1

/

/

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY 0120-2002 English PDF (YY0120-2002)

YY 0120-2002 English PDF (YY0120-2002)

常规价格

$150.00 USD

常规价格

促销价

$150.00 USD

单价

/

单价

结账时计算的运费。

无法加载取货服务可用情况

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY 0120-2002

Historical versions: YY 0120-2002

Preview True-PDF (Reload/Scroll if blank)

YY 0120-2002: Implants for osteosynthesis--Metal correctional stick

YY 0120-2002

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.40

C 35

Replacing YY 0120-1993

Implants for osteosynthesis - Metal correctional stick

ISSUED ON: SEPTEMBER 24, 2002

IMPLEMENTED ON: APRIL 01, 2003

Issued by: National Medical Products Administration

Replaced

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Classification ... 4

4 Requirements ... 9

5 Test methods ... 10

6 Inspection rules ... 11

7 Instructions for use ... 11

8 Marks ... 11

9 Packaging ... 11

10 Transportation and storage ... 11

11 Requirements for use ... 11

Implants for osteosynthesis - Metal correctional stick

1 Scope

This Standard specifies classification, requirements, test methods, inspection

rules, instructions for use, marks, packaging, transportation and storage for

metal correctional stick [Translator note: Term “rod” is adopted in YY/T 0119.4-

2014].

This Standard is applicable to metal correctional stick (hereinafter referred to

as the correctional stick). This product is used for correction and internal fixation

when the spine bones are diseased or deformed.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For dated references, the subsequent

amendments (excluding corrigendum) or revisions do not apply to this Standard,

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 228, Metallic materials - Tensile testing at ambient temperature

GB/T 4234, Stainless steel for surgical implants

GB/T 4340, Metallic materials - Vickers hardness test

GB/T 13810, Wrought titanium and titanium alloy for surgical implants (GB/T

13810-1997, eqv ISO 5832-2: 1993)

