1

/

/

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

Q/BQB 401-2019 English PDF

Q/BQB 401-2019 English PDF

定價

$330.00 USD

定價

售價

$330.00 USD

單價

/

每

結帳時計算運費。

無法載入取貨服務供應情況

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click Q/BQB 401-2019

Historical versions: Q/BQB 401-2019

Preview True-PDF (Reload/Scroll if blank)

Q/BQB 401-2019: Dimension, shape, weight and tolerances for cold-rolled steel sheet and strip

Q/BQB 401-2019

BQB

ENTERPRISE STANDARD OF

BAOSHAN IRON AND STEEL CO., LTD

Replacing Q/BQB 401-2018

Dimension, Shape, Weight and Tolerances

for Cold-Rolled Steel Sheet and Strip

ISSUED ON: FEBRUARY 02, 2019

IMPLEMENTED ON: APRIL 10, 2019

Issued by: Baoshan Iron and Steel Co., Ltd.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Classification and Code ... 5

4 Dimension ... 6

5 Allowable Deviation of Dimension ... 7

6 Appearance ... 10

7 Measurement of Dimension and Shape ... 13

8 Weight ... 13

9 If the User Has Other Special Requirements for Dimension, Shape, Weight

and Tolerances, they Can Be Negotiated when Ordering and Specified in the

Contract ... 14

10 Numerical Rounding-Off Rules ... 14

Appendix A (Normative) Weight Calculation Method when Taking Theoretical

Weight Method ... 16

Foreword

This Standard was drafted as per the rules specified in GB/T 1.1-2009 Directives for

Standardization – Part 1: Structure and Drafting of Standards.

This Standard formulated by reference of EN 10131:2006, EN 10143:2006, and JIS G

3141:2017.

This Standard replaced Q/BQB 401-2018.

Compared with Q/BQB 401-2018, this Standard mainly made the following content

modifications:

--- Revise the lower limit of nominal width of product supplying from 700mm to

600mm;

--- Revise the description of the relevant definition of thickness tolerance in 5.1;

--- Revise the lower limit of the minimum nominal thickness for the file strength of

PT.C thickness allowable deviation of 260 ~ < 360MPa from 0.20mm to 0.30mm;

--- Revise the width tolerance table in the original Table 7 into the width accuracy

requirements for the separately specified untrimmed products; and add the basic

accuracy control requirements of PW.W;

--- Add new Table 8, which separately specifies the technical requirements for the

width tolerance of the trimmed products;

--- Revise Table 9 (original Table 8) Nominal thickness files and tolerance technical

requirements of longitudinally-cut steel strip width tolerance;

--- Revise the description in 6.2 sickle bend control requirements and supplement

the sickle bend control requirements of longitudinally-cut steel strip;

--- Revise Table 11 (original Table 10) nominal width file and corresponding index

requirements for unevenness accuracy;

--- Supplement the unevenness diagram of the steel sheet (see Figure 1).

The Appendix A of this Standard is normative.

This Standard was proposed by Manufacture and Management Department of

Baoshan Iron and Steel Co., Ltd.

This Standard shall be under the jurisdiction of Manufacture and Management

Department of Baoshan Iron and Steel Co., Ltd.

Dimension, Shape, Weight and Tolerances

for Cold-Rolled Steel Sheet and Strip

1 Scope

This Standard specifies the requirements for classification and code, dimension, shape,

weight and allowable deviation of cold-rolled steel sheet and strip.

This Standard is applicable to cold-rolled steel strips with a thickness of

0.17mm~3.50mm and a rolling width of 600mm~2080mm, and the steel sheet

horizontally-cut from it and steel strip longitudinally-cut from it produced by Baoshan

Iron and Steel Co., hereinafter referred to as steel sheet and strip.

NOTE: The cold-rolled products referred to in this Standard include cold-rolled uncoated

products and cold-rolled coated products, etc.

2 Normative References

The following documents are essential to the application of this Standard. For the dated

documents, only the versions with the dates indicated are applicable to this Standard;

for the undated documents, only the latest version (including all the amendments) are

applicable to this Standard.

GB/T 8170-2008 Rules of Rounding off for Numerical Values and Expression and

Judgement of Limiting Values

3 Classification and Code

According to different product forms, the classification and code of the edge state and

dimensional accuracy of steel sheets and strips shall meet the requirements of Table

1.

