1

/

trong số

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1160-2022 English PDF (QCT1160-2022)

QC/T 1160-2022 English PDF (QCT1160-2022)

Giá thông thường

$335.00 USD

Giá thông thường

Giá ưu đãi

$335.00 USD

Đơn giá

/

trên

Phí vận chuyển được tính khi thanh toán.

Không thể tải khả năng nhận hàng tại cửa hàng

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1160-2022

Historical versions: QC/T 1160-2022

Preview True-PDF (Reload/Scroll if blank)

QC/T 1160-2022: Guidelines on evaluation of whole vehicle manufacturing green factory in automobile industry

QC/T 1160-2022

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

CCS T 40

Guidelines on evaluation of whole vehicle manufacturing

green factory in automobile industry

ISSUED ON: APRIL 08, 2022

IMPLEMENTED ON: OCTOBER 01, 2022

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 6

1 Scope ... 7

2 Normative references ... 7

3 Terms and definitions ... 8

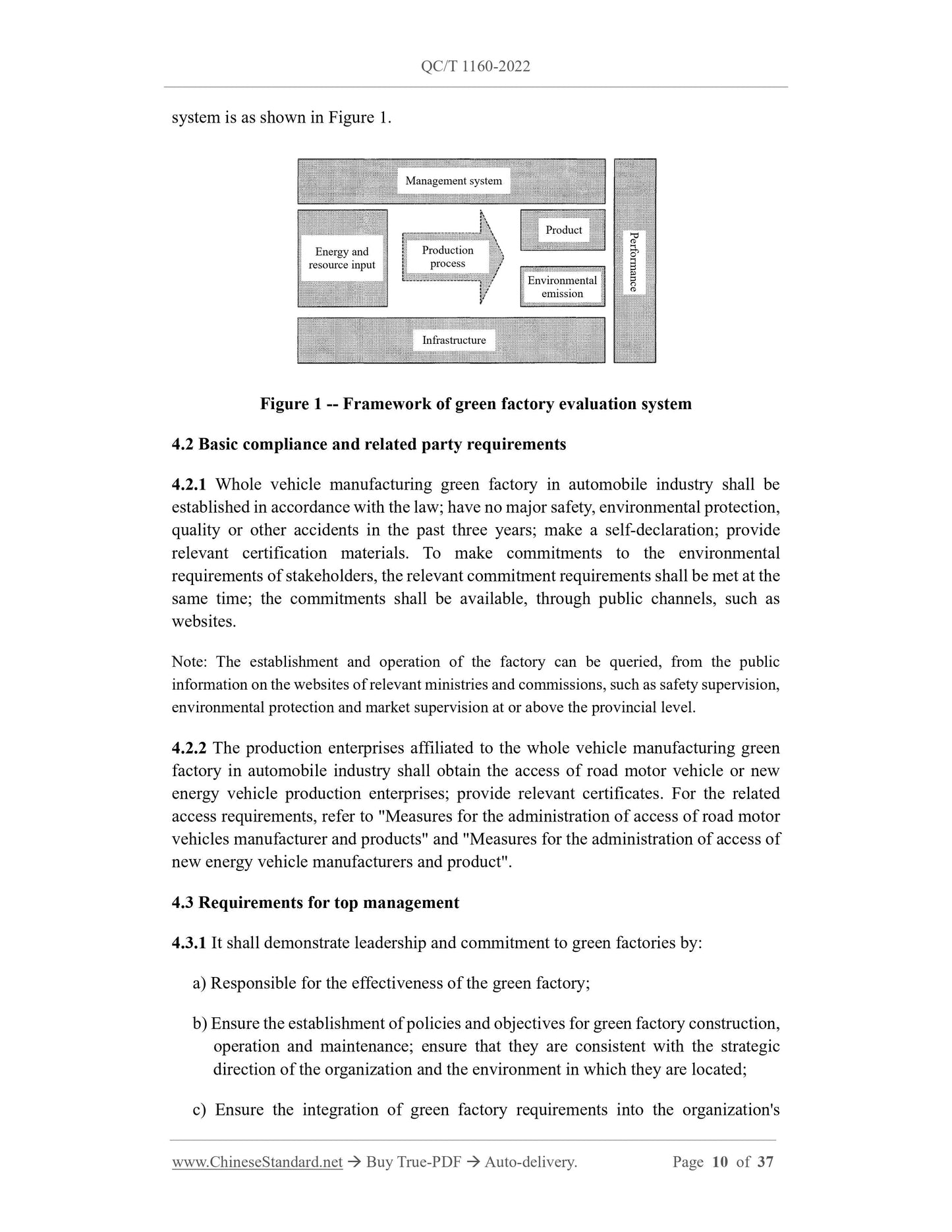

4 Basic requirements ... 9

5 Infrastructure ... 12

6 Management system ... 13

7 Energy and resource input ... 15

8 Products ... 16

9 Environmental emissions ... 16

10 Performance ... 17

11 Evaluation ... 19

Appendix A (Normative) Calculation method of green factory performance index ... 21

Appendix B (Normative) Evaluation indicators of green factory ... 25

References ... 37

Guidelines on evaluation of whole vehicle manufacturing

green factory in automobile industry

1 Scope

This document specifies the terms and definitions, basic requirements, infrastructure,

management system, energy and resource input, products, environmental emissions,

performance, evaluation methods, etc. of the guidelines on evaluation of whole vehicle

manufacturing green factory in automobile industry.

This document is applicable to the evaluation of whole vehicle manufacturing green

factory in automobile industry.

2 Normative references

The contents of the following documents constitute the essential provisions of this

document through normative references in the text. Among them, for dated references,

only the version corresponding to the date applies to this document; for undated

references, the latest version (including all amendments) applies to this document.

GB 8978 Integrated wastewater discharge standard

GB 12348 Emission standard for industrial enterprises noise at boundary

GB 14554 Emission standards for odor pollutants

GB 16297 Comprehensive emission standard of air pollutants

GB 17167 General principle for equipping and managing of the measuring

instrument of energy in organization of energy using

GB 18597 Standard for pollution control on hazardous waste storage

GB 18599 Standard for pollution control on the non-hazardous industrial solid waste

storage and landfill