YY/T 0343, Liquid penetrant inspection of metallic surgical implants

YY0341, General technological requirements for non-active metallic surgery

implants of osteosynthesis

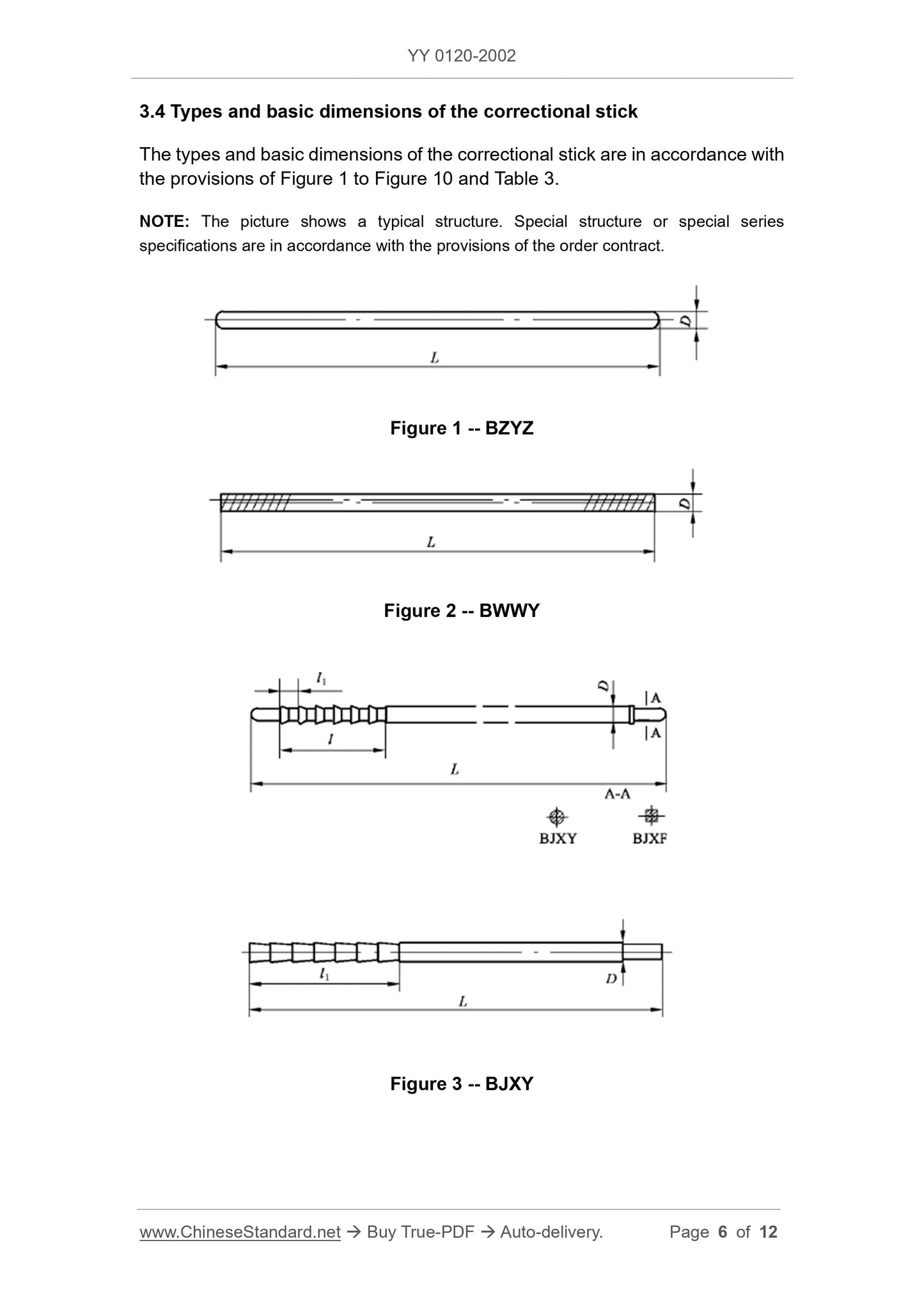

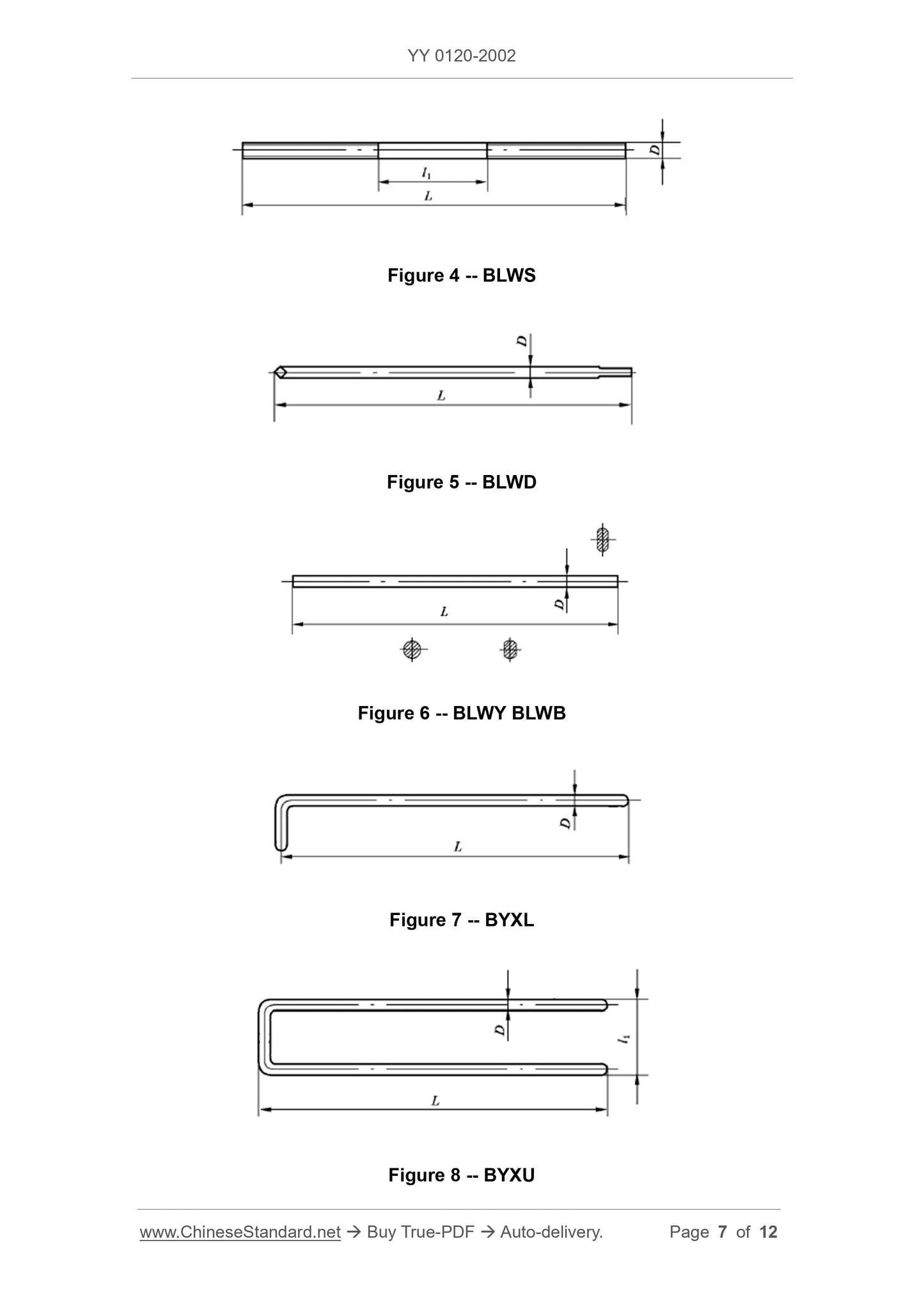

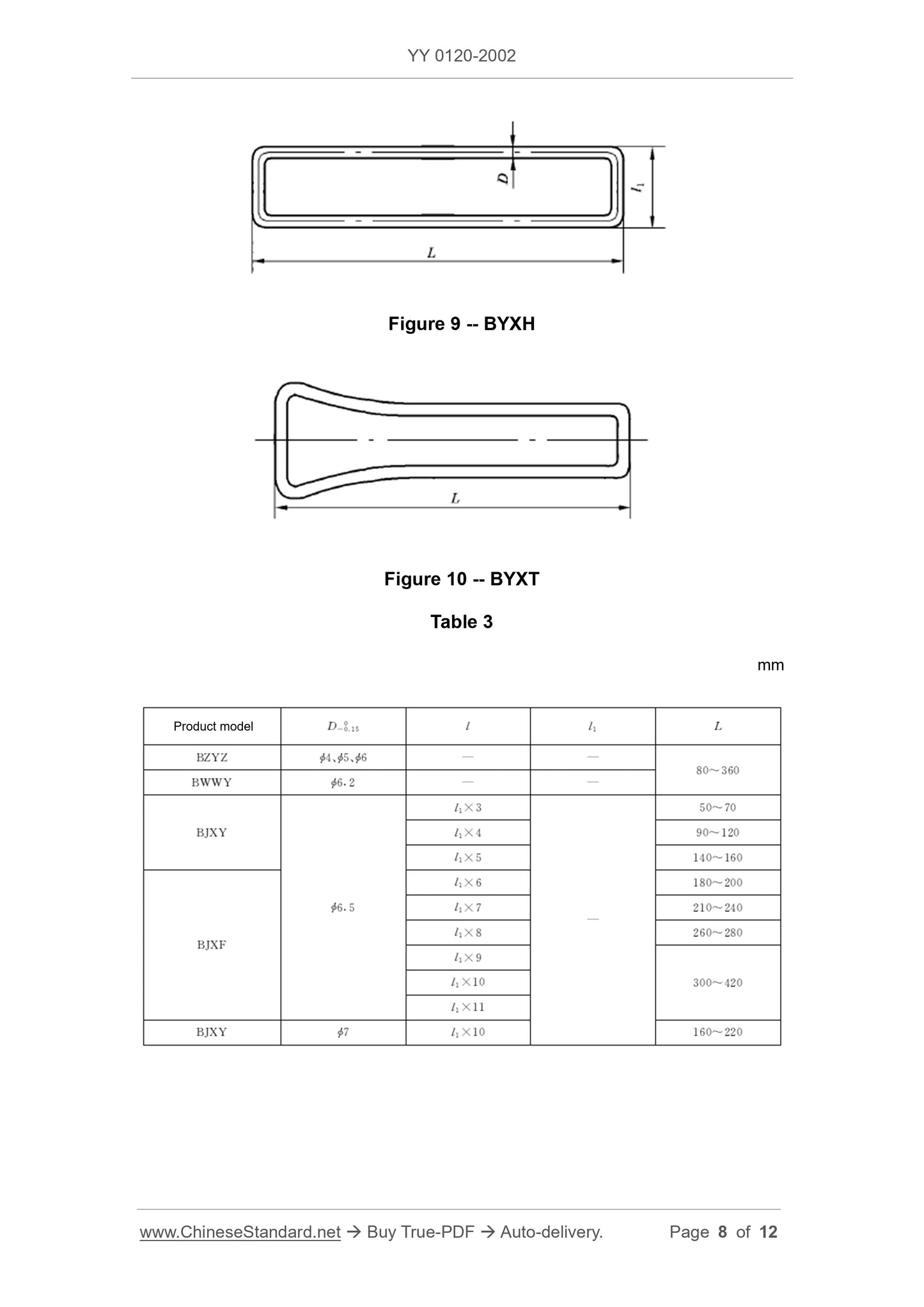

3 Classification

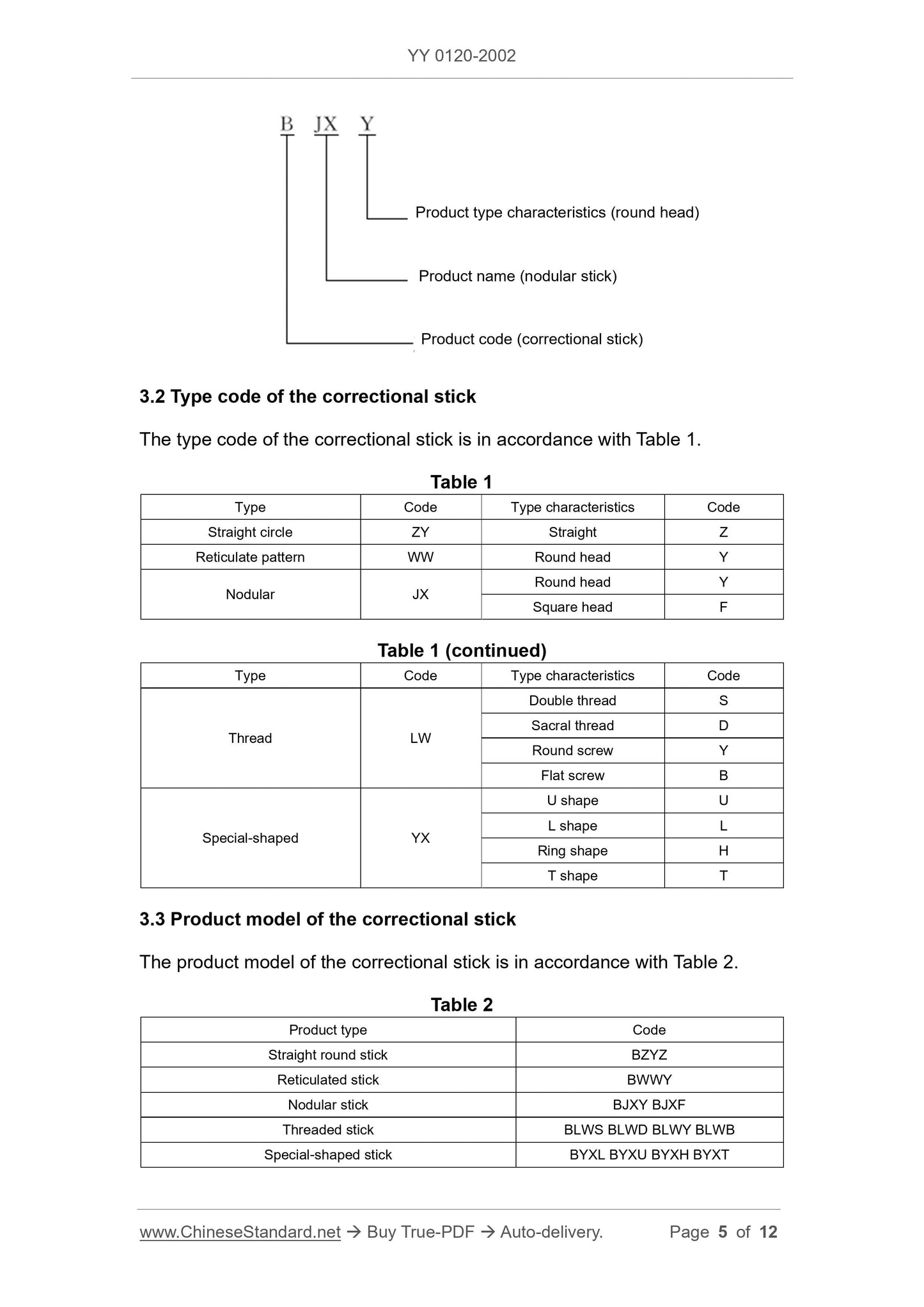

3.1 Example of product model of the correctional stick

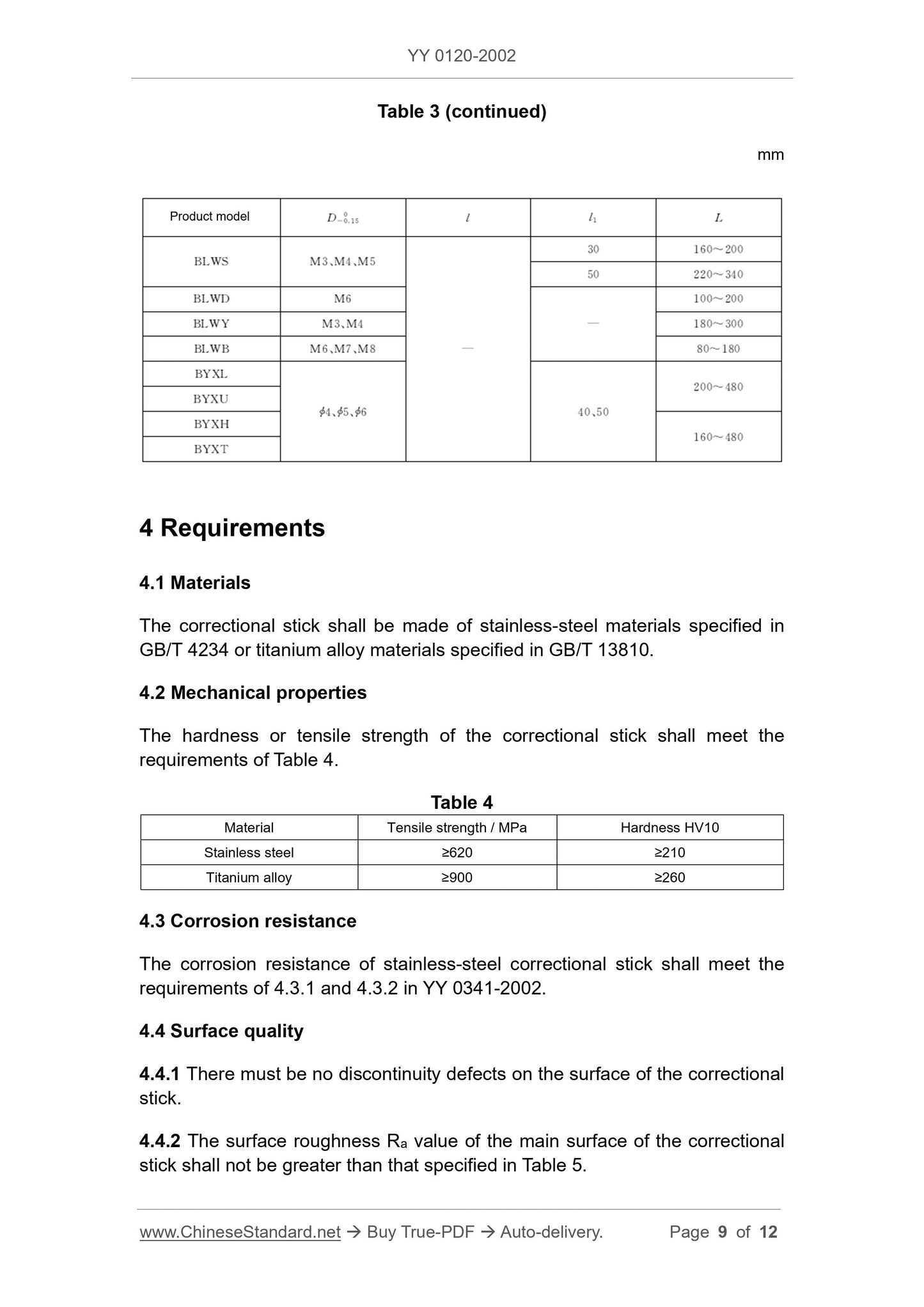

