1

/

/

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

YS/T 951-2014 English PDF (YST951-2014)

YS/T 951-2014 English PDF (YST951-2014)

定價

$160.00 USD

定價

售價

$160.00 USD

單價

/

每

結帳時計算運費。

無法載入取貨服務供應情況

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YS/T 951-2014

Historical versions: YS/T 951-2014

Preview True-PDF (Reload/Scroll if blank)

YS/T 951-2014: Laterite nickel ores. Determination of moisture content of a consignment

YS/T 951-2014

NON-FERROUS METAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 77.120.01

D 42

Laterite nickel ores - Determination of moisture

content of a consignment

ISSUED ON: OCTOBER 14, 2014

IMPLEMENTED ON: APRIL 01, 2015

Issued by: Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Method summary ... 5

5 Instruments and equipment ... 5

6 Sample ... 6

7 Determination steps ... 6

8 Result calculation and expression ... 7

9 Test report ... 9

Annex A (normative) Determination of moisture content of over-wet or sticky

laterite nickel ore consignment ... 11

Laterite nickel ores - Determination of moisture

content of a consignment

1 Scope

This Standard specifies the determination method of moisture content of a

consignment of laterite nickel ores.

This Standard is applicable to the determination of moisture content of a

consignment of laterite nickel ores.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

YS/T 950, Methods for sampling and sample preparation of laterite nickel

ores in bulk

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 consignment

A certain amount of ores in one delivery. A consignment may consist of a batch,

several batches or partial batches of ores.

3.2 gross sample

A sample that consists of all increments and fully represents all quality

characteristics of a batch.

3.3 partial sample

A sample that is composed of partial increments required to form a gross

sample.

3.4 increment

A certain amount of ores that are obtained in one operation by a sampling

device or a sample reduction device.

3.5 sample

Relatively small amount of ores that are representative and are taken from a

batch of ores of which their quality characteristics are to be evaluated.

3.6 test portion

A certain amount of material that are taken from test samples (if the test sample

is the same as the laboratory sample, take it from the laboratory sample) and

used for inspection or observation.

3.7 mass-basis sampling

A sampling method that takes increments at equal mass intervals and tries to

make the increment size consistent.

3.8 time-basis sampling

A sampling method that, from a free-fall material flow or from a conveyor,

collects increments at equal time intervals; that the amount of each increment

is proportional to the material flow of the taken increment.

4 Method summary

In 105°C±5°C air flow, dry the test portion to constant weight. By determining

the mass loss of test portion, calculate its moisture content.

5 Instruments and equipment

5.1 Drying pan: stainless-steel or enamel; about 1000g of test portion are

placed in the pan and the thickness is about 10mm.

5.2 Blast dryer: equipped with temperature indicator and controller; be able to

control the temperature of any point in the cabinet within 105°C±5°C; the air in

the cabinet can conduct cycling and replacement, so as to make test portion

completely dried without any loss.

5.3 Weighing device: the maximum weighing value is not less than 2000g; the

resolution is not greater than 0.1g.

Annex A

(normative)

Determination of moisture content of over-wet or sticky laterite nickel

ore consignment

A.1 When the moisture sample is too wet or sticky to sieve, break and divide, it

shall pre-dry the moisture sample till it is easy to prepare.

NOTE: It shall carefully distribute the pre-dried test portion, weigh the initial mass of test

portion and the mass of pre-dried test portion, so as to ensure the determination precision

of pre-dried moisture content.

A.2 Weigh the initial mass of test portion.

A.3 Flatten the test portion to the same thickness. Pre-dry it in the air or in a

drying device of which the temperature is not higher than 105°C till it is easy to

prepare.

NOTE: The temperature and time selected in the pre-drying stage must not exceed the

state when it is easy to re-absorb water in the subsequent processing.

A.4 After pre-drying, re-weigh the mass of test portion.

