1

/

/

6

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1048-2016 English PDF (QCT1048-2016)

QC/T 1048-2016 English PDF (QCT1048-2016)

Normal fiyat

$160.00 USD

Normal fiyat

İndirimli fiyat

$160.00 USD

Birim fiyat

/

/

Kargo, ödeme sayfasında hesaplanır.

Teslim alım stok durumu yüklenemedi

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1048-2016

Historical versions: QC/T 1048-2016

Preview True-PDF (Reload/Scroll if blank)

QC/T 1048-2016: Bus emergency hammer

QC/T 1048-2016

QC

AUTOMOTIVE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.080.20

T 42

Bus emergency hammer

ISSUED ON. APRIL 05, 2016

IMPLEMENTED ON. SEPTEMBER 01, 2016

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

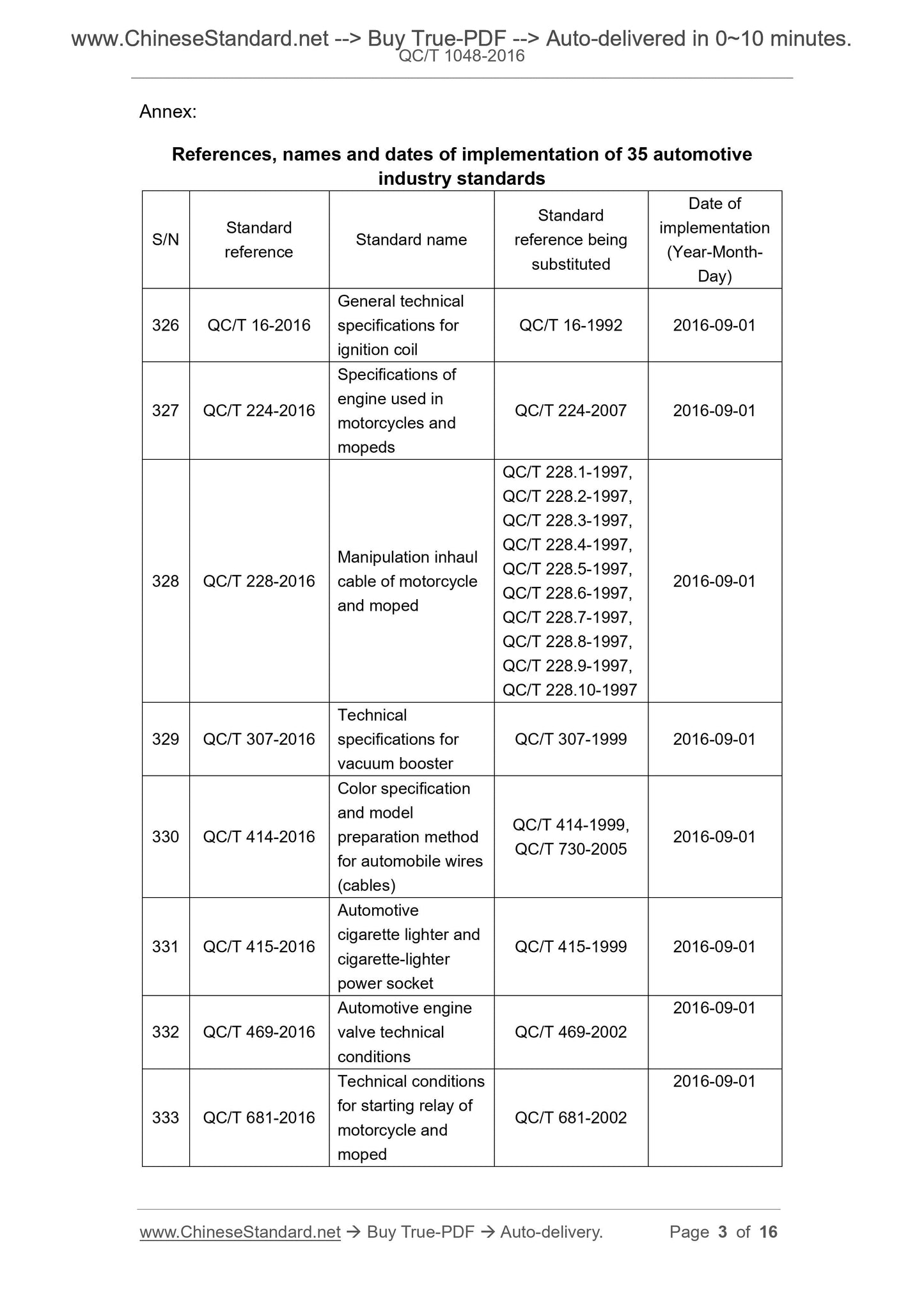

Annex.