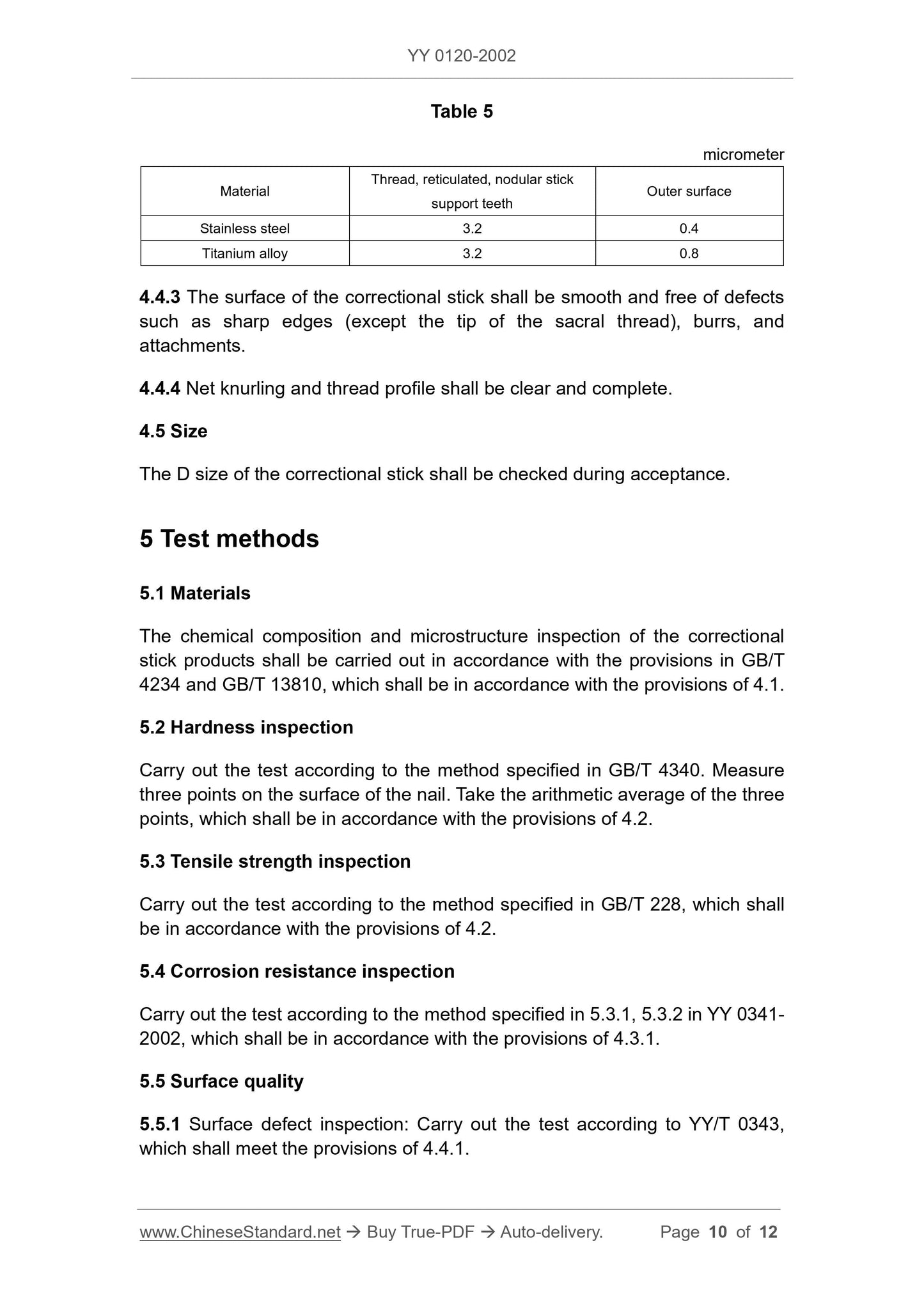

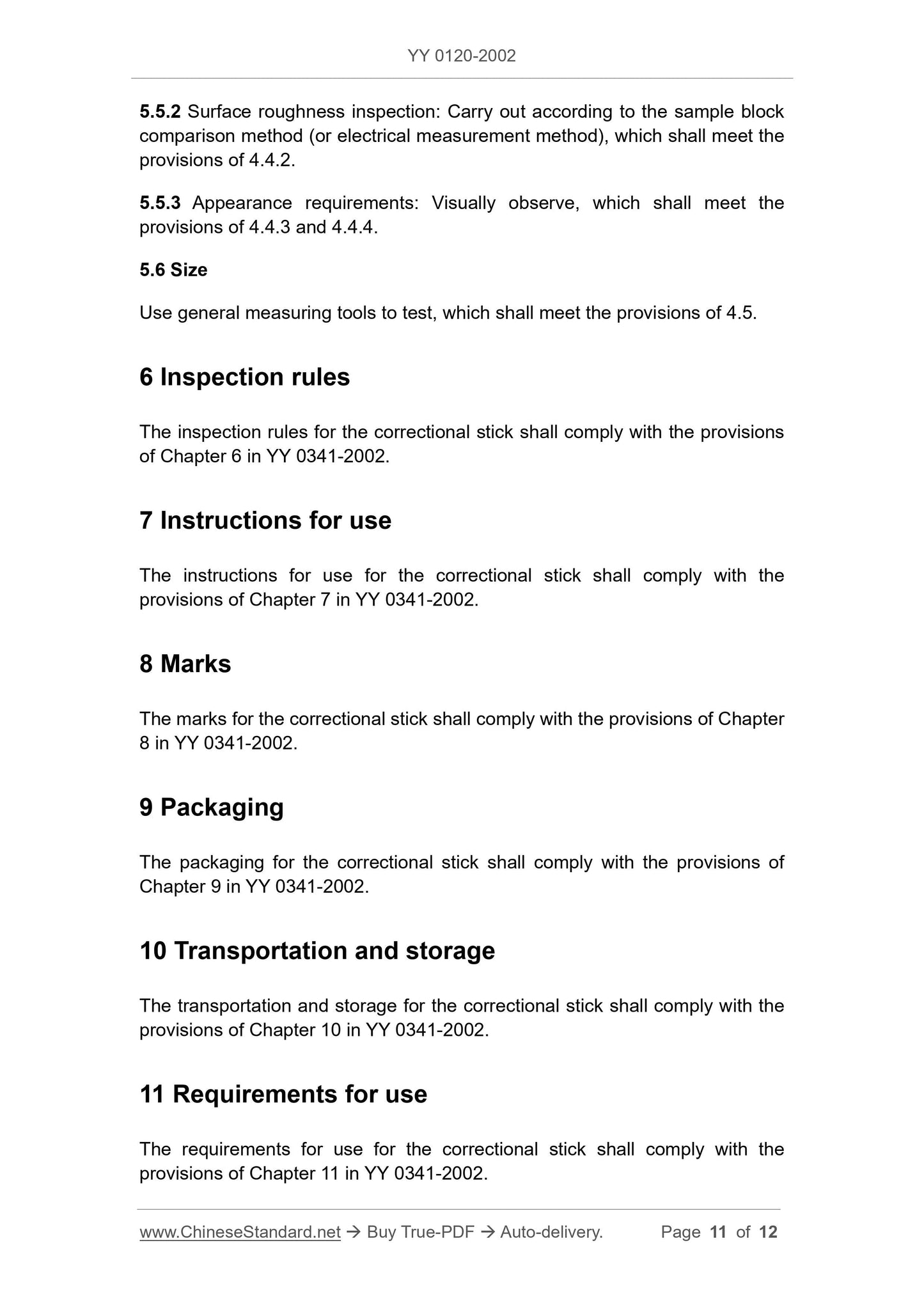

Table 5

4.4.3 The surface of the correctional stick shall be smooth and free of defects

such as sharp edges (except the tip of the sacral thread), burrs, and

attachments.

4.4.4 Net knurling and thread profile shall be clear and complete.

4.5 Size

The D size of the correctional stick shall be checked during acceptance.

5 Test methods

5.1 Materials