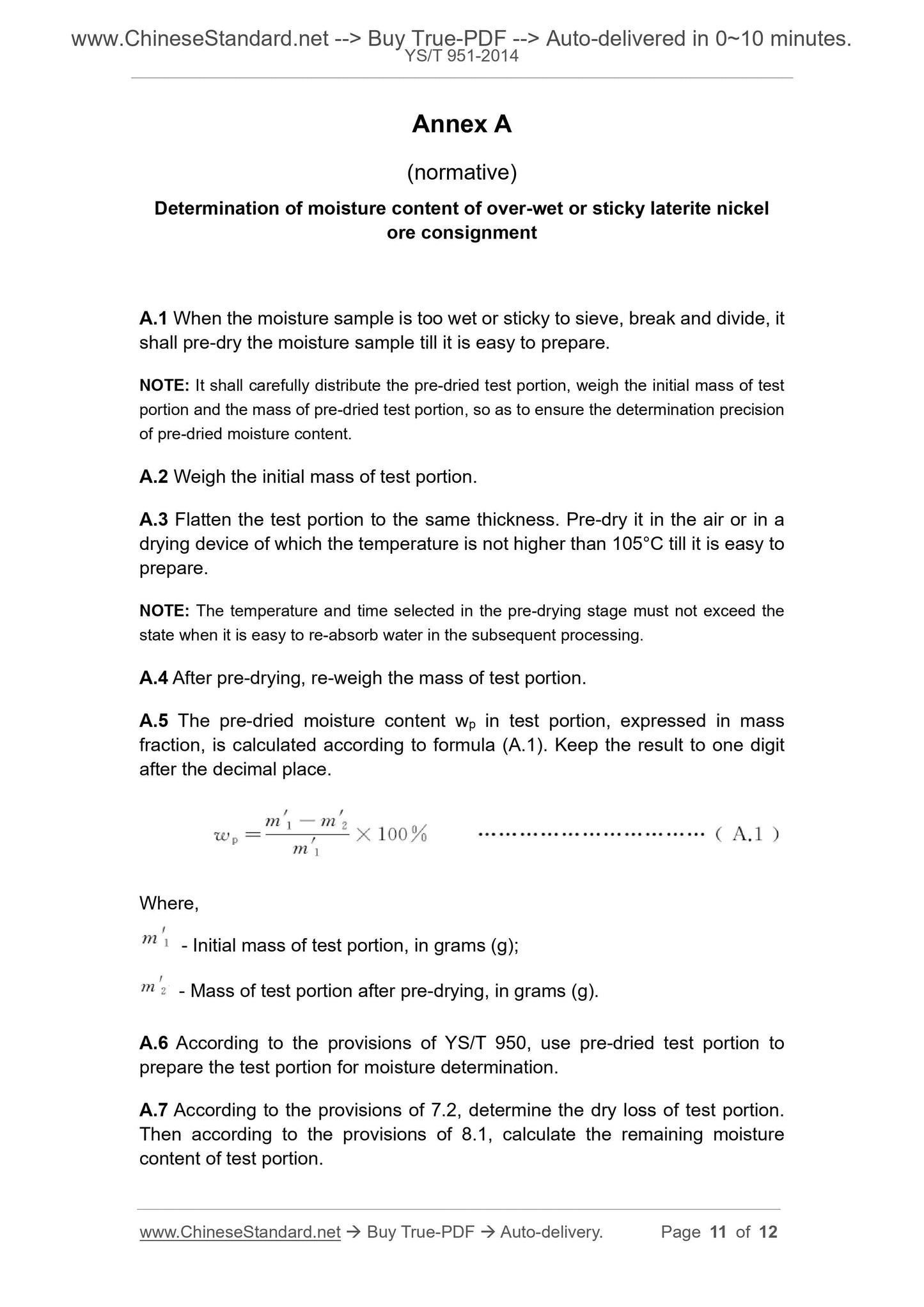

A.5 The pre-dried moisture content wp in test portion, expressed in mass

fraction, is calculated according to formula (A.1). Keep the result to one digit

after the decimal place.

Where,

- Initial mass of test portion, in grams (g);

- Mass of test portion after pre-drying, in grams (g).

A.6 According to the provisions of YS/T 950, use pre-dried test portion to

prepare the test portion for moisture determination.

A.7 According to the provisions of 7.2, determine the dry loss of test portion.

Then according to the provisions of 8.1, calculate the remaining moisture

content of test portion.