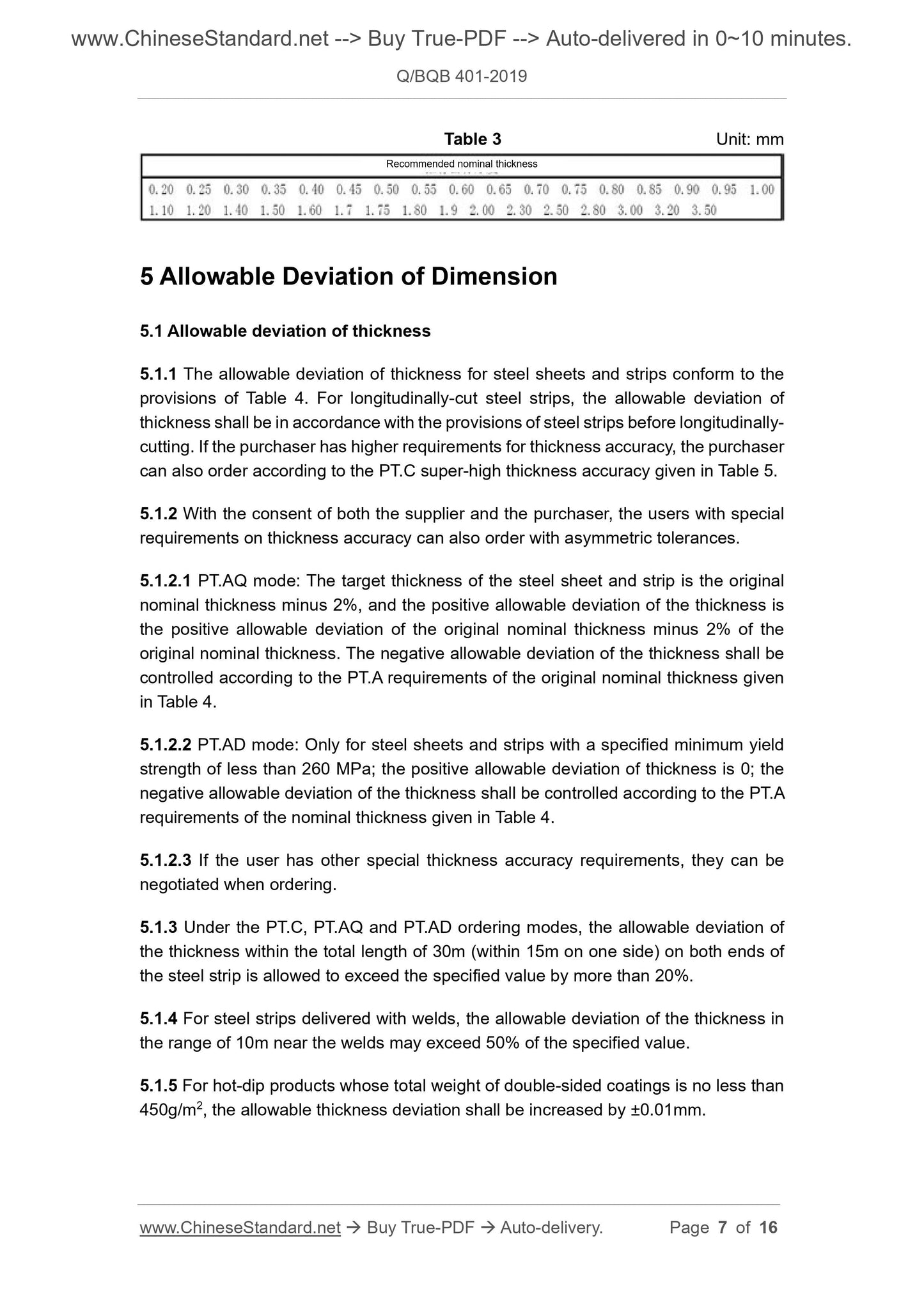

Table 3 Unit: mm

5 Allowable Deviation of Dimension

5.1 Allowable deviation of thickness

5.1.1 The allowable deviation of thickness for steel sheets and strips conform to the

provisions of Table 4. For longitudinally-cut steel strips, the allowable deviation of

thickness shall be in accordance with the provisions of steel strips before longitudinally-

cutting. If the purchaser has higher requirements for thickness accuracy, the purchaser

can also order according to the PT.C super-high thickness accuracy given in Table 5.

5.1.2 With the consent of both the supplier and the purchaser, the users with special

requirements on thickness accuracy can also order with asymmetric tolerances.