References, names and dates of implementation of 35 automotive

industry standards

S/N Standard reference Standard name

Standard

reference being

substituted

Date of

implementation

(Year-Month-

Day)

326 QC/T 16-2016

General technical

specifications for

ignition coil

QC/T 16-1992 2016-09-01

327 QC/T 224-2016

Specifications of

engine used in

motorcycles and

mopeds

QC/T 224-2007 2016-09-01

328 QC/T 228-2016

Manipulation inhaul

cable of motorcycle

and moped

QC/T 228.1-1997,

QC/T 228.2-1997,

QC/T 228.3-1997,

QC/T 228.4-1997,

QC/T 228.5-1997,

QC/T 228.6-1997,

QC/T 228.7-1997,

QC/T 228.8-1997,

QC/T 228.9-1997,

QC/T 228.10-1997

2016-09-01

329 QC/T 307-2016

Technical

specifications for

vacuum booster

QC/T 307-1999 2016-09-01

330 QC/T 414-2016

Color specification

and model

preparation method

for automobile wires

(cables)

QC/T 414-1999,

QC/T 730-2005 2016-09-01

331 QC/T 415-2016

Automotive

cigarette lighter and

cigarette-lighter

power socket

QC/T 415-1999 2016-09-01

332 QC/T 469-2016

Automotive engine

valve technical

conditions

QC/T 469-2002

2016-09-01

333 QC/T 681-2016

Technical conditions

for starting relay of

motorcycle and

moped

QC/T 681-2002

2016-09-01

Table of Contents

Announcement ... 2

Foreword ... 8

1 Scope ... 9

2 Normative references ... 9

3 Terms and definitions ... 10

4 Technical requirements ... 10

5 Test methods ... 12

6 Inspection rules ... 14

7 Marks, packaging, transport, storage ... 15

Bus emergency hammer

1 Scope

This Standard specifies the technical requirements, test methods, inspection

rules as well as marks, packaging, transport, storage of bus emergency

hammer.

This Standard is applicable to bus emergency hammer used for M2, M3 buses.

The emergency hammer used by other type bus shall refer to this Standard for

implementation.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 191, Packaging and storage marks

GB/T 2423.1, Environmental testing - Part 2. Test methods - Tests A. Cold

(GB/T 2423.1-2008, IEC 60068-2-1.2007, IDT)

GB/T 2423.2, Environmental testing - Part 2. Test methods - Tests B. Dry

heat (GB/T 2423. 2-2008, IEC 60068-2-2.2007, IDT)

GB/T 3785.1, Electroacoustics - Sound level meters - Part 1. Specifications

GB 7258, Safety specifications for power-driven vehicles operating on roads

GB 8410, Flammability of automotive interior materials

GB/T 15173, Electroacoustics - Sound calibrators

GB/T 28046.1-2011, Road vehicles - Environmental conditions and testing

for electrical and electronic equipment - Part 1. General

GB/T 28046.4-2011, Road vehicles - Environmental conditions and testing

for electrical and electronic equipment - Part 4. Climatic loads

GB/T 30512, Requirements for Prohibited Substances on Automobiles

4.1.3 The emergency hammer handle shall have anti-slip and protection handle

design. The non-metallic materials used in the hammer handle and bracket

shall be flame retardant, low-smoke, non-toxic (low-toxic), halogen-free non-

flame-retardant materials. Its flame retardancy shall comply with the relevant

provisions of GB 7258.

4.1.4 The materials used for emergency hammers shall meet the requirements

of GB/T 30512.

4.1.5 There shall be no flash burrs around the emergency hammer and the

surface shall be rustproof.

4.1.6 The Emergency hammer handle, bracket shall be free of flash burrs. The

surface is flat and smooth, without deformation. The color shall be red, no color

difference, which can withstand slight-acid, slight-alkali.

4.1.7 The emergency hammer head and handle shall be assembled tightly and

firmly.

4.1.8 Emergency hammer and bracket are reliably cooperated, without

loosening. It shall be easy to remove in an emergency.

4.1.9 When the emergency hammer is removed from the bracket, it shall have

an audible alarm function. When the alarm device is working, the alarm sound

shall be no less than 75 dB(A) at a height of 1000 mm from the ground and

2500 mm at a horizontal distance. If the alarm device is installed with a battery,

it shall be easy to replace. Indicate the battery installation position and

replacement cycle.