The chemical composition and microstructure inspection of the correctional

stick products shall be carried out in accordance with the provisions in GB/T

4234 and GB/T 13810, which shall be in accordance with the provisions of 4.1.

5.2 Hardness inspection

Carry out the test according to the method specified in GB/T 4340. Measure

three points on the surface of the nail. Take the arithmetic average of the three

points, which shall be in accordance with the provisions of 4.2.

5.3 Tensile strength inspection

Carry out the test according to the method specified in GB/T 228, which shall

be in accordance with the provisions of 4.2.

5.4 Corrosion resistance inspection

Carry out the test according to the method specified in 5.3.1, 5.3.2 in YY 0341-

2002, which shall be in accordance with the provisions of 4.3.1.

5.5 Surface quality

5.5.1 Surface defect inspection: Carry out the test according to YY/T 0343,

which shall meet the provisions of 4.4.1.

5.5.2 Surface roughness inspection: Carry out according to the sample block

comparison method (or electrical measurement method), which shall meet the

provisions of 4.4.2.

5.5.3 Appearance requirements: Visually observe, which shall meet the

provisions of 4.4.3 and 4.4.4.

5.6 Size

Use general measuring tools to test, which shall meet the provisions of 4.5.

6 Inspection rules

The inspection rules for the correctional stick shall comply with the provisions

of Chapter 6 in YY 0341-2002.

7 Instructions for use

The instructions for use for the correctional stick shall comply with the

provisions of Chapter 7 in YY 0341-2002.

8 Marks

The marks for the correctional stick shall comply with the provisions of Chapter

8 in YY 0341-2002.

9 Packaging

The packaging for the correctional stick shall comply with the provisions of

Chapter 9 in YY 0341-2002.

