in 1-minute)

Historical versions (Master-website): YY/T 1746-2020

Preview True-PDF (Reload/Scroll-down if blank)

YY/T 1746-2020: Absorbable surgical suture -- Test method for breaking strength in vitro hydrolytic degradation

YY/T 1746-2020

Absorbable surgical suture - Test method for breaking strength in vitro hydrolytic degradation

People's Republic of China Pharmaceutical Industry Standards

Released on 2020-09-27

Implementation of 2021-09-01

Issued by the National Medical Products Administration

Preface

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some of the contents of this document may involve patents. Publication of this document

The agency is not responsible for identifying these patents.

This standard was proposed by the State Drug Administration.

This standard is under the jurisdiction of the National Technical Committee for Standardization of Surgical Instruments (SAC/TC94).

Drafting organizations of this standard. Shanghai Pudong Jinhuan Medical Products Co., Ltd., Shanghai Medical Device Testing Institute, Huaiyin Medical Devices Co., Ltd.

Co., Ltd., Jiangsu Medical Device Inspection Institute.

The main drafters of this standard. Wang Fengcai, Zou Fengping, Gao Bai, Hu Yuwen, Zhang Yanqing, Qian Xinyi, Lu Guangheng, Shi Yang, Zhang Lihua.

Test method for breaking strength of absorbable surgical suture after hydrolysis in vitro

1 Scope

This standard specifies the test for retention of breaking strength of absorbable surgical sutures (hereinafter referred to as sutures) in an in vitro simulated environment

method.

This standard applies to absorbable surgical sutures processed from synthetic polymers that are hydrolyzed and degraded.

2 Principle

The retention value of the suture breaking strength is tested in different time periods under the in vitro simulated environment to determine whether the suture is in the critical period of wound healing.

Can maintain sufficient tension to provide reference information.

3 Apparatus and reagents

3.1 Material testing machine

The tensile speed is 300mm/min±10mm/min, and the test gauge length is 130mm±5mm.

Note. If the length of the suture cannot meet the requirements of the specified test gauge length, the test gauge length can be adjusted according to the actual length of the suture, and the corresponding stretching speed is set as

Adjust the test gauge length of 2 times. For example, the adjusted test gauge length is set to 50mm, and the stretching speed is set to 2×50=100mm/min.

3.2 Electric heating constant temperature oscillating water tank or constant temperature oscillator

The temperature is 37°C±1°C, and the oscillation frequency. 60r/min (or other suitable oscillation methods).

The accuracy of the pH meter is not less than 0.02.

3.4 Container

Inert plastic or glass containers (such as bottles, cans and vials) can hold test samples of various materials and the required soaking liquid for the required time.

Each container should be sealed to prevent loss of solution due to evaporation and to prevent microbial contamination.

3.5 Test solution

The test solution is. phosphate buffer (pH 7.4).

Phosphate buffer is a mixture of 18.2% solution a) and 81.8% solution b) (volume fraction). The salt used to prepare the following solution should be

For analytical purity, the water used to dissolve the salt should be sterile double-distilled water.

a) 1/15mol/L potassium dihydrogen phosphate. Dissolve 9.08g potassium dihydrogen phosphate (KH2PO4) per liter of water;

b) 1/15mol/L disodium hydrogen phosphate. Dissolve 11.9 g of disodium hydrogen phosphate dihydrate (Na2HPO4.2H2O) per liter of water.

When prepared in this way, the pH value of the buffer solution is 7.4 ± 0.2.

Note. According to different physiological environments, other buffers with suitable pH values can also be used.

4 Test procedure

4.1 Preparation

Record the characteristics of the suture and set the instrument parameters (3.1 and 3.2).

4.2 Test of initial breaking strength

4.2.1 Take out the suture from the package, tie a simple knot in its middle position, and tighten the knot. Class B sutures with specifications less than 8-0 are not knotted.

4.2.2 Fix both ends of the suture on the fixing clamps of the material testing machine (3.1). The knot is located in the middle of the two fixing clamps so that the suture

Tighten, pull the suture off at the specified speed, and record the maximum force value.

Note 1.The suture can be selected according to the clinical use without knotting.

Note 2.If the suture breaks within 1cm from the fixture, the test is invalid.

4.2.3 Repeat steps 4.2.1 and 4.2.2.

4.2.4 Calculate the average of the 10 recorded force values, which is the initial breaking strength.

4.3 Test of residual breaking strength

4.3.1 Take 10 sutures of the same batch as the initial value of the test (4.2), put them into the container (3.4), make the test solution (3.5) completely immerse the sutures (test)

The ratio of the volume of the test solution to the mass of the suture is at least 10mL. 1g).

Note. If the length of the suture can meet the test conditions, take the same suture to test the initial breaking strength value and the residual breaking strength value.

4.3.2 Place the container in the electric heating constant temperature oscillating water tank (3.2), select the corresponding test period according to the material of the suture and the intended use, and test

During the test cycle, the pH value of the test solution in the container should be monitored as needed. If the pH value of the buffer solution drifts beyond the specified limit value (7.4±0.2), then

Adjust or replace the buffer with 0.1 mol/L sodium hydroxide solution or dilute phosphoric acid to meet the requirements (3.5).

4.3.3 At the end of the test period, take out the suture and remove the water on the surface of the suture until there is no dripping.

Note. The method of removing moisture should not affect the breaking strength of the suture.

4.3.4 Carry out the test according to the steps from 4.2.1 to 4.2.3.

4.3.5 Calculate the average of the 10 recorded force values, which is the residual fracture strength.

4.4 Calculation of results

The retention value of fracture strength is calculated according to formula (1).

B5 test report

The test report should include at least the following.

a) Suture material, production batch number, specification and quantity;

b) Test solution and test temperature;

c) Test period;

d) Test results (initial breaking strength, residual breaking strength and retention value of breaking strength).

Share