4.2 Size and quality requirements

4.2.1 The distance from the tip of the emergency hammer to the center of the

hammer handle is l≥130mm. The inner part of the hammer handle is l1 ≥85mm

(see Figure 1).

4.2.2 The emergency hammer diameter d≥14mm, hammer head anteversion

angle β≤20°. The hammer cone angle α≤60°, hammer cone tip radius of

curvature is 0.2mm (see Figure 1).

4.2.3 The mass of emergency hammer head is ≥70g. The total mass of

emergency hammer (excluding the bracket) is ≥170g.

4.3 Installation requirements

4.3.1 The emergency hammer is usually placed in the bracket. The bracket shall

be installed adjacent to the emergency window and easy to see and access.

The installation height is 1000mm ~ 1700mm above the floor surface of the

vehicle.

in the low temperature for 2h according to the test conditions in Table 1. The

sample shall be taken out of the cryostat and the drop test shall be completed

within 5 min.

5.2.2 The emergency hammer (mounted on the bracket and the warning

indicator light level upwards) is freely dropped from the height of 1.5 m on the

concrete floor (the cement floor is made of concrete of which strength class is

C30, thickness is at least 20 cm), twice in succession.

5.2.3 The results of the emergency hammer test shall comply with the

requirements of 4.5.

5.3 Alarm device test

5.3.1 Remove the emergency hammer from the fixed bracket. The alarm device

shall sound an audible alarm. Use sound level meter to test. The test results

shall comply with the requirements of 4.1.9.

5.3.2 The sound level meter for measurement shall meet the requirements of

the Class 1 sound level meter specified in GB/T 3785.1. “A” frequency weighting

characteristics and “F” time weighting characteristics shall be used for

measurement. Before and after measurement, the sound level meter shall be

calibrated according to the manufacturer's specifications by using a Class 1

acoustic calibrator in accordance with GB/T 15173.

5.3.3 Measurement shall be made on open concrete flat floors and where the

effects of reflections are less. The background noise shall be measured before

the formal measurement and the background noise shall be less than 70 dB(A).