10 Transportation and storage

The transportation and storage for the correctional stick shall comply with the

provisions of Chapter 10 in YY 0341-2002.

11 Requirements for use

The requirements for use for the correctional stick shall comply with the

provisions of Chapter 11 in YY 0341-2002.

Get QUOTATION in 1-minute: Click YY 0120-2002

Historical versions: YY 0120-2002

Preview True-PDF (Reload/Scroll if blank)

YY 0120-2002: Implants for osteosynthesis--Metal correctional stick

YY 0120-2002

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.40

C 35

Replacing YY 0120-1993

Implants for osteosynthesis - Metal correctional stick

ISSUED ON: SEPTEMBER 24, 2002

IMPLEMENTED ON: APRIL 01, 2003

Issued by: National Medical Products Administration

Replaced

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Classification ... 4

4 Requirements ... 9

5 Test methods ... 10

6 Inspection rules ... 11

7 Instructions for use ... 11

8 Marks ... 11

9 Packaging ... 11

10 Transportation and storage ... 11

11 Requirements for use ... 11

Implants for osteosynthesis - Metal correctional stick

1 Scope

This Standard specifies classification, requirements, test methods, inspection

rules, instructions for use, marks, packaging, transportation and storage for

metal correctional stick [Translator note: Term “rod” is adopted in YY/T 0119.4-

2014].

This Standard is applicable to metal correctional stick (hereinafter referred to

as the correctional stick). This product is used for correction and internal fixation

when the spine bones are diseased or deformed.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For dated references, the subsequent

amendments (excluding corrigendum) or revisions do not apply to this Standard,

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 228, Metallic materials - Tensile testing at ambient temperature

GB/T 4234, Stainless steel for surgical implants

GB/T 4340, Metallic materials - Vickers hardness test

GB/T 13810, Wrought titanium and titanium alloy for surgical implants (GB/T

13810-1997, eqv ISO 5832-2: 1993)

YY/T 0343, Liquid penetrant inspection of metallic surgical implants

YY0341, General technological requirements for non-active metallic surgery

implants of osteosynthesis

3 Classification

3.1 Example of product model of the correctional stick

Table 5

4.4.3 The surface of the correctional stick shall be smooth and free of defects

such as sharp edges (except the tip of the sacral thread), burrs, and

attachments.

4.4.4 Net knurling and thread profile shall be clear and complete.

4.5 Size

The D size of the correctional stick shall be checked during acceptance.

5 Test methods

5.1 Materials

The chemical composition and microstructure inspection of the correctional

stick products shall be carried out in accordance with the provisions in GB/T

4234 and GB/T 13810, which shall be in accordance with the provisions of 4.1.

5.2 Hardness inspection

Carry out the test according to the method specified in GB/T 4340. Measure

three points on the surface of the nail. Take the arithmetic average of the three

points, which shall be in accordance with the provisions of 4.2.

5.3 Tensile strength inspection

Carry out the test according to the method specified in GB/T 228, which shall

be in accordance with the provisions of 4.2.

5.4 Corrosion resistance inspection

Carry out the test according to the method specified in 5.3.1, 5.3.2 in YY 0341-

2002, which shall be in accordance with the provisions of 4.3.1.

5.5 Surface quality

5.5.1 Surface defect inspection: Carry out the test according to YY/T 0343,

which shall meet the provisions of 4.4.1.

5.5.2 Surface roughness inspection: Carry out according to the sample block

comparison method (or electrical measurement method), which shall meet the

provisions of 4.4.2.

5.5.3 Appearance requirements: Visually observe, which shall meet the

provisions of 4.4.3 and 4.4.4.

5.6 Size

Use general measuring tools to test, which shall meet the provisions of 4.5.

6 Inspection rules

The inspection rules for the correctional stick shall comply with the provisions

of Chapter 6 in YY 0341-2002.

7 Instructions for use

The instructions for use for the correctional stick shall comply with the

provisions of Chapter 7 in YY 0341-2002.

8 Marks

The marks for the correctional stick shall comply with the provisions of Chapter

8 in YY 0341-2002.

9 Packaging

The packaging for the correctional stick shall comply with the provisions of

Chapter 9 in YY 0341-2002.

10 Transportation and storage

The transportation and storage for the correctional stick shall comply with the

provisions of Chapter 10 in YY 0341-2002.

11 Requirements for use

The requirements for use for the correctional stick shall comply with the

provisions of Chapter 11 in YY 0341-2002.

Share