5.1.2.1 PT.AQ mode: The target thickness of the steel sheet and strip is the original

nominal thickness minus 2%, and the positive allowable deviation of the thickness is

the positive allowable deviation of the original nominal thickness minus 2% of the

original nominal thickness. The negative allowable deviation of the thickness shall be

controlled according to the PT.A requirements of the original nominal thickness given

in Table 4.

5.1.2.2 PT.AD mode: Only for steel sheets and strips with a specified minimum yield

strength of less than 260 MPa; the positive allowable deviation of thickness is 0; the

negative allowable deviation of the thickness shall be controlled according to the PT.A

requirements of the nominal thickness given in Table 4.

5.1.2.3 If the user has other special thickness accuracy requirements, they can be

negotiated when ordering.

5.1.3 Under the PT.C, PT.AQ and PT.AD ordering modes, the allowable deviation of

the thickness within the total length of 30m (within 15m on one side) on both ends of

the steel strip is allowed to exceed the specified value by more than 20%.

5.1.4 For steel strips delivered with welds, the allowable deviation of the thickness in

the range of 10m near the welds may exceed 50% of the specified value.

5.1.5 For hot-dip products whose total weight of double-sided coatings is no less than

450g/m2, the allowable thickness deviation shall be increased by ±0.01mm.