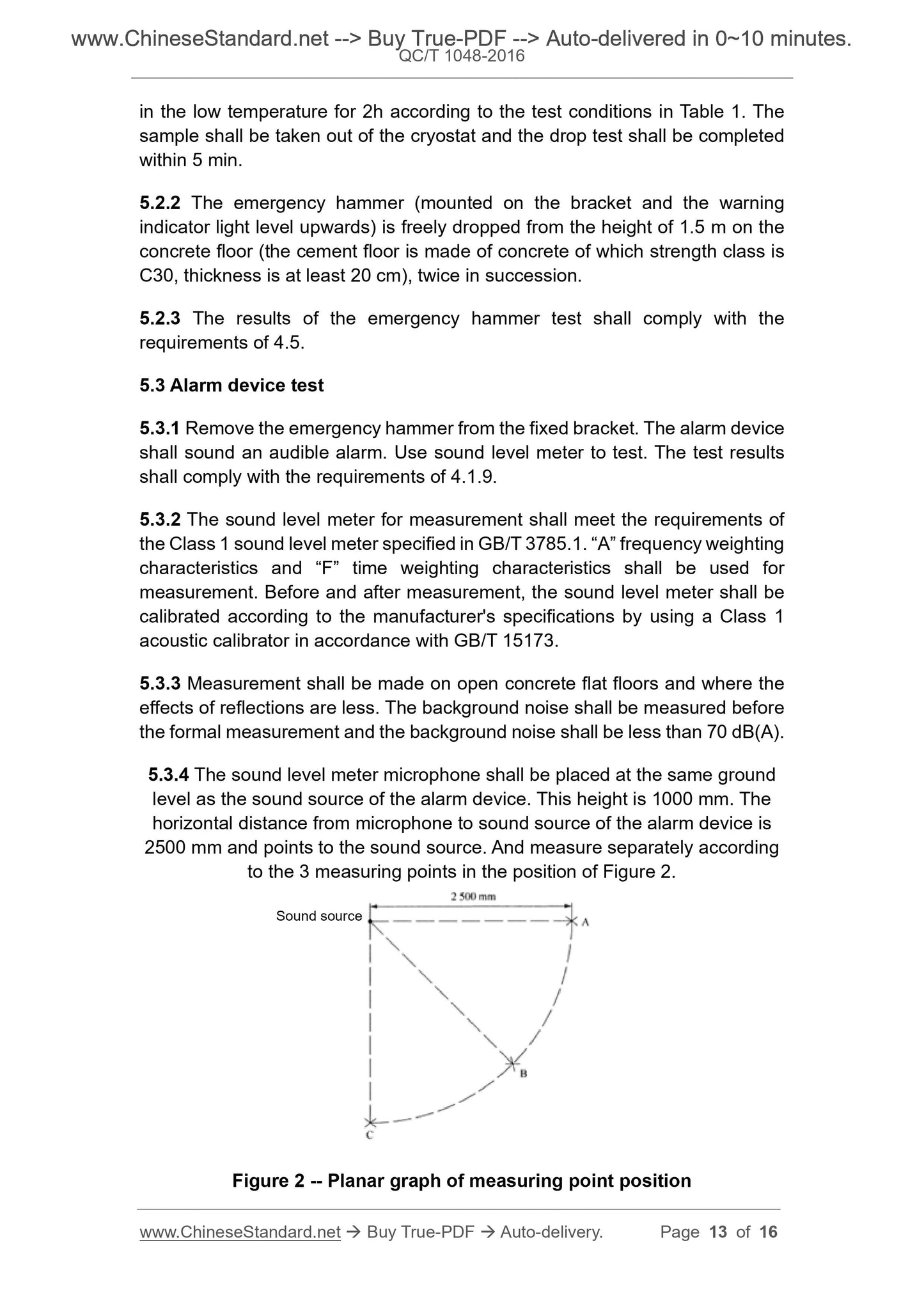

5.3.4 The sound level meter microphone shall be placed at the same ground

level as the sound source of the alarm device. This height is 1000 mm. The

horizontal distance from microphone to sound source of the alarm device is

2500 mm and points to the sound source. And measure separately according

to the 3 measuring points in the position of Figure 2.

Figure 2 -- Plan...

Get QUOTATION in 1-minute: Click QC/T 1048-2016

Historical versions: QC/T 1048-2016

Preview True-PDF (Reload/Scroll if blank)

QC/T 1048-2016: Bus emergency hammer

QC/T 1048-2016

QC

AUTOMOTIVE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.080.20

T 42

Bus emergency hammer

ISSUED ON. APRIL 05, 2016

IMPLEMENTED ON. SEPTEMBER 01, 2016

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

Annex.

References, names and dates of implementation of 35 automotive

industry standards

S/N Standard reference Standard name

Standard

reference being

substituted

Date of

implementation

(Year-Month-

Day)

326 QC/T 16-2016

General technical

specifications for

ignition coil

QC/T 16-1992 2016-09-01

327 QC/T 224-2016

Specifications of

engine used in

motorcycles and

mopeds

QC/T 224-2007 2016-09-01

328 QC/T 228-2016

Manipulation inhaul

cable of motorcycle

and moped

QC/T 228.1-1997,

QC/T 228.2-1997,

QC/T 228.3-1997,

QC/T 228.4-1997,

QC/T 228.5-1997,

QC/T 228.6-1997,

QC/T 228.7-1997,

QC/T 228.8-1997,

QC/T 228.9-1997,

QC/T 228.10-1997

2016-09-01

329 QC/T 307-2016

Technical

specifications for

vacuum booster

QC/T 307-1999 2016-09-01

330 QC/T 414-2016

Color specification

and model

preparation method

for automobile wires

(cables)

QC/T 414-1999,

QC/T 730-2005 2016-09-01

331 QC/T 415-2016

Automotive

cigarette lighter and

cigarette-lighter

power socket

QC/T 415-1999 2016-09-01

332 QC/T 469-2016

Automotive engine

valve technical

conditions

QC/T 469-2002

2016-09-01

333 QC/T 681-2016

Technical conditions

for starting relay of

motorcycle and

moped

QC/T 681-2002

2016-09-01

Table of Contents

Announcement ... 2

Foreword ... 8

1 Scope ... 9

2 Normative references ... 9

3 Terms and definitions ... 10

4 Technical requirements ... 10

5 Test methods ... 12

6 Inspection rules ... 14

7 Marks, packaging, transport, storage ... 15

Bus emergency hammer

1 Scope

This Standard specifies the technical requirements, test methods, inspection

rules as well as marks, packaging, transport, storage of bus emergency

hammer.

This Standard is applicable to bus emergency hammer used for M2, M3 buses.