GB/T 19001 Quality management systems - Requirements

GB/T 19515 Road vehicles - Recyclability and recoverability - Calculation method

GB/T 23331 Energy management systems - Requirements with guidance for use

GB/T 24001 Environmental management systems - Requirements with guidance for

use

GB 24409 Limit of harmful substances of vehicle coatings

GB 24789 General rules for equipping and managing of the water measuring

instrument in water-use organization

GB/T 30512 Requirements for prohibited substances on automobiles

GB/T 32150 General guideline of the greenhouse gas emissions accounting and

reporting for industrial enterprises

GB/T 32327-2015 Guide for evaluating industrial wastewater treatment and reuse

technology

GB/T 33460 Specifications for compiling dismantling manual of end-of-life

vehicles

GB/T 33761-2017 General principles for green product assessment

GB/T 36132-2018 General principles for assessment of green factory

GB/T 37393 Digital factory - General technical requirements

GB 37822 Standard for fugitive emission of volatile organic compounds

GB/T 45001 Occupational health and safety management systems - Requirements

with guidance for use

GB 50033 Standard for daylighting design of buildings

GB 50034 Standard for lighting design of buildings

GB/T 50353 Standard measurement for construction area of building

GB/T 50878 Evaluation standards for green industrial buildings

QC/T 1157-2022 Method of calculating comprehensive energy consumption for unit

output of automobile products

ISO 14001 Environmental management systems - Requirements with guidance for

use

3 Terms and definitions

The following terms and definitions apply to this document.

business processes;

d) Ensure that the resources required for green factory construction, operation and

maintenance are available;

e) Communicate the importance of effective green manufacturing and the

importance of meeting green factory requirements;

f) Ensure that the factory achieves the expected results of its green manufacturing;

g) Guide and support employees to contribute to the effectiveness of the green

factory;

h) Promote continual improvement;

i) Support other relevant management personnel to demonstrate leadership, within

their area of responsibility.

4.3.2 It shall be ensured that the responsibilities and authorities of relevant roles are

assigned and communicated within the factory. Assigned responsibilities and

authorities shall include at least the following:

a) Ensure that factory construction, operation, maintenance meet the requirements

of this document;

b) Collect and maintain the evidence, that the factory meets the green factory

evaluation requirements;

c) Report to top management on green factory performance, including green

manufacturing performance.