Recommended nominal thickness

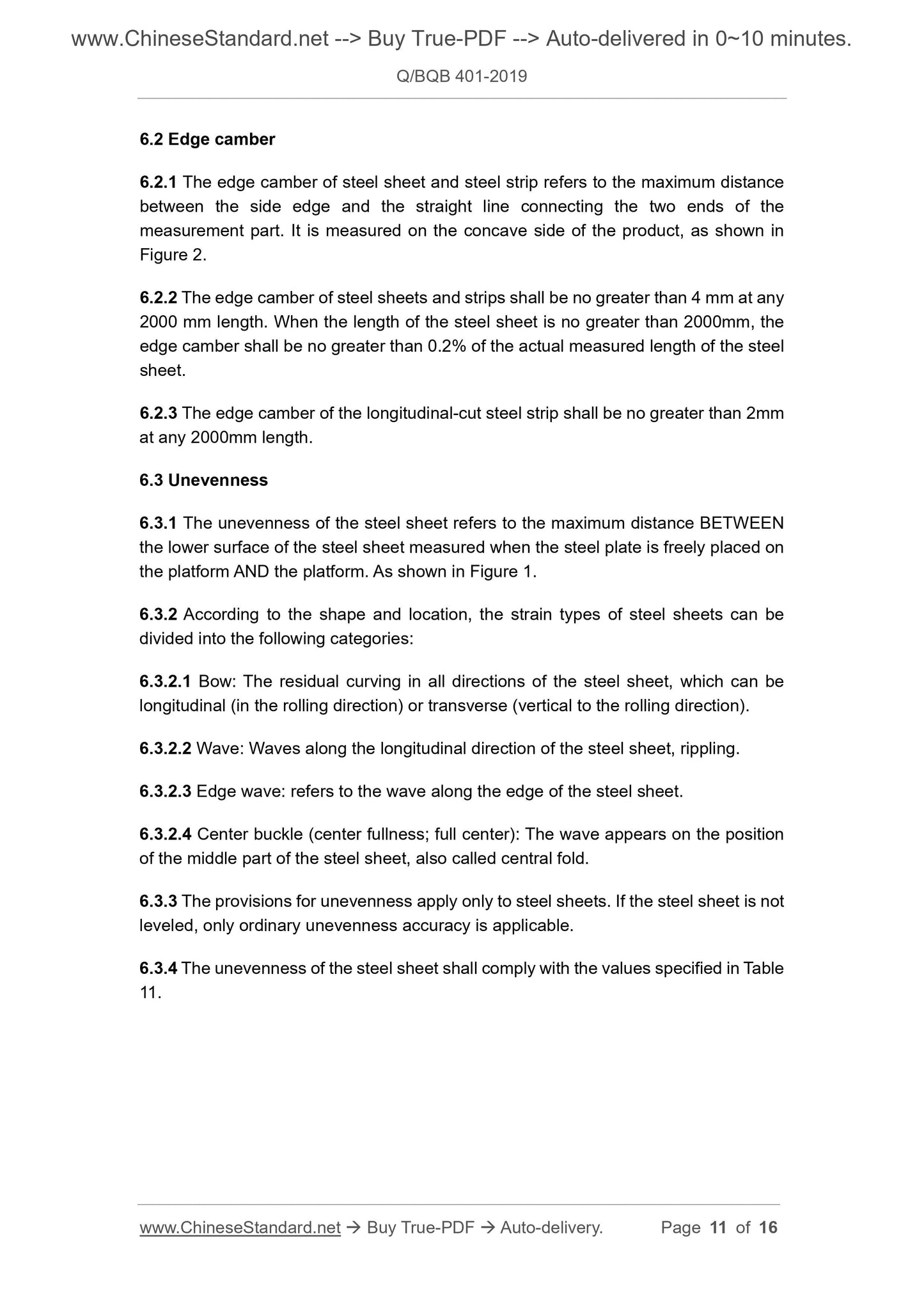

6.2 Edge camber

6.2.1 The edge camber of steel sheet and steel strip refers to the maximum distance

between the side edge and the straight line connecting the two ends of the

measurement part. It is measured on the concave side of the product, as shown in

Figure 2.

6.2.2 The edge camber of steel sheets and strips shall be no greater than 4 mm at any

2000 mm length. When the length of the steel sheet is no greater than 2000mm, the

edge camber shall be no greater than 0.2% of the actual measured length of the steel

sheet.

6.2.3 The edge camber of the longitudinal-cut steel strip shall be no greater than 2mm

at any 2000mm length.

6.3 Unevenness

6.3.1 The unevenness of the steel sheet refers to the maximum distance BETWEEN

the lower surface of the steel sheet measured when the steel plate is freely placed on

the platform AND the platform. As shown in Figure 1.

6.3.2 According to the shape and location, the strain types of steel sheets can be

divided into the following categories:

6.3.2.1 Bow: The residual curving in all directions of the steel sheet, which can be

longitudinal (in the rolling direction) or transverse (vertical to the rolling direction).

6.3.2.2 Wave: Waves along the longitudinal direction of the steel sheet, rippling.

6.3.2.3 Edge wave: ref...

Get QUOTATION in 1-minute: Click Q/BQB 401-2019

Historical versions: Q/BQB 401-2019

Preview True-PDF (Reload/Scroll if blank)

Q/BQB 401-2019: Dimension, shape, weight and tolerances for cold-rolled steel sheet and strip

Q/BQB 401-2019

BQB

ENTERPRISE STANDARD OF

BAOSHAN IRON AND STEEL CO., LTD

Replacing Q/BQB 401-2018

Dimension, Shape, Weight and Tolerances

for Cold-Rolled Steel Sheet and Strip

ISSUED ON: FEBRUARY 02, 2019

IMPLEMENTED ON: APRIL 10, 2019

Issued by: Baoshan Iron and Steel Co., Ltd.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Classification and Code ... 5

4 Dimension ... 6

5 Allowable Deviation of Dimension ... 7

6 Appearance ... 10

7 Measurement of Dimension and Shape ... 13

8 Weight ... 13

9 If the User Has Other Special Requirements for Dimension, Shape, Weight

and Tolerances, they Can Be Negotiated when Ordering and Specified in the

Contract ... 14

10 Numerical Rounding-Off Rules ... 14

Appendix A (Normative) Weight Calculation Method when Taking Theoretical

Weight Method ... 16

Foreword

This Standard was drafted as per the rules specified in GB/T 1.1-2009 Directives for

Standardization – Part 1: Structure and Drafting of Standards.

This Standard formulated by reference of EN 10131:2006, EN 10143:2006, and JIS G

3141:2017.

This Standard replaced Q/BQB 401-2018.

Compared with Q/BQB 401-2018, this Standard mainly made the following content

modifications:

--- Revise the lower limit of nominal width of product supplying from 700mm to

600mm;

--- Revise the description of the relevant definition of thickness tolerance in 5.1;

--- Revise the lower limit of the minimum nominal thickness for the file strength of

PT.C thickness allowable deviation of 260 ~ < 360MPa from 0.20mm to 0.30mm;

--- Revise the width tolerance table in the original Table 7 into the width accuracy

requirements for the separately specified untrimmed products; and add the basic

accuracy control requirements of PW.W;

--- Add new Table 8, which separately specifies the technical requirements for the

width tolerance of the trimmed products;

--- Revise Table 9 (original Table 8) Nominal thickness files and tolerance technical

requirements of longitudinally-cut steel strip width tolerance;

--- Revise the description in 6.2 sickle bend control requirements and supplement

the sickle bend control requirements of longitudinally-cut steel strip;

--- Revise Table 11 (original Table 10) nominal width file and corresponding index

requirements for unevenness accuracy;

--- Supplement the unevenness diagram of the steel sheet (see Figure 1).

The Appendix A of this Standard is normative.