The emergency hammer used by other type bus shall refer to this Standard for

implementation.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 191, Packaging and storage marks

GB/T 2423.1, Environmental testing - Part 2. Test methods - Tests A. Cold

(GB/T 2423.1-2008, IEC 60068-2-1.2007, IDT)

GB/T 2423.2, Environmental testing - Part 2. Test methods - Tests B. Dry

heat (GB/T 2423. 2-2008, IEC 60068-2-2.2007, IDT)

GB/T 3785.1, Electroacoustics - Sound level meters - Part 1. Specifications

GB 7258, Safety specifications for power-driven vehicles operating on roads

GB 8410, Flammability of automotive interior materials

GB/T 15173, Electroacoustics - Sound calibrators

GB/T 28046.1-2011, Road vehicles - Environmental conditions and testing

for electrical and electronic equipment - Part 1. General

GB/T 28046.4-2011, Road vehicles - Environmental conditions and testing

for electrical and electronic equipment - Part 4. Climatic loads

GB/T 30512, Requirements for Prohibited Substances on Automobiles

4.1.3 The emergency hammer handle shall have anti-slip and protection handle

design. The non-metallic materials used in the hammer handle and bracket

shall be flame retardant, low-smoke, non-toxic (low-toxic), halogen-free non-

flame-retardant materials. Its flame retardancy shall comply with the relevant

provisions of GB 7258.

4.1.4 The materials used for emergency hammers shall meet the requirements

of GB/T 30512.

4.1.5 There shall be no flash burrs around the emergency hammer and the

surface shall be rustproof.

4.1.6 The Emergency hammer handle, bracket shall be free of flash burrs. The

surface is flat and smooth, without deformation. The color shall be red, no color

difference, which can withstand slight-acid, slight-alkali.

4.1.7 The emergency hammer head and handle shall be assembled tightly and

firmly.

4.1.8 Emergency hammer and bracket are reliably cooperated, without

loosening. It shall be easy to remove in an emergency.

4.1.9 When the emergency hammer is removed from the bracket, it shall have

an audible alarm function. When the alarm device is working, the alarm sound

shall be no less than 75 dB(A) at a height of 1000 mm from the ground and

2500 mm at a horizontal distance. If the alarm device is installed with a battery,

it shall be easy to replace. Indicate the battery installation position and

replacement cycle.

4.2 Size and quality requirements

4.2.1 The distance from the tip of the emergency hammer to the center of the

hammer handle is l≥130mm. The inner part of the hammer handle is l1 ≥85mm

(see Figure 1).

4.2.2 The emergency hammer diameter d≥14mm, hammer head anteversion

angle β≤20°. The hammer cone angle α≤60°, hammer cone tip radius of

curvature is 0.2mm (see Figure 1).

4.2.3 The mass of emergency hammer head is ≥70g. The total mass of

emergency hammer (excluding the bracket) is ≥170g.

4.3 Installation requirements

4.3.1 The emergency hammer is usually placed in the bracket. The bracket shall

be installed adjacent to the emergency window and easy to see and access.

The installation height is 1000mm ~ 1700mm above the floor surface of the

vehicle.

in the low temperature for 2h according to the test conditions in Table 1. The

sample shall be taken out of the cryostat and the drop test shall be completed

within 5 min.

5.2.2 The emergency hammer (mounted on the bracket and the warning

indicator light level upwards) is freely dropped from the height of 1.5 m on the

concrete floor (the cement floor is made of concrete of which strength class is

C30, thickness is at least 20 cm), twice in succession.

5.2.3 The results of the emergency hammer test shall comply with the

requirements of 4.5.

5.3 Alarm device test

5.3.1 Remove the emergency hammer from the fixed bracket. The alarm device

shall sound an audible alarm. Use sound level meter to test. The test results

shall comply with the requirements of 4.1.9.

5.3.2 The sound level meter for measurement shall meet the requirements of

the Class 1 sound level meter specified in GB/T 3785.1. “A” frequency weighting

characteristics and “F” time weighting characteristics shall be used for

measurement. Before and after measurement, the sound level meter shall be

calibrated according to the manufacturer's specifications by using a Class 1

acoustic calibrator in accordance with GB/T 15173.

5.3.3 Measurement shall be made on open concrete flat floors and where the

effects of reflections are less. The background noise shall be measured before

the formal measurement and the background noise shall be less than 70 dB(A).

5.3.4 The sound level meter microphone shall be placed at the same ground

level as the sound source of the alarm device. This height is 1000 mm. The

horizontal distance from microphone to sound source of the alarm device is

2500 mm and points to the sound source. And measure separately according

to the 3 measuring points in the position of Figure 2.

Figure 2 -- Plan...

Share