4.4 Requirements for the factory

4.4.1 There shall be a green factory management organization, which is responsible for

the system construction, implementation, assessment, rewards related to green

manufacturing; establish a target responsibility system.

4.4.2 There shall be medium and long-term plans for green factories, as well as annual

goals, indicators, implementation plans. The above plans, objectives, indicators,

programs shall be feasible; the indicators shall be clear and quantifiable.

4.4.3 The concept and knowledge of green manufacturing shall be disseminated;

employees shall be provided with education and training on green manufacturing-

related knowledge on a regular basis; the results of education and training shall be

evaluated.

5 Infrastructure

5.1 Architecture

5.1.1 The buildings of whole vehicle manufacturing green factory in automobile

industry shall obtain certificates of land use rights, construction land planning permits,

environmental impact assessment approvals, construction project planning permits, etc.

5.1.2 It shall comply with the "three simultaneous" system (i.e., "it shall be designed,

constructed, put into production and use simultaneously"), which is stipulated in

national laws and regulations, such as environmental protection law, labor law, safety

production law, occupational disease prevention law and fire protection law; provide

relevant acceptance and evaluation reports.

5.1.3 The dangerous goods warehouse, toxic and harmful operation room, waste

treatment room of green factories in the automotive industry, that produce pollutants,

shall be set up independently.

5.1.4 The floor of the painting workshop for the pre-treatment of automobiles and the

electrophoresis process shall be subject to anti-leakage treatment.

5.1.5 The whole vehicle manufacturing green factory in automobile industry should

save materials, energy, water, land, renewable energy in construction, from the aspects

of building materials, building structure, lighting, greening and site, renewable

resources and energy utilization. It shall conform to the evaluation criteria of GB/T

50878.

5.1.6 The whole vehicle manufacturing green factory in automobile industry should

adopt multi-floored buildings.

5.2 Lighting

5.2.1 The artificial lighting of the factory area and each room or place of the whole

vehicle man...

Get QUOTATION in 1-minute: Click QC/T 1160-2022

Historical versions: QC/T 1160-2022

Preview True-PDF (Reload/Scroll if blank)

QC/T 1160-2022: Guidelines on evaluation of whole vehicle manufacturing green factory in automobile industry

QC/T 1160-2022

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

CCS T 40

Guidelines on evaluation of whole vehicle manufacturing

green factory in automobile industry

ISSUED ON: APRIL 08, 2022

IMPLEMENTED ON: OCTOBER 01, 2022

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 6

1 Scope ... 7

2 Normative references ... 7

3 Terms and definitions ... 8

4 Basic requirements ... 9

5 Infrastructure ... 12

6 Management system ... 13

7 Energy and resource input ... 15

8 Products ... 16

9 Environmental emissions ... 16

10 Performance ... 17

11 Evaluation ... 19

Appendix A (Normative) Calculation method of green factory performance index ... 21

Appendix B (Normative) Evaluation indicators of green factory ... 25

References ... 37

Guidelines on evaluation of whole vehicle manufacturing

green factory in automobile industry

1 Scope

This document specifies the terms and definitions, basic requirements, infrastructure,

management system, energy and resource input, products, environmental emissions,

performance, evaluation methods, etc. of the guidelines on evaluation of whole vehicle

manufacturing green factory in automobile industry.

This document is applicable to the evaluation of whole vehicle manufacturing green

factory in automobile industry.

2 Normative references

The contents of the following documents constitute the essential provisions of this

document through normative references in the text. Among them, for dated references,

only the version corresponding to the date applies to this document; for undated

references, the latest version (including all amendments) applies to this document.