This Standard was proposed by Manufacture and Management Department of

Baoshan Iron and Steel Co., Ltd.

This Standard shall be under the jurisdiction of Manufacture and Management

Department of Baoshan Iron and Steel Co., Ltd.

Dimension, Shape, Weight and Tolerances

for Cold-Rolled Steel Sheet and Strip

1 Scope

This Standard specifies the requirements for classification and code, dimension, shape,

weight and allowable deviation of cold-rolled steel sheet and strip.

This Standard is applicable to cold-rolled steel strips with a thickness of

0.17mm~3.50mm and a rolling width of 600mm~2080mm, and the steel sheet

horizontally-cut from it and steel strip longitudinally-cut from it produced by Baoshan

Iron and Steel Co., hereinafter referred to as steel sheet and strip.

NOTE: The cold-rolled products referred to in this Standard include cold-rolled uncoated

products and cold-rolled coated products, etc.

2 Normative References

The following documents are essential to the application of this Standard. For the dated

documents, only the versions with the dates indicated are applicable to this Standard;

for the undated documents, only the latest version (including all the amendments) are

applicable to this Standard.

GB/T 8170-2008 Rules of Rounding off for Numerical Values and Expression and

Judgement of Limiting Values

3 Classification and Code

According to different product forms, the classification and code of the edge state and

dimensional accuracy of steel sheets and strips shall meet the requirements of Table

1.

Table 3 Unit: mm

5 Allowable Deviation of Dimension

5.1 Allowable deviation of thickness

5.1.1 The allowable deviation of thickness for steel sheets and strips conform to the

provisions of Table 4. For longitudinally-cut steel strips, the allowable deviation of

thickness shall be in accordance with the provisions of steel strips before longitudinally-

cutting. If the purchaser has higher requirements for thickness accuracy, the purchaser

can also order according to the PT.C super-high thickness accuracy given in Table 5.

5.1.2 With the consent of both the supplier and the purchaser, the users with special

requirements on thickness accuracy can also order with asymmetric tolerances.

5.1.2.1 PT.AQ mode: The target thickness of the steel sheet and strip is the original

nominal thickness minus 2%, and the positive allowable deviation of the thickness is

the positive allowable deviation of the original nominal thickness minus 2% of the

original nominal thickness. The negative allowable deviation of the thickness shall be

controlled according to the PT.A requirements of the original nominal thickness given

in Table 4.

5.1.2.2 PT.AD mode: Only for steel sheets and strips with a specified minimum yield

strength of less than 260 MPa; the positive allowable deviation of thickness is 0; the

negative allowable deviation of the thickness shall be controlled according to the PT.A

requirements of the nominal thickness given in Table 4.

5.1.2.3 If the user has other special thickness accuracy requirements, they can be

negotiated when ordering.

5.1.3 Under the PT.C, PT.AQ and PT.AD ordering modes, the allowable deviation of

the thickness within the total length of 30m (within 15m on one side) on both ends of

the steel strip is allowed to exceed the specified value by more than 20%.

5.1.4 For steel strips delivered with welds, the allowable deviation of the thickness in

the range of 10m near the welds may exceed 50% of the specified value.

5.1.5 For hot-dip products whose total weight of double-sided coatings is no less than

450g/m2, the allowable thickness deviation shall be increased by ±0.01mm.

Recommended nominal thickness

6.2 Edge camber

6.2.1 The edge camber of steel sheet and steel strip refers to the maximum distance

between the side edge and the straight line connecting the two ends of the

measurement part. It is measured on the concave side of the product, as shown in

Figure 2.

6.2.2 The edge camber of steel sheets and strips shall be no greater than 4 mm at any

2000 mm length. When the length of the steel sheet is no greater than 2000mm, the

edge camber shall be no greater than 0.2% of the actual measured length of the steel

sheet.

6.2.3 The edge camber of the longitudinal-cut steel strip shall be no greater than 2mm

at any 2000mm length.

6.3 Unevenness

6.3.1 The unevenness of the steel sheet refers to the maximum distance BETWEEN

the lower surface of the steel sheet measured when the steel plate is freely placed on

the platform AND the platform. As shown in Figure 1.

6.3.2 According to the shape and location, the strain types of steel sheets can be

divided into the following categories:

6.3.2.1 Bow: The residual curving in all directions of the steel sheet, which can be

longitudinal (in the rolling direction) or transverse (vertical to the rolling direction).

6.3.2.2 Wave: Waves along the longitudinal direction of the steel sheet, rippling.

6.3.2.3 Edge wave: ref...

Share