Get QUOTATION in 1-minute: Click YS/T 951-2014

Historical versions: YS/T 951-2014

Preview True-PDF (Reload/Scroll if blank)

YS/T 951-2014: Laterite nickel ores. Determination of moisture content of a consignment

YS/T 951-2014

NON-FERROUS METAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 77.120.01

D 42

Laterite nickel ores - Determination of moisture

content of a consignment

ISSUED ON: OCTOBER 14, 2014

IMPLEMENTED ON: APRIL 01, 2015

Issued by: Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Method summary ... 5

5 Instruments and equipment ... 5

6 Sample ... 6

7 Determination steps ... 6

8 Result calculation and expression ... 7

9 Test report ... 9

Annex A (normative) Determination of moisture content of over-wet or sticky

laterite nickel ore consignment ... 11

Laterite nickel ores - Determination of moisture

content of a consignment

1 Scope

This Standard specifies the determination method of moisture content of a

consignment of laterite nickel ores.

This Standard is applicable to the determination of moisture content of a

consignment of laterite nickel ores.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

YS/T 950, Methods for sampling and sample preparation of laterite nickel

ores in bulk

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 consignment

A certain amount of ores in one delivery. A consignment may consist of a batch,

several batches or partial batches of ores.

3.2 gross sample

A sample that consists of all increments and fully represents all quality

characteristics of a batch.

3.3 partial sample

A sample that is composed of partial increments required to form a gross

sample.

3.4 increment

A certain amount of ores that are obtained in one operation by a sampling

device or a sample reduction device.

3.5 sample

Relatively small amount of ores that are representative and are taken from a

batch of ores of which their quality characteristics are to be evaluated.

3.6 test portion

A certain amount of material that are taken from test samples (if the test sample

is the same as the laboratory sample, take it from the laboratory sample) and

used for inspection or observation.

3.7 mass-basis sampling

A sampling method that takes increments at equal mass intervals and tries to

make the increment size consistent.

3.8 time-basis sampling

A sampling method that, from a free-fall material flow or from a conveyor,

collects increments at equal time intervals; that the amount of each increment

is proportional to the material flow of the taken increment.

4 Method summary

In 105°C±5°C air flow, dry the test portion to constant weight. By determining

the mass loss of test portion, calculate its moisture content.

5 Instruments and equipment

5.1 Drying pan: stainless-steel or enamel; about 1000g of test portion are

placed in the pan and the thickness is about 10mm.

5.2 Blast dryer: equipped with temperature indicator and controller; be able to

control the temperature of any point in the cabinet within 105°C±5°C; the air in

the cabinet can conduct cycling and replacement, so as to make test portion

completely dried without any loss.

5.3 Weighing device: the maximum weighing value is not less than 2000g; the

resolution is not greater than 0.1g.

Annex A

(normative)

Determination of moisture content of over-wet or sticky laterite nickel

ore consignment

A.1 When the moisture sample is too wet or sticky to sieve, break and divide, it

shall pre-dry the moisture sample till it is easy to prepare.

NOTE: It shall carefully distribute the pre-dried test portion, weigh the initial mass of test

portion and the mass of pre-dried test portion, so as to ensure the determination precision

of pre-dried moisture content.

A.2 Weigh the initial mass of test portion.

A.3 Flatten the test portion to the same thickness. Pre-dry it in the air or in a

drying device of which the temperature is not higher than 105°C till it is easy to

prepare.

NOTE: The temperature and time selected in the pre-drying stage must not exceed the

state when it is easy to re-absorb water in the subsequent processing.

A.4 After pre-drying, re-weigh the mass of test portion.

A.5 The pre-dried moisture content wp in test portion, expressed in mass

fraction, is calculated according to formula (A.1). Keep the result to one digit

after the decimal place.

Where,

- Initial mass of test portion, in grams (g);

- Mass of test portion after pre-drying, in grams (g).

A.6 According to the provisions of YS/T 950, use pre-dried test portion to

prepare the test portion for moisture determination.

A.7 According to the provisions of 7.2, determine the dry loss of test portion.

Then according to the provisions of 8.1, calculate the remaining moisture

content of test portion.

Share