GB 8978 Integrated wastewater discharge standard

GB 12348 Emission standard for industrial enterprises noise at boundary

GB 14554 Emission standards for odor pollutants

GB 16297 Comprehensive emission standard of air pollutants

GB 17167 General principle for equipping and managing of the measuring

instrument of energy in organization of energy using

GB 18597 Standard for pollution control on hazardous waste storage

GB 18599 Standard for pollution control on the non-hazardous industrial solid waste

storage and landfill

GB/T 19001 Quality management systems - Requirements

GB/T 19515 Road vehicles - Recyclability and recoverability - Calculation method

GB/T 23331 Energy management systems - Requirements with guidance for use

GB/T 24001 Environmental management systems - Requirements with guidance for

use

GB 24409 Limit of harmful substances of vehicle coatings

GB 24789 General rules for equipping and managing of the water measuring

instrument in water-use organization

GB/T 30512 Requirements for prohibited substances on automobiles

GB/T 32150 General guideline of the greenhouse gas emissions accounting and

reporting for industrial enterprises

GB/T 32327-2015 Guide for evaluating industrial wastewater treatment and reuse

technology

GB/T 33460 Specifications for compiling dismantling manual of end-of-life

vehicles

GB/T 33761-2017 General principles for green product assessment

GB/T 36132-2018 General principles for assessment of green factory

GB/T 37393 Digital factory - General technical requirements

GB 37822 Standard for fugitive emission of volatile organic compounds

GB/T 45001 Occupational health and safety management systems - Requirements

with guidance for use

GB 50033 Standard for daylighting design of buildings

GB 50034 Standard for lighting design of buildings

GB/T 50353 Standard measurement for construction area of building

GB/T 50878 Evaluation standards for green industrial buildings

QC/T 1157-2022 Method of calculating comprehensive energy consumption for unit

output of automobile products

ISO 14001 Environmental management systems - Requirements with guidance for

use

3 Terms and definitions

The following terms and definitions apply to this document.

business processes;

d) Ensure that the resources required for green factory construction, operation and

maintenance are available;

e) Communicate the importance of effective green manufacturing and the

importance of meeting green factory requirements;

f) Ensure that the factory achieves the expected results of its green manufacturing;

g) Guide and support employees to contribute to the effectiveness of the green

factory;

h) Promote continual improvement;

i) Support other relevant management personnel to demonstrate leadership, within

their area of responsibility.

4.3.2 It shall be ensured that the responsibilities and authorities of relevant roles are

assigned and communicated within the factory. Assigned responsibilities and

authorities shall include at least the following:

a) Ensure that factory construction, operation, maintenance meet the requirements

of this document;

b) Collect and maintain the evidence, that the factory meets the green factory

evaluation requirements;

c) Report to top management on green factory performance, including green

manufacturing performance.

4.4 Requirements for the factory

4.4.1 There shall be a green factory management organization, which is responsible for

the system construction, implementation, assessment, rewards related to green

manufacturing; establish a target responsibility system.

4.4.2 There shall be medium and long-term plans for green factories, as well as annual

goals, indicators, implementation plans. The above plans, objectives, indicators,

programs shall be feasible; the indicators shall be clear and quantifiable.

4.4.3 The concept and knowledge of green manufacturing shall be disseminated;

employees shall be provided with education and training on green manufacturing-

related knowledge on a regular basis; the results of education and training shall be

evaluated.

5 Infrastructure

5.1 Architecture

5.1.1 The buildings of whole vehicle manufacturing green factory in automobile

industry shall obtain certificates of land use rights, construction land planning permits,

environmental impact assessment approvals, construction project planning permits, etc.

5.1.2 It shall comply with the "three simultaneous" system (i.e., "it shall be designed,

constructed, put into production and use simultaneously"), which is stipulated in

national laws and regulations, such as environmental protection law, labor law, safety

production law, occupational disease prevention law and fire protection law; provide

relevant acceptance and evaluation reports.

5.1.3 The dangerous goods warehouse, toxic and harmful operation room, waste

treatment room of green factories in the automotive industry, that produce pollutants,

shall be set up independently.

5.1.4 The floor of the painting workshop for the pre-treatment of automobiles and the

electrophoresis process shall be subject to anti-leakage treatment.

5.1.5 The whole vehicle manufacturing green factory in automobile industry should

save materials, energy, water, land, renewable energy in construction, from the aspects

of building materials, building structure, lighting, greening and site, renewable

resources and energy utilization. It shall conform to the evaluation criteria of GB/T

50878.

5.1.6 The whole vehicle manufacturing green factory in automobile industry should

adopt multi-floored buildings.

5.2 Lighting

5.2.1 The artificial lighting of the factory area and each room or place of the whole

vehicle man...

Share